U.S. dairy faces a labor crisis. Discover how top farms are slashing turnover, boosting profits, and rethinking workforce strategies.

The U.S. dairy industry finds itself at a critical crossroads where traditional workforce solutions no longer suffice. The growing dependency on non-family labor amid unprecedented recruitment challenges demands nothing short of a revolution in human resource management. Leading operations are implementing multi-faceted workforce strategies that deliver measurable improvements in employee longevity and farm profitability. At the same time, those clinging to outdated labor practices continue to bleed talent and money. The stark reality? Your approach to workforce management will likely determine whether your operation thrives or merely survives in the next decade.

Understanding Today’s Labor Landscape

Let’s face it, the labor situation in dairy has evolved from a chronic headache to an existential threat. If you’re treating it as anything less, you’re positioning your operation for failure.

“Labor is one of our biggest issues,” says Hank Hafliger of Cedar Ridge Dairy in the Magic Valley. But this statement barely scratches the surface of a fundamental transformation reshaping our industry. Rick Naerebout, chief executive officer of the Idaho Dairyman’s Association, cuts to the heart of it: “It used to be that the dairy industry was primarily run on family labor. There is much less dependence on family labor now.”

The numbers tell a compelling story that can’t be ignored: non-family members now constitute at least 50% of the workforce on many dairy operations, with immigrant workers playing a crucial role, accounting for an estimated 40% to 51% of all dairy labor. Even more significantly, these immigrant-employing dairies produce approximately 79% of the U.S. milk supply, making them as vital to the industry as proper nutrition is to peak milk production.

