Visual observation misses 40% of sick cows—smart sensors detect mastitis 4 days early, delivering $210/cow returns. Time to ditch the guesswork.

Here’s a number that’ll make you question everything you thought you knew about herd health: Michigan State University research tracking 20,625 mastitis cases across 37 Wisconsin dairy farms reveals the average cost per case ranges from $118 to $337, with milk discard accounting for 87% of total costs when using intramammary treatments only. But here’s the part that should keep you awake at night—31% of these cases received no antimicrobial treatment at all, yet still cost farmers an average of $192 per case.

What if I told you the entire foundation of dairy health management is built on a lie? What if the future isn’t about getting better at treating sick cows, but about seeing inside healthy ones before they get sick?

Whether you want to admit it or not, you’re living in the last days of reactive cattle management. With global antibiotic use in livestock projected to reach 143,481 tons by 2040—a staggering 29.5% increase—the regulatory noose is tightening around traditional health protocols. Meanwhile, producers using internal monitoring technology are documenting returns that should make every traditionalist in the industry deeply uncomfortable.

Here’s what the industry establishment doesn’t want you to know: An independent 2024 study by the International Farm Comparison Network (IFCN) documented a $210 per cow increase in returns and an additional $190 per cow in income from farms using smart bolus technology. Wisconsin producer Amber Horn-Leiterman calculated a 7.8x return on investment based solely on improvements in her cull rate, saving over $500,000 in 2023. These aren’t feel-good technology stories—they’re economic game-changers threatening the entire reactive medicine industry.

Think about this: you wouldn’t manage your breeding program by hoping cows get pregnant without tracking heat cycles or using genomic testing. Yet that’s exactly what you’re doing with health management—playing catch-up while early adopters capture massive competitive advantages.

Why Everything the Industry Taught You About Herd Health Is Wrong

Let’s challenge the most sacred cow in dairy management: the belief that visual observation and clinical examination represent the gold standard for animal health assessment. This assumption has cost the industry billions and will cost unprepared producers their competitive position.

Research from the comprehensive industry analysis “Beyond the Bolus” reveals that cattle identified as sick through visual appraisal already show clear clinical symptoms and may have been sick for extended periods. For example, clinical signs of bovine respiratory disease might occur later than the onset of fever, or even without the occurrence. Clinical signs of neonatal calf diarrhea are visible only when much of the associated tissue damage to the intestinal submucosa has already occurred.

Here’s the uncomfortable truth the equipment dealers won’t tell you: By the time you see symptoms, you’ve already lost the profitable intervention window. You’re not managing herd health—you’re managing herd damage control.

Whether you acknowledge it or not, the regulatory landscape is shifting beneath your feet. Since the EU banned antibiotic growth promoters in 1999, followed by the FDA’s restrictions on medically important antibiotics in 2017, the writing has been on the wall. Nature Communications research projects that under business-as-usual scenarios, global antibiotic use in livestock could reach 143,481 tons by 2040, representing a 29.5% increase. Cattle farming currently accounts for the largest portion, at 53.5% of global livestock antimicrobial usage.

But here’s what separates industry leaders from followers: While everyone else scrambles to maintain failing protocols with fewer tools, forward-thinking operations have discovered that proactive health management isn’t just better for regulatory compliance—it’s dramatically more profitable. The data proves that farms using continuous monitoring systems reduce disease incidence by up to 30% and veterinary costs by 25%.

Why This Revolution Matters for Your Bottom Line: Consumer demand for antibiotic-free products is creating premium market opportunities, but it’s also creating existential pressure on producers who haven’t developed alternative strategies. The global economic impact of dairy cattle diseases is estimated at $65 billion annually, with subclinical ketosis alone accounting for $18 billion in losses.

Inside Your Cow: The Austrian Technology That’s Disrupting North American Dairy

Here’s where we challenge another industry assumption: that external monitoring is “good enough” for modern dairy operations. SmaXtec, an Austrian company that’s been quietly revolutionizing European dairy management since 2009, has cracked the code on something that seemed impossible just a decade ago—turning every cow into her own personal health monitor through internal sensing technology.

