Explore how dairy farmers are navigating record-breaking profit margins even amidst a constrained heifer supply and reduced feed costs. Will they be able to maintain this surge in profitability? Find out more.

Dairy farming is presently experiencing a surge of prosperity, contrasting sharply with years of financial distress. Record profit margins, boosted by increased agricultural yields, higher cheese prices, and careful debt management, indicate a substantial change. Margins are anticipated to be $10.91 per hundredweight, the greatest in recent history. These advances are critical for the dairy sector and anyone studying agricultural economics and food supply networks. Current profitability enables farmers to enhance their financial position and prepare for market unpredictability.

As we delve into the evolving landscape of dairy farming, it’s crucial to understand the financial metrics that define this sector’s current profitability. Here, we present the key data pertaining to dairy farm margins, interest rates, and heifer inventories, all of which are influencing farmers’ decisions and shaping market trends.

| Metric | Value | Notes |

|---|---|---|

| Average Margin per Hundredweight | $10.91 | Estimated for this year, highest in recent history |

| Interest Rates | Higher | Compared to a few years ago, affecting debt repayment |

| Heifer Inventory | Tight | Replacement heifers are expensive and hard to find |

| USDA Corn Yield Estimate | 68% good to excellent | Reflecting potential for high crop production, impacting feed prices |

| USDA Soybean Yield Estimate | 68% good to excellent | Also contributing to favorable feed costs |

Navigating Profitability with Prudence: A Conservative Approach Amidst Optimistic Margins

The present financial landscape is cautiously optimistic for dairy producers. Improved margins indicate profitability, but farmers are wary of expanding. Following a financially challenging year, their primary emphasis is on debt repayment. Higher interest rates contribute to the reluctance to take out additional loans. Furthermore, limited heifer stocks and high replacement prices make herd growth problematic. Instead, improvements improve feed quality while benefiting from lower feed costs. Profit locking today may assist in handling future market volatility. The takeaway: Prudent debt management and strategic investments in feed and herd quality may provide stability in the face of economic uncertainty.

From Strain to Gain: A Landmark Year in Dairy Farm Profit Margins

| Month | Margin ($/cwt) | Price ($/cwt) |

|---|---|---|

| March 2024 | 8.50 | 17.30 |

| April 2024 | 9.10 | 18.20 |

| May 2024 | 9.70 | 19.00 |

| June 2024 | 10.10 | 20.10 |

| July 2024 | 10.50 | 21.50 |

| August 2024 | 10.91 | 22.00 |

This year, dairy producers’ profit margins have improved significantly. Tight margins and high feed prices first put the business under pressure. However, the latest figures are more hopeful, with margins estimated at $10.91 per hundredweight. This would make this year the most lucrative in recent memory regarding revenue over feed expenses.

Six months ago, margins were much lower owing to dropping class three cheese prices and excessive feed costs. Rising cheese prices since late March, high crop output projections, and lower maize and soybean prices have all contributed to improvements. The USDA estimates these crops are rated 68% good to outstanding, resulting in decreased feed prices. This margin improvement is more than a rebound; it establishes a new industry standard. It highlights the need for strategic financial planning and risk management to capitalize on these advantageous circumstances.

The Challenge of Expansion: Navigating Tight Heifer Inventories and Rising Costs

| Year | Heifer Inventory (Thousands) | Replacement Heifer Costs ($ per head) |

|---|---|---|

| 2020 | 4,400 | 1,200 |

| 2021 | 4,300 | 1,250 |

| 2022 | 4,150 | 1,350 |

| 2023 | 4,000 | 1,450 |

| 2024 | 3,900 | 1,500 |

The current heifer supply scenario presents a considerable barrier to dairy farms seeking to grow. Tight heifer supplies have made replacement heifers scarce and costly. This shortage results from historical financial constraints that hindered breeding and current market changes. As a consequence, the high cost of replacement heifers increases financial hardship. Instead of expanding, many farmers pay down debt and maintain their present enterprises. This conservative strategy promotes economic stability, even if it slows development potential.

