What happens when cows actually choose? German researchers tested it—and found $1,400/cow in costs disappeared. Here’s what they discovered.

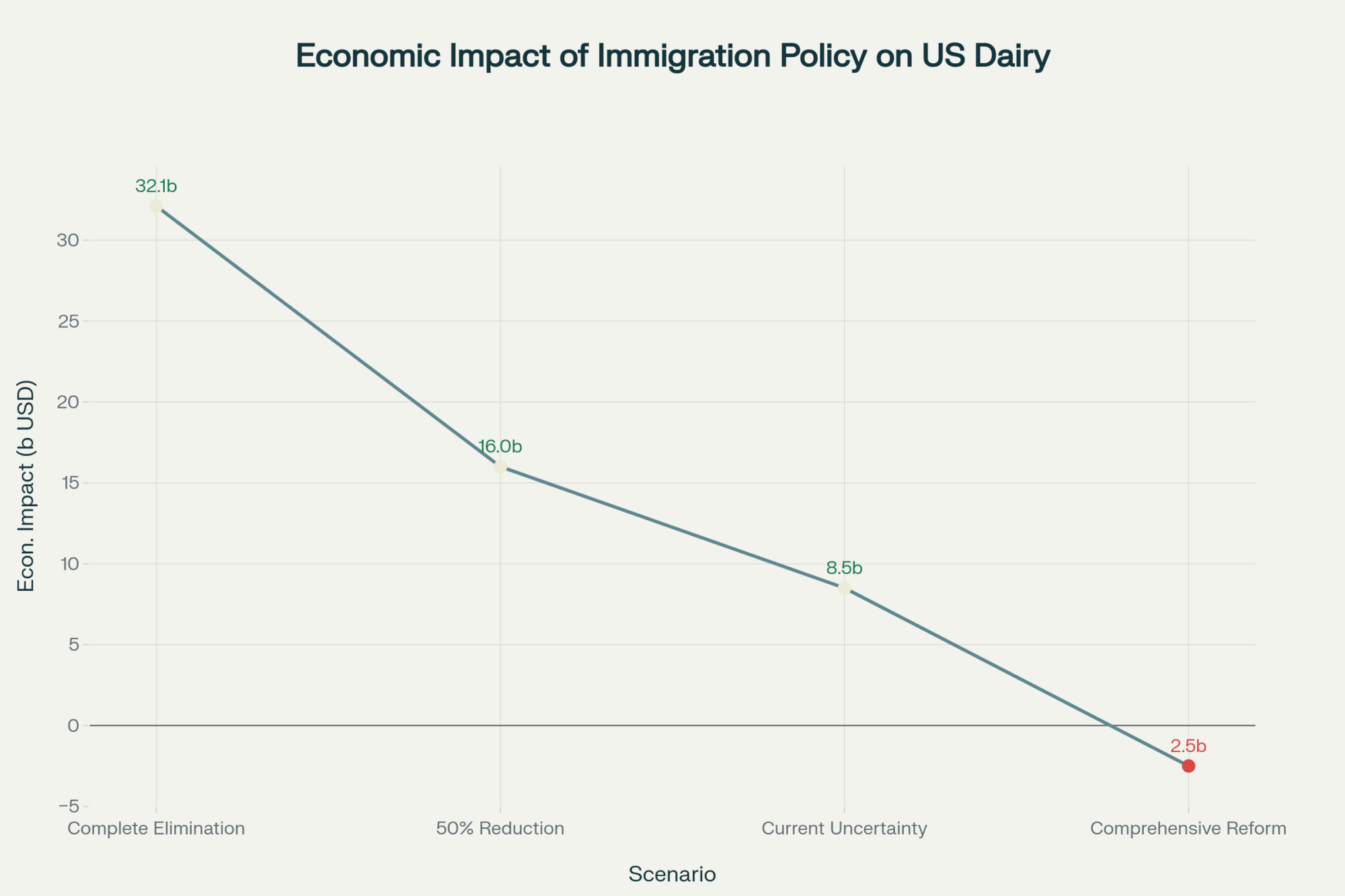

Executive Summary: Conventional dairy practices are costing you $1,400 per cow annually in hidden losses from regrouping stress, transition disease, and premature culling—costs most farmers don’t even track. German researchers just proved these losses are preventable through an integrated approach: let cows choose their environment, maintain stable social groups, and keep calves with mothers longer. The data are striking: regrouping alone costs $3,400/year in a 500-cow herd, while their approach reduces lameness by 30-40% and produces calves gaining 3+ pounds daily. Implementation means rethinking barn design and investing 18-24 months in learning new management practices, but the returns justify the effort—$400,000-500,000 in annual benefit potential with a 4-6 year payback. With retailers like Walmart already demanding welfare-certified products and the market growing to .4 billion by 2033, early adopters gain a competitive advantage. The bottom line: when cows get choice, hidden costs disappear and everybody wins—especially your profit margin.

You know what caught my attention last week? A group of German agricultural researchers posed a question that’s got me rethinking everything about barn design: What if we actually let cows decide how they want to spend their day?

Prof. Dr. Lisa Bachmann and her team at the Research Institute for Farm Animal Biology in Dummerstorf, Germany, published their findings this fall in the Journal of Dairy Science, and honestly… some of these insights are making me reconsider assumptions I’ve held since I started in this business.

What makes German research distinctive is its integrated design concept, which combines stable family herds, cow-calf contact, free indoor-outdoor movement, and automation—a comprehensive approach documented in their published research. Their design concept maintains stable social groups throughout production, provides genuine barn-and-pasture choice during favorable seasons, and integrates cow-calf contact with automated milking. And here’s what’s really interesting—their research documents how this integrated approach addresses multiple cost drivers simultaneously—regrouping stress, transition disease incidence, and culling patterns—suggesting substantial economic advantages we haven’t really considered before.

Here’s the context that makes this relevant right now. USDA’s latest census shows we’ve gone from 105,250 dairy farms in 2000 to about 31,600 operations today. That’s a 70% drop, folks. So when we’re talking about alternative approaches to dairy infrastructure, we’re no longer just having an academic discussion. For a lot of mid-sized operations—maybe yours—this could be about finding a viable path forward.

What We’re Learning About Cow Preferences

What’s fascinating is how consistent cow behavior becomes when they actually have choices. Research on grazing behavior shows cows utilizing outdoor areas extensively, particularly during evening and nighttime hours. And get this—their motivation for pasture access rivals their drive for fresh feed. That’s saying something.

