Bigger isn’t better. 2,500+ cow farms plateau. 1,200-cow farms thrive. Here’s the math nobody talks about.

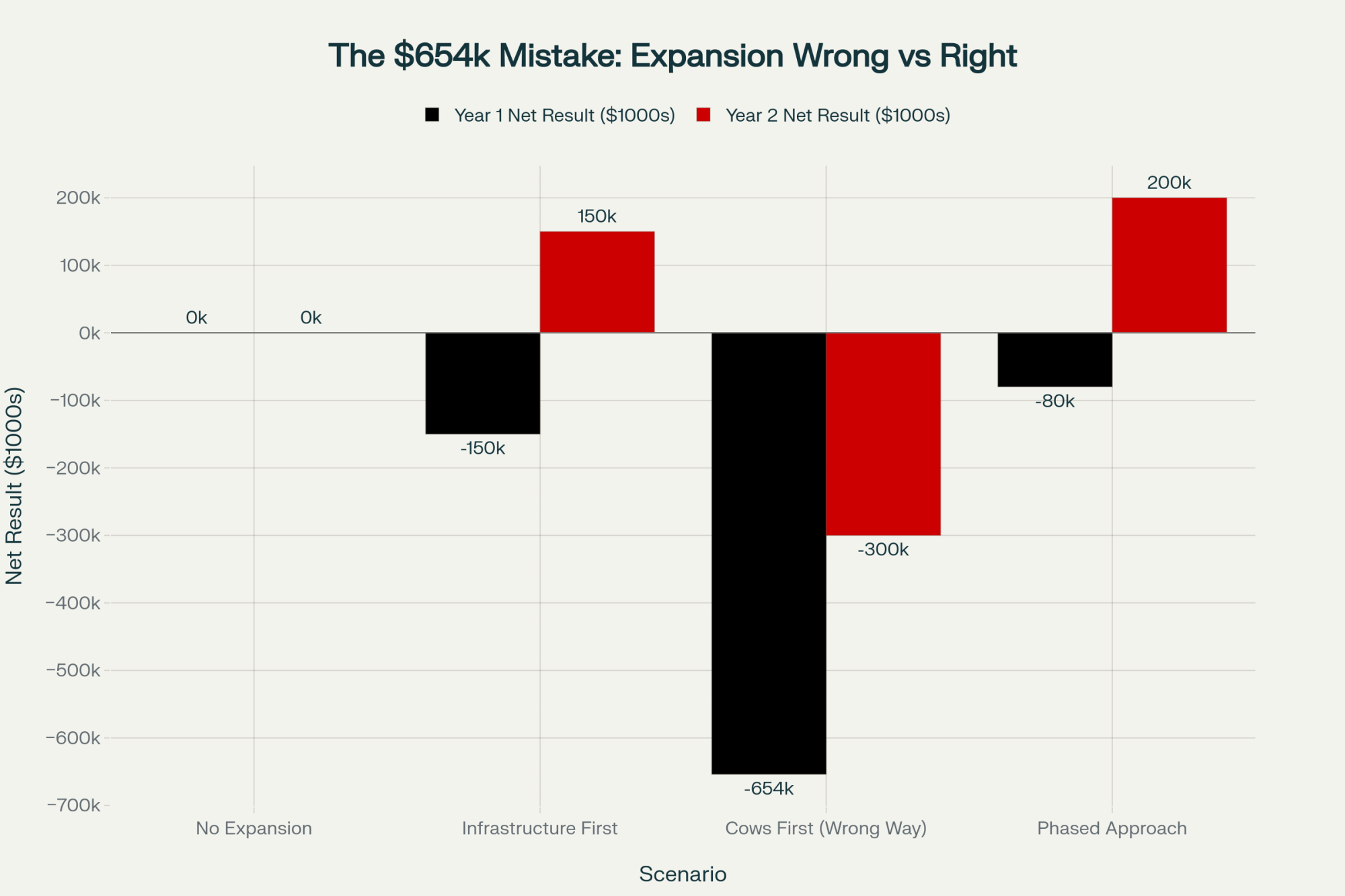

EXECUTIVE SUMMARY: The 3.5-hour rule changes everything: when cows spend more than 3.5 hours away from pens for milking, even ‘successful’ expansions fail. A Wisconsin producer who added 150 cows without upgrading infrastructure now hemorrhages $4,000 daily—a pattern replicated across farms that put cows before concrete. The industry data is unforgiving: proper expansion requires 18-24 months of infrastructure-first planning, $50,000-100,000 in management development, and debt-to-equity ratios under 0.50. Those who expand backwards face average first-year losses of $654,000 and 18-month recovery periods that many don’t survive. With 15,000 dairy farms already gone and processors building for mega-operations, mid-sized farms face a stark choice: master the expansion paradox of building for tomorrow’s herd today, or join the 2,500-3,000 operations projected to close in 2025. The survivors won’t be those who grew fastest, but those who counted minutes, not just cows.

As we head into winter planning season, I was talking with a producer the other day—a guy up near Eau Claire who expanded last spring—and his story really got me thinking. He went from 450 to 600 cows, following that logic we’ve all considered at some point: more cows equals more milk equals more revenue. Makes perfect sense on paper, doesn’t it?

