Smart farms aren’t just switching to digital feed management—they’re discovering money they never knew they were losing.

EXECUTIVE SUMMARY: Recent University of Minnesota research reveals that 100-cow dairies can save $58,400 annually by reducing feed shrink through precision tracking—losses that traditional paper logs simply can’t detect. What’s particularly noteworthy is how mobile feed management systems aren’t just improving efficiency; they’re uncovering waste patterns that experienced operators never saw coming, with some operations discovering 3-8% shrinkage they’d been accepting as normal. With feed costs representing 20-45% of gross income according to agricultural financial consultants, even modest improvements in accuracy can determine yearly profitability. The precision dairy technology market is expanding 9-15% annually as mid-size operations realize they can’t afford to operate blind on their largest expense. Beyond immediate cost savings, these systems are reshaping the relationships between nutritionists and farms, enabling real-time adjustments instead of reactive monthly reviews, and positioning farms for environmental compliance programs that increasingly require detailed documentation. Current feed price volatility makes this visibility particularly valuable—when corn and soy swing dramatically, knowing exactly where every ingredient goes becomes a competitive advantage rather than a luxury.

You know, I’ve been following the shift toward mobile feed management for a few years now, and what strikes me is how many farms are discovering money they never knew they were losing.

Here’s what’s interesting—Dr. Jim Salfer from the University of Minnesota Extension puts a number on it that really gets your attention: a 100-cow dairy can save $58,400 in one year just by reducing feed shrink from high to low levels. That’s real money walking out the barn door every day… and most operations using paper logs simply can’t see where that shrink is happening.

What I’ve found is that this technology isn’t just improving efficiency—it’s revealing losses that were always there but impossible to track. Gary Sipiorski, who does agricultural financial consulting, points out that feed costs range from 20% to 45% of gross income, and if you’re purchasing all your feed, it pushes toward 50% of your milk check. With numbers like that, even small improvements in accuracy can determine whether you’re profitable this year.

This development suggests something important about where our industry is heading. The precision dairy technology market is projected to reach $5.59 billion by 2025, expanding at 9-15% annually, but what’s driving that growth isn’t just bigger farms going high-tech. Mid-sized operations are realizing they can’t afford not to know where their feed dollars are going.

When the Old System Finally Shows Its Cracks

Now, I should mention that I’ve seen some excellent operations that stick with paper and clipboards and do just fine. Usually, these are smaller farms with one consistent mixer operator who’s been doing it for years—someone who knows every ingredient by feel and rarely makes mistakes. There’s something to be said for that kind of experience and consistency.

But there’s usually a specific moment when traditional systems fail spectacularly… and that’s what forces change. As many of us have seen, busy weeks when communication breaks down between shifts can create expensive problems. Ingredients get mixed into the wrong pens, quantities get miscalculated during hectic mornings, and suddenly you’re looking at thousands in losses trying to figure out what went wrong through handwritten notes.

Dr. Mike Hutjens from the University of Illinois—who’s probably forgotten more about dairy nutrition than most of us will ever know—puts it this way: “The problem with paper is you don’t know you have a problem until it’s too late.” And here’s the thing—with feed representing half of total farm expenses according to recent industry data, these mistakes add up fast.

What’s encouraging is that farms making the switch to real-time tracking often discover patterns of inefficiency they’d been accepting as “normal” for years. I’ve noticed that the operations pushing toward digital aren’t necessarily the most tech-savvy farms. They’re often the ones that got tired of losing money on preventable mistakes and decided the investment was worth trying.

What Digital Systems Actually Reveal

| Management Aspect | Paper-Based Systems | Digital Systems |

| Waste Tracking | Limited visibility | Real-time alerts |

| Cost per Cow/Year | $0 | $15-40 |

| ROI Timeline | N/A | 6-12 months |

| Labor Efficiency | High manual effort | Automated reporting |

| Data Accuracy | Human error prone | Precise measurements |

| Integration Capability | None | Full herd management |

| Environmental Compliance | Manual documentation | Automated records |

Modern mobile feed management captures information that paper logs simply can’t match. When your mixer operator scans a barcode, the system pulls up target ingredients and pen assignments instantly. As each component hits the scale, you’re seeing actual versus target weights with tolerance indicators, live deviation tracking, and alerts if someone’s about to feed the wrong group.

But here’s where it gets really valuable—those post-mix report cards that generate automatically after each batch. They show exact weights, deviations, and final nutrient profiles, then get stored digitally with timestamps. No more hunting through clipboards trying to reconstruct what happened three days ago when butterfat performance started dropping.

