What if I told you the biggest threat to your dairy isn’t feed costs—it’s walking out your barn door daily?

What I find most frustrating about this industry is… Everyone’s obsessing over milk prices and feed costs while the real crisis is happening right in your barn, twice a day, every day.

Here’s what the numbers actually show: immigrant workers make up about 51% of the dairy workforce, and farms employing them produce roughly 79% of America’s milk. This isn’t just a staffing challenge—it has become the foundation our entire industry quietly depends on, and most producers have no idea how exposed that makes them.

The Real Cost of Churn That Nobody Wants to Discuss

Look, I get it. Turnover feels like just another headache when you’re already juggling feed bills, equipment breakdowns, and everything else that goes sideways on a dairy. But here’s the thing—workforce churn has become a productivity killer that’s bleeding operations dry.

The latest FARM survey data indicate that annual turnover is approximately 39% across participating dairies. That means nearly 4 out of 10 workers walk out your door every year, leaving chaos in their wake.

What’s particularly eye-opening is the emerging research from Cornell’s agricultural workforce program, which suggests significant ripple effects. Studies indicate that even modest turnover correlates with 1-2% drops in milk production and measurable impacts on animal health—more sick calves and higher cow mortality. Those aren’t just statistics; they show up in your butterfat tests and vet bills, whether you’re tracking them or not.

