California: No water to buy. Wisconsin: Can’t spread when you need to. Texas: Just add cows. Geography is destiny in dairy.

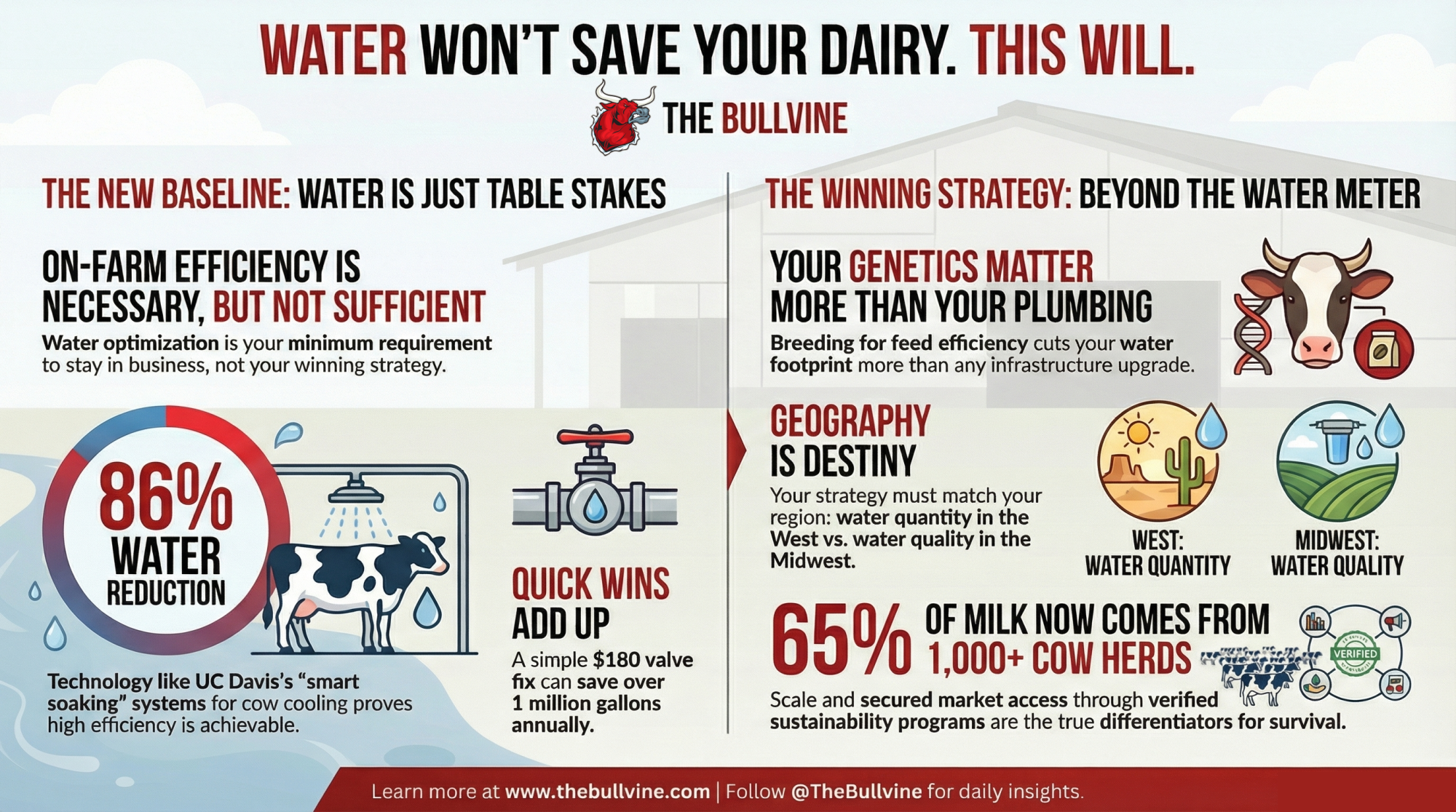

Executive Summary: Water management has shifted from competitive advantage to survival requirement—but paradoxically, excellence alone won’t save your farm. As California’s SGMA eliminates up to one million irrigated acres by 2040 and drives $2.2 billion in feed cost impacts, the industry is discovering that breeding for feed efficiency reduces water footprint more dramatically than infrastructure improvements. Meanwhile, consolidation has concentrated 65% of milk production in 1,000+ cow operations, where scale economics overcome any efficiency gains smaller farms achieve. Yes, that $180 valve fix, saving a million gallons, matters, and UC Davis’s smart soaking systems, cutting water use by 86%, are revolutionary—but only if you have market access and verification infrastructure to monetize sustainability, which drives 1.7% higher sales growth. The uncomfortable truth: water optimization is your entry fee to stay in business, while genetics, scale, and secured buyer relationships determine whether you’re still milking cows in 2035.

You know, sitting here thinking about where we’ve ended up with water management, it’s pretty remarkable how fast things have shifted. Just a couple of years ago, we were mostly talking about upgrading plate coolers and fixing leaky valves. Now? Water’s become this baseline competency that basically determines who’s still milking cows five years from now. But here’s what keeps me up at night—and maybe you’ve been thinking this too—water excellence alone won’t save your operation. The farms that survive the next decade? They’re the ones who’ve figured out market access, understood their regional water reality, and locked in the right scale or specialty positioning. That’s the uncomfortable conversation most of us are having over coffee these days.

Why This Matters Now (Even Though It Won’t Save Us by Itself)

