Feed efficiency isn’t just another metric—it’s determining who thrives in today’s tight margins

EXECUTIVE SUMMARY: What’s fascinating about the current dairy economy is how producers who focus on feed efficiency are weathering market volatility better than those still chasing production records. Recent data from land-grant universities confirm that improving feed conversion from 1.55 to 1.65 ECM/DMI can generate $40,000-$ 75,000 in additional annual profit for a 500-cow operation—and that’s with feed costs consuming 50-60% of variable expenses, according to the USDA’s latest numbers. Scandinavian breeding programs have been incorporating these efficiency traits for years, achieving heritability rates between 0.15 and 0.40 that rival traditional production traits we’ve selected for decades. The technology exists, from $35 genomic tests to precision feeding systems with 18-36 month ROI for larger operations, but what’s really driving success is how producers integrate genetics, nutrition, and management rather than tackling them piecemeal. With milk processors increasingly selective about production attributes and lenders beginning to factor efficiency metrics into credit decisions, those operations that move thoughtfully on this now will have significant competitive advantages. The knowledge and tools are available—what matters is thoughtful implementation that fits each farm’s unique situation, whether that’s a 150-cow grazing operation in Pennsylvania or a 3,000-head dry lot in California.

Certain topics consistently resurface at every meeting, conference, and gathering of producers. Feed efficiency has become one of those discussions—and honestly, for good reason. We’ve tracked this ratio of energy-corrected milk to dry matter intake for years, but lately, it’s shifting from something we monitor in the background to a metric that might determine who stays profitable when markets get tight.

What’s encouraging is the pattern I’m seeing across different operations and regions. Producers who focus intensely on feed conversion generally report better financial resilience, especially when milk prices fluctuate and feed costs… well, when don’t they remain stubbornly high? Not overnight transformations, mind you. But those steady improvements that compound over time? That’s where the real opportunity sits.

Let’s Break Down What These Numbers Actually Mean

Here’s what we know from research coming out of universities like the University of Wisconsin, Cornell, and Penn State. Feed efficiency typically runs between 1.3 and 1.8 ECM per pound of DMI, depending on where your girls are in lactation—that’s been pretty consistent in the dairy science literature for quite a while. Recent work from the University of Wisconsin’s Dairy Management program (2024) confirms these ranges hold true across different production systems. Even the latest research presented at the 2025 Joint Annual Meeting shows similar patterns. But here’s what’s interesting: the economics behind those numbers have shifted considerably.

With feed costs accounting for 50 to 60 percent of variable expenses (and, yes, the USDA’s 2024 cost of production data backs this up year after year), every little bump in that efficiency ratio matters more than it might have five or ten years ago. Simple math, really. When your biggest expense category keeps climbing, managing it better becomes… well, it becomes everything. Feed prices vary significantly by region, too—ranging from $200 to $300 per ton in the Midwest versus $250 to $350 in California, depending on the season.

The principle holds whether you’re running a California dry-lot with 3,000 head, a Wisconsin freestall barn with 500, or a grazing system in Pennsylvania with 150. Sure, the specific numbers vary—I mean, desert dairies dealing with heat stress face completely different challenges than those of us managing through Midwest winters—but improving feed conversion? That generally translates to better margins across the board. It is worth noting that Jersey herds often exhibit slightly higher efficiency ratios than Holsteins, while crossbred operations report their own unique optimization points.