I was looking at production research from Ireland the other day, and the lying time data really stood out. Cows with pasture access were averaging about 9.9 hours of daily lying time compared to 9.5 hours for confined animals. Now, you might think, “That’s only 24 minutes, what’s the big deal?” But here’s what’s interesting—those pasture cows had fewer but longer lying bouts. Less getting up and down, more quality rest. You know how much that matters for rumination and production.

“Conservative estimates suggest we’re looking at $1,000-1,400 annually per cow in hidden costs from stress, disease, and management practices we’ve just accepted as normal.”

Marina von Keyserlingk’s animal welfare lab at UBC documented another noteworthy finding: cows with overnight pasture access show significantly more walking activity. And for those of us dealing with lameness issues—which is basically everyone, right?—that natural movement pattern correlates with better hoof health.

Speaking of lameness, research comparing different housing systems shows some pretty dramatic differences. We’re seeing lameness prevalence vary significantly by bedding and housing type, with comprehensive studies documenting reductions of 30-40% in systems incorporating pasture access. Penn State Extension puts lameness costs at around $337 per case. Do the math on that for your herd—it adds up fast.

The Real Cost of Moving Cows Around

Here’s something we don’t talk about enough. Most of us regroup cows four to six times per lactation. It’s just… what we do, right? But Daniel Weary’s group at UBC has been quantifying what that actually costs us, and the numbers are sobering.

They’re documenting an immediate 8.5% production drop when you regroup—going from about 95 pounds down to 87 pounds daily. Feed intake drops 9% during that adjustment period. The behavioral chaos lasts 3-7 days. And there’s a clear negative correlation between aggressive interactions and butterfat levels.

So I ran the numbers for a typical 500-cow herd averaging 80 pounds at $20/cwt. Each regrouping event? That’s about $1.36 in lost production per cow. Five times across a lactation, you’re looking at $3,400 in revenue just… gone. And that’s before we even think about what stress does to breeding or somatic cell counts.

The German research proposes maintaining what they call “stable family herds”—basically keeping cows and their offspring together without constant pen changes. Yeah, it means rethinking your entire barn layout and cow flow. But when you add up all these hidden costs? The economics start looking different.

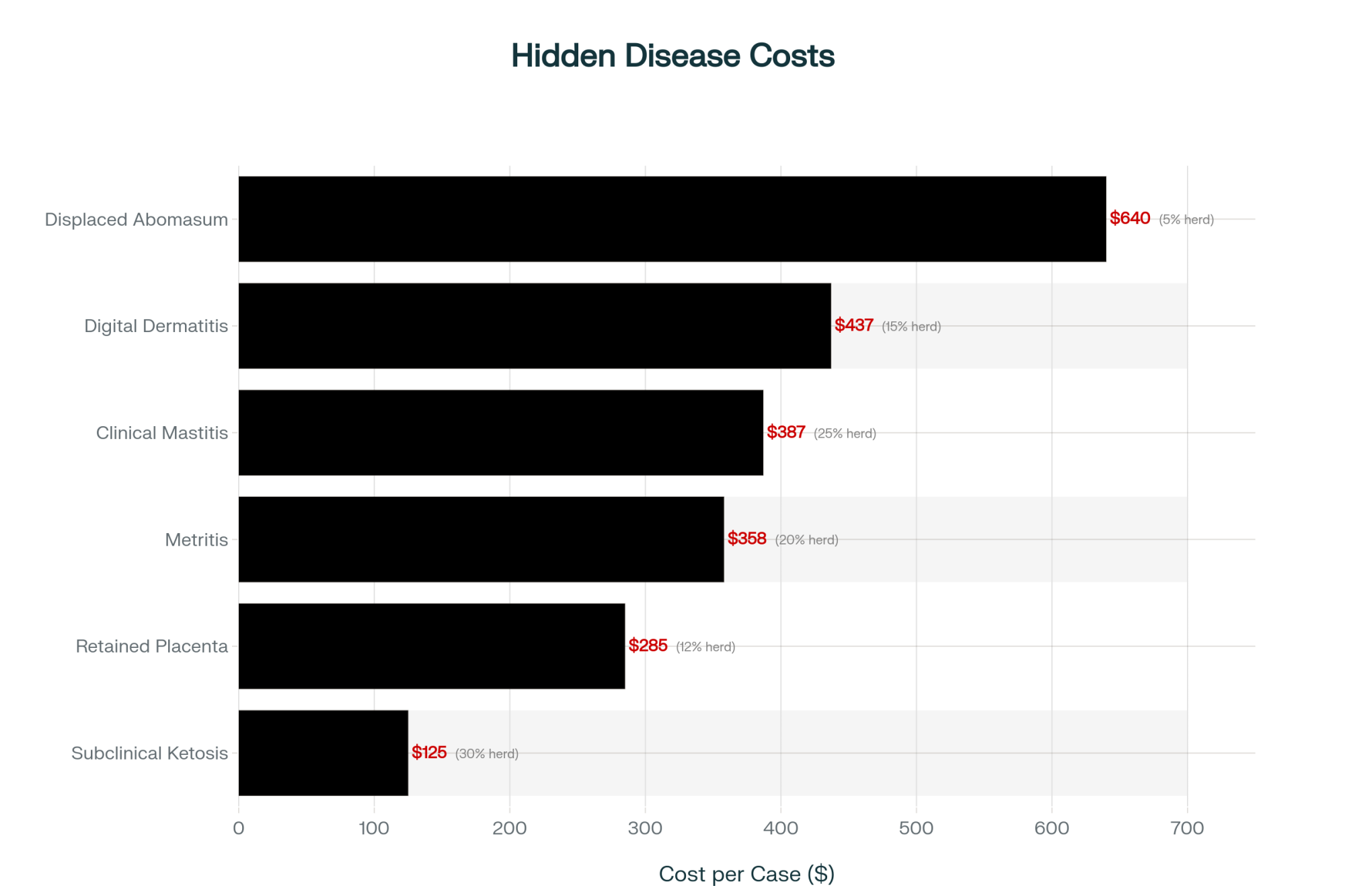

Hidden Costs Summary

| Cost Category | Impact Per Event/Case |

| Regrouping | $6-10/cow per event |

| Transition disease | $125-450/case |

| Lameness | $337/case |

| Annual total per cow | $1,000-1,400 |

Reconsidering Cow-Calf Contact

I’ll be honest—I’ve always been pretty skeptical about extended cow-calf contact. The colostrum management concerns are real, and disease control matters. But the data coming out of European research institutions is making me think twice.