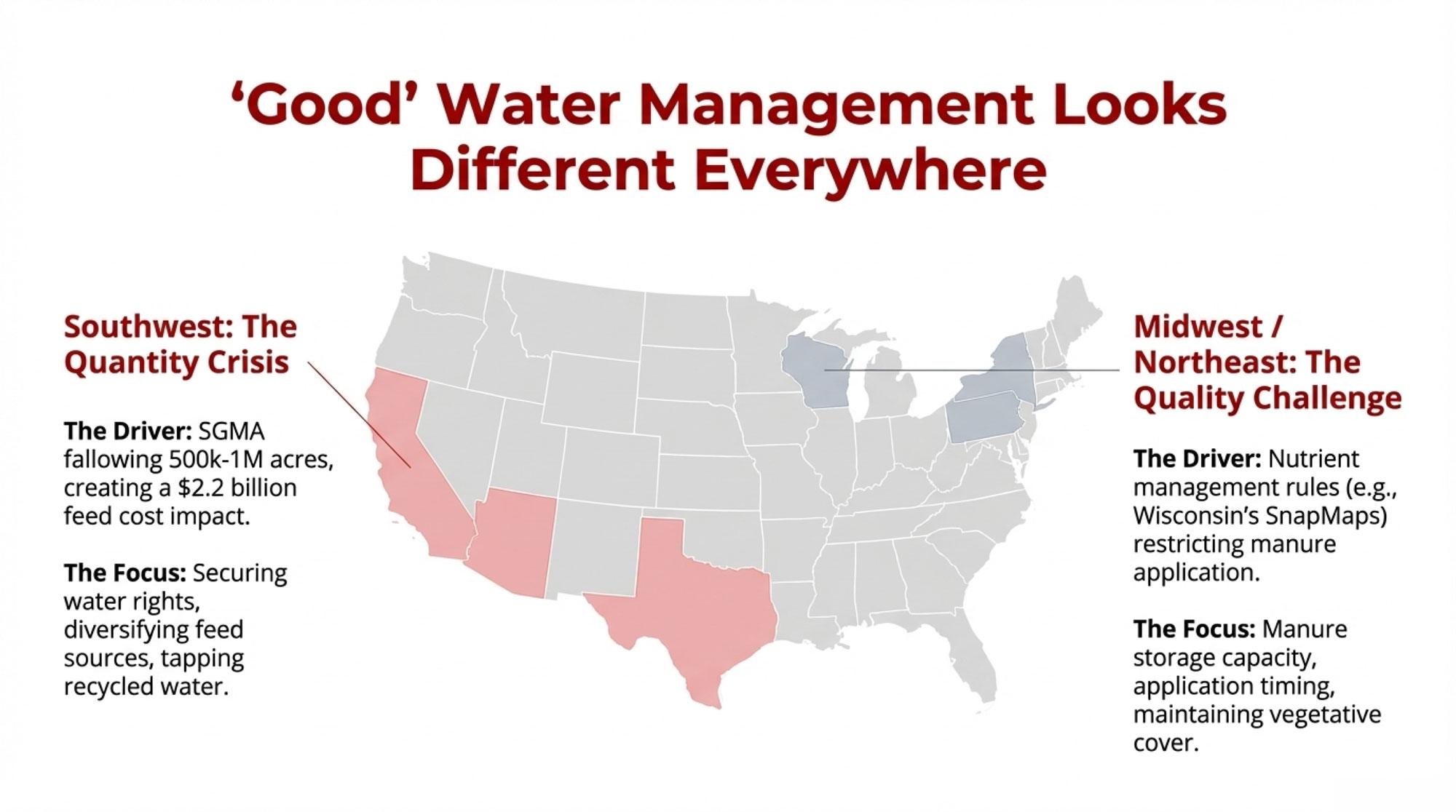

So here’s what’s driving all this. Out West, you’ve probably heard about SGMA—California’s Sustainable Groundwater Management Act—, and it’s systematically pulling irrigated acres out of production. The Public Policy Institute of California (PPIC) projects that one-fifth of irrigated acreage in the San Joaquin Valley will go offline by 2040. We’re talking somewhere between 500,000 and nearly a million acres getting fallowed, with counties like Kern, Tulare, and Fresno taking the worst of it. And you know what? That’s not a drought we can wait out. That’s permanent structural change in how we access water for growing feed.

What’s encouraging, though—and this caught my attention in the latest McKinsey research with the dairy executives—is that products marketed as sustainable are growing sales at a rate 1.7 percentage points higher than conventional products—accumulating 28% total growth versus 20% over the last five-year cycle. So when farms can credibly verify and tell their water story, the market responds. That’s real money sitting there.

What I’ve found talking to producers across different regions is that these two realities—the physical water limits out West and these measurable market rewards for doing sustainability right—they’re completely redefining what “good water management” even looks like. And it’s not the same everywhere, which is something we all need to understand better.

The Four-Stage System We’ve All Settled On (And Why It Actually Works)

Here’s what’s interesting about where most progressive operations have landed—and maybe you’re already doing this. We’ve pretty much standardized on this four-stage cascade that gets every drop working multiple times. You start with clean cold water to plate-cool the milk, then capture that warmed water for sanitizing equipment, move it to barn cleaning, and finally, that nutrient-rich effluent goes out to irrigate feed crops.