Why Workers Walk Away

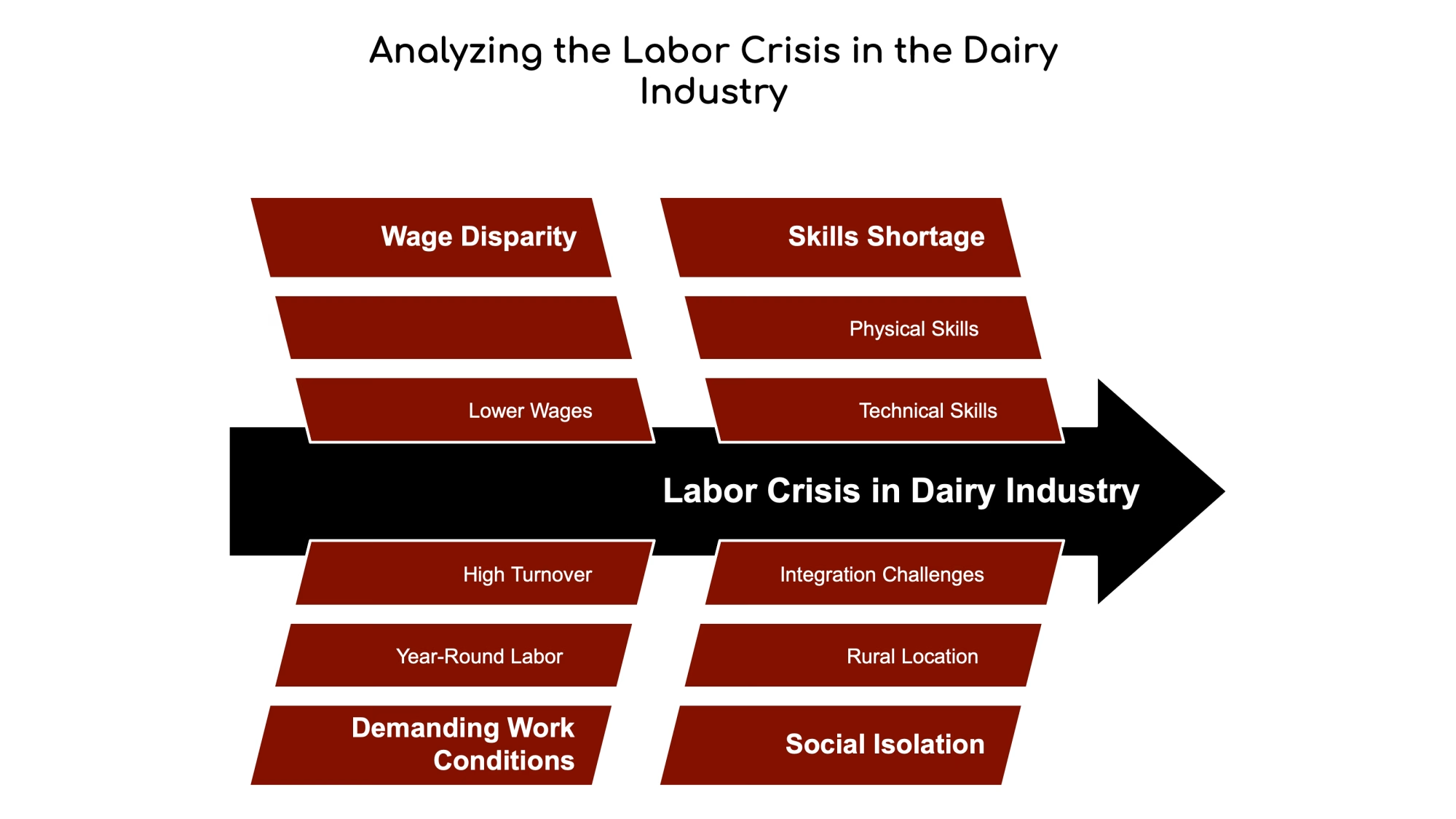

Have we been asking the wrong questions about labor retention all along? While most discussions focus exclusively on wages, the reality is far more complex.

Despite rising wages, dairy farms struggle to compete financially with other sectors. In 2023, the average wage for nonsupervisory farm workers was $17.55 per hour, only 61% of the $28.93 paid to nonfarm counterparts. This wage gap persists even as inflation-adjusted farm wages grew at an annual rate of 2.1% between 2019 and 2023, nearly double the long-term average.

But the challenges extend well beyond compensation. Let’s call it what it is: dairy work is demanding in ways that few other industries can match. Unlike seasonal cropping operations, our farms require consistent labor year-round for thrice-daily milking, TMR mixing and delivery, fresh cow monitoring, calf care, and facility maintenance. The industry’s “grueling lifestyle” contributes significantly to turnover rates between 30% and 38.8% 38.8annually, higher than the culling rates in most well-managed herds.

Here’s an uncomfortable truth: We often ask workers to endure conditions we’ve spent millions improving for our cows. We invest heavily in cow comfort, recognize that stress impacts production, and understand that consistency is vital for animal health. Yet, many operations fail to apply these principles to their human workforce.

If you spend more on metabolic disease prevention than on employee onboarding, you’re fundamentally misallocating resources. Research shows that employees with a positive onboarding experience are 69% more likely to remain with an employer for three years and are approximately 50% more productive. Yet many operations invest minimally in bringing new employees up to speed, then wonder why turnover remains stubbornly high.

Housing availability in rural areas presents another significant hurdle. Many dairy farms are located where housing options are as scarce as prime replacement heifers during a market upswing, creating both a problem and an opportunity for employers who can provide this valuable benefit.

Finding employees with the right skills has become increasingly difficult, with 70% of dairy farms reporting this challenge. Today’s operations face a dual skills shortage: workers willing to perform physically demanding agricultural tasks, and those with the technical and data literacy skills essential for operating modern dairy technologies like parlor automation systems, activity monitors, and milk component analyzers.

The rural setting of most dairy farms contributes to social isolation for both owners and employees, particularly immigrant workers who may be far from their cultural communities. These workers often face significant health and safety risks, with limited access to healthcare services and integration challenges due to language barriers, a situation that compounds stress like mastitis in an already challenged cow.

Forging a Resilient Workforce: Strategies That Work

While some producers lament the labor situation as an unsolvable problem, others are aggressively innovating with impressive results. The difference between these two groups isn’t resources, it’s mindset. Are you still viewing labor as merely a cost to minimize, or have you recognized it as a critical investment directly impacting your bottom line?

Beyond the Paycheck

Leading dairy operations understand that while competitive wages are foundational, benefits beyond the direct paycheck are increasingly essential. Much like balanced rations require more than adequate crude protein, today’s compensation packages must address multiple needs to support optimal performance.

Farms offering wages and benefits above industry standards generally report longer employee tenure and greater stability. Quality farm-provided housing has emerged as a particularly effective retention strategy, as essential to workforce stability as proper transition cow management is to lactation success. In a compelling example from Wisconsin, a dairy farm that invested strategically in employee housing options saw its turnover rate plummet from 7% to less than 1%, creating such an attractive workplace that the farm developed a waiting list for employment.

Ask yourself: If you were in your employees’ position, would you choose to work at your farm over competitors in the area? If not, what specific value proposition would change your answer?

Performance bonuses tied to specific metrics like bulk tank somatic cell count targets, calf survival rates, or component-adjusted production goals can motivate employees and reward their contributions to the farm’s success. Some farms also utilize “Total Compensation Statements” that provide a detailed breakdown of both direct pay and the monetary value of indirect benefits, making the overall financial commitment more tangible, similar to how DHI records quantify both production and reproductive performance.

Consider what benefits might resonate most with your specific workforce. For some, transportation assistance might be crucial, while others might value flexible scheduling that accommodates family needs. The goal is to create a comprehensive package that addresses your employees’ most significant pain points, just as a well-designed treatment protocol addresses specific pathogens rather than applying blanket therapy.

