His hospital pen is empty. His antibiotic bill is zero. His cows make $775 more each. Here’s how

If you ever visit Trevor Nutcher’s dairy operation out in California’s Central Valley, something will immediately catch your eye—the hospital pen was empty. Not just quiet for the day, but consistently empty. For those of us who recall his operation a few years ago, which involved 20-plus cows cycling through treatment protocols, this is worth discussing.

What’s interesting here is that Nutcher didn’t achieve this through gradual reduction or selective dry cow therapy. He went cold turkey on antibiotics—completely eliminated them. And before you think he’s taking unnecessary risks, let me share what’s actually happened to his operation.

The Real Economics We’re Not Calculating

So here’s what I’ve been thinking about lately—we all know treating mastitis costs money, right? But it’s the hidden expenses that really add up. The milk we’re dumping during those extended withdrawal periods, the productive days lost to chronic cases, those early culling decisions we’re forced to make.

In my conversations with producers from Wisconsin to California, as well as some individuals in the Northeast and Southeast, I’m hearing that resistant cases often cost significantly more than straightforward treatments. What’s particularly interesting is that many producers are reporting higher retreatment rates than a few years ago.

A producer in Pennsylvania mentioned something that stuck with me: “We’re so focused on the treatment cost, we forget about the cow that never quite comes back.” That’s the hidden math we’re not doing.

Examining operations in Georgia and North Carolina, where heat stress exacerbates these issues, the economics become even more challenging. One producer near Athens told me his resistant cases during summer can cost three times as much as winter treatments when you factor in extended recovery.

Understanding What’s Really Happening

Dr. Geoff Ackaert, the technical director and global head of ruminants at AHV International, shared something with me that really shifted my perspective. He described our traditional approach as trying to defeat an organized army by capturing individual soldiers.

Emerging research suggests that bacterial communities form protective structures known as biofilms. You know that stubborn slime that builds up in water tanks? Same basic idea, except it’s happening in udder tissue. These biofilms function like protective shields, making bacteria 10- to 1,000-fold more resistant to traditional treatments, according to AHV’s research documentation.

Here’s what really got my attention—bacteria actually talk to each other using chemical signals. They coordinate their attacks for when the cow’s stressed. That’s why we often see mastitis blow up during transition, heat stress, or when we change the ration. The bacteria aren’t getting stronger; they’re getting better organized.

Joe Soares’ Unintentional Experiment

The Joe Soares operation gave us valuable data during last year’s H5N1 outbreak. His Chowchilla facility followed traditional protocols, including electrolyte support, aspirin powder, and B12 supplementation. Cost them $26.71 per treated cow according to their records. Meanwhile, his Turlock operation implemented AHV’s communication-disruption protocol at $54.02 per cow.

That initial cost difference would make anyone nervous. But here’s what happened: Turlock cows returned to normal production in three days. The Chowchilla group? Some took weeks, with several never returning to previous production levels. The milk production data showed that Turlock maintained 11 pounds more milk per cow per day during recovery. When you do the math, that higher upfront cost turned into a $775 advantage per cow.

What really convinced me was the collar monitoring data—Turlock cows showed measurable improvement in eating and chewing cud within 24 hours.

The Numbers That Matter:

- Traditional protocol: $26.71/cow with weeks of recovery

- Alternative protocol: $54.02/cow with 3-day recovery

- Net advantage: $775 per cow when factoring in production

- Irish trial results: 74.8% antibiotic reduction

- Fertility improvement: 9.3% better conception, 28 fewer days open

COMPARISON AT A GLANCE:

| Factor | Traditional Approach | Communication Disruption |

| Initial Cost | $26.71/cow | $54.02/cow |

| Recovery Time | Weeks | 3 days |

| Production Loss | Variable, often permanent | Minimal |

| Retreatment Rate | High (30%+ in some operations) | Low |

| Long-term ROI | Declining due to resistance | $775/cow advantage |

| Works With Robots | Yes | Yes, with monitoring benefits |

How This Works (And Where It Doesn’t)

So instead of trying to kill bacteria—which just breeds tougher ones—this method scrambles their communication. Think of it like jamming their cell phone signals so they can’t coordinate.