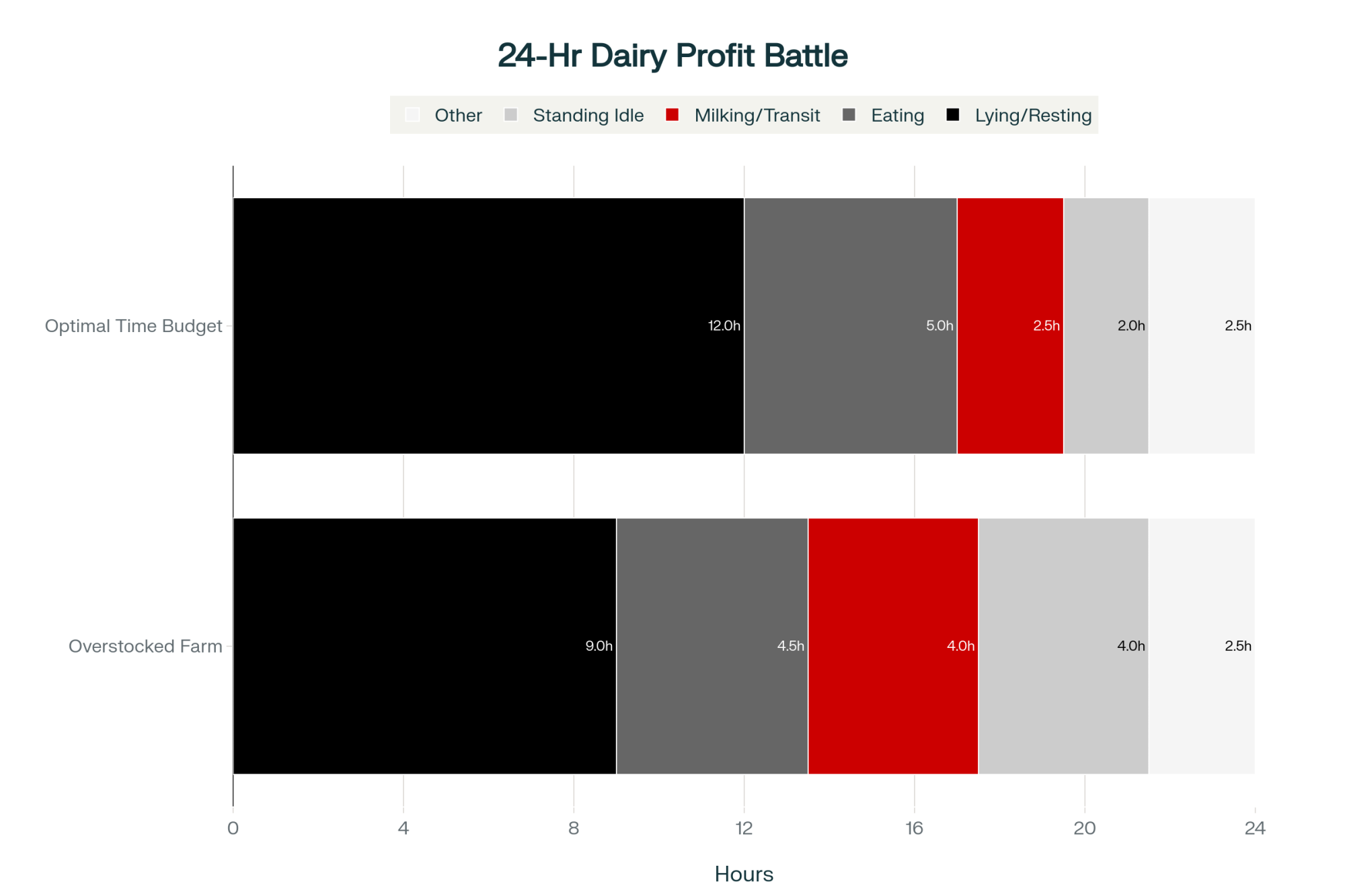

But here’s what’s interesting… those extra 90 minutes his cows are now spending cycling through the parlor? It’s creating challenges he never anticipated. And from what I’m hearing at meetings and co-op discussions, he’s far from alone.