WORKFORCE SELF-ASSESSMENT:

Rate your operation on these five critical factors:

- Competitive total compensation (including benefits)

- Structured onboarding and training program

- Clear career advancement opportunities

- Recognition and feedback systems

- Safe, comfortable working conditions

How many of these areas would you rate as “excellent” versus “needs improvement”?

Investing in People

Would you invest in a new TMR mixer that delivered a $250,000+ return in a year? That’s exactly what structured training and development programs can provide.

One Southwestern calf ranch that invested in comprehensive leadership and employee development programs saw its turnover rate drop from 81% to 54% within just one year. This reduction yielded direct savings of $11,256 in turnover-related costs, with a total return on investment calculated at $263,096 when accounting for improved efficiency and productivity, comparable to the returns from implementing an effective transition cow program.

Why do many dairy operations meticulously track reproductive performance, milk components, and feed conversion while ignoring employee turnover costs? This blind spot represents one of the industry’s most expensive oversight failures.

Research indicates that employees with a positive onboarding experience are 69% more likely to remain with an employer for three or more years and are approximately 50% more productive. The most effective training approaches incorporate visual aids, hands-on practice, and concise instruction, carefully considering language differences, much like the most successful herdsperson training combines observation, demonstration, and practical application.

Mentoring programs that pair new hires with experienced staff build confidence and foster knowledge transfer, similar to how skilled hoof trimmers train apprentices in proper technique and lesion identification. E-learning platforms offer flexible delivery of consistent information, as demonstrated by a study on Northern New York farms where 95% of participants in an e-learning program felt capable of performing equipment checks afterward.

The payoff from these investments can be substantial. Over 70% of successful dairy farms implement continuous learning programs, with some data indicating that such initiatives can lead to a 50% decrease in employee turnover and a 30% increase in milk production, results that would make any nutritionist or veterinarian proud.

Cultivating Culture

Beyond compensation and training, workplace culture plays a pivotal role in retention, as critical to workforce stability as cow comfort is to milk production. Proactive farms focus on creating positive, respectful, and engaging environments through open communication, fair treatment, and consistent recognition of employee contributions.

Recognition programs, ranging from simple daily acknowledgments to formal awards, boost morale and motivation. Regular team meetings, constructive feedback, and involving employees in relevant decision-making processes cultivate a sense of value and belonging, the human equivalent of providing comfortable stalls, clean water, and adequate bunk space.

If your management style involves yelling, intimidation, or treating employees as disposable resources, you’re not just failing at human resources but actively damaging your operation’s profitability. The data is clear: farms with positive workplace cultures consistently outperform those with toxic environments.

A Midwest dairy that partnered with Purina’s Hispanic Employee Training Services to develop accessible, often bilingual, operational protocols and foster continuous employee support through regular weekly meetings saw dramatic improvements. The dairy significantly reduced its somatic cell count from an average of 300,000 to consistently below 200,000. At the same time, employee turnover was cut from one to two departures per month to only one departure over six months, proof that human and animal performance are inextricably linked.

Building Bridges

For farms with diverse workforces that include immigrant workers, fostering community integration can significantly impact employee well-being and retention. Proactive managers help foreign-born workers connect with the local community by offering transportation assistance, facilitating introductions to neighbors, and providing information about local events and services. Much like good herd management, a community-based approach to preventing isolation prevents lameness through prevention rather than treatment.

Organizations like the Migrant Clinicians Network contribute through projects that utilize community health workers to deliver culturally and linguistically appropriate health and safety information. These integration efforts directly address the challenge of rural isolation that contributes to high turnover rates.

The Technology Equation: Finding Your Balance

Technology plays an increasingly pivotal role in how the dairy industry addresses its labor challenges, with complex implications for the future workforce, much like genomics transformed breeding decisions while creating new demands for data interpretation.

Alleviating the Burden

Automatic Milking Systems (AMS), commonly known as robotic milking, can significantly reduce the direct human labor required for milking, with estimates suggesting a reduction of approximately 60% in direct milking labor. These systems can save an estimated $32,000 to $45,000 annually per robot in labor costs, similar to how activity monitoring systems reduce labor needs for heat detection while improving reproduction metrics.

Beyond milking, wearable sensors for individual cow monitoring improve herd management efficiency, allowing existing staff to oversee more animals or dedicate more time to higher-value tasks. Automated feed pushers ensure consistent TMR availability without requiring manual intervention multiple times daily, addressing feed refusal issues that impact component production and dry matter intake.

The Hinchley Dairy Farm, faced with persistent labor shortages and escalating costs, installed Lely robotic milking and automated feeding systems. This technological shift led to a 10% boost in milk production while allowing cows to choose their milking times, contributing to improved animal health and welfare. It demonstrates how solving a labor problem can simultaneously address production and welfare challenges.