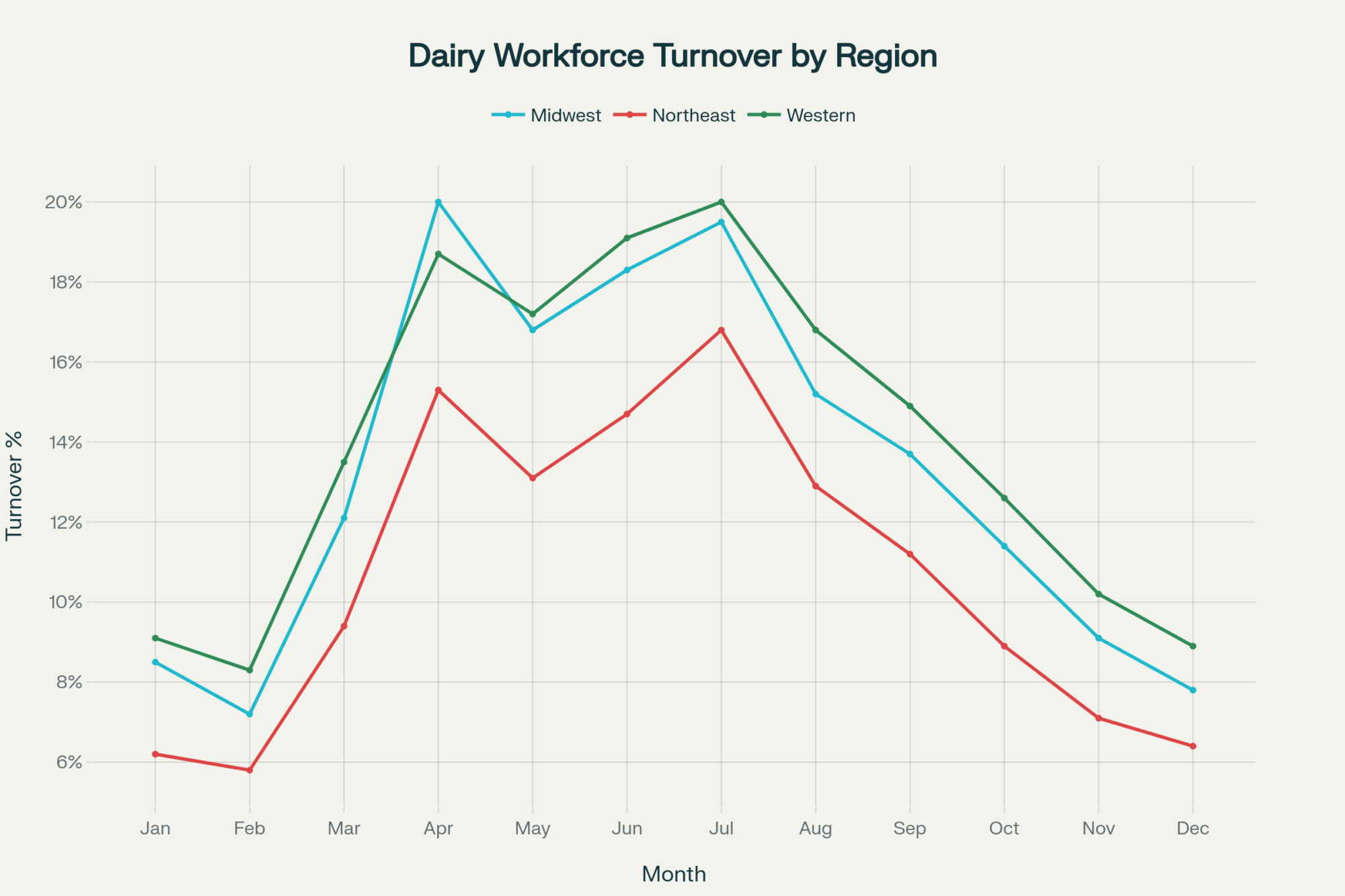

And the seasonal swings? That’s where it gets really painful. Some regions report monthly turnover spiking to 20% during peak stress periods—April, when everyone’s scrambling for field work, and July, when the heat becomes unbearable. Try running efficient operations when one in five workers might disappear any given month.

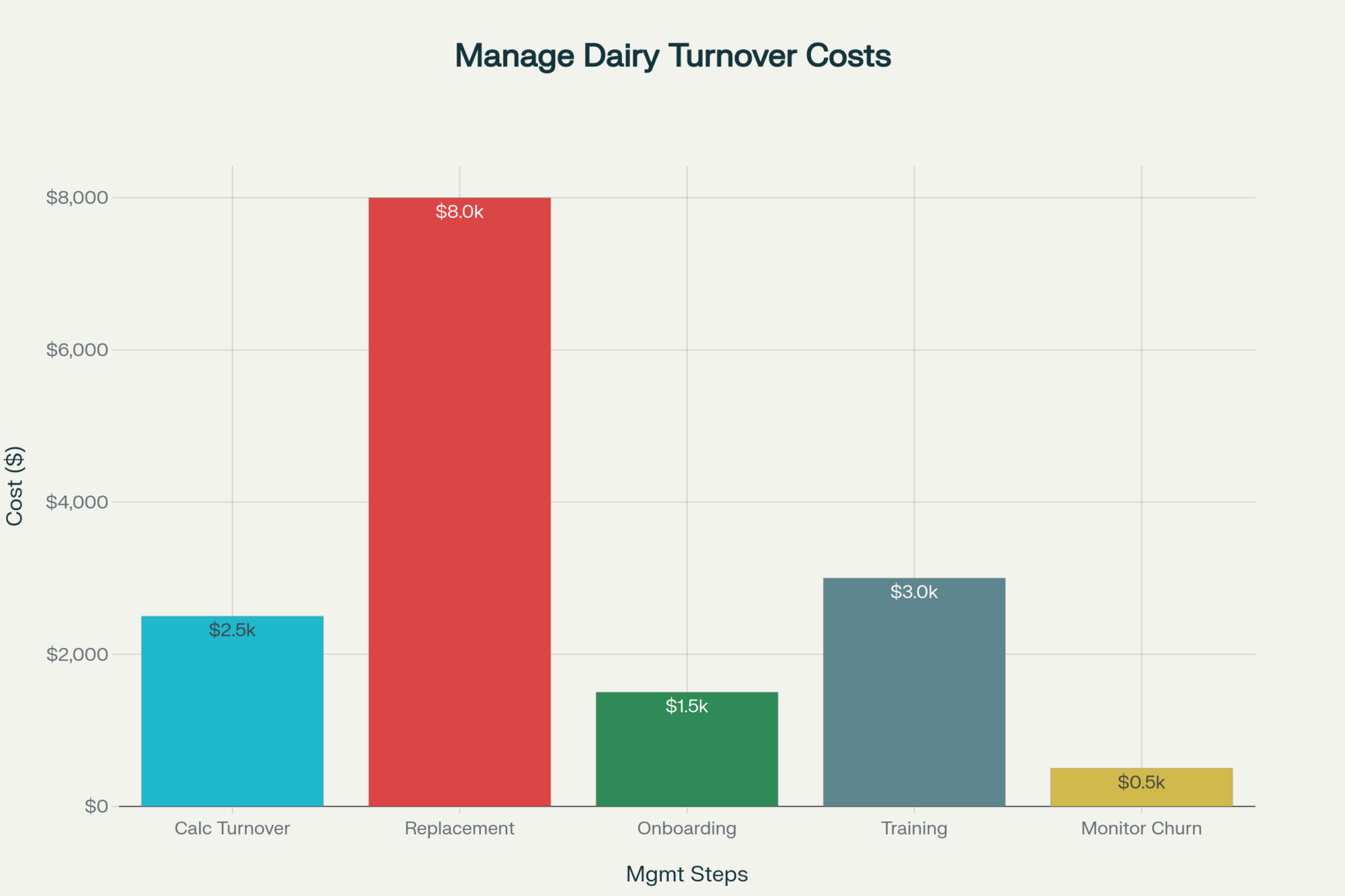

Here’s what really gets expensive, though: new hires take 3 to 6 months to reach full productivity. During that extended learning curve, your experienced workers spend up to 30% of their time training newcomers, rather than focusing on their actual jobs.

