What if the key to a family farm’s survival isn’t working harder, but working smarter?

The thing about dairying? It’s a relentless cycle, right? Long hours, early mornings, and weeks that just seem to run into one another. Now, picture sitting on your porch this Labor Day, coffee warm in your hands, kids playing nearby, and the sound of robotic milkers humming instead of you hustling through another 4 a.m. barn routine.

Sounds almost too good to be true? That’s exactly what Tom, a no-nonsense operator milking 180 Holsteins from Wisconsin, thought—until his DeLaval robots proved otherwise.

“Back when I was doing the milking myself, calving seasons meant 75-hour weeks,” Tom shared. “Now? I’m at my daughter’s softball games without worrying about missing a beat. Those robots? They did the heavy lifting.”

He’s not the outlier, either. Farms across the heartland and beyond are waking up to just how much smarter labor and technology can rewrite the dairy grind.

Why So Many Family Farms Are Burning Out

Here’s the thing: the USDA Farm Labor Survey from April 2025 shows dairy operators clocking 45–60 hours weekly—sometimes more as calving hits full throttle. That kind of Grind wears folks thin.

What’s tougher: almost 9 out of 10 family dairies don’t make it past the third generation, according to research from the Farm Bureau and USDA ERS.

But this paints with a broad brush. If you’re up in the Northeast, farms benefit from processors like Cabot Creamery and Agri-Mark, with extension programs run by Cornell delivering succession help that keeps farms in the family longer. Midwest operations, though? They’re facing staggering consolidation pressures.