This approach (called quorum sensing inhibition if you want the technical term) prevents bacteria from organizing their group attacks. A cow’s immune system handles individual bacteria just fine—it’s when they all attack at once that problems arise.

The field data from Ireland that AHV tracked is pretty compelling. Six farms with 1,344 cows achieved 74.8% reduction in antibiotic use. But here’s what’s really interesting—conception rates went up 9.3% and days open dropped by 28. We’re talking about overall health improvement, not just udder health.

Now, I should mention that not everyone sees these results. A Vermont grazing operation I heard about had mixed outcomes, partly because their system already had low infection rates. A 200-cow tie-stall barn in Wisconsin found it tough to implement with their setup. Some Southeast operations, which deal with year-round high humidity, report needing adjusted protocols.

For operations with robotic milking systems, there’s actually an advantage—the constant monitoring helps catch that 24-72 hour response window better than visual observation alone.

What Implementation Really Looks Like

Nutcher was candid about his transition. “Those first 72 hours test everything you’ve learned,” he told me. “You see swelling developing, and every instinct says reach for that mastitis tube.”

The difference lies in how quickly it works. Traditional antibiotics provide a familiar, quick knock-down effect within hours. Communication disruption takes 24 to 72 hours as the cow’s own immune system clears out the now-confused bacteria. It’s a different healing, not slower.

From what I’m seeing, successful transitions share these traits:

- Start with prevention during dry-off and fresh cow periods

- Look beyond per-treatment costs to total economics

- Get your vet on board early

Several producers have mentioned that once they calculated milk dump plus early culling, the economics became clearer. But if you’re just comparing tube prices? Yeah, it’s harder to justify.

Dr. Sarah Mitchell, a practicing veterinarian in Wisconsin who has worked with three operations making this transition, told me, “The biggest challenge isn’t the science—it’s changing 30 years of muscle memory when you see that first swollen quarter.”

Is Your Operation Ready?

This approach may not be suitable for every situation. If you’re exiting dairy within two years, you may not recoup your investments. Small operations with fewer than 100 cows may find the per-cow investment challenging. But for operations that keep getting the same cows sick over and over? That’s when it becomes compelling.

Examining different regions reveals varying economic conditions. Texas operations dealing with heat stress see different results than Idaho’s large-scale dairies or New Mexico’s dry lot systems. Grazing operations in the Southeast—places like Tennessee and Kentucky—report different outcomes than large freestall barns out West. Florida producers dealing with year-round humidity face unique challenges that require a different approach.

Consider market access, too. Premium contracts for antibiotic-free milk vary widely by region and processor. Even modest premiums can add up to real money when you’re shipping year-round.

Based on documented trials, operations can see significant reductions in treatment needs—those Irish farms achieved nearly a 75% reduction. Though results vary by system.