But let’s be clear: technology is not a silver bullet for your labor woes. Even the most automated dairy operations still require skilled people to manage systems, interpret data, and provide essential animal care. The question isn’t whether to invest in people or technology, it’s how to optimize their relationship.

The New Dairy Professional

Automation integration is fundamentally reshaping the skill set required of dairy workers. New roles are emerging, such as dedicated robot operators or automation technicians, responsible for the daily functioning and oversight of these complex systems, similar to how specialized nutritionists and reproduction specialists have replaced general consulting roles.

Workers on technologically advanced dairy farms increasingly need proficiency in operating and maintaining sophisticated equipment, strong problem-solving abilities, and the capacity to troubleshoot when automated systems malfunction. Skills in data interpretation, critical thinking, and systems-level thinking are becoming essential, alongside traditional expertise in animal handling, a combination as important as understanding cow biology and feed chemistry is to successful nutrition programs.

This evolution creates both challenges and opportunities. While requiring substantial retraining of existing workers, these emerging technological roles, which are more analytical and less physically strenuous than traditional farm tasks, could potentially attract a younger, more technologically inclined generation to dairy farming.

Finding the Right Mix

The journey of technology adoption isn’t always smooth or universally successful. How many farms purchased and abandoned expensive technology when the implementation challenges became apparent? After investing in robotic systems, some dairy operations have encountered challenges with ongoing maintenance costs, system reliability, or the technical expertise required for management, much like early adopters of any new technology in the industry, from sexed semen to activity monitoring systems.

Even with increasing automation, there remains a significant reliance on human labor for tasks that robots cannot perform effectively or economically. This includes complex animal health procedures, reproductive management protocols, colostrum management for newborn calves, and the overall management and oversight of the technological systems.

The most resilient and productive dairy farms will likely be those that master the art of “human-technology augmentation”-creating synergistic relationships where technology enhances human capabilities, and human expertise guides and optimizes the use of technology, similar to how the most successful breeding programs combine genomic testing data with experienced breeder judgment.

TECHNOLOGY DECISION FLOWCHART

Step 1: Assess Your Labor Challenges

- Which specific tasks consume the most labor hours?

- Where are your most frequent errors or quality issues occurring?

- Which roles experience the highest turnover?

Step 2: Evaluate Technology Solutions

- Which technologies directly address your highest-priority challenges?

- What’s the total cost of ownership (purchase, installation, maintenance)?

- What infrastructure changes would be required?

- What new skills would your team need to develop?

Step 3: Calculate ROI

- Labor cost savings (hours × wage rate)

- Potential production improvements

- Quality/consistency benefits

- Reduced turnover costs

- Compared to alternative investments (facility upgrades, increased wages, etc.)