Quick Reference: The 3.5-Hour Rule

- When cows spend over 3.5-4 hours away from pens, profitability declines

- Each extra hour of rest can mean 2-3 pounds more milk per cow daily

- $150+ daily losses are common when rest time drops by 90 minutes

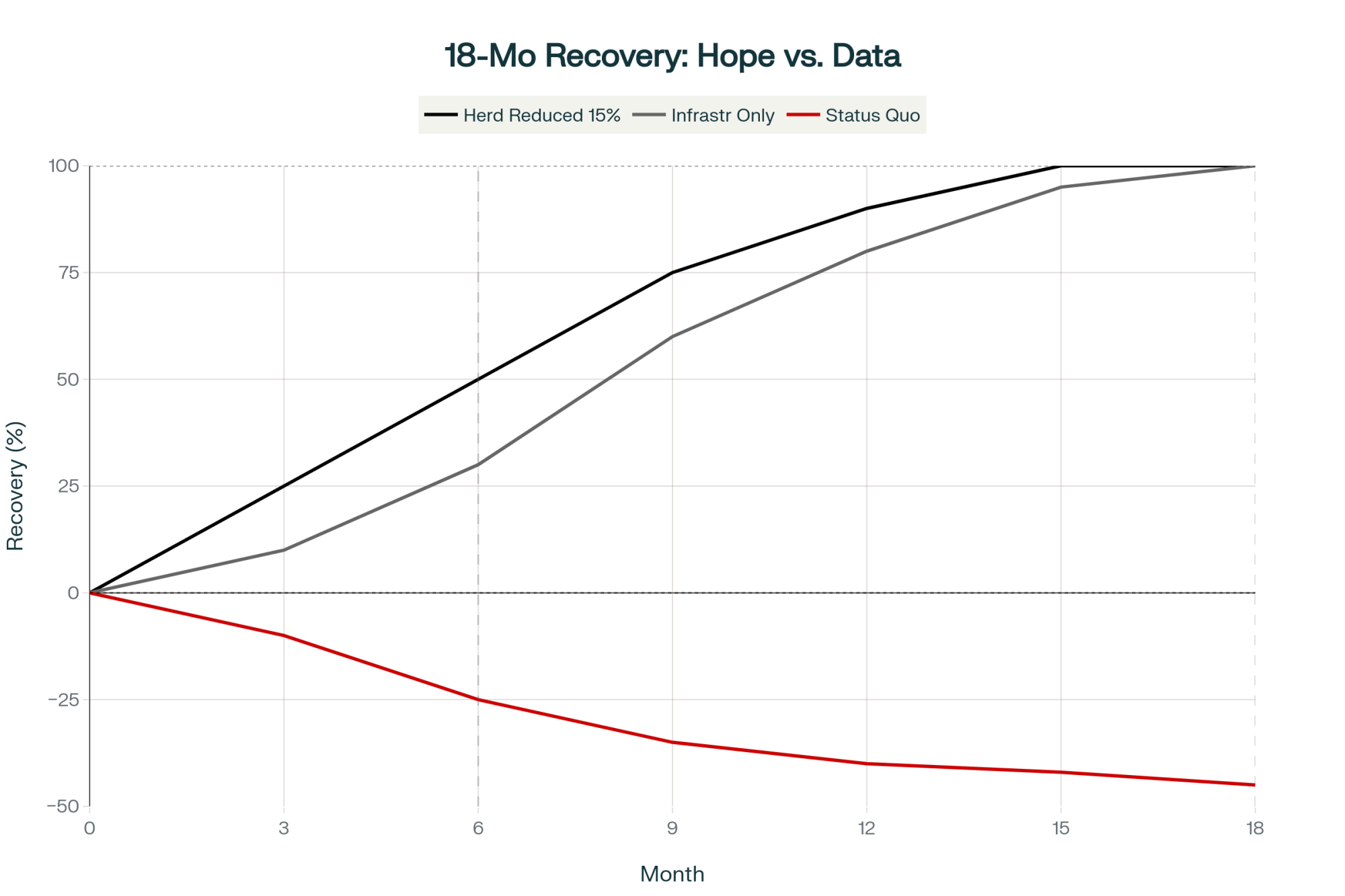

- Recovery from expansion problems typically takes 18 months, not 6

- Smart operators build infrastructure before adding cows

A lot of folks—could be 40 percent or more based on recent industry conversations—are thinking about expansion right now. With all the investment flowing into processing facilities, we’re learning something that maybe should’ve been obvious all along. The difference between profitable growth and just getting bigger often comes down to something we haven’t traditionally measured: how long our cows spend away from their pens.

What’s fascinating is the work coming out of places like Cornell and Wisconsin’s extension programs (particularly their 2024 dairy expansion guides). They’re suggesting that when cows spend more than about 3.5 to 4 hours away from their pens for milking, something shifts. The economics change. Some folks are calling it the “3.5-hour rule,” and honestly, it’s making a lot of us rethink our expansion plans.