Cornell Extension’s cost analysis framework estimates the total cost at $15,000 to $25,000 per departed worker, factoring in recruiting, training, lost productivity, equipment damage, and quality issues. Multiply that by your annual turnover rate, and you’re looking at potentially six-figure annual losses.

Dairy Turnover Loss Calculator

- Number of full-time-equivalent (FTE) workers: ______

- Annual turnover rate (%): ______

- Estimated cost per departing worker ($15,000–$25,000): ______

Estimated Annual Turnover Cost:

FTE workers x turnover rate (as a decimal) x cost per departed worker = total turnover cost

Example:

20 workers x 0.39 x $18,000 = $140,400 per year

Don’t forget to include training time, lower early productivity, and possible vet or quality losses!

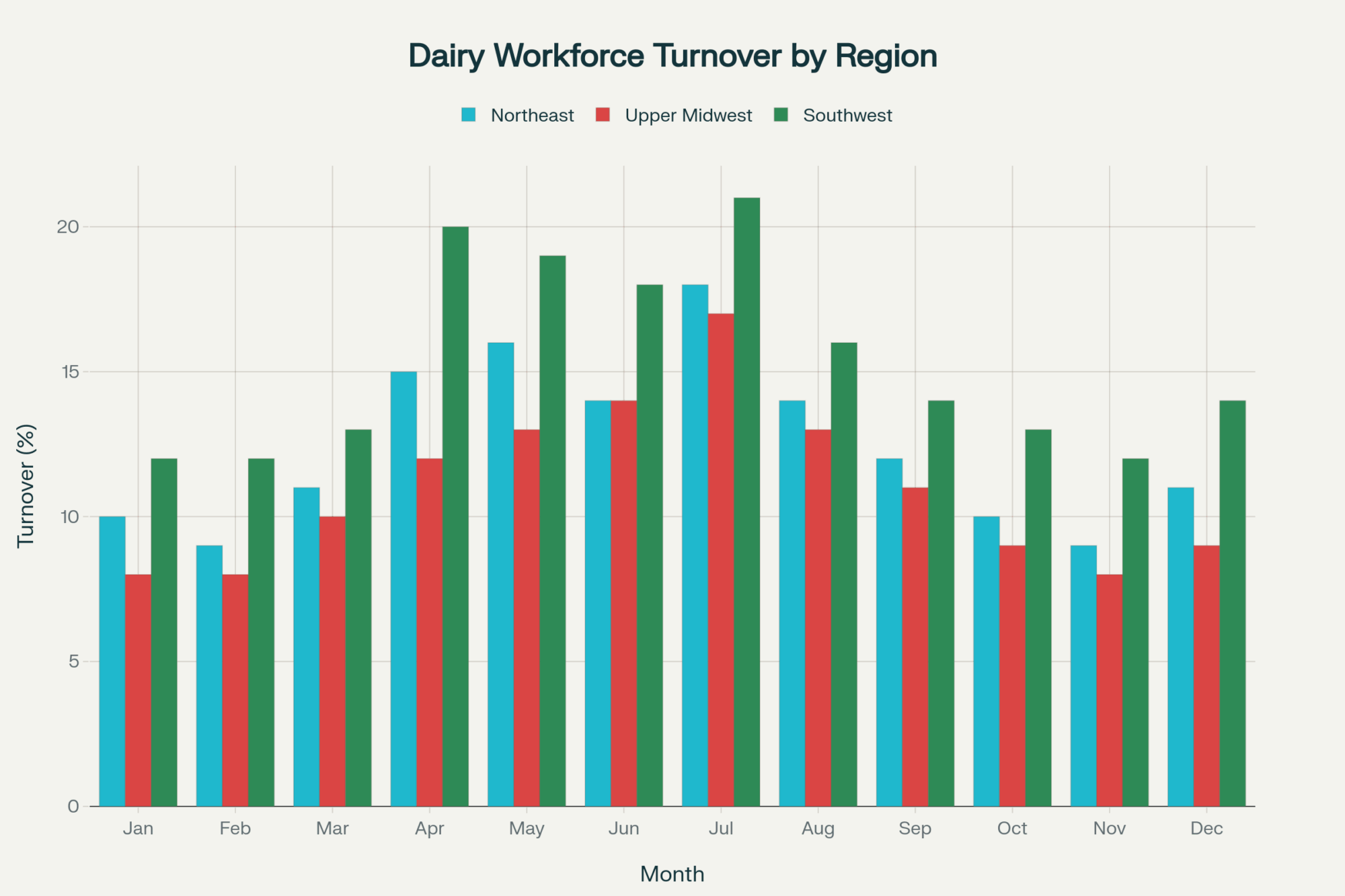

Where You Farm Determines Everything

What strikes me about this workforce crisis is how differently it plays out depending on your location. And I’m not just talking about obvious stuff like wages or cost of living.

In traditional dairy states like Wisconsin and New York, USDA data shows immigrant workers typically make up 50-70% of the workforce. However, head west to the large confined operations in Idaho or California’s Central Valley, and University of Minnesota extension research indicates that those percentages climb to 70-90%.

The concentration becomes even more pronounced on larger operations. Those 1,000+ cow dairies that dominate production? They’ve built their entire labor model around experienced immigrant workers who often bring generational dairy knowledge from their home countries.

Climate adds another layer of complexity that most analyses ignore entirely. Summer heat in Arizona and Southern California creates working conditions that drive seasonal workforce migration toward indoor jobs. Meanwhile, brutal winters in the northern tier trigger departures when farm housing isn’t adequate.

The result? American dairy’s geographic footprint is quietly reshaping itself around workforce availability—operations are expanding where labor is accessible and consolidating where it’s not.

Robots: Let’s Talk Real ROI, Not Marketing Hype

Every conversation about dairy labor eventually comes around to automation, and there’s definitely momentum building. The global robotic milking market reached approximately $2.5 billion in 2025, with North America accounting for about 30% of that total.

But here’s where I need to be brutally honest about the economics. Those glossy equipment brochures promising 2-3 year paybacks? Joint analyses from Minnesota and Wisconsin dairy extension programs consistently show more realistic timelines of 5-7 years under typical operating conditions.

The shorter paybacks only happen under very specific circumstances—extremely high labor costs, perfect cow adaptation, and exceptional management. Most operations face a much bumpier road.