Norwegian researchers tracking cow-calf systems in automated milking herds are seeing calves achieve average daily gains around 1.4 kg—that’s over 3 pounds a day. That’s beef calf territory, way beyond the 1.25 to 1.9 pounds we typically see with conventional feeding. Research shows that calves with extended dam access consume substantially higher milk volumes than those in conventional feeding programs.

Now, Swedish agricultural research acknowledges these systems can reduce your contribution margin by 1-5%, primarily from milk you’re not selling. Fair point. But here’s what that analysis often misses…

Research indicates significant labor reductions during the calving period when cows manage their own calves. Think about it—no milk replacer costs, no feeding equipment to clean, fewer health treatments. Studies consistently show improved calf health metrics in these contact systems. And for those of us struggling to find reliable calf feeders (which seems to be everyone these days), the labor savings alone might tip the scales.

How Automation Changes Everything

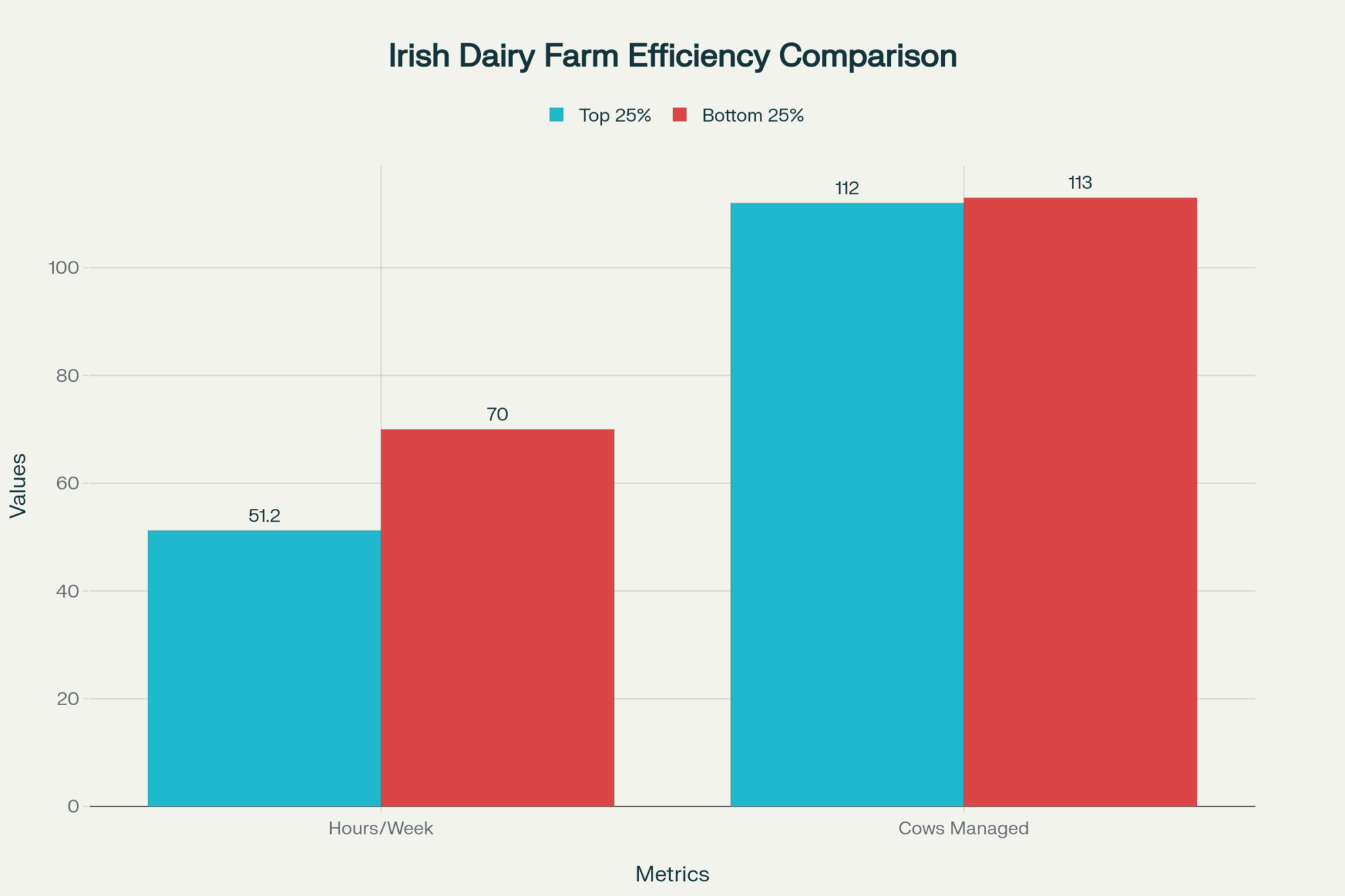

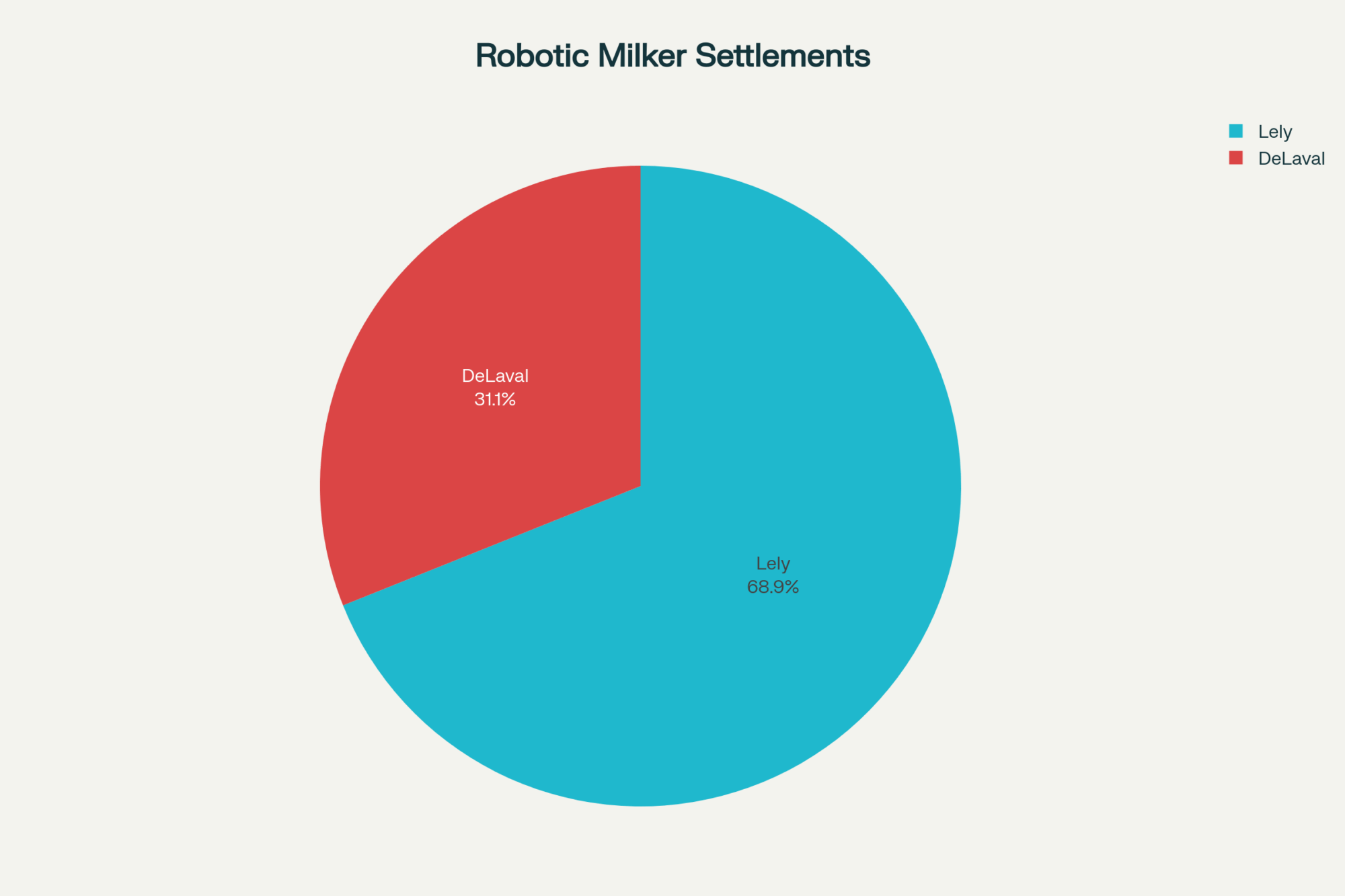

What’s really interesting is how automation is shifting the whole welfare conversation. Michigan State’s recent survey of large dairy farms with robots found something telling: 84.6% cited labor cost reduction as their main reason for automating, but 76.9% also reported improved cow welfare.

“Each regrouping event costs about $1.36 per cow in lost production. Five times across a lactation, you’re looking at $3,400 in revenue just… gone.”