What Time Away Really Costs

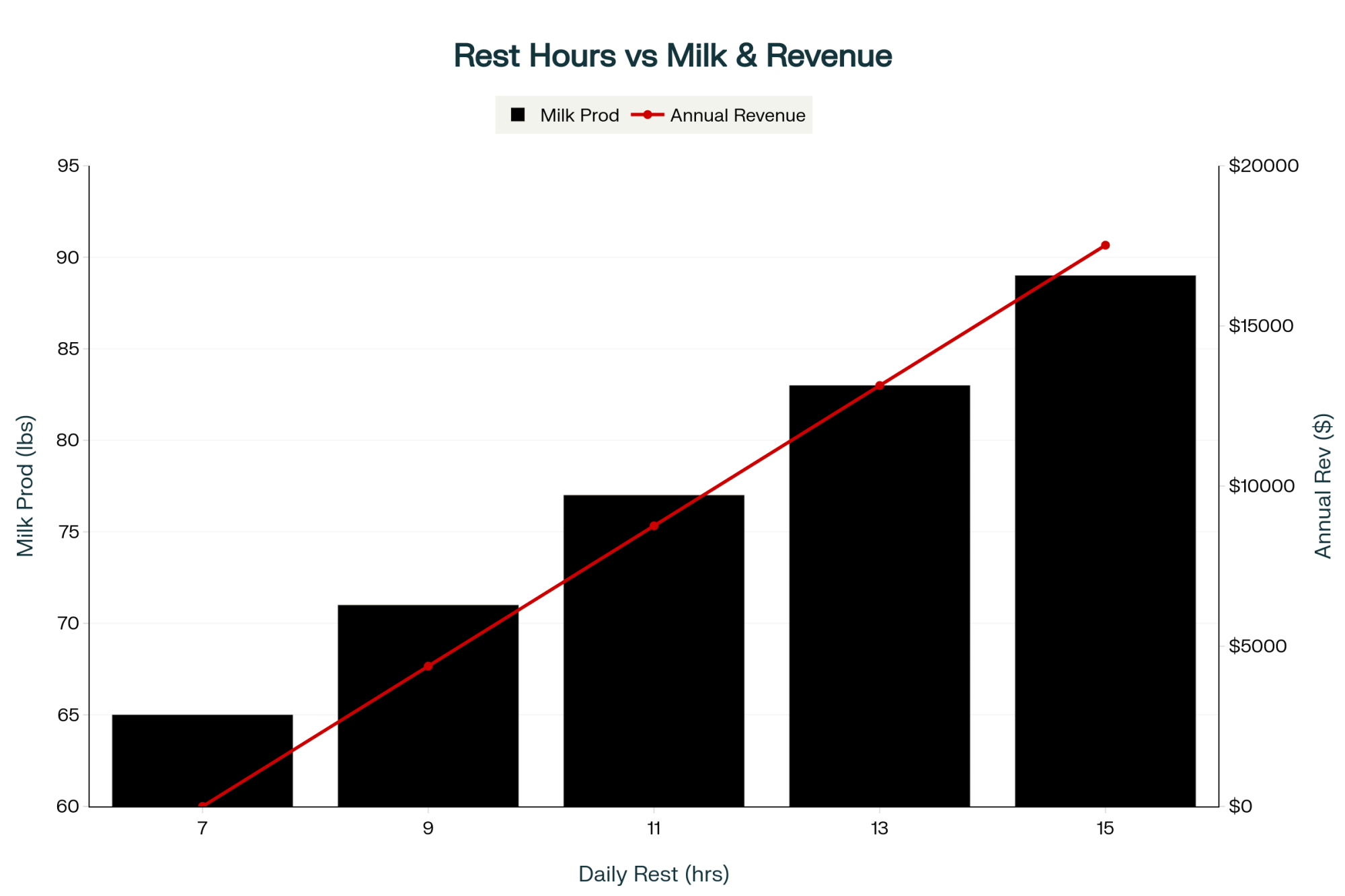

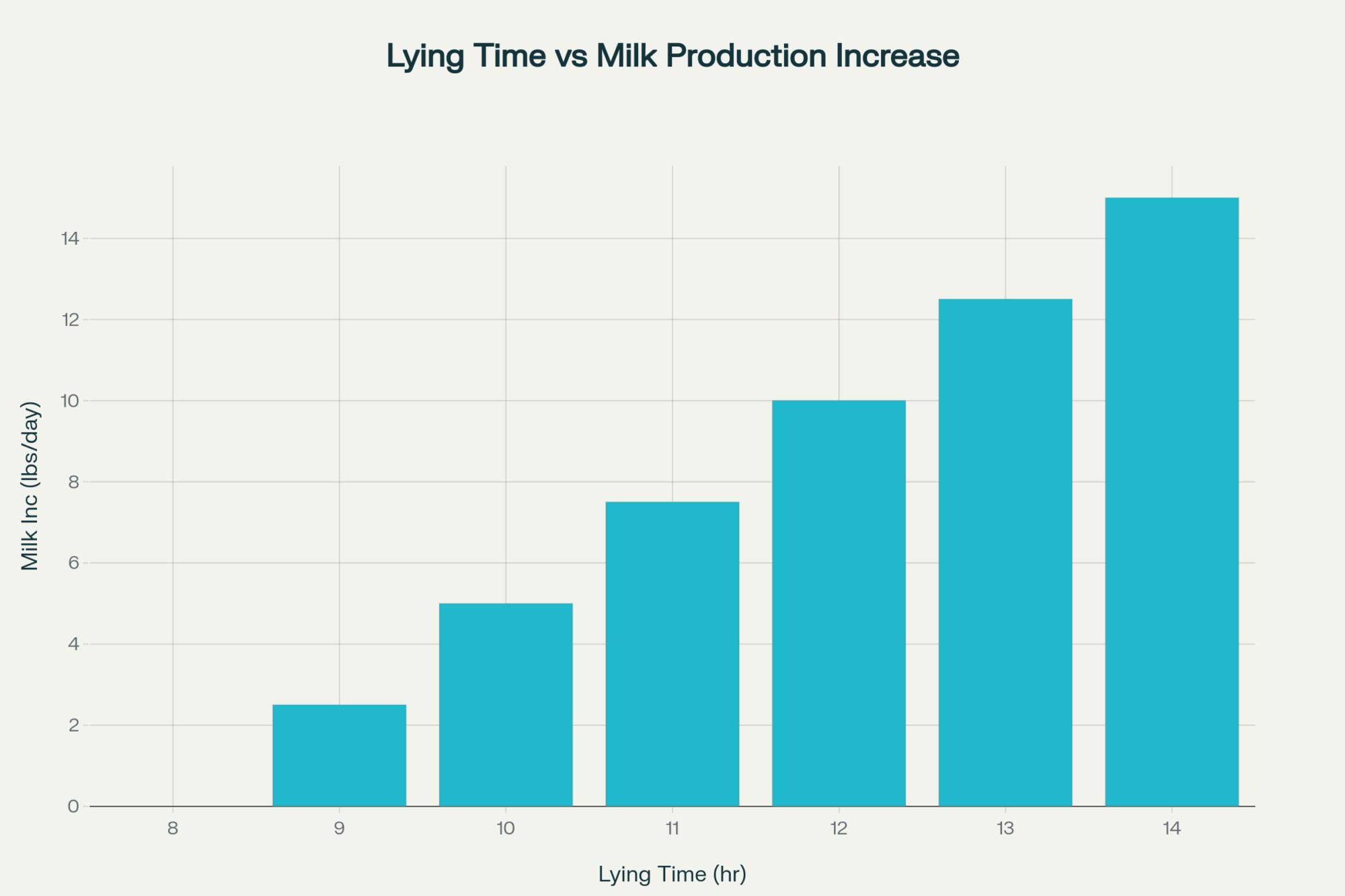

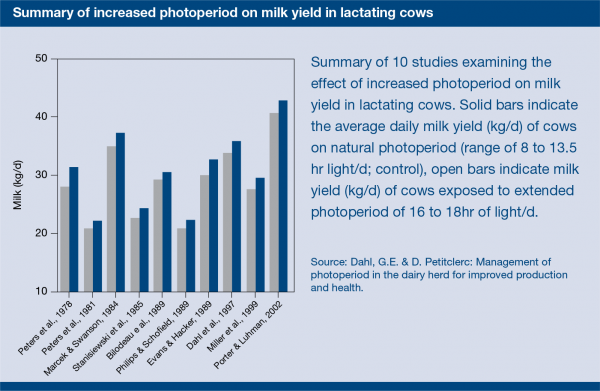

I’ve been reading research from folks at the Miner Institute and other dairy research centers, and what they’re finding is eye-opening. You probably sense this intuitively, but they’re putting numbers to it—every additional hour of rest can mean significant production gains. We’re talking potentially 2-3 pounds per cow per day, maybe more. Sometimes up to 3.7 pounds, according to some studies, though your mileage may vary.

Think about it—when your girls are standing in the holding area instead of lying down, that’s lost production time. And it compounds.

Here’s what extension folks are telling us happens when operations run their parlors for more than 20 hours a day: everything gets compressed. Milking routines get rushed. Holding areas get crowded. The cows get stressed. Your people get stressed. It all adds up.

Let’s walk through the math, because this is where it gets real. Say you’ve got 500 cows losing even 90 minutes of rest time. That could mean 750 pounds less milk daily.

At today’s prices—what, around $20/cwt?—that’s $150 or more walking out the door every single day. And that’s just the beginning.