Multiple case studies from 2022 to 2024 document initial production volatility, with some farms experiencing drops of 8-15% during the first year as both cows and operators adapt to new routines. One producer described it to me as “like teaching calculus to cows while learning it yourself.”

However, what’s truly interesting is that successful automation doesn’t eliminate labor needs—it fundamentally transforms them. You go from needing experienced milkers who understand cow behavior to needing technical specialists who can troubleshoot sensors, interpret data analytics, and manage complex automated systems.

Policy Paralysis and What’s Actually Working

Let’s address the elephant in the room: federal immigration policy remains completely disconnected from the operational reality of dairy.

The H-2A program certified nearly 385,000 positions in 2024, but it’s virtually useless for year-round dairy operations. Designed decades ago for seasonal crop work, it can’t accommodate our biological requirements—cows don’t take vacations.

Processing delays make an already inadequate system actively harmful. Workers often arrive weeks after they’re needed, if they arrive at all. When you’re milking twice daily regardless of staffing problems, these delays aren’t just inconvenient; they’re operationally catastrophic.

What’s actually working? State-level innovation that ignores federal paralysis. Vermont’s Milk with Dignity Program—a worker-driven, advocacy-supported initiative—now covers 20% of the state’s dairy production. The program succeeds because workers helped write the standards, participate in monitoring, and farms receive economic premiums for participation.

Smart producers are investing in comprehensive retention strategies that show measurable results. Quality housing investments of $50,000 to $100,000 per unit demonstrate clear returns through reduced turnover. Operations implementing structured career development, language training, and genuine advancement opportunities report a drop in turnover from over 45% to under 15% within two years.

Your Monday Morning Action Plan

Here’s what successful operations are doing while others are still debating policy:

- Start with brutal honesty about your vulnerabilities. Document your current workforce composition, identify critical positions, and develop emergency protocols for various disruption scenarios. Most operations have no idea how exposed they really are.

- Plan technology adoption in phases alongside investments in retention. Don’t put all your resources into either automation or workforce development—you need both strategies working together.

- Build community partnerships before you need them. Establish relationships with neighboring operations for labor sharing, connect with community colleges for training programs, and develop agreements with reliable staffing services.