Step 4: Implementation Planning

- Training requirements for existing staff

- Transition strategy and timeline

- Monitoring metrics for success

Technology Comparison: Making Informed Investment Decisions

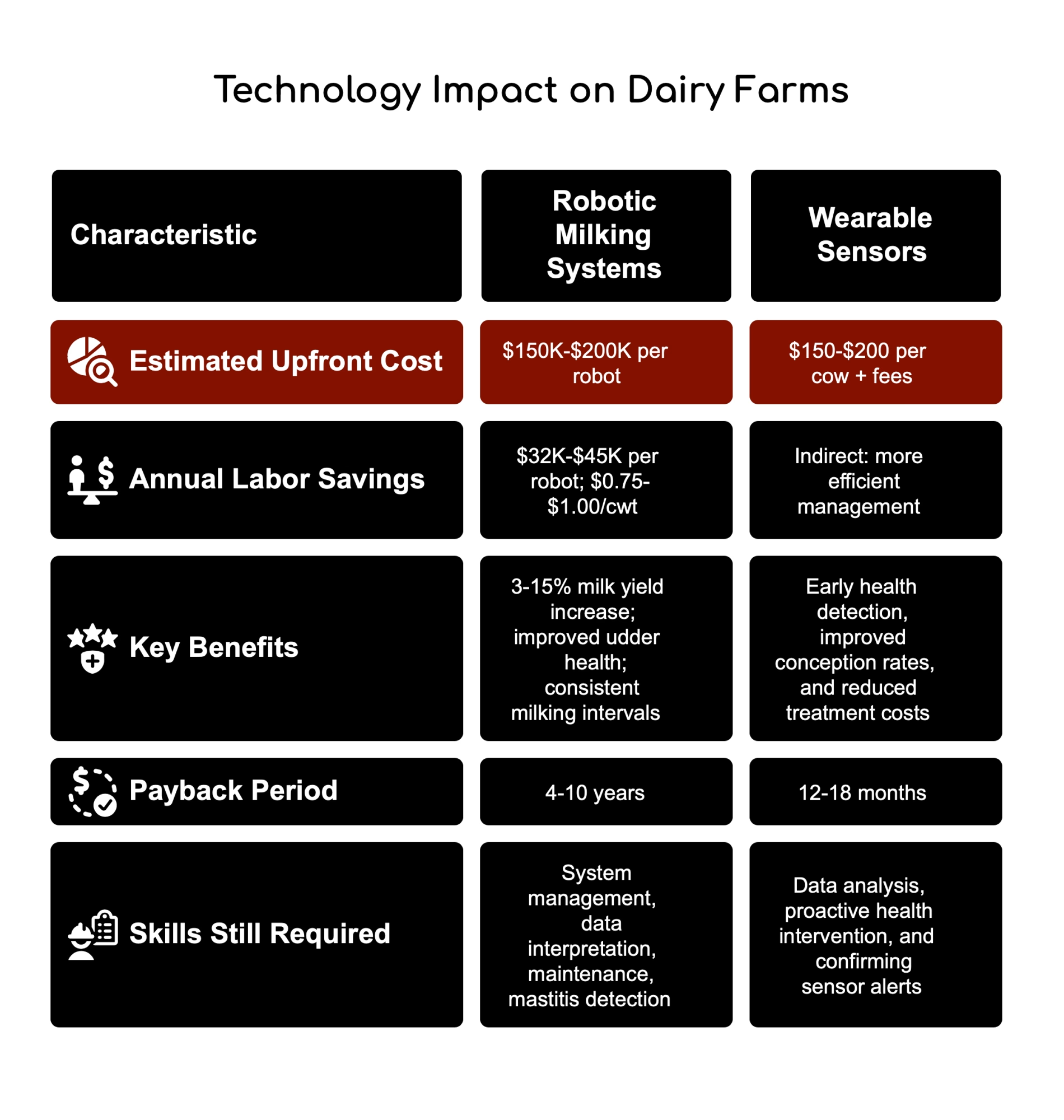

When considering technology investments to address labor challenges, it’s crucial to understand the full picture of costs, benefits, and ongoing requirements, just as you would evaluate a major genetic, nutrition, or facility investment:

| Technology Type | Estimated Upfront Cost | Annual Labor Savings | Key Benefits | Payback Period | Skills Still Required |

| Robotic Milking Systems | $ 150 K-$200 K per robot | $ 32 K-$45 K per robot; $0.75-$1.00/cwt | 3-15% milk yield increase; improved udder health; consistent milking intervals | 4-10 years | System management, data interpretation, maintenance, mastitis detection |

| Wearable Sensors | $150-$200 per cow + software fees | Indirect: more efficient management | Early health detection, improved conception rates, and reduced treatment costs | 12-18 months | Data analysis, proactive health intervention, and confirming sensor alerts |

| Automated Feed Pushers | Varies by system | Reduces manual push labor | 24/7 TMR availability; improved DMI; reduced feed sorting | Varies | System monitoring, maintenance, and ration formulation |

| Automated Calf Feeders | Varies by capacity | Reduces individual feeding labor | Individualized feeding plans, data collection on intake, and consistent milk replacer mixing | Varies | System calibration & cleaning, calf health monitoring, colostrum management |

| Robotic Manure Scrapers | Varies by barn size | Reduces manual cleaning labor | Improved stall hygiene; potentially fewer digital dermatitis cases | Varies | System programming, maintenance, and manure management |

Policy Challenges and Industry Solutions

Let’s be honest: our industry has been extraordinarily ineffective at achieving meaningful policy reform to address our labor needs. Despite years of advocacy and broad recognition of the problem, we remain hamstrung by immigration policies that fundamentally fail to align with dairy’s year-round labor requirements.

The Immigration Policy Disconnect

Federal immigration policy significantly shapes labor availability for U.S. dairy farms. A critical challenge is that the primary agricultural guest worker program, the H-2A visa, is designed for temporary or seasonal labor needs, making it fundamentally unsuitable for the dairy industry’s year-round workforce requirements, as disconnected from dairy reality as a corn silage ration would be for a high-producing herd.

Hank Hafliger of Cedar Ridge Dairy highlights this disconnect: “We need these foreign workers, and the workers themselves want to be documented but also want to have visas to remain long term at their jobs… We need to have a long-term program available. The dairy industry is so technical, with the knowledge required, you don’t want to train a guy and then lose him after three months.”

While some dairy producers can use H-2A for seasonal crop-related tasks, any dairy-specific livestock handling would violate visa terms. This leaves the industry without a reliable legal channel to hire foreign workers for essential year-round positions, forcing many to rely on an undocumented workforce, creating vulnerability as significant as depending on a single water source for your entire operation.