Their bolus technology—a battery-powered sensor that lives in the cow’s reticulum for five years—measures what truly matters for dairy profitability: core body temperature with clinical-grade accuracy of ±0.018°F, individual water intake patterns through their patented TruDrinking™ technology, rumination activity via TruRumi™ sensors, and optional rumen pH monitoring.

Why does this matter more than your current protocols? Because research demonstrates that internal body temperature changes occur up to four days before visual symptoms appear for conditions like mastitis. That’s not just early detection—that’s economic time travel for your treatment protocols.

The technology’s artificial intelligence analyzes multiple data streams simultaneously, much like how modern genetic evaluations combine production, health, and fertility traits into comprehensive indices. A temperature spike with stable rumination but dropped water intake suggests a different problem than one with crashed rumination and low rumen pH. You’re not just getting alerts—you’re getting qualified diagnostic leads.

The Economics That Should Terrify Your Competition

The independent 2024 IFCN study found that SmaXtec enabled a $210 per cow increase in returns and an additional $190 per cow in income, with milk yield increases of 330 kg of solids-corrected milk annually. The study concluded that the technology resulted in “a positive effect on the most important indicators like milk yield, labor, returns, income, and carbon footprint.”

Let’s consider this, which should make every traditional producer uncomfortable. On a 500-cow dairy, that’s $105,000 in additional returns and $95,000 in extra income annually. Even accounting for technology costs, early adopters are capturing massive competitive advantages while their neighbors are still walking pens with thermometers.

The Producer Testimonials That Challenge Everything

Amber Horn-Leiterman, who milks over 2,100 cows in Brillion, Wisconsin, states: “We recently analyzed our cull rates for our dairy, comparing our last year before investing in smaXtec in 2021 with this past year (2023). With smaXtec, we see a 7.8 ROI just from the improvements on cull rates.” Her operation calculated total savings within its replacement program of over $500,000 in 2023.

Think about that for a moment: $500,000 in savings from just one aspect of the technology’s capabilities. Horn-Leiterman adds: “The inner body temperature monitoring that smaXtec provides has been a game changer for us. The inner temperature allows us to provide preventative and supportive care to our cows and helps catch inflammation and metabolic issues in transition cows before these issues get out of hand.”

Beyond Antibiotics: The Singapore Startup That’s Engineering Your Future

While smart boluses are revolutionizing detection, companies like Peptobiotics are engineering the future of treatment using synthetic biology to create antimicrobial peptides (AMPs)—nature’s own antibiotics that promise efficacy without resistance risk.

Research published in PMC demonstrates that AMPs are “ubiquitous in living organisms, spanning from bacteria to humans” and work by physically disrupting bacterial cell membranes rather than targeting specific metabolic pathways. This direct, physical attack is much more difficult for bacteria to develop resistance against, meaning AMPs don’t create the same selective pressure that drives the evolution of drug-resistant superbugs.

Recent studies have shown that AMPs are effective against important livestock pathogens, including Staphylococcus aureus-associated mastitis, with significant antibacterial effects in both in vitro and in vivo experiments.

The Reality Check on Timeline: Peptobiotics is currently focused on aquaculture and poultry, with no announced timeline for cattle applications in North America. But their $6.2 million Series A funding in April 2024 signals serious investor confidence in post-antibiotic agriculture. This represents what industry experts call a “beachhead strategy”—prove the technology in markets with acute disease problems, then expand to larger opportunities like cattle.

The Veterinarian Relationship Revolution: Disrupting Decades of Tradition

Perhaps the most profound disruption isn’t technological—it’s relational. Smart monitoring is fundamentally challenging the decades-old business model of veterinary services, transforming veterinarians from emergency responders into strategic health advisors.

Dr. Rachel Budd with Metzger Veterinary Services represents this transformation: “There are actually a lot of things that we get called on farm to do as dairy vets that the farmer is more than capable of handling themselves. We’re trying to provide training and tools, number one, but also some new technologies that’ll help people be more self-sufficient.”