What You Can Do Today

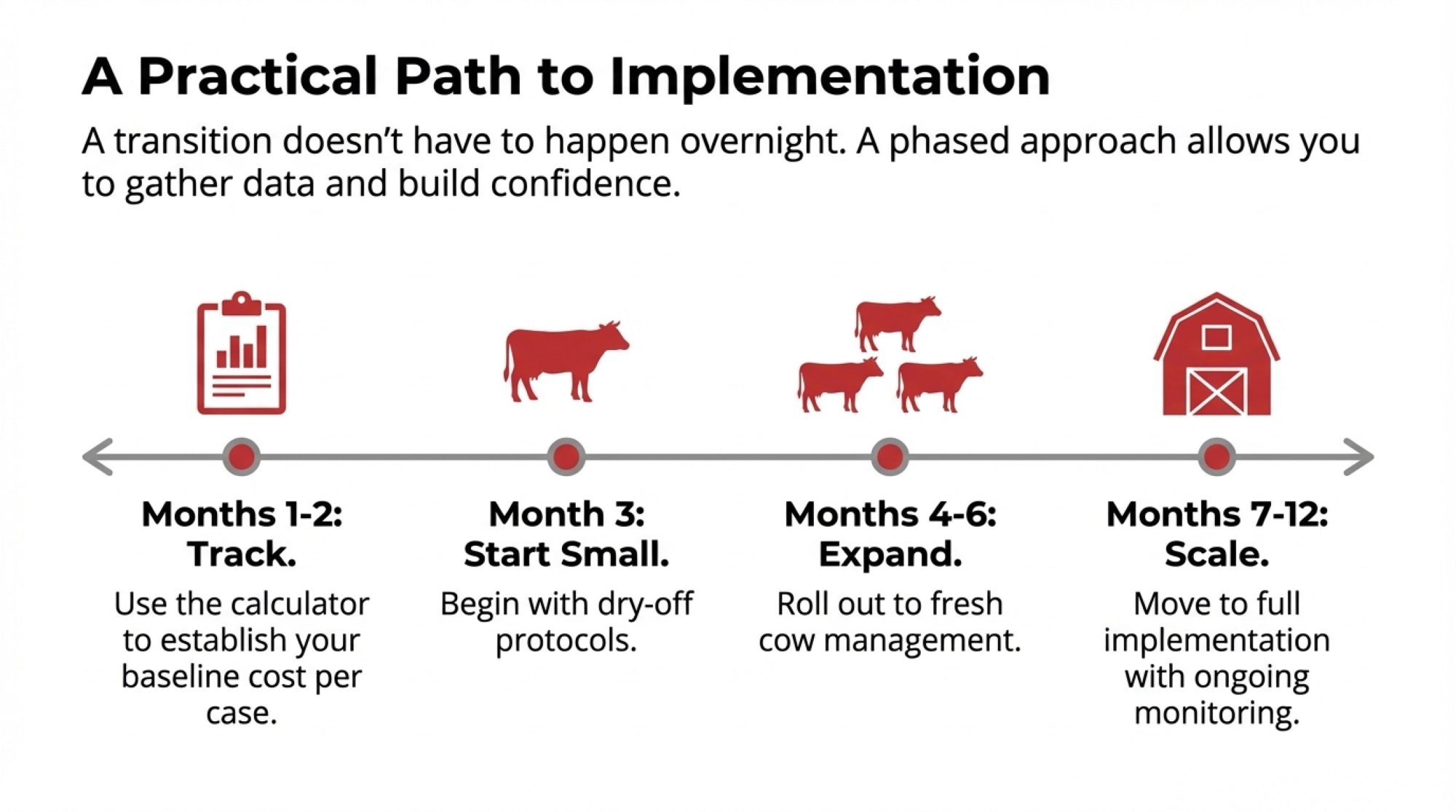

For operations considering change, here’s a practical timeline:

- Month 1-2: Start tracking current treatment costs using the calculator below

- Month 3: Begin with dry-off protocols

- Month 4-6: Expand to fresh cow management

- Month 7-12: Full implementation with ongoing monitoring

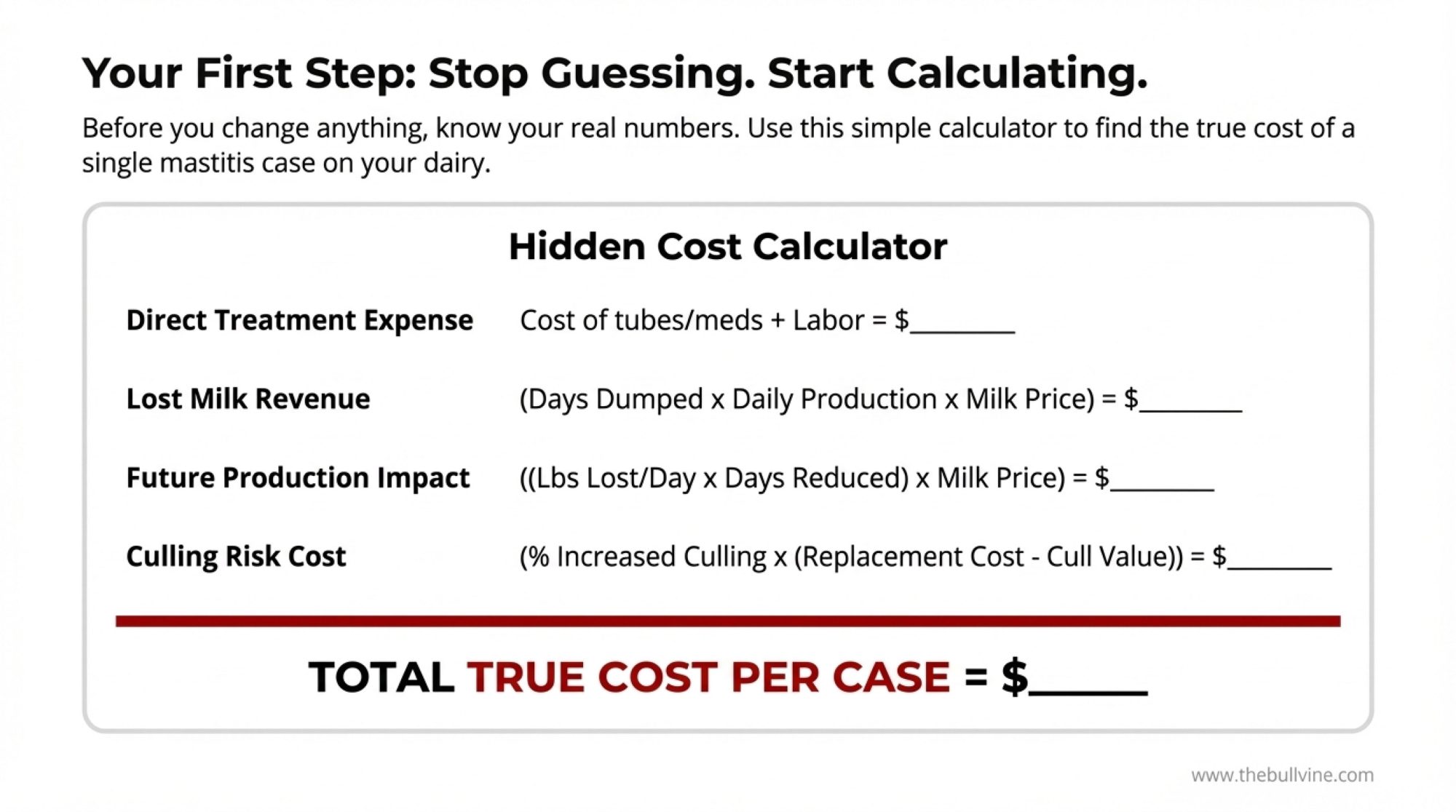

HIDDEN COST CALCULATOR:

Calculate Your True Treatment Cost Per Case:

1. Direct Treatment Expense

- Cost of tubes/medications: $_____

- Labor (hours × hourly rate): $_____

2. Lost Milk Revenue

- Days of dumped milk: _____ days

- Daily production × milk price: $_____/day

- Total milk loss: $_____

3. Future Production Impact

- Expected production drop: _____ lbs/day

- Days of reduced production: _____ days

- Production loss value: $_____

4. Culling Risk Cost

- Increased culling probability: _____ %

- Replacement cost – cull value: $_____

- Risk-adjusted culling cost: $_____

5. TOTAL TRUE COST PER CASE: $_____

Even if you’re maintaining current protocols, track failure rates carefully. Document retreatment rates, identify chronic cases, and calculate true per-incident costs using the calculator above. This baseline data proves invaluable whether you transition now or later.