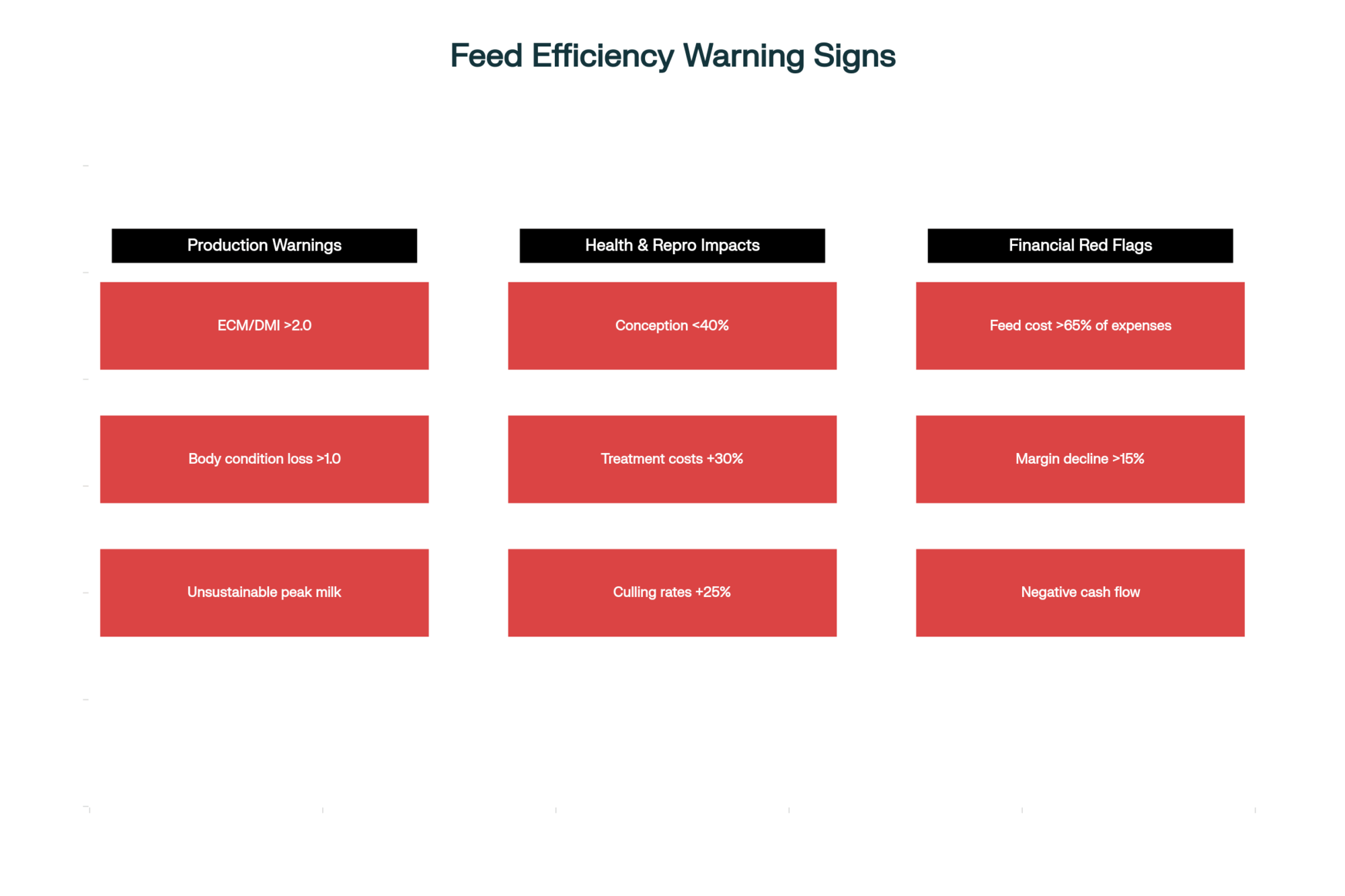

When Those “Impressive” Numbers Are Actually Red Flags

This is something we need to talk about more. University research from institutions like the University of Wisconsin-Madison and Michigan State suggests that cows showing efficiency ratios above 2.0—sometimes reaching 2.4—aren’t achieving some magical feed conversion. They’re burning through body reserves at rates that create real problems down the road.

The transition cow research published in the Journal of Dairy Science over recent years is pretty clear on this. When you see excessive body tissue mobilization in early lactation, you tend to see:

- Conception rates that tank compared to your herd averages

- Treatment costs that eat up any perceived efficiency gains (and then some)

- Higher culling rates in cows that should be hitting their stride

It’s that classic situation where what looks fantastic on your morning reports creates expensive headaches by summer. A cow showing exceptional early lactation efficiency through body condition loss? She often becomes that problem cow by mid-lactation. We’ve probably all had those animals—the ones that start strong but fade fast—even if we didn’t always connect the dots back to those early efficiency measurements.