Feeding Profit with Lower Costs: The Strategic Impact of Cheap Feed on Dairy Farming

| Year | Average Feed Cost per cwt | Trend |

|---|---|---|

| 2020 | $11.23 | Decreasing |

| 2021 | $10.75 | Decreasing |

| 2022 | $10.50 | Decreasing |

| 2023 | $9.82 | Decreasing |

| 2024 (Estimated) | $9.20 | Decreasing |

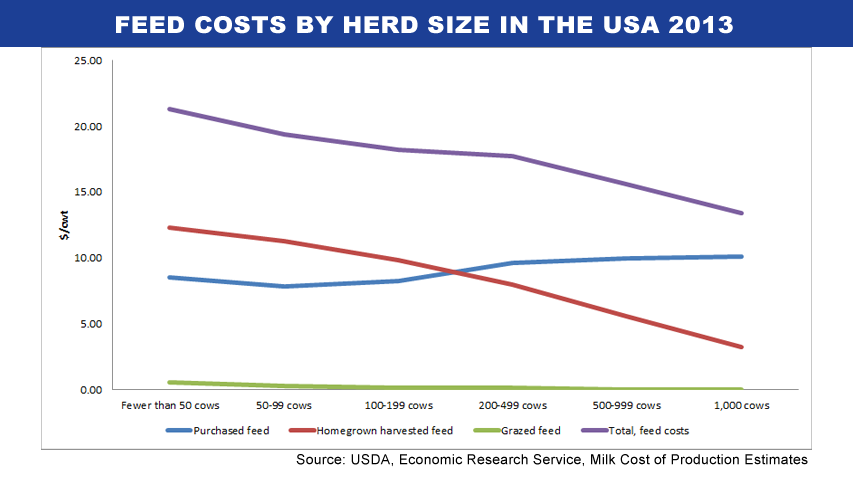

Lower feed costs are critical in increasing dairy farm profitability. Farmers may enjoy higher profit margins after considerably cutting one of their significant expenditures. These cost reductions allow farmers to focus resources on critical areas, such as providing high-quality feeds to their dairy cows. Cows enjoy a nutrient-rich diet thanks to affordable, high-quality feed, which promotes improved milk production and general health. Improved feed quality leads to increased milk outputs and improved milk component quality, which is crucial for profitability in dairy operations.

Improved cow diet boosts productivity and promotes dairy herd sustainability. Furthermore, these low-cost, high-quality diets help farmers better manage market volatility. Farmers are better equipped to deal with economic swings and market variations because they manage operating expenditures effectively. As a result, the present feed cost decrease serves as both an immediate earnings boost and a strategic benefit for keeping a competitive edge in the market.

Proactive Risk Management: Ensuring Stability Amid Market Volatility

Dairy producers face severe market volatility, making proactive methods critical to profitability. Futures contracts are an excellent technique for mitigating financial risk. Farmers may protect themselves against market volatility by locking in milk prices, providing a consistent income even during price drops. Another method is to use insurance mechanisms intended specifically for agricultural farmers. Programs such as Dairy Margin Coverage (DMC) and Livestock Gross Margin (LGM) insurance payout when margins fall below a certain level provide a financial cushion. Combining futures contracts with insurance programs provides a strong defense against volatility, allowing farmers to keep a consistent income while focusing on operational improvements. This dual method mitigates market downturns while promoting long-term development and strategic planning.

The Crucial Role of Crop Development: Navigating Feed Prices and Profit Margins

Crop development significantly affects feed costs, directly affecting dairy producers’ cost structures and profit margins. Recent USDA yield projections for soybeans and corn are at all-time highs, with the latest WASDE report indicating solid output levels. Corn and soybean harvests are now rated 68% good to exceptional, implying decreased feed prices.

The significance of these advances cannot be emphasized. Lower feed costs allow farmers to improve feed quality, cow health, and production and increase profit margins. Since feed is a significant operating expense, excellent crop conditions provide considerable financial relief to dairy farmers.

However, it is critical to be attentive. Changing weather patterns, insect infestations, and rapid market adjustments may still influence production. Farmers should lock in existing margins with risk management instruments like futures contracts or insurance to hedge against anticipated volatility as the season unfolds.

Global Market Dynamics: Navigating the Complexities of Cheese and Nonfat Dry Milk Exports

| Year | Cheese Exports (metric tons) | NFDM Exports (metric tons) | Change in Cheese Exports (%) | Change in NFDM Exports (%) |

|---|---|---|---|---|

| 2020 | 317,000 | 600,000 | – | – |

| 2021 | 330,000 | 630,000 | 4.10% | 5.00% |

| 2022 | 315,000 | 580,000 | -4.50% | -7.90% |

| 2023 | 340,000 | 550,000 | 7.90% | -5.20% |

| 2024 (Projected) | 350,000 | 520,000 | 2.90% | -5.50% |

Two essential things stand out in the dairy export industry: cheese and nonfat dry milk (NFDM). Cheese exports in the United States prosper when local prices are lower than those of worldwide rivals. This pattern boosted exports from late 2023 to early 2024. However, when prices recover, anticipate a slowdown. International competitiveness and trade policy can have an impact on exports.