UC Davis laid out the science on why that first stage—the plate cooler—is such a workhorse. The countercurrent heat exchanger pulls heat out way more efficiently than relying only on bulk tank refrigeration. And when you capture that warmed water for the next job, you’re essentially getting free preheating for your sanitation cycle. Pretty slick when you think about it.

What’s also catching attention—especially for those of us dealing with summer heat—is the innovation happening in cow cooling. UC Davis has been running trials showing ‘smart soaking’ systems—which rely on sensors to spray only when cows are present—that cut cooling water use by up to 86% while also dropping energy use. In those Central Valley operations where it’s triple digits all summer, that’s huge. The field results suggest you can maintain cow comfort with targeted, intermittent cooling, using a fraction of the energy traditional systems require.

Now, the technical playbook for all this is proven and honestly not that expensive—we’re talking $3,000 to $5,000 for basic improvements on a 200-cow dairy. But here’s the thing we need to be honest about: doing this well in 2025 is table stakes. It’s not your winning strategy by itself anymore.

The Genetics Piece Nobody’s Talking About (But Should Be)

While we’re all focused on plumbing and plate coolers—and those matter—we can’t ignore the cow herself. You probably know this already, but feed production accounts for the lion’s share of our water footprint, especially when we irrigate alfalfa and corn silage. So, the fastest way to cut water use? Breed a more efficient cow that needs less feed to make the same pounds of fat and protein.