From what extension services documented in their 2023-2024 research, here’s what tends to happen:

- Lameness that normally runs, maybe 15 percent? It can climb to 25-30 percent over a few months

- Cell counts start creeping up past 300,000, and there go your quality premiums

- Fresh cow problems—instead of 12 percent, you might see 20-25 percent or higher

- And culling… well, that tends to jump 8-12 percent above normal

What Wisconsin’s Teaching Us

What’s happening in Wisconsin really tells the story. According to Wisconsin Extension’s 2024 dairy statistics, average herd sizes have grown from around 140 to over 200 cows in recent years—that’s roughly a 45 percent jump. And honestly? Most of us weren’t ready for it.

I’ve walked through a lot of these expanded operations, and you can see the challenges. These parlors—many built decades ago for different herd sizes—they’re showing the strain. The cows bunch up in holding areas. The milkers look frustrated. Everyone’s feeling it.

What the university folks have documented makes sense when you see it firsthand. When holding areas get tight—less than 15-20 square feet per cow—things happen physiologically. Stress hormones go up. That oxytocin we need for good letdown? It gets suppressed.

Cows stand on concrete for hours, and we all know where that leads.

First-lactation heifers have it worst. They’re still figuring out the routine, and now they’re competing with mature cows in tight spaces. Some research suggests they might produce 2 pounds less daily just from that stress. That’s potential walking away before it ever hits the tank.

As veterinarians keep reminding us, this isn’t just about cow comfort—though that matters. It’s about profitability. Some extension models suggest that operations expanding without proper infrastructure could face significant losses in the first year. We’re talking potentially hundreds of thousands, depending on your situation.

Rethinking What “Big Enough” Means

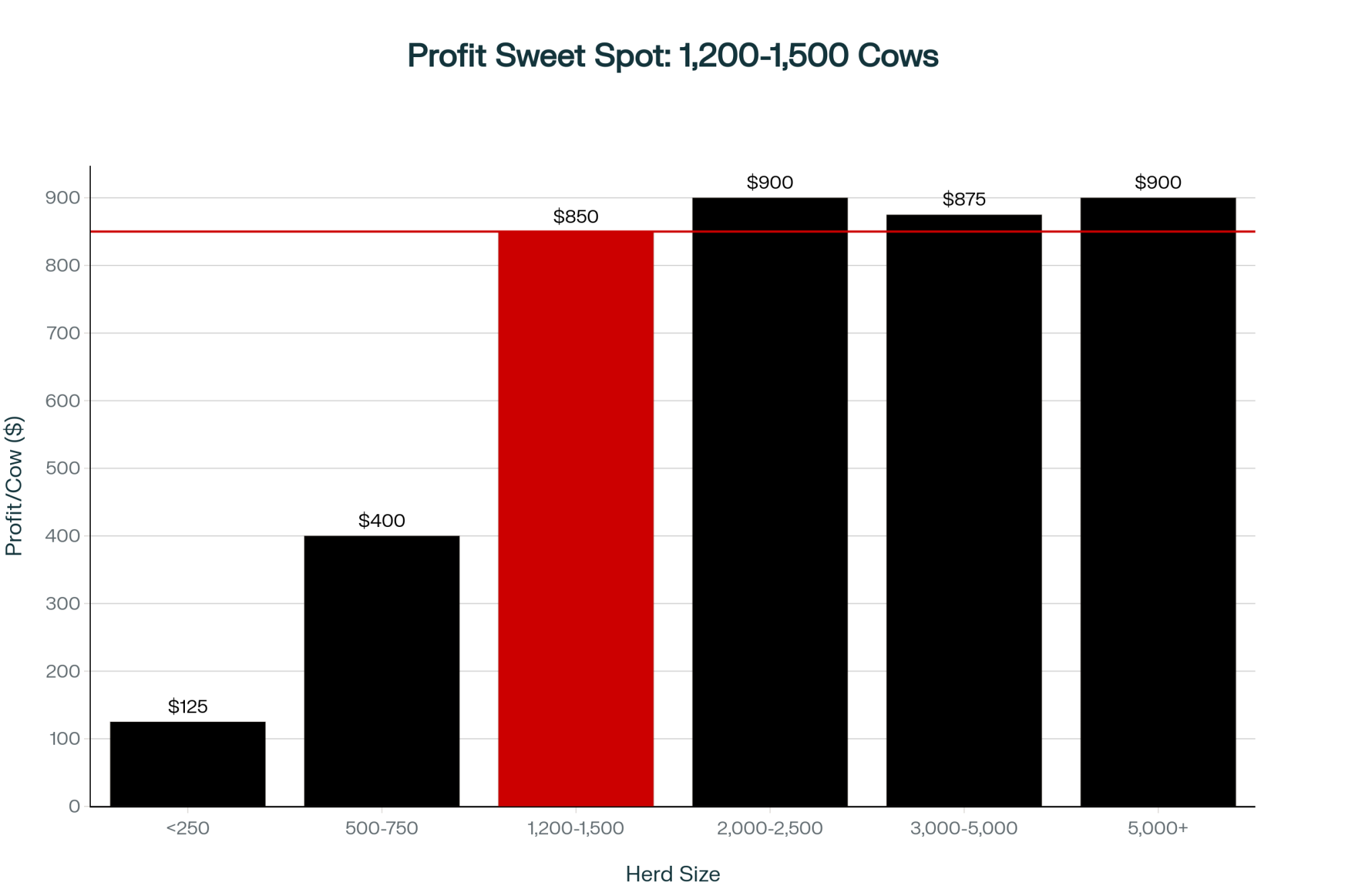

Here’s something that surprised me when I started digging into recent data. You’d think bigger is always more profitable, right? But profitability seems to level off around 2,000-2,500 cows, and sometimes even declines in really large operations.

Profitability by Herd Size (Typical Ranges)

| Herd Size | Profit per Cow | Key Characteristics |

| < 250 | $125-$250 | Family ops, scale challenges |

| 500-750 | $350-$450 | Sweet spot for independents |

| 1,000+ | $600-$800 | Economies of scale emerge |

| 2,500+ | $750-$900 | Efficiency gains plateau |

| 5,000+ | $900-$1,000 | Complexity offsets benefits |

Source: USDA Economic Research Service data and industry analyses, 2023-2024

Sure, total profit keeps going up with size. But the efficiency gains? They really taper off after a certain point.