Has our industry’s approach to policy advocacy been too timid and fragmented? While individual producers navigate the daily reality of labor shortages, unified political action with real consequences for legislators who fail to support reform has been notably absent.

Reform proposals have included provisions to grant year-round access to the H-2A program for industries like dairy, establish pathways to legal status for currently undocumented agricultural workers who meet certain criteria, and adjust the methodologies for calculating required wages. The Farm Workforce Modernization Act, which has passed the House of Representatives in previous sessions but not the Senate, has included such provisions.

Industry-Led Initiatives

In response to ongoing labor challenges, various industry organizations have launched programs to provide resources and best practices to dairy producers, similar to how the industry developed unified protocols for antibiotic stewardship and animal welfare certification.

The National Dairy FARM (Farmers Assuring Responsible Management) Program’s Workforce Development initiative encourages adopting human resources and safety best practices on dairy farms. It provides educational resources, customizable HR templates, and a voluntary evaluation tool to help farms become “employers of choice”-complementing the program’s animal care and environmental stewardship components.

Regional initiatives include the Northeast Dairy Business Innovation Center’s “Catalyzing Regional Dairy Workforce Grant” program, which aims to expand dairy workforce development programs, including apprenticeships and training initiatives, addressing workforce gaps with the same regional focus that cooperative field staff bring to milk quality improvement.

Organizations like the Migrant Clinicians Network provide specialized health and safety training for immigrant dairy workers, often incorporating English-as-a-Second-Language learning activities directly into the safety modules, a practical approach as sensible as integrating hoof care into routine parlor procedures.

Building Your Farm’s Future Workforce

Looking ahead, your dairy operation must prepare for a labor landscape that will likely continue to be characterized by scarcity and evolving demands, requiring the same strategic planning you apply to genetic improvement or facility expansion.

Long-Term Outlook

Labor shortages and rising costs aren’t temporary challenges-they’re the new normal. The USDA’s 2025 forecast anticipates a 3.6% increase in agricultural labor costs, reaching a record $53.5 billion, a trend as consistent as the genetic improvement in production potential.

Several demographic factors contribute to this outlook. The pool of workers from traditional immigrant source countries is anticipated to shrink due to declining birth rates and improving economic opportunities in those countries. This is reflected in the rising average age of foreign-born employees on U.S. farms (42 years compared to 36 for U.S.-born farm employees), a demographic shift as significant as the aging of the American farmer population.

As Rick Naerebout notes about the Idaho dairy industry, “About 90% of dairy workers in the western U.S. are foreign-born, with about 85% of the total coming from Mexico.” With this traditional labor pool diminishing, the industry faces a critical need to develop alternative workforce strategies, much like the need to develop alternative feeding strategies when faced with forage shortages.

Creating Sustainable Solutions

Addressing the dairy labor crisis effectively requires systemic changes encompassing industry practices, policy frameworks, and societal perceptions of agricultural work. A sustainable dairy system must include fair and equitable labor practices, safe working conditions, and robust support for farmers and their communities as integral components, as essential to long-term success as preventive herd health programs.

Why are we still treating workforce development as an individual farm problem rather than an industry-wide imperative? Just as our industry successfully mobilized around genetic improvement, milk quality enhancement, and animal welfare, we need coordinated action on labor sustainability.

Systemic solutions include fostering cooperative models where farmers can pool resources and potentially share labor, encouraging diversification into value-added products to enhance farm income, and providing greater technology assistance, particularly for small and medium-sized farms, and collaborative approaches similar to how producers once shared equipment or breeding bulls.

Policy support remains crucial, especially reforms to immigration and guest worker programs to better align with dairy’s year-round needs and provide pathways to legal status for the existing experienced immigrant workforce, a regulatory solution, as necessary, and the development of appropriate antibiotic withdrawal guidelines.

Strengthening agricultural education and vocational training programs is essential for building a pipeline of future dairy professionals. Current statistics indicate a significant gap: an estimated 60,000 ag-related job openings are expected annually in the U.S. At the same time, the supply of graduates from agricultural programs is only around 35,000, a talent deficit comparable to the shortage of large-animal veterinarians in rural areas.

Q&A WITH JEFF ENDRES, CO-OWNER OF ENDRES BERRYRIDGE FARMS, WISCONSIN

Q: What was your biggest labor challenge before implementing your current strategy?

A: “Finding reliable employees who would stay long-term was nearly impossible. We were constantly training new people, which affected our productivity and milk quality and took time away from focusing on improving the operation.”

Q: What specific changes have had the biggest impact on your workforce stability?