How the System Shapes Our Decisions

One thing worth considering—and this might ruffle some feathers—is how our payment structures influence management choices. The milk check doesn’t care if your cow is maintaining condition while producing sustainably or if she’s essentially eating herself. Volume is volume, components are components, and the check clears the same.

This connects to genetic selection in interesting ways. When the Council on Dairy Cattle Breeding added Feed Saved to the Net Merit index back in 2021, it got about 13 percent of the total weighting. That’s progress, absolutely. But we’re still heavily selecting for production traits that might actually increase total feed consumption rather than improve conversion efficiency. Makes you think about our priorities, doesn’t it?

And then there’s what I call the specialist challenge. Many operations have different advisors optimizing different aspects—your nutritionist is laser-focused on the ration, your reproductive specialist on pregnancy rates, and your geneticist on their favorite traits. But who’s looking at how it all fits together? It’s understandable, given the increasing specialization of dairy management. Still, you can end up optimizing the parts while missing the whole picture.

Learning from What’s Working Elsewhere

What’s particularly interesting is how Scandinavian breeding programs—especially in Denmark, Sweden, and Norway—have incorporated feed efficiency for years now. Not as the only thing, but as one important piece of the profitability puzzle. They’re using data from commercial farms (not just research herds) to identify genetics that reduce feed requirements while maintaining production.

What is the heritability for these efficiency traits? Generally falls between 0.15 and 0.40, according to published genetic studies from various universities and breeding programs. That’s right in line with many traits we’ve successfully selected for over the past few decades. So the genetic potential is there—it’s more about how we choose to use it.

Why hasn’t this gained more widespread adoption here? Tradition certainly plays a role. Next time you’re at a sale, notice what gets emphasized—it’s still production records, maybe some show wins, but rarely efficiency or lifetime profitability metrics. That takes courage to change. Different operations have different priorities. However, it reveals how deeply certain evaluation methods are ingrained in our thinking.

Practical Approaches That Are Actually Working

Getting Your Numbers Right

Based on what’s succeeding across different operations—and keeping in mind that what works beautifully on one farm might need serious tweaking on another—some patterns are emerging.

First off, you need accurate baseline data. I can’t tell you how many producers discover their estimated feed efficiency is way off once they actually measure it properly. Not because they were doing anything wrong, but because eyeballing it is no longer precise enough. Yeah, measurement systems aren’t cheap. But producers generally say the better decision-making pays for itself pretty quickly—often within 6-12 months for well-managed operations.

Small management adjustments often yield surprising results. Take feed bunk management—just ensuring consistent availability throughout the day. Nothing fancy. Good push-up schedules, adequate bunk space, and keeping feed fresh. These fundamentals don’t require huge investments but can deliver solid returns. Sometimes the basics are basic for a reason.

The Technology Question

Technology definitely has its place, although its implementation varies widely. Some operations dive straight into precision feeding systems and achieve great results. Others build gradually—measurement first, then management tweaks, then maybe technology. Both can work. It depends on your capital situation, your comfort with technology, and your labor availability… there’s no one-size-fits-all solution here.

Companies like DeLaval, Lely, BouMatic, and GEA Farm Technologies offer various precision feeding options, but honestly? The brand matters less than having good support and training. I’ve seen operations struggle with top-tier systems because they didn’t invest in learning how to use them properly. The ROI on these systems typically ranges from 18 to 36 months for operations with over 500 cows, and longer for smaller herds.

Regional Differences Really Do Matter

| Region | Feed Cost Range ($/ton) | Heat Stress Factor | Primary Challenge |

| Midwest | $200–300 | Low | Weather swings |

| California | $250–350 | Very High | Heat mgmt. |

| Southeast | $220–320 | High | Humidity/intake |

| Northeast | $230–330 | Medium | Cold stress |

| Great Plains | $180–280 | Medium | Drought conds |

What works to optimize efficiency in Arizona’s 115-degree summers bears little resemblance to strategies for Vermont’s minus-20 winters. Missouri grazing operations have completely different optimization points than California’s total confinement systems. Mountain state producers, who deal with elevation and temperature swings, face their own unique set of challenges. And that’s before we even talk about feed availability and pricing differences.