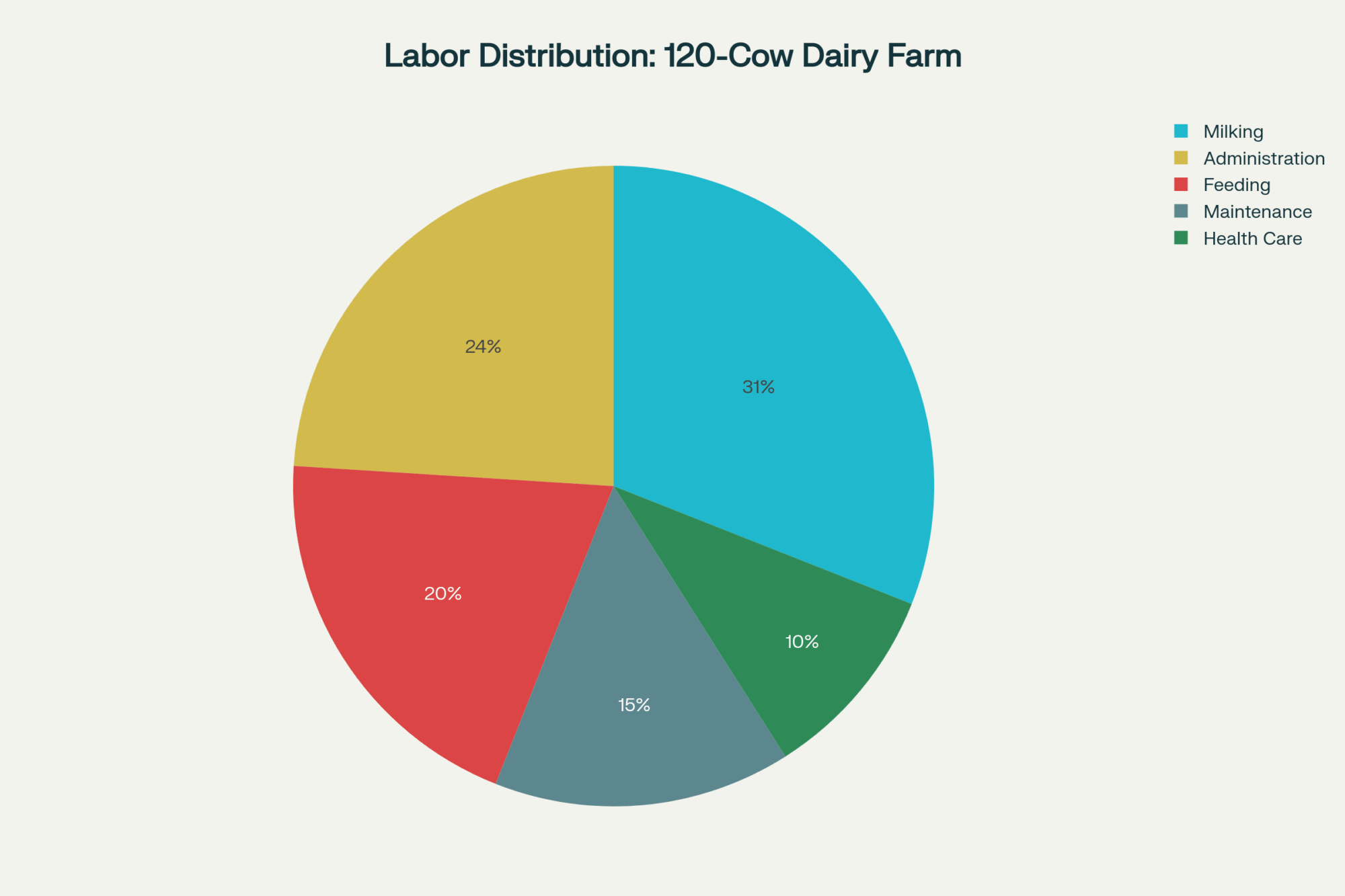

What’s Eating Your Time at the Barn

Milking takes up about a third of your day, no matter how you slice it. That’s four to five hours, easy. Smaller herds—say 50 to 90 cows—are spending well over 26 hours per cow annually, according to University of Wisconsin Extension labor studies. What’s interesting is that those same cows in herds of over 200 take only half that time, thanks to economies of scale. And let’s not forget that we manage approximately 9.45 million dairy cows in the U.S., which is no small feat.

The Labor Crunch is Very Real

Labor woes are no surprise, but the numbers still make you stop and stare. According to the latest USDA Farm Labor report, we’ve lost 3.4% of farmworkers this past year, with dairy farms feeling it more than others.

Hourly wages are averaging $17.55—which is fair, but you can’t put a dollar figure on those early mornings and backbreaking shifts.

Recruiting and training a new hand? Expect to spend over $4,400, including those hours and headaches.

And then there’s the mental health toll. A peer-reviewed study reveals that dairy workers experience sleep disorders twice as frequently as the general workforce, primarily due to the unforgiving pre-dawn milking schedules.

Jake, a fifth-generation farmer from Wisconsin, puts it like this: “Sometimes, it feels like the farm owns me. At home? My family barely sees me.”

Automation: The Game Changer You Didn’t See Coming

Automation isn’t just science fiction anymore. The robotic milking market is projected to balloon to $2.5–$3.4 billion by 2025 and is expected to grow steadily at a 6.4% annual rate through 2035, according to Fact.MR’s comprehensive 2024 analysis.

Look at a documented Wisconsin case study—six DeLaval VMS units on a 450-cow operation. The University of Wisconsin Extension research reported a 5-pound increase in milk production per cow, alongside a reduction in labor hours by half. The farm manager told researchers, “The best part? Being able to catch my kid’s school play without guilt.”

Think Outside the Box—Flexible Milking Pays Off

Now, this is fascinating: John Totty, a New Zealand dairyman, cut his milking sessions from 14 to 10 a week and still saw profits surge by 60%. Oh, and his team saves six hours weekly per worker, too.

The gains come not just from volume, but also from improved cow health and fertility—those butterfat numbers tell a story.

You Can’t Automate Without People

Automation helps, nobody’s denying it. But it’s how you share labor that makes or breaks your sanity.

Irish producers have pooled labor and leaned on trusted contractors, trimming fatigue and boosting efficiency. Data also supports this: shared labor reduces the time spent per cow, keeping farms more agile.