The Bottom Line

What we’re witnessing here is something fundamental—the conversation shifting from “How do we kill bacteria?” to “How do we prevent them from organizing?” That’s more than a technical change. It’s a whole new way of thinking about animal health.

The producers successfully navigating this aren’t abandoning proven practices completely. They’re combining new understanding with established principles. Sure, it requires education, patience, and sometimes stepping away from familiar protocols. But for operations embracing evidence-based innovation, the rewards look compelling.

The dairy industry has consistently evolved through cycles of innovation. Bacterial communication disruption may represent the next significant advance. Producers exploring these approaches today? They’re writing the management playbooks others will follow tomorrow.

As we all know, change in dairy comes slowly, then suddenly. That empty hospital pen at Nutcher’s operation might be showing us what sudden change looks like when it finally arrives. And for those of us still figuring out our path, it’s worth remembering—we don’t all have to take the same route, but understanding the options? That’s just good business.

KEY TAKEAWAYS

- Zero sick cows is achievable: Trevor Nutcher’s hospital pen went from 20+ cows to consistently empty—no antibiotics—by disrupting bacterial communication instead of fighting bacteria directly

- $775 per cow ROI is documented: Joe Soares proved this during H5N1 with 3-day recoveries versus weeks and 11 lbs more daily milk production

- Benefits go beyond mastitis: Irish trials (1,344 cows) achieved 74.8% antibiotic reduction while improving conception by 9.3% and cutting 28 days open

- This rewards high-challenge herds most: Operations with already-low infection rates reported mixed results—know your baseline before investing

- Your first step: calculate true costs: Most producers underestimate what chronic mastitis really costs when you add milk dump, retreatment, and early culling

EXECUTIVE SUMMARY:

Trevor Nutcher’s hospital pen used to hold 20+ sick cows—now it stays empty, and he hasn’t used an antibiotic tube since switching protocols. The breakthrough: instead of killing bacteria (which breeds resistance), this approach disrupts their communication, preventing them from coordinating attacks. Real-world proof came during Joe Soares’ H5N1 outbreak—cows on the new protocol recovered in 3 days versus weeks, produced 11 pounds more milk daily, and delivered a $775-per-cow advantage. Irish trials across 1,344 cows documented a 74.8% reduction in antibiotics, while improving conception by 9.3% and cutting days open by 28. This approach isn’t universal—operations with already-low infection rates and small tie-stall setups report mixed results. But for dairies trapped in chronic retreatment cycles, the economics of bacterial communication disruption are becoming impossible to ignore.

Complete references and supporting documentation are available upon request by contacting the editorial team at editor@thebullvine.com.

Learn More:

- The $50,000 Biofilm Crisis Your ATP Test Will Expose – Reveals how the same biofilm shields protecting mastitis bacteria also thrive in water lines, demonstrating a step-by-step enzymatic cleaning protocol to eliminate this hidden drag on herd health.

- Bird Flu Bombshell: Dairy Cows Losing a Full Ton of Milk with No Recovery – Validates the economic urgency of immune resilience, detailing the staggering $950-per-cow losses from recent H5N1 outbreaks and why recovery speed is the new competitive advantage.

- Vermont’s Robot Tipping Point: Automation Is No Longer Optional for Smart Dairies – Expands on the “robot advantage” mentioned above, demonstrating how automated data collection creates the specific 24-72 hour response window needed to make communication-disruption protocols profitable.

Join the Revolution!

Join the Revolution!

Join over 30,000 successful dairy professionals who rely on Bullvine Weekly for their competitive edge. Delivered directly to your inbox each week, our exclusive industry insights help you make smarter decisions while saving precious hours every week. Never miss critical updates on milk production trends, breakthrough technologies, and profit-boosting strategies that top producers are already implementing. Subscribe now to transform your dairy operation’s efficiency and profitability—your future success is just one click away.

Join the Revolution!

Join the Revolution!