This season has been particularly interesting. Southeast producers dealing with this extended heat and humidity—their intake challenges are real. Meanwhile, Midwest operations are managing through these weather swings, while Pacific Northwest dairies, with their unique forage options, and Great Plains producers are dealing with drought conditions. Everyone has their own puzzle to solve.

These aren’t just academic differences. They fundamentally change which strategies pencil out economically. Heat abatement systems, which are absolutely essential in Texas, are increasingly needed even in Wisconsin during those brutal July heatwaves—climate patterns are shifting, and what worked 20 years ago might not be effective today. Conversely, cold weather housing critical in Minnesota would still be a wasted investment in most of Florida.

The Human Side Nobody Talks About

Here’s something we don’t discuss enough at meetings: the psychological piece of changing management focus. Many of us—myself included—come from families that built successful operations emphasizing production above all else. Changing that approach, even when the data supports it… that takes real courage.

The operations I’ve seen successfully evolve don’t frame it as abandoning what worked before; instead, they focus on building upon it. They talk about adapting proven principles to today’s economic reality. It’s still about excellence in dairy farming. We’re just measuring it more comprehensively than maybe our parents or grandparents did.

And peer influence? That’s huge. When a respected neighbor reports success with a different approach, that carries more weight than any university study or industry recommendation. We’re a community that learns from each other’s experiences. Always have been.

These psychological factors don’t exist in isolation, though. They’re intertwined with the very real economic and environmental pressures reshaping our industry. Understanding how we think about change is just as important as understanding why change is necessary.

Why This Matters More Now Than Ever

Several trends are converging that make efficiency increasingly important—and they’re all connected to those human decisions we just discussed.

Milk processing consolidation continues reshaping how we market milk. While specifics vary by region, buyers are generally becoming more selective about various production attributes beyond just volume and butterfat. Some areas are starting to see pricing that reflects sustainability metrics. That trend isn’t going away.

Environmental considerations keep evolving, too. Whether you’re dealing with methane regulations out West or nutrient management in the Chesapeake watershed, operations producing milk with fewer resources per hundredweight generally have advantages. What’s voluntary today often becomes required tomorrow.

Agricultural lenders are also paying attention. Increasingly, more of them are considering efficiency metrics alongside traditional production measures when making credit decisions. Farm Credit Services and various regional banks are incorporating these factors into their lending criteria. It’s not yet universal, but if you’re planning expansion or need operating capital, it’s worth knowing that this is on their radar.

Some Practical Steps to Consider

If you’re considering focusing more on efficiency, here are some approaches that seem to work—though, obviously, your specific situation will determine what makes sense.

Start with measurement. Even pen-level intake data beats guessing. If you’re already conducting genomic testing (and at around $35 per animal through companies like Zoetis, Neogen, or STgenetics, it’s quite affordable these days), ensure you’re evaluating efficiency traits alongside production markers. The tools are there—might as well use them.

For making changes, many producers find value in balanced genetic selection—picking bulls that perform decently across multiple traits rather than spectacularly in just one or two. Focus on optimizing what you have: consistent feed availability, solid transition cow protocols, and basic comfort measures. These fundamentals often deliver better returns than any fancy technology.

Speaking of technology, those investments might make sense down the road—such as precision feeding, advanced monitoring, and perhaps some automation. But by then, you’ll know what fits your specific operation rather than hoping something works.

The Economics in Practice

Let’s talk real-world impact. Producers report gains ranging from $50 to $150 per cow annually, depending on their starting efficiency and the effectiveness of the implemented changes. A 500-cow dairy that improves efficiency modestly might see $40,000 to $ 75,000 in additional annual profit. Not life-changing overnight, but compound that over several years? That’s serious money.

The key is to start somewhere and measure progress. You don’t need to revolutionize everything overnight.

Pulling It All Together

After considering this from various angles, a few things seem clear.

First, improving feed efficiency doesn’t mean backing off on production. The successful approaches I’m seeing maintain or even increase total output while reducing input costs per hundredweight. That’s the sweet spot—not less milk, but more efficient milk production.