A: “Two things transformed our situation. First, invest in quality housing on the property. Second, a structured mentorship program should be implemented where experienced employees train newcomers. These changes reduced our turnover from 35% annually to under 10%.”

Q: How has your approach to technology balanced with your labor strategy?

A: “We’ve found that technology works best when it enhances what our people do rather than replacing them. Our activity monitoring system lets our herdsperson manage breeding more efficiently, but we still need their expertise to make the final decisions. The key is using tech to eliminate the tedious tasks so people can focus on where they add the most value.”

Q: What advice would you give producers still struggling with high turnover?

A: “Stop viewing labor as just another input cost to minimize. Start thinking of your workforce as an investment that directly impacts your profitability. When we changed our mindset and started treating employees like the valuable assets they are, everything else improved, from our production numbers to our quality premiums to our quality of life.”

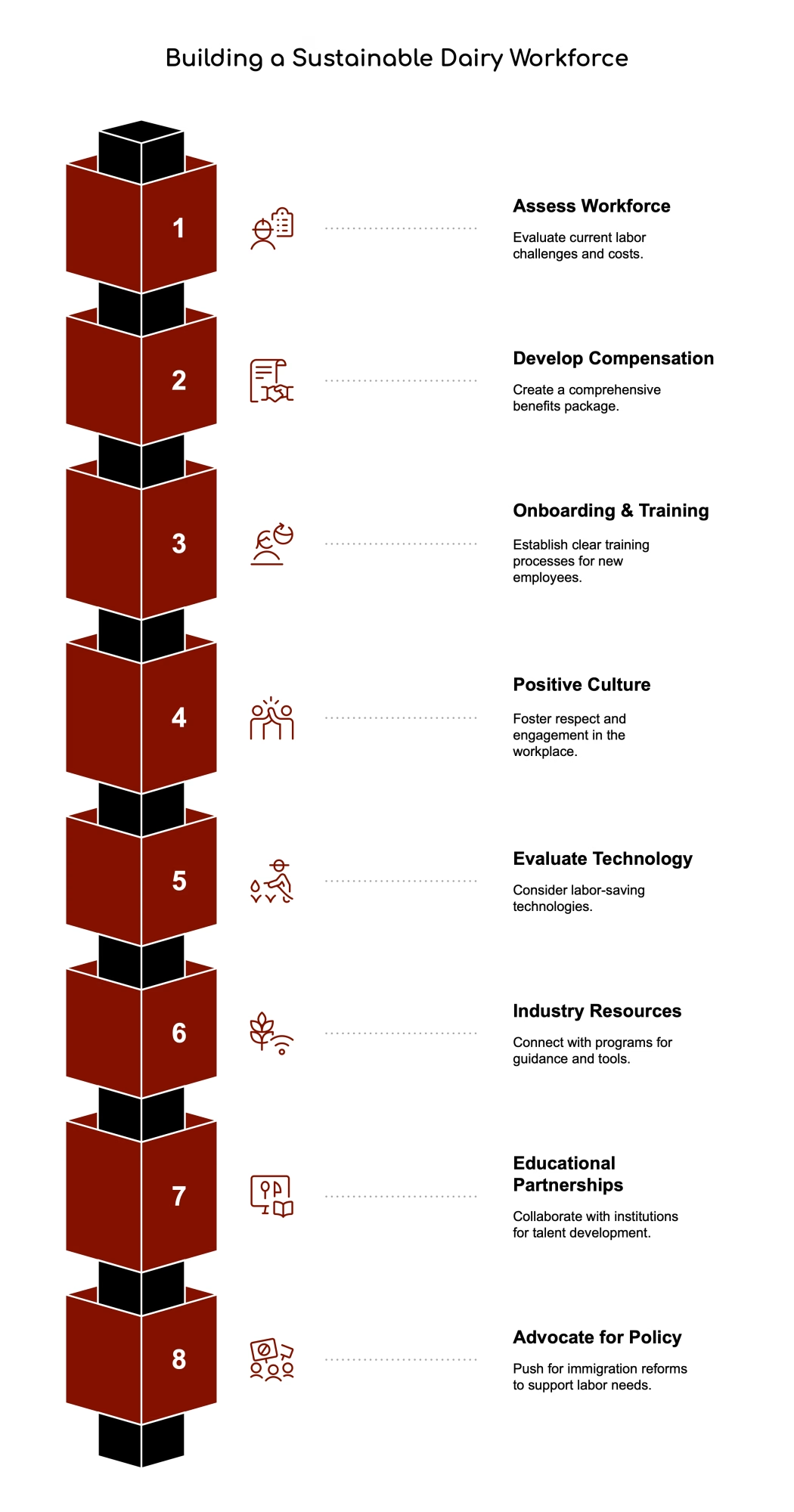

Steps You Can Take Today

- Assess your current workforce situation: Document turnover rates, identify specific pain points, and quantify the costs of your current labor challenges, just as you would track key performance indicators like pregnancy rate or feed conversion efficiency.

