For the 1% of breeders who deal in seed stock Proof Days are like Christmas 3x times a year. But for the remaining 99% of dairy breeders proof days, the days when the latest Genetic Evaluations are released, are not that big a deal. But they should be.

The following are three reasons all dairy producers should be checking out the latest genetic evaluations.

All producers should be using the best genetics possible

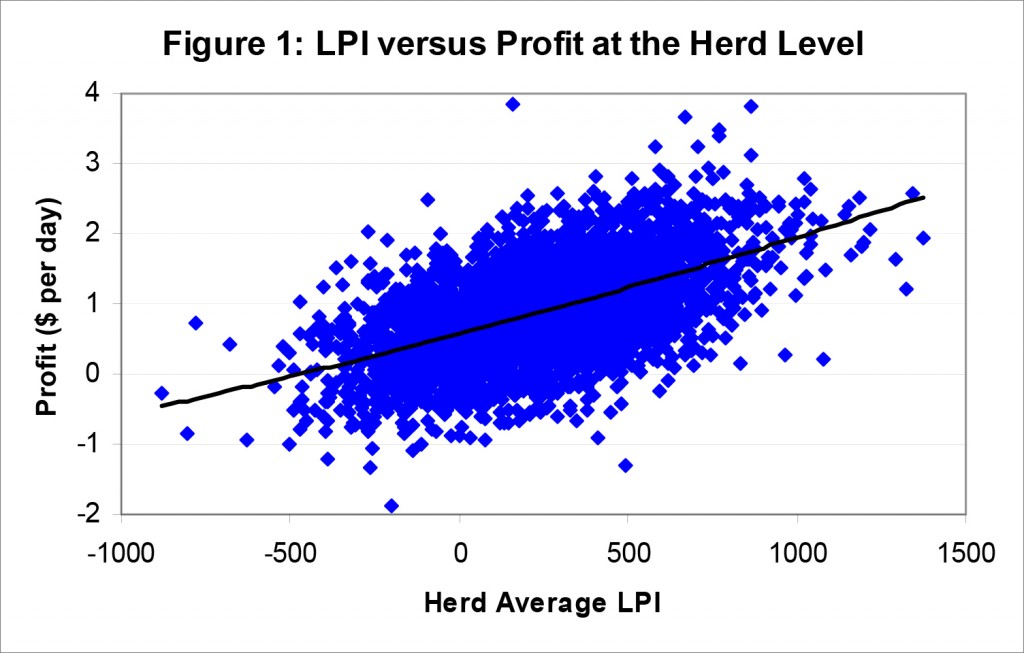

Analysis conducted as a cooperative effort between Canadian Dairy Network (CDN) and the milk-recording agency in Québec, Valacta, examined the association between the average profit per cow at the herd level and the genetic potential of the herd for various traits.

Figure 1 shows the relationship between the average LPI and the average profit per cow per day in each herd studied. While there are some exceptions to the rule, the dark line in the graph reflects the average relationship across the LPI scale, which indicates that herds with higher average LPI levels of their cows also have higher profit values. This positive correlation between LPI and profit clearly shows that genetics is a significant contributing factor but that management also plays a major role. On average, for every 100-point difference in LPI at the herd level there is an increase in profit per cow per year of $50, which accumulates from year to year. From a sire selection perspective, this equivalence translates to a difference of $50 more profit per daughter per year for every 200-point difference in the sire’s LPI value. Based on a 50% conception rate, that would indicate that the semen from a sire who is 400 LPI points higher than the average sire, should cost $50 more. Applying this to the current sires available, by using a sire such as AltaRazor who has an LPI of +3038 you will generate and extra $187.50 compared to a sire with an LPI of 1500. This is from direct daughter profitably and does not even factor in the increased performance of any progeny this cow would produce. So then investing $50 to $100 more for semen that will deliver over $180 in return is certainly a profitable decision even for commercial milk producers.

The Grass Is Always Greener on the Other Side of the Fence

I often hear many producers quote the minimum levels for certain traits that they are willing to use. The challenge with that is while this approach is great for setting basic criteria, it fails to look at how these sires compare to other sires. By using “any” sire that meets their criteria they are missing out on maximizing the genetics gain, and therefore the profitability of their herd. As demonstrated above setting a minimum threshold, instead of going for maximum return, is leaving dollars on the table, and not in the milk check. Then there is the case where some milk producers prefer to deal with only one semen sales representative or A.I. company. No A.I. company has all the best sires (Read more: Stud Wars: Episode II – April 2014), so by employing this practices any savings or efficiencies you gain from negations, are negated by the amount you are costing yourself in loss of genetic potential. (Read more: Rumors, Lies, and other stuff Salesmen will tell you and Are There Too Many Semen Salesmen Coming In The Lane?)

Are You Sure You Are Getting What You Pay For?

With the latest reports indicating that genomic young sire use is approaching 60% in North America, many producers have embraced genomics in a significant way (Read more: Why 84% of Dairy Breeders Will Soon Be Using Genomic Sires!). I have even come across herds that have gone to 100% genomic young sire use. With such a heavy usage of sires that are 60-70% reliable, are you sure that the sires that you are using are delivering on the other end? A great way to check this is to see how the sires you are investing in, are doing when they receive their official daughter proof. Sure that may not mean that you go back and use these sires once they are proven, but it does help you get a better understanding of the reliability of the genetics that you have invested in.

The Bullvine Bottom Line

I am not saying that all dairy producers should be waiting with baited breath at 8 am on proof day. However, there is certainly value in taking the time to check out the latest sire evaluations, to see how the sires you have been using are performing and what other sires are out there that could help you increase the profitability of your herd. No matter what your management style, there are certainly enough reasons for you to get excited on proof day.

Check out the latest Holstein Sires Proofs in our Genetics Section

Not sure what all this hype about genomics is all about?

Want to learn what it is and what it means to your breeding program?

Get original “Bullvine” content sent straight to your email inbox for free.