Second, this isn’t something you can tackle piecemeal. Genetics, nutrition, facilities, management—they’re all connected. I’ve watched operations invest heavily in one area while ignoring others, then wonder why results didn’t match expectations. It rarely works that way.

Third, there’s still an opportunity for operations to move thoughtfully in this direction. Right now, superior efficiency can differentiate your business. Five years from now? It might just be table stakes for staying in the game.

Look, we’re all trying to build operations that are sustainable—financially, environmentally, and personally. Operations we can hand off to the next generation with confidence. Feed efficiency isn’t the magic bullet, but it’s probably a bigger piece of the puzzle than many of us have been treating it.

The knowledge is out there. Research from land-grant universities, data from commercial farms, tools from genetics companies—it’s all available. What’s needed is thoughtful implementation that fits each farm’s unique situation. Your challenges are different from mine, your resources are different, and your markets are different.

What’s your take on all this? I’m always curious to hear what others are seeing in their operations and regions. Sometimes the best insights come from comparing notes with someone dealing with similar challenges from a different angle. Please share your thoughts—whether you think efficiency is overhyped or undervalued, I’d be interested in hearing your perspective.

After all, that’s what makes these conversations valuable—learning from each other while figuring out what works for our own places.

KEY TAKEAWAYS:

- Producers report $50-150 more profit per cow annually through modest feed efficiency improvements, with measurement systems typically paying for themselves within 6-12 months when properly managed

- Start with accurate baseline data and simple management tweaks—consistent feed availability, proper push-up schedules, and transition cow protocols often deliver better returns than expensive technology investments

- Regional differences fundamentally change the economics: Heat abatement essential in Texas is increasingly needed even in Wisconsin’s July heat waves, while cold weather housing critical in Minnesota remains unnecessary in Florida

- The heritability of feed efficiency traits (0.15-0.40) matches many production traits, yet it only receives 13% weighting in Net Merit, while we continue selecting for genetics that may actually increase total feed consumption

- By 2030, superior feed efficiency will shift from a competitive advantage to a survival requirement as environmental regulations tighten, processors become more selective, and agricultural lenders incorporate efficiency metrics into lending criteria

Complete references and supporting documentation are available upon request by contacting the editorial team at editor@thebullvine.com.

Learn More:

- 11 Proven Strategies to Lower Feed Costs and Boost Efficiency on Your Dairy (https://www.thebullvine.com/management/11-proven-strategies-to-lower-feed-costs-and-boost-efficiency-on-your-dairy/) – This article provides a comprehensive tactical checklist, detailing how to implement immediate changes through feed bunk management, cow grouping strategies, and rumen health protocols. It reveals tangible, low-cost actions producers can take now to begin capturing those critical efficiency gains.

- 2025 Dairy Market Reality Check: Why Everything You Think You Know About This Year’s Outlook is Wrong (https://www.thebullvine.com/news/2025-dairy-market-reality-check-why-everything-you-think-you-know-about-this-years-outlook-is-wrong/) – This strategic analysis provides the broader context for why feed efficiency is so crucial. It breaks down current trends in component pricing, labor costs, and global policy, demonstrating how focusing on efficiency is essential for navigating market volatility and securing future profitability amidst changing industry dynamics.

- Unlocking Dairy Robot Financing: How Smart Farmers Are Funding Their Automated Future (https://www.thebullvine.com/management/robotic-milking/unlocking-dairy-robot-financing-how-smart-farmers-are-funding-their-automated-future/) – This article directly addresses the practical and financial barriers to adopting efficiency-enhancing technology. It reveals creative financing and leasing strategies that progressive dairy producers can use to fund capital-intensive projects like robotic milking, connecting technology to real-world ROI and labor savings.

Join the Revolution!

Join the Revolution!

Join over 30,000 successful dairy professionals who rely on Bullvine Weekly for their competitive edge. Delivered directly to your inbox each week, our exclusive industry insights help you make smarter decisions while saving precious hours every week. Never miss critical updates on milk production trends, breakthrough technologies, and profit-boosting strategies that top producers are already implementing. Subscribe now to transform your dairy operation’s efficiency and profitability—your future success is just one click away.

Join the Revolution!

Join the Revolution!