Here’s what challenges the traditional vet-client relationship: Instead of reactive farm calls, technology enables vets to review continuous data streams and provide proactive consultation remotely. This shift allows veterinarians to become strategic advisors who help interpret complex data patterns, recommend preventative strategies, and evaluate treatment effectiveness with objective evidence.

But this evolution threatens traditional veterinary business models built on billable hours for on-farm visits. Progressive practices are developing subscription-based remote monitoring services—think of it as a health insurance plan for your herd that actually prevents claims rather than just paying them.

The Economic Reality That Should Change Your Strategy

Here’s what the verified numbers actually look like when you implement comprehensive monitoring:

| Economic Driver | Quantified Impact | Verified Source |

| Mastitis Cost Range | $118-$337 per case | MSU study of 20,625 cases across 37 farms |

| Treatment Duration Cost | $65 per additional day | MSU research on dairy treatment economics |

| Milk Discard Impact | 87% of total treatment costs | MSU analysis of intramammary treatments |

| Production Gains | +330 kg SCM per cow annually | Independent IFCN study on US dairies |

| Overall Return Increase | +$210 per cow | IFCN study documentation |

| Additional Income | +$190 per cow | IFCN study results |

| Documented ROI | 7.8x return on investment | Wisconsin dairy: $500,000 savings in 2023 |

Think about this: MSU research shows that reducing treatment duration by just one day saves approximately $65 per case. When you can detect problems four days earlier than visual observation, you’re not just saving money—you’re capturing competitive advantages that compound across your entire operation.

Implementation Strategy: Your Evidence-Based Disruption Roadmap

Month 1: Reality Assessment

- Calculate your current mastitis costs using the verified $118-$337 per case range from MSU research

- Evaluate your existing herd management software for integration compatibility with proven monitoring systems

- Schedule a veterinary consultation to discuss moving beyond reactive protocols

Month 2: Technology Evaluation

- Request demonstrations from monitoring system providers with published research validation

- Review independent case studies from operations similar to your size and management approach

- Develop an implementation timeline that positions you ahead of industry adoption curves

Month 3: Competitive Advantage Implementation

- Start with a subset of cows to validate system performance in your specific environment

- Establish baseline metrics for health costs, treatment protocols, and production outcomes

- Train staff on data interpretation protocols that move beyond traditional observation methods

What Industry Leaders Don’t Want You to Know

The controversial truth threatens established industry power structures: The dairy industry’s addiction to reactive medicine is subsidizing inefficiency and undermining long-term competitiveness. We’ve been conditioned to accept that visual observation and clinical examination represent the pinnacle of animal health management, when research proves this approach captures less than half of actual health events.

The industry’s resistance to change isn’t just about technology adoption—it’s about protecting revenue streams built on treating problems rather than preventing them. While you’re debating the value of monitoring technology, early adopters capture documented returns of $210 per cow and 7.8x ROI.

Meanwhile, research from Nature Communications shows that under business-as-usual scenarios, global antibiotic use in livestock could reach 143,481 tons by 2040. The regulatory environment is shifting, whether you participate or not. Consumer demand for antibiotic-free products creates market premiums that early adopters capture while traditionalists pay catch-up costs.

The Bottom Line: Your Competitive Window Is Closing

Remember that MSU statistic we opened with—mastitis costs ranging from $118-$337 per case, with 87% of costs coming from milk discard in traditional treatment protocols? That’s not just industry data anymore. It’s your specific benchmark for measuring the cost of continuing reactive management versus investing in predictive technology.

The economic case is overwhelming when viewed through current market realities. With documented benefits of $210 per cow in additional returns, $190 per cow in additional income, and milk yield increases of 330 kg SCM annually, these technologies represent the largest operational advantage opportunity the industry has seen in decades.

Here’s what separates industry leaders from followers: While traditionalists debate the value of technology, early adopters like Amber Horn-Leiterman are documenting $500,000 in annual savings from just one aspect of comprehensive monitoring. They’re not just improving animal welfare but capturing competitive advantages that compound annually.

The convergence of internal monitoring and antibiotic alternatives represents the biggest disruption in livestock health management since the development of modern veterinary medicine. With global antimicrobial use projected to reach 143,481 tons by 2040 and regulatory pressure intensifying, the question isn’t whether this transformation will occur—it’s whether you’ll lead it or be forced to follow.