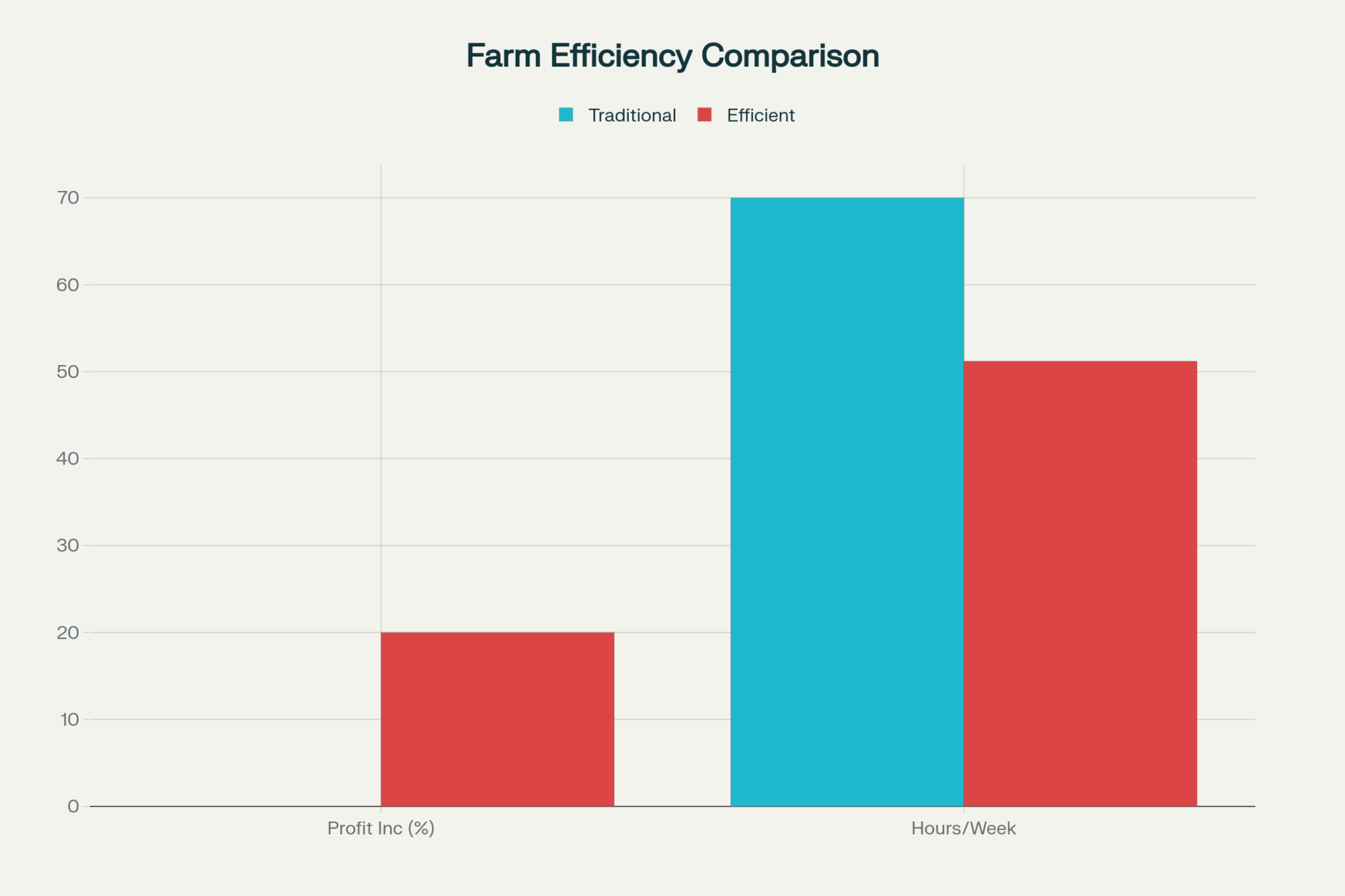

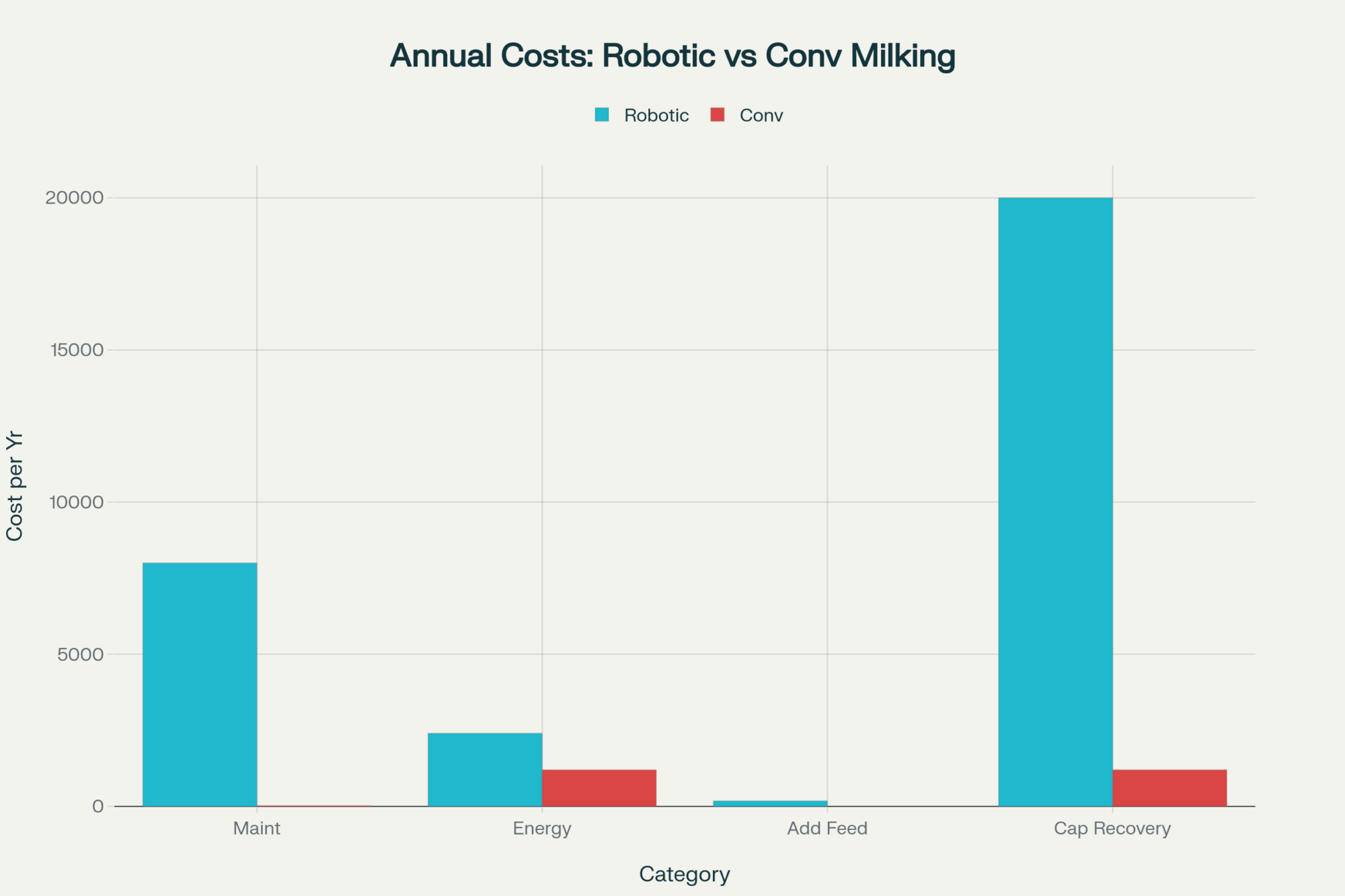

The financials are compelling. University of Wisconsin data shows that operations with robots reduced labor costs from about 8.4% of revenue to 4.4%. That’s a 38-43% reduction in time per cow, with milking-related tasks down 62%.

But here’s what I’ve been noticing during farm visits… Most robot installations are still optimizing the same old confinement model rather than enabling the kind of cow choice that German research suggests could improve both welfare and profitability. Current designs assume conventional freestall housing with standard routing. Want to add real outdoor access? That requires completely different thinking.

Industry experts increasingly acknowledge that while technical solutions exist, our infrastructure tends to reinforce conventional approaches rather than enabling alternatives. Some equipment manufacturers are exploring systems compatible with grazing, especially for markets where that’s standard practice, but North American options remain pretty limited.

Understanding the Full Cost Picture

Recent research on dairy economics has been eye-opening about costs we usually don’t track properly:

You know transition cow challenges—nearly half of fresh cows deal with some metabolic issue. Subclinical ketosis alone runs about $125 per case based on recent studies. Clinical mastitis? USDA data puts it at $325-450 per case, with 71% of those costs from lost production, not treatment.