That’s why we’re seeing such rapid uptake of feed efficiency indices. Feed Saved, which the Council on Dairy Cattle Breeding publishes, is fascinating—it combines residual feed intake with body weight composite to tell you expected pounds of feed saved per lactation. Higher is better, obviously. It’s our first national evaluation that directly targets feed efficiency in dairy cattle, and the logic is pretty straightforward: cows delivering the same components on less dry matter need fewer irrigated acres behind them.

We’re also seeing proprietary indices like EcoFeed gaining traction, with independent trials showing real improvements in feed conversion on participating herds. The direction is clear—if you’re selecting sires today, you want high feed efficiency and moderate mature size. That cuts your feed needs for both maintenance and production, freeing up water without sacrificing butterfat performance.

I’ll be direct here: if water efficiency isn’t part of your sire selection today, you’re basically locking in higher resource costs for the next three generations of cows. That’s a long time to be on the wrong side of this trend. And with the current heifer shortage limiting expansion options, genetic progress becomes even more critical for improving efficiency within your existing herd size.

Regional Realities (Because California’s Crisis Isn’t Wisconsin’s Challenge)

Looking at this across regions, what’s become clear is that we’re not all dealing with the same problem.

Out in the Southwest, it’s all about quantity. SGMA enforcement is fundamentally a water-access story more than a parlor-efficiency story. The PPIC figures that about one-fifth of Valley irrigated acres could be gone by 2040, which flows straight into feed costs. California’s dairy and beef sectors are looking at impacts of about $2.2 billion by 2040, mostly through higher feed costs as those acres go offline.

Ryan Junio, who runs 4,200 Jerseys over in Pixley, put it pretty bluntly: “As a dairy producer, this is an ever-growing challenge and is my top concern.” And he’s not worried about some future problem—he’s looking at potential 50% groundwater cuts in the next couple of years. For operations like his, “good” water management means securing allocations, maybe tapping recycled municipal water, definitely diversifying feed sourcing, including outside the basin.

Now, flip over to the Northeast and Upper Midwest—completely different game. Water’s abundant, sometimes too abundant. The focus is solely on protecting groundwater and surface water from nutrient pollution. Wisconsin’s SnapMaps system, for instance, doesn’t care about your gallons per cow. It maps where you can spread manure based on soil vulnerability and groundwater flow.

Jim Risser, who farms 700 acres in Pennsylvania’s Susquehanna watershed, explained it well: keep fields planted and vegetated, and you’re creating a natural filter before water hits the streams. His operation maintains vegetation cover for about 50 weeks a year, specifically to improve water quality.

In those Midwest operations with sandy soils and shallow water tables, storage capacity and timing become everything. Producers there are investing heavily in concrete storage and injection equipment—not to save water, but to protect it. The April spreading windows that used to work don’t anymore with our changing weather patterns.

Market Signals That Are Reshaping Everything

Three things are steering every water investment decision I’m seeing in 2025:

First, these structural constraints aren’t temporary. SGMA’s glide path and surface flow rules will idle acreage regardless of how efficient any single farm gets. That repricing rations everywhere—not just in California—because the West supplies a huge chunk of U.S. dairy production.

Second, sustainability has become a baseline. McKinsey’s latest survey found it dropped from executives’ “priority” lists, but not because it matters less—it’s because 84% of companies already have programs running. Still, that cumulative growth advantage for sustainable products? That keeps everyone’s attention.

Third, the innovation pipeline is now all about water performance. Those UC Davis smart-soaking trials showing up to an 86% reduction? They’re attracting serious interest from operations where summer cooling can run $20,000 to $30,000 monthly when the heat really sets in.

What Actually Works (The Practical Toolkit)

Here’s something you can literally do tomorrow for zero cash outlay (just 20 minutes of your time). Grab a 20-liter bucket and a stopwatch. Time how long does it takes to fill that bucket at your plate cooler discharge. Do the same at your wash hoses, alley flush lines. Now you’ve got flow rates. During a full milking, track how long each run lasts. Multiply it out. You’ve just mapped your water use by process, and I guarantee you’ll find surprises.