Dollars and Sense of It All

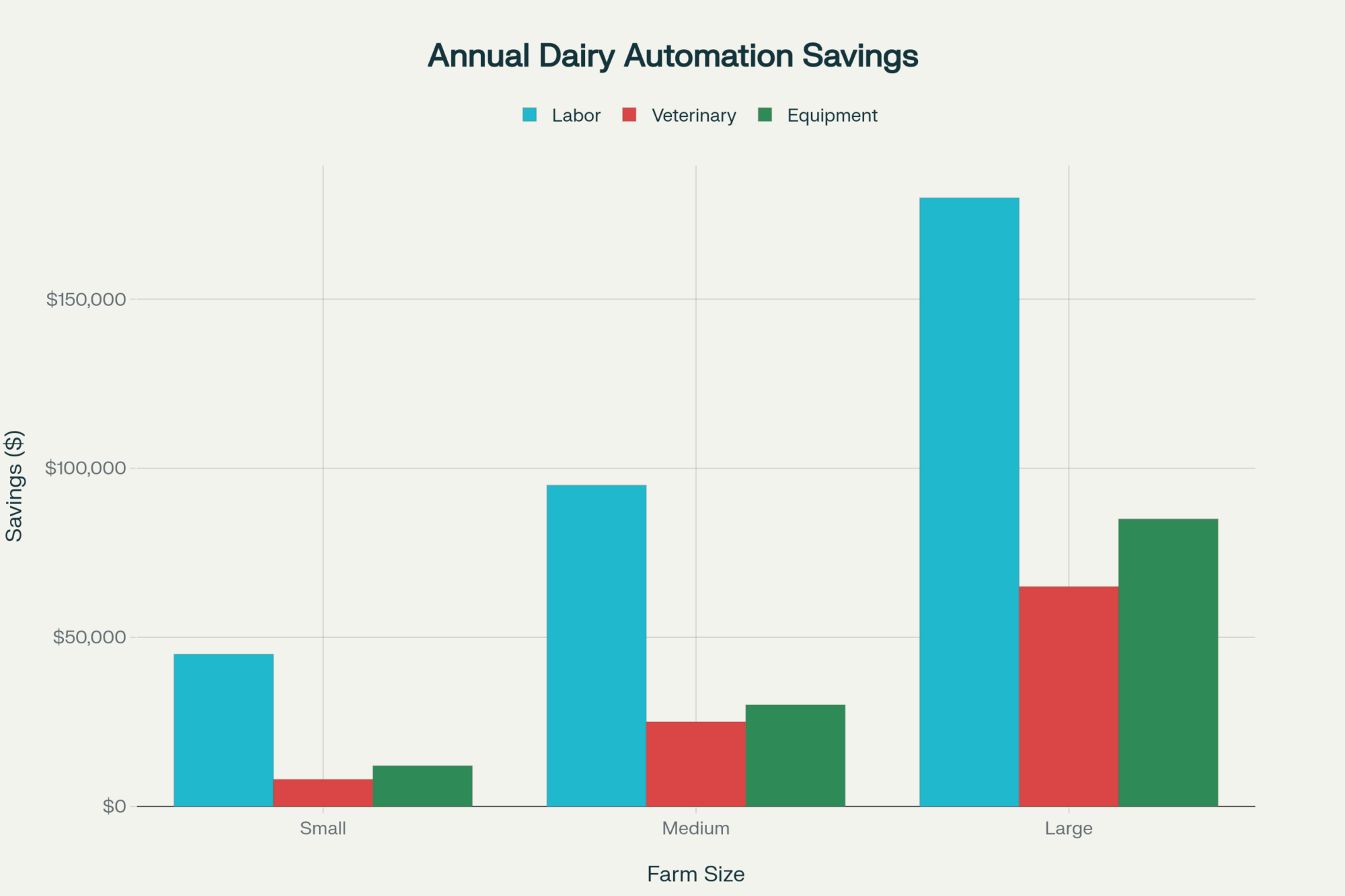

According to the University of Wisconsin’s 2024 enterprise budgets, a hypothetical 120-cow Holstein dairy farm spends approximately $356,000 annually on labor, veterinary care, and equipment maintenance. Smart automation, paired with purposeful health monitoring, can potentially reduce that to $200,000 or less—saving over $150,000, although results vary by individual operation.

Vet costs drop because problems are spotted sooner, while equipment maintenance falls—but watch out, service contracts may push some costs back up.

| Cost Category | Before Automation | After Automation |

| Labor | $190,000 | $95,000 |

| Veterinary | $38,000 | $25,000 |

| Equipment | $52,000 | $26,000 |

Note: Annualized Estimated Costs

It’s Not Just About the Bottom Line

Environmental benefits are no joke today. Automated systems cut energy use between 15 to 20%, according to Penn State University’s 2025 life cycle assessment.

Feed’s precision use saves water and lowers methane emissions, too—an environmental triple threat.

Family First—The Heart of the Matter

Family farms adopting a tech-savvy, balanced approach see 23% fewer costly errors and a whopping 340% increase in next-generation farm interest, according to American Farm Bureau Federation research.

One Vermont producer told me, “It wasn’t just the cows that got automated—automation saved my marriage.”