- Two low-cost moves you can implement this week: First, standardize your onboarding process with written protocols and milestone reviews. Second, train supervisors in basic coaching techniques—many turnover decisions occur within the first 90 days, often based on management relationships.

- Use extension data to benchmark and track progress. Stop making workforce decisions based on gut feelings when objective data is available through university extension programs.

The Bottom Line That Changes Everything

Here’s the question that should reshape your planning: if you lost 40% of your workforce tomorrow—not gradually over months, but suddenly—could you still milk your cows and maintain animal welfare standards?

That scenario isn’t theoretical anymore. Agricultural regions across the country have experienced similar workforce reductions following enforcement actions, economic disruptions, and changes in the competitive labor market.

I’ve watched dairy operations that seemed bulletproof suddenly scramble to find emergency staffing solutions that often don’t exist. The difference between survival and bankruptcy comes down to preparation and strategic thinking.

The workforce foundation supporting American dairy is fundamentally unstable, and that instability is accelerating whether we acknowledge it or not. The operations that survive and thrive will be those that acknowledge current realities, invest strategically in both technology and people, and build operational resilience before crisis forces their hand.

Your response to this workforce challenge—starting right now—will determine whether you’re leading the dairy industry’s next evolution or becoming a statistic in its ongoing consolidation. Because at the end of the day, those cows are still waiting twice daily, and they’re not negotiating schedules based on workforce availability.

Your cows don’t negotiate milking schedules based on who shows up. Time to get serious about the people who make it all happen.

KEY TAKEAWAYS

- Save $15,000-$25,000 per worker by investing in decent housing and career pathways—some Vermont farms cut turnover from 45% to 15% in two years using this approach

- Budget 3-6 months for new hire productivity, while your veterans spend 30% of their time training instead of milking—streamline onboarding to cut this waste

- Prepare staffing around seasonal peaks that can hit 20% monthly turnover in April and July—schedule accordingly, or watch your operation spiral

- Don’t believe robotic milking paybacks under 5 years—Minnesota and Wisconsin extension data shows 5-7 years is realistic, and you’ll still need tech-savvy workers

- Leverage proven retention programs like Vermont’s Milk with Dignity, which covers 20% of state production and demonstrates measurable improvements in workforce stability

EXECUTIVE SUMMARY

Here’s what kept me up last night after diving into the latest workforce data: farms employing immigrant workers now produce 79% of America’s milk, while those workers make up just over half of our entire workforce. But there’s a gut punch coming—turnover is hitting nearly 40% annually, and that’s not just an HR headache, it’s shaving 1-2% right off your production. Even worse, seasonal spikes can push monthly churn above 20% during spring and summer—try running efficient operations when one in five workers might leave at any given time. The global dairy industry is scrambling toward automation, but realistic robotic paybacks take 5-7 years, not the fairy tale 2-3 years vendors promise. Smart money says fix your people problems first, then layer in the tech—because at $25,000 per departed worker, you can’t afford to keep bleeding talent.

Complete references and supporting documentation are available upon request by contacting the editorial team at editor@thebullvine.com.

Learn More:

- The Labor Crisis Hidden in Plain Sight: How Dairy’s Worker Shortage Will Reshape Your Farm by 2030 – This deep-dive article provides a strategic roadmap for navigating the workforce crisis. It models scenarios for both inaction and adaptation, demonstrating how investing in a full operational transformation can lead to a significant competitive advantage and higher ROI.

- Robotic Milking Revolution: Why Modern Dairy Farms Are Choosing Automation in 2025 – Cut through the hype with this comprehensive piece on robotic milking. It challenges common myths and provides a realistic economic comparison between traditional parlors and automated systems, helping you determine if a robot is the right fit for your operation.

- How to Attract and Retain Exceptional Labor for Your Dairy Farm – This tactical guide provides immediate, actionable strategies for solving your labor problems on the ground. It offers practical advice on modern recruitment, effective onboarding, and low-cost retention programs that significantly reduce turnover and boost productivity.

Join the Revolution!

Join the Revolution!

Join over 30,000 successful dairy professionals who rely on Bullvine Weekly for their competitive edge. Delivered directly to your inbox each week, our exclusive industry insights help you make smarter decisions while saving precious hours every week. Never miss critical updates on milk production trends, breakthrough technologies, and profit-boosting strategies that top producers are already implementing. Subscribe now to transform your dairy operation’s efficiency and profitability—your future success is just one click away.

Join the Revolution!

Join the Revolution!