In Wisconsin operations, audits often reveal that yard wash varies by 15 gallons per cow or more between morning and afternoon milkings. Usually, it’s a sticky valve, or someone changed protocols seasonally and forgot to change back. Cost to fix that sticky valve? Often less than $200 for a plumber, or $20 for parts if you do it yourself. If that saves 15 gallons per cow per day year-round on a 200-cow dairy, you’re looking at roughly 1,095,000 gallons saved annually. Even if it’s just during the 165 hot days when you’re doing heavier yard washing, that’s still about 495,000 gallons. Either way, the math gets impressive fast.

From there, your biggest return is completing that reuse loop. Capture plate-cooler water—it’s already done its cooling job—route it to equipment cleaning, then to barn washing, and finally to irrigation. Every progressive operation I know runs some version of this.

💧 WATER SAVINGS QUICK WINS

Things you can do this month that actually matter:

- Fix those leaky valves – Usually $50-200 for repair; saves 10,000-50,000 gallons yearly, depending on how bad the leak is

- Install trigger nozzles – About $400-600 total; typically cuts parlor water 15-25% just by eliminating continuous flow

- Adjust cooling timers or sensors – $400-600; can reduce cooling water up to 70% when tied to cow presence and actual heat load

- Capture plate-cooler water – $500-1,500 in basic plumbing; recovers 50-70% of your cooling water for the next job

The Follow-Through Problem We Don’t Talk About

Let’s be honest about something. Most of us don’t struggle to start these projects—we struggle to keep going when fresh cows start coming hard, feed prices jump, or we lose a key employee. That’s why those cooperative and processor programs actually matter. They provide benchmarking, third-party verification, and—this is key—those quarterly check-ins that keep us honest.

The industry tracking shows farms in structured programs maintain their measurement discipline at 3 to 4 times the rate of farms trying to go it alone. That’s the difference between having a good idea at a conference and actually improving your operation.

Making Water Performance Mean Something to Consumers

The data suggests consumers really do reward credible stewardship—that 28% versus 20% growth differential over five years is real money. But only when they can understand and trust what you’re claiming.

Try framing it like this: “Our 200-cow dairy saves about half a million gallons annually—that’s enough water for roughly 35 families for a year.” People get that. Then explain the cascade simply: “The water that cools our milk then cleans our equipment, flushes our barns, and finally irrigates our crops with captured nutrients.”

And always, always anchor it to third-party verification—whether that’s your co-op’s sustainability report or your processor’s benchmarking program. Verified beats vague every single time.

The Uncomfortable Truth About Who Survives

I’m going to say the quiet part out loud here, because I think we owe each other honesty. Water excellence won’t overcome structural gaps in market access and scale. Consolidation has shifted most milk to bigger operations—about 65% now comes from herds over 1,000 cows—and that percentage keeps climbing.

In the West, SGMA will reduce irrigated acres regardless of your parlor efficiency. In the Northeast, nutrient rules are a manageable cost if you plan ahead. But everywhere, the farms positioned actually to thrive tend to fit three profiles: larger herds with committed buyers and capital; regional operations embedded in verified sustainability programs; or specialty producers—organic, regenerative, grass-fed—with contracts that support the extra cost of certification and long-term measurement.

Water management is a baseline competency now. Important? Absolutely. But it’s not the differentiator by itself.

What California’s Teaching the Rest of Us

California’s showing us all a preview of water-constrained dairying. UC Davis and the state energy folks are deploying cooling tech that cuts both water and energy use. It’s promising stuff. But even with those wins, SGMA-driven acreage losses keep feed pressure high.

A Central Valley nutritionist I know recently told me, “We’re completely reworking our rotations, partnering with growers outside the basin, even bringing in more feed from the Midwest. The efficiency helps, but feed sourcing is the real challenge now.”

And this is where that breeding piece pays off—higher feed efficiency and moderate cow size reduce the feed needed per unit of fat and protein you’re shipping. It all connects.

Your Action Plan (Because We All Need One)

I know you’re juggling all this alongside transition cows, labor issues, trying to hold butterfat levels, maintaining drylots—everything that makes dairy farming what it is. The key is starting somewhere. Even that bucket-and-stopwatch audit gives you a baseline.