Lameness economics are brutal. Penn State’s research shows an average of $337 per case, with each additional week adding about $13. Digital dermatitis typically runs almost $100 more than other lameness causes. And here’s what really gets me—research consistently shows lameness hammering fertility, with reproduction-related costs representing a huge chunk of the total economic hit.

Then there’s culling and replacement. Canadian dairy industry data shows turnover at 35-40%, with replacement costs of $2,500-3,500, depending on where you are. Lose a cow before her third lactation? You never recover that rearing investment.

Add it all up, and conservative estimates suggest we’re looking at $1,000-1,400 in hidden costs per cow annually from stress, disease, and management practices we’ve just accepted as normal. That’s… that’s a lot of milk checks.

| Metric | Conventional System | Welfare-Integrated System | Net Difference |

|---|---|---|---|

| Annual Cost Per Cow | $1,400 hidden losses | $400 reduced losses | $1,000 savings/cow |

| Regrouping Events/Lactation | 4-6 times | 0-1 times | 4-5 fewer events |

| Lameness Prevalence | 20-25% | 12-15% (-40%) | -40% cases |

| Lameness Cost Impact | $337/case × 100+ cases | $337/case × 60 cases | ~$13,500 savings |

| Transition Disease Rate | ~50% of fresh cows | ~25% of fresh cows | -50% incidence |

| Calf Daily Gain (lbs) | 1.25-1.9 lbs | 3+ lbs | +1+ lb improvement |

| Average Culling Rate | 35-40% | 22-25% (-35%) | -13-15% points |

| Replacement Cost | $2,500-3,500/cow | $2,500-3,500/cow | Earlier ROI |

| Labor Cost (% of revenue) | 8.4% | 4.4% | -48% labor |

| Milk Production Stability | High variability | More consistent | Improved flow |

| Veterinary Costs | Baseline | -30 to -35% | $35K+ savings |

| Total Herd Cost (500 cows) | $700,000 in losses | $200,000 in losses | $500,000 annual gain |