- Develop a comprehensive compensation strategy: Look beyond basic wages to create a package that includes benefits, bonuses, and non-monetary perks that address your employees’ specific needs, as tailored to your workforce as your nutrition program is to your herd.

- Create structured onboarding and training processes: Establish clear procedures for bringing new employees into your operation and providing continuous learning opportunities, as systematic as your protocols for fresh cow monitoring or heifer development.

- Build a positive workplace culture: Implement regular team meetings, recognition programs, and other initiatives that foster respect and engagement, creating a working environment as comfortable and productive as your cow housing.

- Evaluate technology options: Consider which labor-saving technologies might best suit your operation’s needs and financial capacity. Conduct the same thorough assessment you would for a major upgrade to your milking system or manure handling equipment.

- Connect with industry resources: Reach out to programs like the National Dairy FARM Program’s Workforce Development initiative for templates, guidance, and assessment tools, leveraging industry expertise as you would from your nutritionist or veterinarian.

- Engage with educational institutions: Partner with local agricultural programs to develop internships, apprenticeships, or other pathways that can bring new talent to your farm, investing in future human capital as you would in genetic improvement.

- Advocate for policy reform: Join industry organizations in pushing for immigration policies that better serve dairy’s year-round labor needs, adding your voice to collective efforts like those that have advanced other industry priorities.

The Bottom Line

Here’s the hard truth: Many dairy operations invest more strategic thinking in their breeding programs than in their approach to human resources. The consequences of this misalignment are becoming increasingly costly and threaten the very foundation of our industry.

The U.S. dairy industry stands at a critical juncture, with workforce shortages posing a substantial threat to its productivity, sustainability, and the well-being of its farmers. Successfully navigating this challenge requires a multi-faceted approach combining innovative on-farm strategies, technological adoption, supportive policies, and systemic changes to how labor is valued and developed.

For your dairy operation, the path forward involves viewing labor not merely as a cost but as a critical asset requiring sustained investment in training, development, competitive compensation, and positive workplace environments. The stakes are high, not just for individual farms but for food security, rural communities, and the future viability of American dairy.

The most successful dairy farms will be those that effectively balance technological innovation with human expertise, creating workplaces that attract and retain skilled, motivated employees while leveraging the efficiency and precision of modern technology. By addressing these challenges head-on with creative solutions and a long-term perspective, your operation can transform a critical vulnerability into a significant competitive advantage, much like how the most progressive dairies have transformed other industry challenges into opportunities for differentiation and growth.

The question isn’t whether you can afford to invest in developing a resilient workforce; it’s whether you can afford not to. What steps will you take to build your farm’s future workforce this month? Your answer may determine whether your operation is viable five years from now.

Key Takeaways:

- Invest in people: Competitive wages + housing/benefits reduce turnover by up to 54% (ROI: $263K/yr).

- Automate wisely: Robotics cut milking labor 60% but demand tech-savvy workers for data/equipment management.

- Fix policy gaps: H-2A visa reforms and pathways to legal status are urgent to stabilize immigrant labor (79% of U.S. milk supply).

- Culture matters: Peer recognition, bilingual training, and mental health support curb isolation and burnout.

- Future-proof skills: Hybrid roles (animal care + data literacy) attract younger workers and bridge tech gaps.

Executive Summary:

The U.S. dairy industry’s reliance on non-family labor is colliding with unprecedented hiring and retention challenges, driven by wage gaps, grueling work conditions, and rural isolation. Innovative farms are combatting shortages with competitive compensation, robust training, and technology like robotic milkers—yielding measurable gains in productivity and employee retention. However, systemic fixes, including immigration reform and industry-wide upskilling, remain critical for long-term stability. Without rethinking labor as a strategic asset, dairy risks losing its competitive edge and rural economic vitality.

Learn more:

- Unraveling the Labor Shortage Crisis: A Deep Dive into Challenges Dairy Farmers Face Today

- Boosting Dairy Farm Efficiency: How Robotic Milking Transforms Workflow and Reduces Labor

- Winning the Workforce War: How Top Dairies Are Solving Labor Shortages in 2025

Join the Revolution!

Join the Revolution!

Join over 30,000 successful dairy professionals who rely on Bullvine Weekly for their competitive edge. Delivered directly to your inbox each week, our exclusive industry insights help you make smarter decisions while saving precious hours every week. Never miss critical updates on milk production trends, breakthrough technologies, and profit-boosting strategies that top producers are already implementing. Subscribe now to transform your dairy operation’s efficiency and profitability—your future success is just one click away.

Join the Revolution!

Join the Revolution!