Today (20 minutes of time): Map those flow rates and run times. Build your baseline.

This month ($500-3,000): Fix the obvious stuff—leaks, oversized nozzles, cleaning protocols that run too long.

This quarter ($5,000-15,000): Complete your reuse loop. If you’re in a hot region, seriously look at the new smart soaking technology.

This year (varies): Connect your numbers to verification—co-op benchmarking, processor reporting—so your performance actually turns into market value.

What’s Coming Next

Watch these three things, because they’ll shape how we all think about water:

Western feed markets under SGMA—as acres get fallowed, expect more cross-regional feed sourcing and different ration economics.

Smart cooling innovation hitting commercial scale—if those UC Davis sensor-based results hold up, expect rapid adoption wherever summer cooling regularly tops $10,000 per month.

Verification infrastructure expanding—more co-ops and processors are tying into the 2050 industry water goals, giving us clearer paths to turn performance into premiums.

The Bottom Line for Your Operation

Water optimization has become necessary but not sufficient for survival. The farms thriving through water pressure aren’t just the ones measuring every gallon—they’re the ones who’ve secured buyers, found their scale or specialty lane, and built the support system to keep measuring when the barn gets crazy.

For Southwest dairies, that means water rights and feed security come first. For Northeast operations, it’s all about nutrient management and water quality. For everyone, it means genetics that deliver higher feed efficiency and moderate mature size to reduce the feed—and water behind it—per unit of milk solids.

Measure and reuse water like the strategic asset it’s become. But make your biggest decisions based on your region and your market position. Water management keeps you in the game. Scale, specialty positioning, efficient genetics, and secured buyers? That’s what determines whether you win it.

KEY TAKEAWAYS:

- Water Is Table Stakes, Not Strategy: That $180 valve fix saving 1M gallons matters for compliance, but 65% of milk production has already shifted to 1,000+ cow herds where scale economics dominate—water excellence alone won’t overcome structural disadvantages

- Your Genetics Matter More Than Your Plumbing: Feed Saved trait and moderate cow size reduce water footprint via less irrigated feed acres—UC Davis smart soaking cuts cooling 86%, but breeding decisions impact water for three cow generations

- Regional Reality Defines “Good”: California’s SGMA will idle 500K-1M acres (quantity crisis), Wisconsin’s SnapMaps dictates spreading windows (quality focus), while Texas operations simply scale up—match strategy to geography

- Solo Measurement Fails, Programs Succeed: Farms in structured co-op/processor programs maintain water tracking 3- 4x longer than independents, and capture the 1.7% sales premium for verified sustainability—accountability infrastructure beats good intentions

- Three Paths Forward: Only larger operations (1,000+ cows), verified regional producers in sustainability programs, or specialty-positioned farms (organic/regenerative) with contracts survive the water-market access squeeze—pick your lane by 2026

Complete references and supporting documentation are available upon request by contacting the editorial team at editor@thebullvine.com.

Learn More:

- Heat Stress 2.0: Why Your Current Cooling Strategy Is Costing You Big Money – Provides actionable protocols for implementing the “smart soaking” systems mentioned above, detailing how to achieve the 86% water reduction while maintaining milk yield during peak heat events.

- Data Centers, Water Rights, and Your Dairy’s Future – Reveals the emerging threat of tech sector competition for rural aquifers, offering strategic advice on how to protect your water access or leverage these new valuation premiums for a profitable exit.

- The Energy Efficient Dairy Cow: Leveraging Genetics and Nutrition – deep dives into the specific heritability of feed efficiency traits, explaining how to select for cows that produce more milk solids with less dry matter intake and a smaller water footprint.

Join the Revolution!

Join the Revolution!

Join over 30,000 successful dairy professionals who rely on Bullvine Weekly for their competitive edge. Delivered directly to your inbox each week, our exclusive industry insights help you make smarter decisions while saving precious hours every week. Never miss critical updates on milk production trends, breakthrough technologies, and profit-boosting strategies that top producers are already implementing. Subscribe now to transform your dairy operation’s efficiency and profitability—your future success is just one click away.

Join the Revolution!

Join the Revolution!