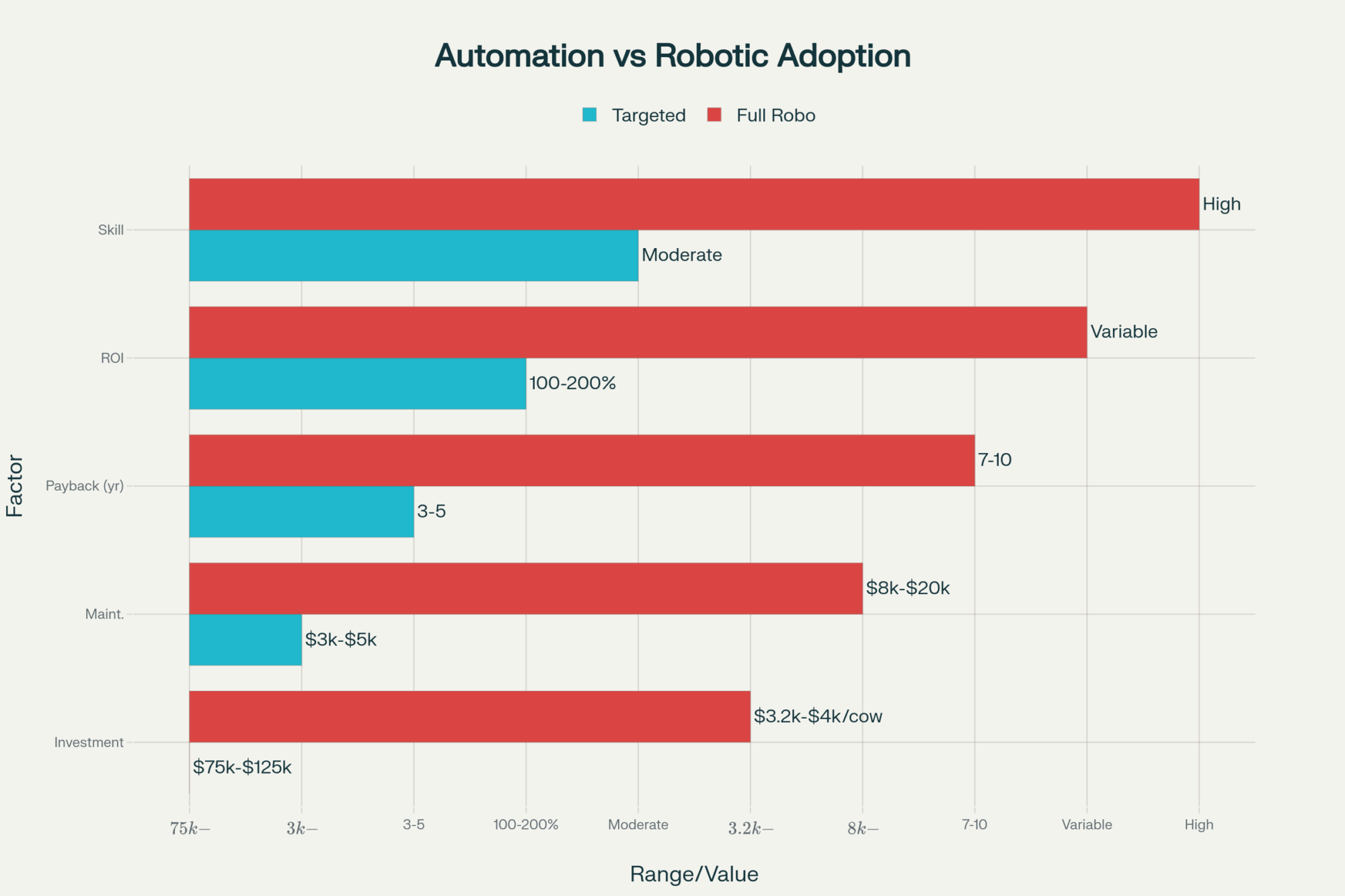

Thinking About Infrastructure Investment

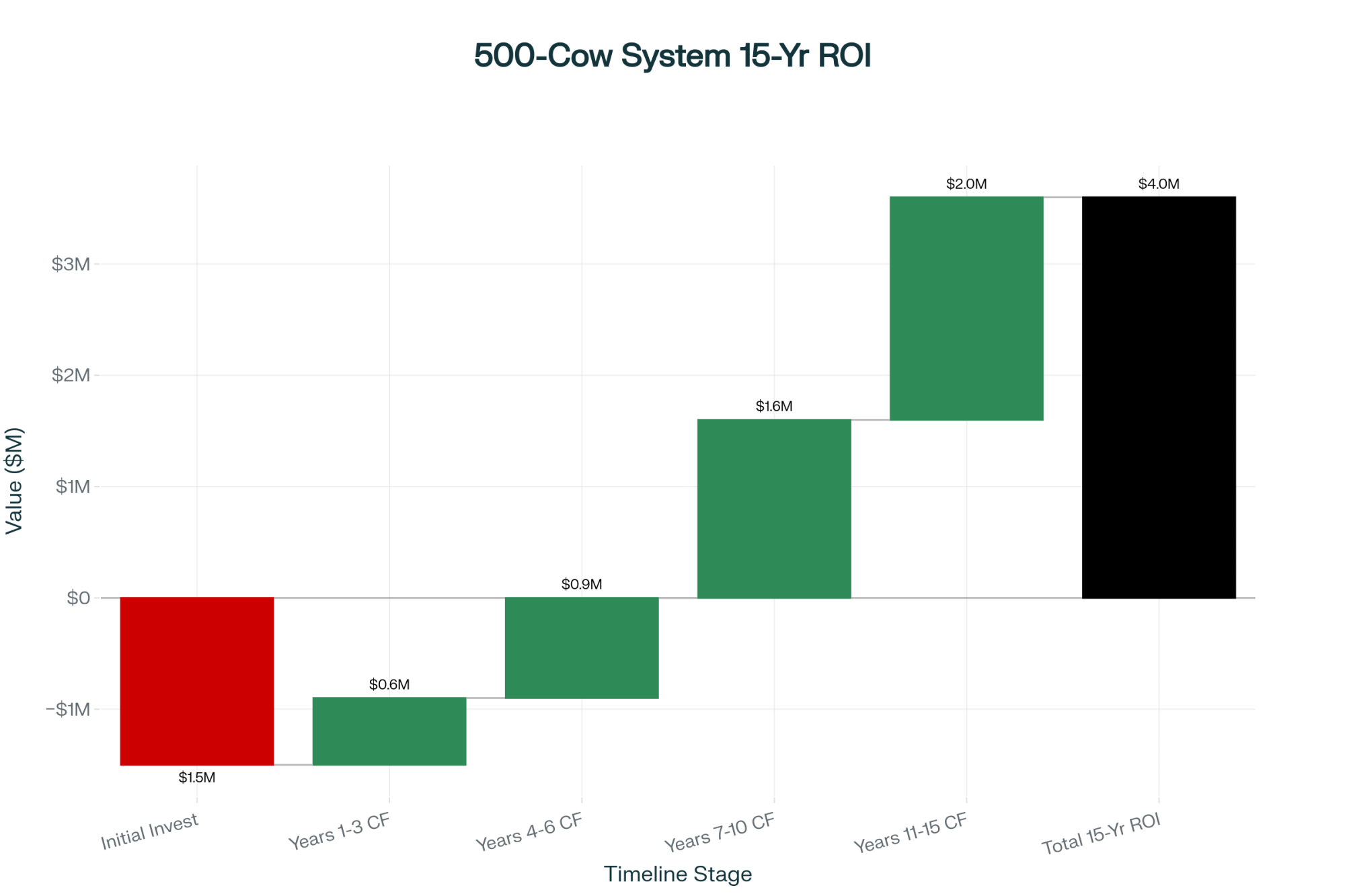

The German team’s estimates for welfare-integrated systems suggest substantially greater capital investment than conventional designs—we’re talking significant money here, potentially thousands of dollars per cow.

But let’s think through the returns. If these systems prevent even $800-1,000 annually in disease, stress, and culling losses, a 500-cow operation could see $400,000-500,000 in annual benefit. Finance that over 15 years at 6%, you’re looking at $200,000-300,000 in debt service, potentially leaving $150,000-250,000 in improved cash flow. That suggests a 4-6 year payback. I’ve seen producers jump on automation for returns that are less attractive than that.

Practical Implementation Thoughts

Based on conversations with producers who’ve made changes, here’s what seems to work:

Start with what you can control. You don’t need to revolutionize everything overnight. Several operations I know in Wisconsin started simple—adding outdoor access areas, reducing regrouping frequency, and trying modified calf management in just one pen.

Really assess your existing setup. Retrofitting current facilities for genuine cow choice is way harder than building it in from the start. If you’re already planning major construction or renovation? That’s your opportunity.

Think carefully about your market position. Nielsen’s 2023 consumer research documented a 57% increase in certified animal welfare products after mainstream retailers began stocking them. There’s a real differentiation opportunity, but you need to know what your milk buyer values.

And budget time for the learning curve. Managing pasture systems, cow-calf contact, stable herds—it’s different than running conventional confinement. Most folks find it takes 18-24 months to really develop the new management skills.

Regional Considerations

One thing the German research doesn’t fully address—and it matters here—is our climate variability. What works in temperate Germany needs adaptation for Arizona heat or Manitoba winters.

I’ve been hearing about different regional approaches. California researchers are testing shade and cooling for outdoor areas in hot climates. Canadian institutions are exploring winter paddock designs that maintain choice even in extreme cold.

In the upper Midwest, some producers are trying hybrid approaches—outdoor access during good weather, modified grouping strategies for winter housing. It’s not the full German model, but they’re seeing meaningful improvements in lameness and culling.

“Lose a cow before her third lactation? You never recover that rearing investment.”

Some producers implementing partial modifications report that eliminating regrouping practices resulted in substantial reductions in veterinary costs, though they acknowledge the learning curve was steep initially. I’ve heard of operations documenting 30-35% drops in vet bills after making these changes, though everyone admits it takes time to figure out the new management approach.