What management experts point out—and this makes sense when you think about it—is that once you get past 3,000 cows, you can’t manage individuals anymore. You’re managing pens. That’s a fundamental shift, and it means accepting different realities about health, variation, and even mortality rates.

What I find really interesting is that the sweet spot for many operations seems to be around 1,200-1,500 cows. Big enough for real economies of scale, but you can still use technology to manage individual animals. That feels like the best of both worlds.

Learning from Folks Who’ve Done It Right

I’ve had the chance to work with several operations that successfully increased from 500 to over 1,200 cows and improved profitability. What’s striking? They all did pretty much the same things.

Getting the Finances Right First

Every successful expansion I’ve seen started from a strong financial position. Debt-to-equity ratios under 0.50, often down around 0.35-0.40. These folks had reserves for at least a year, sometimes 18 months, of potential negative cash flow.

As financial advisors keep telling us—and they’re right—if you’re not testing your plans against milk at $17/cwt for two years, you’re probably being too optimistic.

Building the Team Before the Barn

This one’s huge. I know of operations that spent a year and a half preparing their management systems before pouring any concrete. Hiring people, training them, making sure there’s backup for every critical job.

One producer told me he spent probably $75,000 on management development before construction started. “Best investment we made,” he said, and I believe him.

Actually Talking to Your Milk Buyer

This gets missed so often. You really need to sit down with your processor—really talk about capacity, hauling, components, everything—before you add a single cow.

I know several Wisconsin operations that found out their processor would need to charge significantly more for hauling additional volume. That completely changed their expansion math.

Growing in Stages

The smartest folks I know don’t try to do it all at once anymore. They phase it:

- First, build for maybe 80 percent of where you want to be, and get it running smooth

- Then optimize for a year or so—this is crucial

- Only then finish the expansion

A guy near Fond du Lac told me this approach saved them when milk prices dropped. They could stay at their intermediate size without drowning in debt. Smart.

If You’re Already in a Tight Spot

Look, I realize some of you reading this are thinking, “Great, but I’m already in it up to my neck.” Recovery is possible, but it depends on where you are in the process.

Warning Signs You’re in Trouble:

- Parlor running over 20 hours

- More than 90 minutes in the holding area

- Lameness creeping above 20 percent

- Cell counts are consistently high

- Fresh cow problems over 20 percent

- Your best people are looking burned out

Early Stage Recovery (First Few Months)

If your parlor time is around 90-120 minutes and lameness is still under 20 percent, you can turn this around. According to the University of Minnesota Extension’s 2024 parlor efficiency guide, some quick wins include:

- Automated crowd gates or better cow flow—might save 10-15 minutes right away ($5,000-$15,000 investment)

- Vacuum adjustments—another 5-10 minutes sometimes

- Just splitting into two feeding groups instead of one—that alone can add $400-$500 per cow annually

But here’s the thing—you’ve got to move fast. Every month you wait, it gets harder.

When Problems Are Building (Months 3-6)

If parlor time’s over 2 hours and lameness is approaching 25 percent, you need bigger moves:

- Maybe reduce the herd by 10-15 percent—I know, it hurts, but it works

- Get some ventilation and cooling in that holding area ($30,000-$50,000 typically)

- Consider bringing in outside help for a few months

Recovery takes time—18 months usually, not the 6 months we all hope for.

A producer I know from Marathon County told me, “We sold 80 of our lowest producers. Felt like failure at first. But the rest of the herd jumped 5 pounds per day. Math actually worked out better.”

When You Need Major Changes (Beyond 6 Months)

If you’re running over 3 hours in the parlor with lameness near 30 percent, the options get limited:

- Permanent reduction to sustainable size

- Major infrastructure investment—we’re talking $400,000+

- Sitting down with your lender for some honest conversations

- Maybe looking at bringing in a partner or succession planning

The Bigger Picture

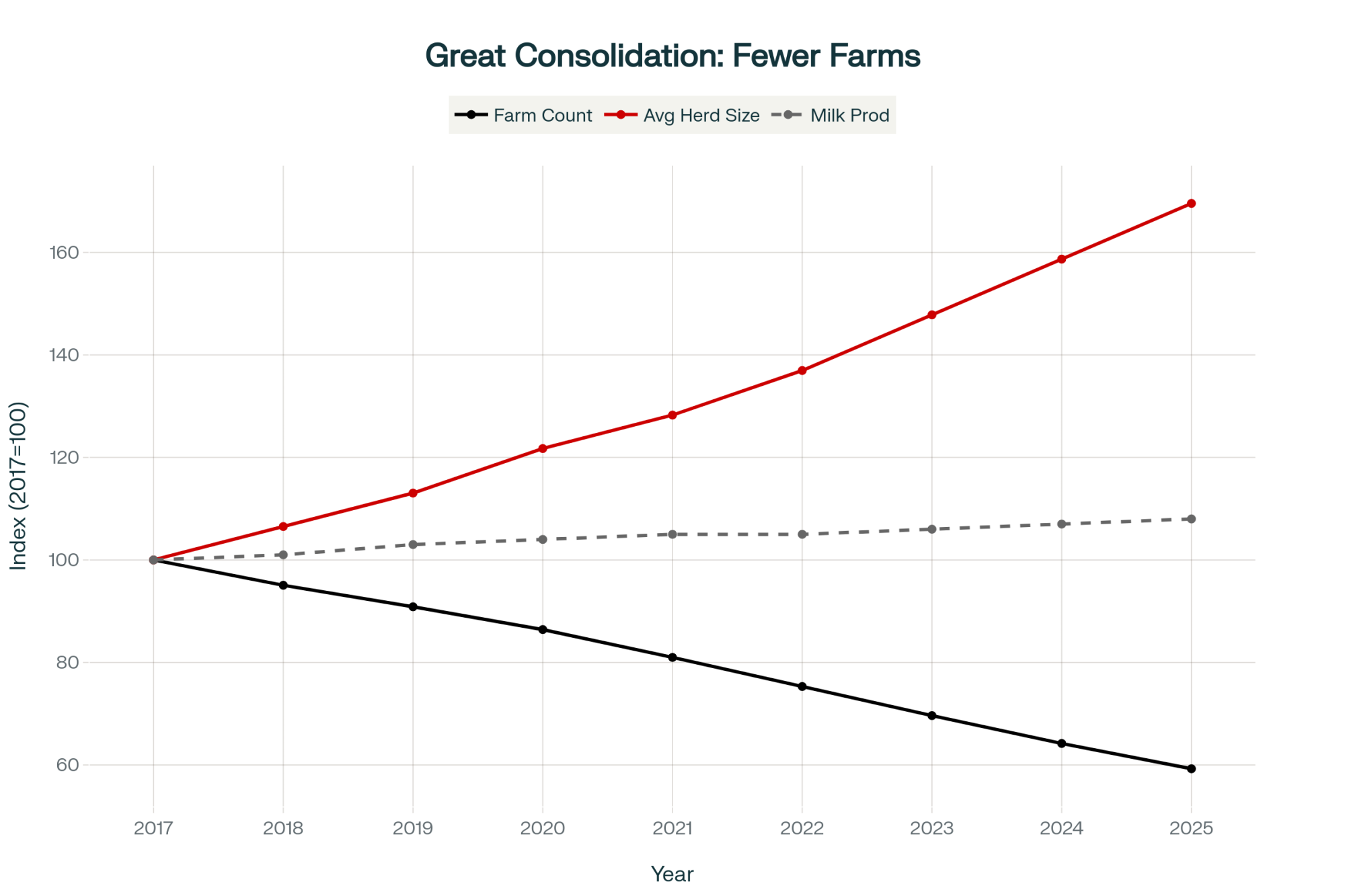

Looking at the industry broadly, we’re in for continued change. Various analyses suggest we might see 2,500-3,000 farms exit in 2025—that’s maybe 7-9 percent of what’s left.

USDA data shows we lost around 15,000-16,000 farms between 2017 and 2022, while milk production increased by 5 percent.

The big operations—over 2,500 cows—now produce nearly half our milk. And all that processor investment? It’s generally aimed at working with larger suppliers, not mid-sized folks like many of us.

The pace varies by region. Wisconsin’s been losing 400-500 farms yearly, according to state ag statistics. Pennsylvania and New York, similar stories. It’s reshaping dairy country as we know it.

Making the Math Work for You

Before any expansion, here’s the one calculation that matters: What’s your actual cost per hundredweight right now, and what happens to that if you add 20 percent more cows without upgrading infrastructure?

Cost Calculation Framework:

- Add up all your annual costs—feed, labor, facilities, health, everything

- Divide by your annual production in hundredweights

- Model what happens with more cows but no infrastructure upgrades:

- Labor costs typically increase 15-20 percent

- Health costs often rise 15-25 percent

- Production might drop 2-3 pounds per cow daily

- Quality premiums could be affected

Say you’ve got 500 cows producing 75 pounds per day. That’s 375 cwt. At $8,250 per day, you’re at $22/cwt.

Add 100 cows without infrastructure? Production might drop to 72 pounds per cow, and costs could rise to about $9,500 per day. Suddenly, you’re looking at $26/cwt.

If expansion pushes you from $22 to $25-26/cwt, that should make you pause.

It’s Different Depending on Where You Farm

These dynamics play out differently across regions, and that matters.

Texas and New Mexico operations often started big with appropriate infrastructure. But in the Upper Midwest? We’re adapting facilities built for our grandparents’ 50-cow herds.

California’s got its own challenges—water, regulations, land costs. A producer there told me that compliance alone can run into the hundreds of thousands.