Your next strategic decision is critical: At your next herd health evaluation, calculate the total cost of your last three mastitis cases using the MSU framework of $118-$337 per case, factoring in the $65 daily cost of extended treatment duration. That number represents your ROI benchmark for investing in predictive health technology. In an industry where early adopters document 7.8x returns while competitors struggle with reactive protocols, waiting isn’t just expensive—it’s strategically devastating.

KEY TAKEAWAYS

- Replace Reactive Guesswork with Predictive Intelligence: Traditional visual observation misses 40% of sick animals, while internal sensors detect temperature spikes up to 4 days before clinical mastitis symptoms appear—transforming your morning pen walks from damage control into strategic data review.

- Capture Documented $400+ Annual Returns Per Cow: Independent IFCN research proves $210 increased returns + $190 additional income per cow annually, with milk yield gains of 330 kg SCM—meaning a 500-cow dairy can generate $200,000 in additional revenue while reducing herd health costs by 40%.

- Eliminate 70% of Reproductive Hormone Usage: Wisconsin producers using smart bolus technology achieved precise heat detection and pregnancy rates approaching 30%, while reducing days open and eliminating costly missed breeding opportunities that traditionally cost $30 per 10-day extension.

- Future-Proof Against Antibiotic Restrictions: With global livestock antimicrobial use projected to hit 143,481 tons by 2040 and consumer demand driving antibiotic-free premiums, early monitoring adoption positions your operation ahead of regulatory pressure and captures premium market access.

- Disrupt the $65-Per-Day Treatment Extension Model: MSU data shows each additional day of mastitis treatment costs $65—when you can intervene 4 days earlier with internal sensor alerts, you’re not just saving treatment costs, you’re capturing competitive advantages that compound across your entire operation.

EXECUTIVE SUMMARY:

The $662 annual mastitis cost you’re accepting per cow isn’t inevitable—it’s evidence that reactive health management is bleeding your operation dry. Michigan State University research tracking 20,625 mastitis cases proves that 87% of treatment costs come from milk discard, yet producers using internal bolus sensors are detecting infections four days before clinical symptoms appear. Independent IFCN studies document $210 per cow increased returns and $190 additional income annually from farms implementing smart monitoring technology. While global antibiotic use is projected to reach 143,481 tons by 2040, early adopters like Wisconsin’s Amber Horn-Leiterman are capturing 7.8x ROI and $500,000 annual savings by replacing visual observation with AI-driven diagnostics. Austrian company SmaXtec’s internal sensors measure core body temperature with ±0.018°F accuracy, rumination patterns, and individual water intake—revolutionizing herd health from inside the reticulum. With traditional visual assessment showing only 61.8% sensitivity for disease detection, the question isn’t whether this technology will become standard practice—it’s whether you’ll capture early adopter advantages or pay catch-up costs. Calculate your current mastitis expenses using MSU’s $118-$337 per case framework and discover why proactive monitoring isn’t just better animal welfare—it’s your competitive survival strategy.

Complete references and supporting documentation are available upon request by contacting the editorial team at editor@thebullvine.com.

Learn More:

- Maximize Milk Quality and Herd Health with Effective Integrated Pest Management Strategies – Discover practical IPM protocols that create the foundation for smart sensor success by eliminating environmental health stressors before technology deployment.