Looking Ahead

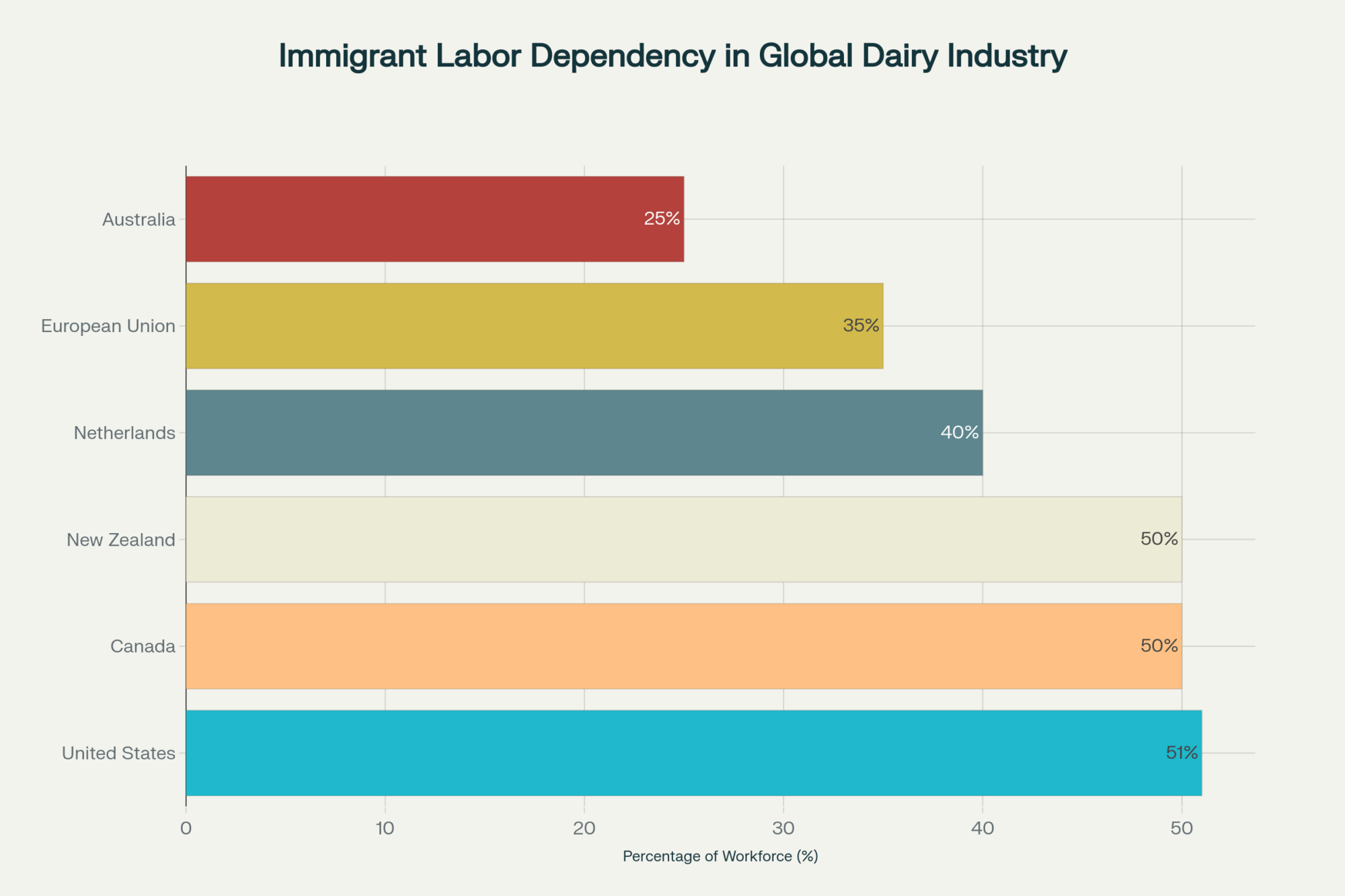

The consolidation trend isn’t slowing. Industry projections show substantial portions of milk production shifting to larger operations in the coming years. For mid-sized farms—those 200 to 1,000 cow operations that are the backbone of many regions—the traditional “get big or get out” message feels pretty heavy.

But this research illuminates other paths. The animal welfare certification market reached $1.2 billion in 2024 and is projected to reach $3.4 billion by 2033, according to Grand View Research (https://www.grandviewresearch.com). Major retailers like Walmart and Kroger have made procurement commitments for certified products. That’s creating a genuine market opportunity for differentiated producers.

Plus, emerging climate regulations are going to reshape the economics. Canada’s carbon framework for agriculture and similar U.S. initiatives will likely favor systems with greater efficiency, enhanced pasture management, and lower replacement rates.

What Producers Are Finding

Producers implementing modified approaches report interesting results. After dealing with steep learning curves around cow flow and grazing management, many are seeing veterinary costs drop significantly, labor requirements decrease, and production metrics improve—outcomes that surprise even them.

Others are taking different approaches, like maintaining limited cow-calf contact as a workable compromise between calf health improvements and milk sales. The key seems to be adapting concepts to specific circumstances rather than trying to copy someone else’s system exactly.

There’s no universal template here. Each operation needs to evaluate how these concepts might work with their unique combination of facilities, labor, markets, and management style.

The Bottom Line: Your Hidden Costs

When you factor in:

- Regrouping losses: $3,400/year for 500 cows

- Transition diseases: 50% of fresh cows are affected

- Lameness: $337/case at 15-20% prevalence

- Premature culling: Never recovering $2,500-3,500 investment

You’re losing $1,000 to $ 1,400 per cow annually in preventable costs.

Quick Takeaways for Action

Looking at all this research, here’s what you can start doing today:

- Calculate your hidden costs: Track regrouping frequency, transition disease rates, and culling patterns for three months

- Test small changes: Pick your highest-stress group and eliminate one regrouping event

- Explore market premiums: Contact your milk buyer about welfare certification opportunities

- Visit operations making changes: Nothing beats seeing these systems in action

- Budget for learning: Any system change requires time—plan for it

Making Sense of It All

After really digging into this research, here’s what stands out to me:

The economics are way more complex than simple comparisons suggest. When you account for regrouping losses, disease costs, premature culling, and genetic potential that never gets expressed, conventional systems carry substantial hidden costs. Alternative approaches could meaningfully reduce those expenses.

Consumer expectations keep evolving. When certified products reach mainstream retail with clear differentiation, sales respond. That’s not a trend—it’s market reality.

Technology can enable choices. Current automation typically optimizes confinement, but alternative technical solutions exist. It’s more about design philosophy than technical barriers.

The transformation already underway creates both risk and opportunity. As margins compress and consolidation accelerates, differentiation becomes increasingly valuable. Whether you pursue commodity efficiency or welfare premiums—that’s a fundamental strategic decision.

And here’s the thing—the knowledge exists right now. The research has been published, the designs are documented, and the technical specifications are available. The question isn’t whether these systems work. It’s how they might fit your specific situation.

Looking at where we’re headed, understanding these alternatives becomes crucial for planning. This German research reminds us that innovation sometimes comes from questioning our basic assumptions.

The path forward varies by operation. A 5,000-cow facility in New Mexico operates under different constraints than a 200-cow farm in Vermont. But having genuine options—economically viable alternatives to consider—that’s what gives us flexibility to build operations aligned with our goals, values, and circumstances.

Maybe the question isn’t whether we can afford to implement such changes. Given the hidden costs already embedded in our operations and where markets are heading… maybe we should be asking: What’s the cost of not exploring these possibilities?

That answer will likely shape the next generation of dairy farming. And honestly? When cows get to make choices, it turns out everybody might win—including our bottom line.

Complete references and supporting documentation are available upon request by contacting the editorial team at editor@thebullvine.com.

Learn More:

- Unlocking Cow Comfort: The Hidden Driver of Milk Production in 2025 – Discover how specific adjustments to lying time and stocking density can unlock an additional 2-3.5 pounds of milk daily per cow, reinforcing the financial case for prioritizing environment over maximizing headcount.

- Decide or Decline: 2025 and the Future of Mid-Size Dairies – Explore the critical “decision window” facing mid-sized operations and evaluate three proven strategic paths—expansion, optimization, or specialized transition—to secure your farm’s equity before market conditions shift further.

- Robot Revolution: Why Smart Dairy Farmers Are Winning with Automated Milking – Learn how automated systems are delivering labor savings of $32,000–$45,000 annually per unit while enabling the exact type of “cow choice” workflow that drives improved welfare and production outcomes.

Join the Revolution!

Join the Revolution!

Join over 30,000 successful dairy professionals who rely on Bullvine Weekly for their competitive edge. Delivered directly to your inbox each week, our exclusive industry insights help you make smarter decisions while saving precious hours every week. Never miss critical updates on milk production trends, breakthrough technologies, and profit-boosting strategies that top producers are already implementing. Subscribe now to transform your dairy operation’s efficiency and profitability—your future success is just one click away.

Join the Revolution!

Join the Revolution!

![VMSFullCow[1]](https://www.thebullvine.com/wp-content/uploads/2013/07/VMSFullCow1.png) Designed as the next tool for top herds

Designed as the next tool for top herds Multi-Purpose Tool

Multi-Purpose Tool