The Danger of Rushing In

There’s a reason folks stress ‘fail to plan, plan to fail.’ Penn State Dairy Alliance studies document automation implementation failures ranging from $20,000 to $75,000 per incident, with electrical inadequacy and insufficient training representing the costliest mistakes.

Common pitfalls? Insufficient power, inadequate staff training, and facility layouts that just don’t fit the new tech.

Takeaways? Do it right. Hire the experts. Train your team like your operation depends on it—because it does.

Is Automation Right for Your Operation?

Look, this isn’t a one-size-fits-all. The systems typically cost $150,000 to $200,000 each, plus upgrades and infrastructure work.

They best fit farms milking 150 cows or more with steady cash flow and tech-savvy staff.

Smaller farms or unconventional setups could start small—with health monitoring or feed push technology—and grow from there.

The 12-Month Roadmap to Freedom

Here’s what the best operators do, broken down by stage:

Months 1-3: Rigorous labor tracking, infrastructure assessment

Months 4-6: Install health monitoring, upgrade record-keeping, cross-train staff

Months 7-9: Add robotic milking or automated feeders, staff training in depth

Months 10-12: Optimize, install backups, finally take a real brea

The Future’s Already Here—Are You In? It’s not coming. It’s humming in barns up and down the continent—from the Finger Lakes to Wisconsin’s Driftless Area.

So, when you grab your next morning coffee, ask yourself: what task, if automated tomorrow, would give you the most breathing room? And if you could take a full week off, what would be the first bottleneck you’d need to address?

Bottom line? The farms that adapt to this stuff are the ones that’ll be around in 20 years. The ones that don’t… well, we both know how that story ends.

What do you think? Worth a deeper conversation?

KEY TAKEAWAYS:

- Cut labor hours nearly in half with automated milking systems—expect up to $95K in savings on a 120-cow operation. Start by tracking your current labor hours this month.

- Boost daily milk production by 5 lbs per cow with proven systems like DeLaval VMS—that’s real money in your pocket while you’re working less.

- Try flexible milking schedules, as seen in New Zealand, which can result in a 60% profit increase and six fewer labor hours per worker per week. Test it on part of your herd first.

- Use health-monitoring tech to slash vet bills by 34%—catch problems early and save thousands. Install basic monitoring systems as your first step in automation.

- Understand 2025 market reality: with labor costs through the roof and margins razor-thin, automation isn’t a luxury anymore—it’s survival.

EXECUTIVE SUMMARY:

Look, here’s what’s keeping me up at night: nearly 85% of family dairies don’t make it to the third generation—and that’s absolutely crushing our industry. But here’s the thing… smart operators are flipping the script with automation. We’re talking labor cost cuts of $150,000+ per year, milk production jumps of 5 pounds per cow daily, and get this—flexible milking in New Zealand is boosting profits by 60%. The USDA data and university extension research don’t lie. This isn’t just about fancy tech… it’s about survival. If you’re serious about leaving your kids something worth inheriting, you need to take a look at this.

Complete references and supporting documentation are available upon request by contacting the editorial team at editor@thebullvine.com.

Learn More:

- 9 Tips for Successfully Managing a Robotic Milking Herd – This article goes beyond the ‘why’ and dives into the ‘how.’ It reveals nine proven strategies for optimizing your robotic milking system, helping you maximize your investment, improve herd health, and avoid common operational pitfalls after installation.

- The 7 Economic Drivers of Dairy Farming That You Need To Know – To make smart investments, you need to understand the market. This piece breaks down the seven key financial forces shaping dairy profitability, providing the strategic context you need to navigate market volatility and make informed long-term business decisions.

- Is this the end of the dairy barn as we know it? – Looking beyond current automation, this forward-thinking piece challenges conventional wisdom about facility design and herd management. It explores the next wave of innovation, revealing what the most progressive dairy operations are considering for future growth and efficiency.

Join the Revolution!

Join the Revolution!

Join over 30,000 successful dairy professionals who rely on Bullvine Weekly for their competitive edge. Delivered directly to your inbox each week, our exclusive industry insights help you make smarter decisions while saving precious hours every week. Never miss critical updates on milk production trends, breakthrough technologies, and profit-boosting strategies that top producers are already implementing. Subscribe now to transform your dairy operation’s efficiency and profitability—your future success is just one click away.

Join the Revolution!

Join the Revolution!