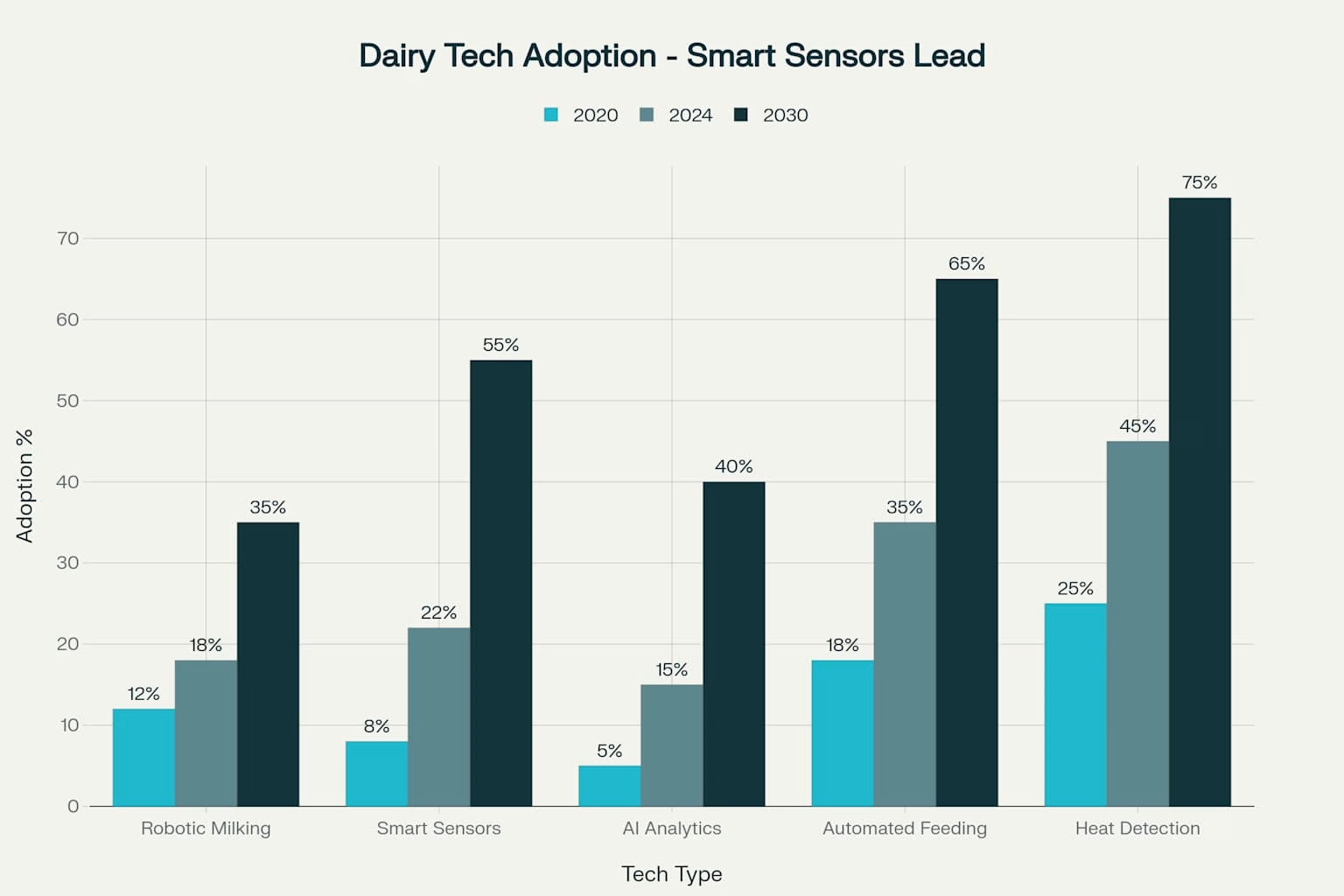

- 5 Technologies That Will Make or Break Your Dairy Farm in 2025 – Explore how smart sensors integrate with robotic milkers, AI analytics, and precision feeding systems to create comprehensive automation strategies delivering 20% yield increases.

- 11 Proven Strategies to Lower Feed Costs and Boost Efficiency on Your Dairy – Learn proactive health and nutritional management techniques that maximize your smart sensor ROI by optimizing the biological foundation sensors monitor.

Join the Revolution!

Join the Revolution!

Join over 30,000 successful dairy professionals who rely on Bullvine Weekly for their competitive edge. Delivered directly to your inbox each week, our exclusive industry insights help you make smarter decisions while saving precious hours every week. Never miss critical updates on milk production trends, breakthrough technologies, and profit-boosting strategies that top producers are already implementing. Subscribe now to transform your dairy operation’s efficiency and profitability—your future success is just one click away.

Join the Revolution!

Join the Revolution!