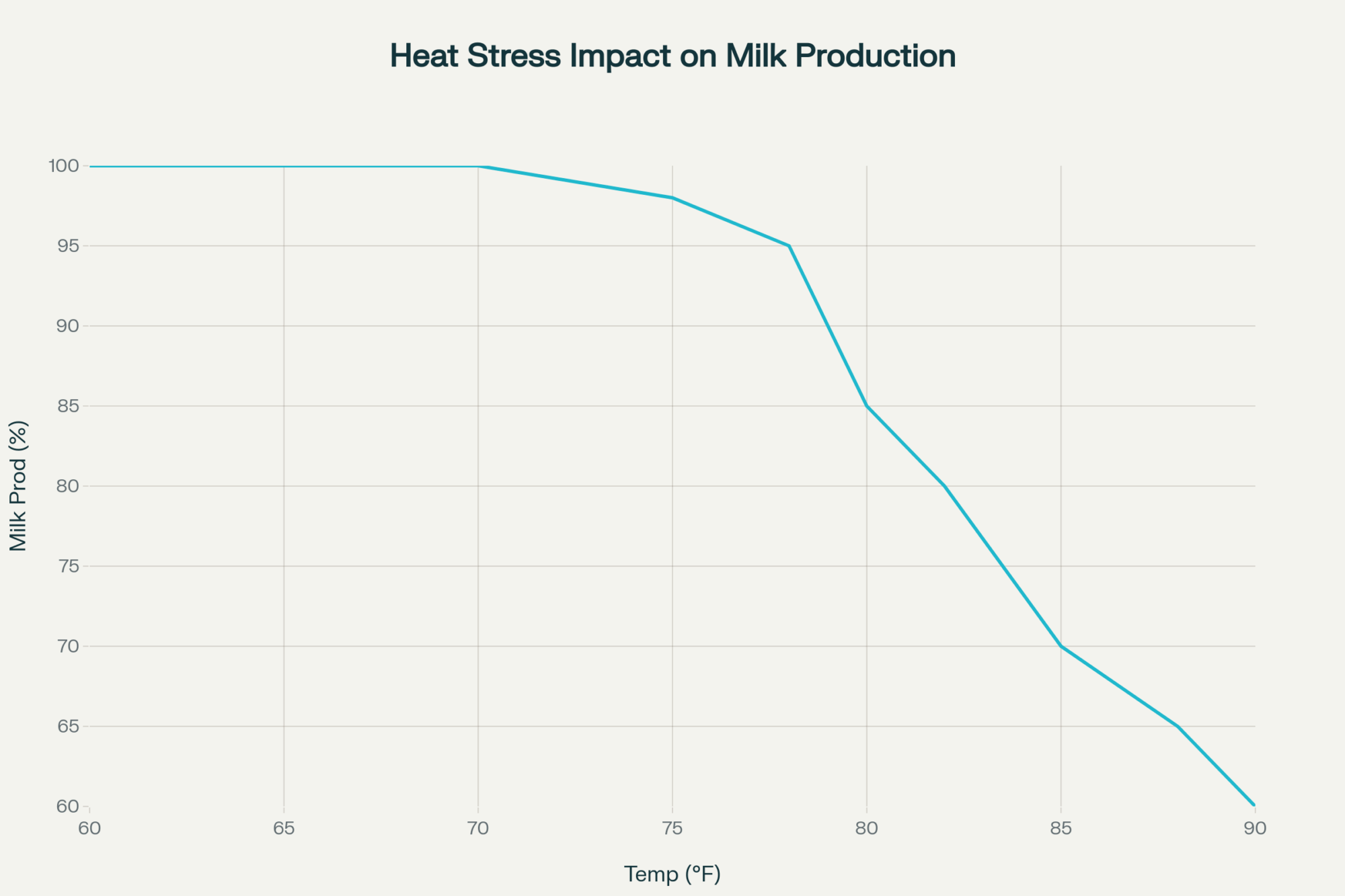

Even within Wisconsin, it varies. Being near a cheese plant in Green County is different from shipping fluid milk from up north. And summer heat? That can easily add 30-45 minutes to your parlor time when cows move more slowly and need extra cooling.

What Really Seems to Matter

After looking at all this, here’s what I keep coming back to:

Build for where you’re going: Get the infrastructure right before adding cows. Yes, it takes longer and costs more upfront. But it’s often the difference between thriving and just surviving.

Watch that time clock: When cows spend over 3.5-4 hours away from pens, things tend to go sideways. Make that your benchmark.

Management matters most: Can your team handle 25 percent more complexity? If not, invest in people first—maybe $50,000-$100,000 in management development.

Know your real costs: Most of us don’t actually know our true cost per hundredweight. Without that, expansion is just gambling.

Consider other paths: Maybe the answer isn’t more cows. Maybe it’s robots for better labor efficiency, or genetic improvement for 10 percent more production, or capturing premium markets for A2A2 or grassfed milk.

The industry’s changing fast—fewer, bigger operations emerging. But bigger isn’t automatically better.

The operations I see thriving are making careful, infrastructure-first decisions based on real analysis. As one successful producer put it to me: “We spent a year planning before adding a single cow. Neighbors thought we were too slow. Now they’re asking how we stayed profitable.”

That conversation brings us full circle, doesn’t it? Remember that producer near Eau Claire I mentioned at the start? He’s working through his challenges now, looking at some of these same solutions. Had another coffee with him last week, actually. And what’s encouraging is he’ll probably come out stronger for it, because he’s learned what many of us are discovering: real growth isn’t about pushing more cows through your existing setup.

It’s about doing right by every cow you milk, keeping them healthy and productive for the long haul. In today’s dairy world—with all its complexity, consolidation, and change—that philosophy might be the smartest expansion strategy of all.

Don’t just count your cows. Count the minutes they stand waiting. The former feeds your ego; the latter feeds your bank account.

KEY TAKEAWAYS

- Count Minutes Before Cows: Parlor time over 3.5 hours = automatic profit loss. Your next cow costs nothing; your next hour costs $150+/day

- $22→$26/cwt = STOP: Before adding even one cow, calculate if expansion increases your cost/cwt by $3+. If yes, you’re planning bankruptcy, not growth

- Build at 0.50 Debt-to-Equity or Don’t Build: Successful expansions require 18-24 months planning, $75K management investment, and reserves for 18 months of negative cash flow

- 1,200-1,500 Cows = Profit Sweet Spot: Beyond 2,500, complexity kills margins. Below 500, scale limits competitiveness. Plan for the middle

- Recovery Takes 18 Months + 15% Herd Cut: If you’re already bottlenecked (20+ hour parlor, 25%+ lameness), reduce first, rebuild second

Complete references and supporting documentation are available upon request by contacting the editorial team at editor@thebullvine.com.

Learn More:

- The Welfare-Profitability Paradox: Why Your ‘Expensive’ Cow Comfort Investments Are Actually Profit Machines – Reveals the direct ROI of “luxury” comfort upgrades, demonstrating how investments in deep bedding and non-slip flooring can yield 3-5% higher feed efficiency and reduce lameness costs by thousands annually.

- Decide or Decline: 2025 and the Future of Mid-Size Dairies – Provides a strategic roadmap for the “squeezed middle,” outlining three specific paths for survival: scaling to 2,500+ cows, optimizing 500-cow herds for efficiency, or capturing niche market value.

- The Tech Reality Check: Why Smart Dairy Operations Are Winning While Others Struggle – Offers a candid look at automation economics, explaining why successful robot implementation requires “operational readiness” and a 3.8-5 year financial runway before a single piece of equipment is installed.

Join the Revolution!

Join the Revolution!

Join over 30,000 successful dairy professionals who rely on Bullvine Weekly for their competitive edge. Delivered directly to your inbox each week, our exclusive industry insights help you make smarter decisions while saving precious hours every week. Never miss critical updates on milk production trends, breakthrough technologies, and profit-boosting strategies that top producers are already implementing. Subscribe now to transform your dairy operation’s efficiency and profitability—your future success is just one click away.

Join the Revolution!

Join the Revolution!