Nonfat dry milk (NFDM) exports have decreased by 24% compared to cheese. Markets such as Mexico and East Asia have reduced their intake owing to global competition, a lack of free-trade agreements, and a strengthening U.S. currency. China’s expanding dairy self-sufficiency minimizes the need for US NFDM.

Understanding these patterns is critical since export demand influences local pricing and market performance. Dairy farmers must adjust their tactics to the evolving global trading scenario.

Butter Market Soars: Domestic Demand Sustains Skyrocketing Prices Amid Stagnant Exports

| Month | 2023 Price (per lb) | 2024 Price (per lb) |

|---|---|---|

| January | $2.50 | $3.10 |

| February | $2.55 | $3.20 |

| March | $2.60 | $3.25 |

| April | $2.70 | $3.30 |

| May | $2.75 | $3.35 |

| June | $2.80 | $3.40 |

| July | $2.85 | $3.45 |

Since early spring, the butter market has seen unprecedentedly high prices, establishing new records. Butter prices rose beyond $3 per pound, defying early 2024 estimates. Robust domestic demand has propelled this bullish economy, with Christmas spending continuing into the new year. Buyers are eager to grab available butter, even at these increased rates. In contrast, U.S. butter exports are non-existent owing to uncompetitive pricing and a lack of trade agreements, leaving domestic consumption as the butter market’s economic lifeblood. Trade considerations and USDA statistics indicate unique shortages, highlighting domestic demand.

Global Influences: How New Zealand, China, and Europe Shape the Dairy Market Landscape

Global forces certainly influence the dairy industry landscape. New Zealand’s dairy season, which is critical because of its considerable international export presence, has the potential to affect global supply and price patterns when it starts dramatically. Meanwhile, China’s drive for dairy independence has lowered import demand, influencing worldwide pricing and supply. European environmental rules, as well as extreme weather patterns such as heat waves, have a significant influence on worldwide supply and cost. These difficulties have far-reaching consequences for supply networks and pricing strategies throughout the globe.

The Bottom Line

Dairy farming is now experiencing a spike in profitability as feed costs fall and cheese prices rise. This cash boost allows farmers to concentrate on debt reduction rather than expansion. Tight heifer supply and high replacement prices need cautious financial planning. Farmers should use their present margins to protect against potential market volatility. Global market variables include New Zealand’s output, China’s dairy self-sufficiency, and European restrictions. Effective risk management is crucial for sustaining these profit levels. Now is the time for dairy producers to establish financial security via strategic planning, assuring a sustainable future.

Key Takeaways:

- Dairy farmers are experiencing significantly higher profit margins compared to the beginning of the year, with estimates pegging margins at $10.91 per hundredweight.

- Due to better margins, farmers are focusing on paying down debt rather than expanding their operations.

- Heifer inventories remain tight, making it expensive and challenging for farmers to find replacement heifers.

- Cheaper feed prices have enabled farmers to maintain high-quality feed rations for their cows, contributing to overall profitability.

- Experts recommend locking in profitable margins now to mitigate future market volatility.

- Crop conditions in the U.S. look promising, with high yields expected for soybeans and corn, potentially lowering feed costs further.

- Despite improved domestic demand, the export market for U.S. dairy products, especially cheese and nonfat dry milk, has seen fluctuations.

- Butter prices have hit record highs due to strong domestic demand, despite non-competitive export prices.

- Global factors, including production trends in New Zealand, China, and Europe, continue to influence the dairy market.

Summary:

Dairy farming is experiencing a surge of prosperity, with record profit margins expected to be $10.91 per hundredweight, the highest in recent history. This is crucial for the dairy sector and anyone studying agricultural economics and food supply networks. Prudent debt management and strategic investments in feed and herd quality may provide stability in the face of economic uncertainty. Lower feed costs are critical for increasing dairy farm profitability, allowing farmers to focus on critical areas such as providing high-quality feeds to their dairy cows. Improved cow diets boost productivity and promote dairy herd sustainability. Combining futures contracts with insurance programs provides a strong defense against volatility, allowing farmers to keep a consistent income while focusing on operational improvements. Crop development plays a crucial role in influencing feed prices and profit margins for dairy producers. Farmers should lock in existing margins with risk management instruments like futures contracts or insurance to hedge against anticipated volatility.