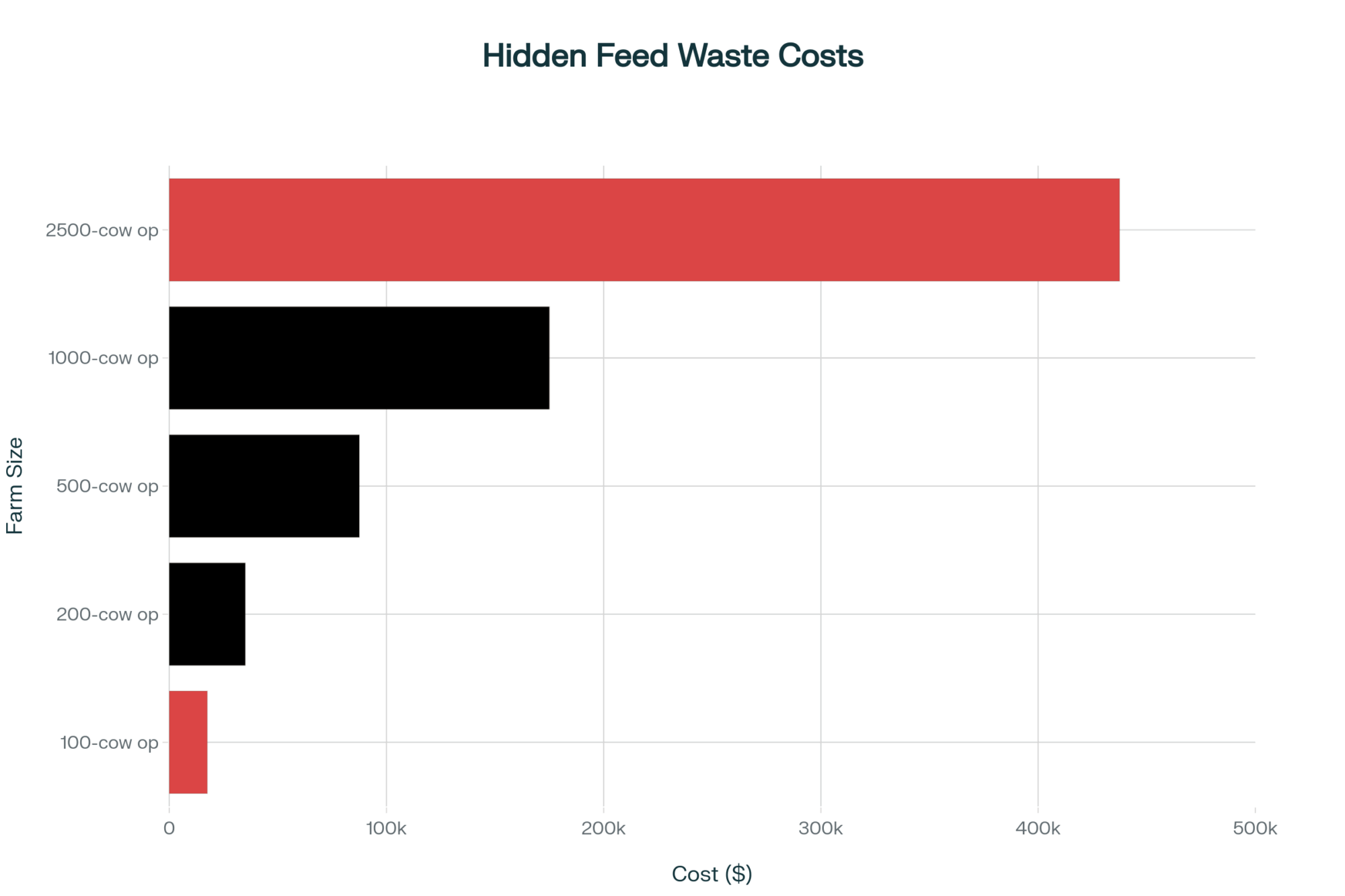

Why is this significant? The economics tell the story. Recent work published in Hoard’s Dairyman showed that farms using precision feeding see feed efficiency improvements from 1.55 to 1.75. On a 2,500-cow operation, that translates to $470 per cow annually—roughly $1.2 million to the bottom line. For smaller operations, the proportional impact is often even greater.

Looking at this trend across different regions, I’m seeing some interesting patterns. Up in Wisconsin and Minnesota, where you’re dealing with corn silage that changes dramatically from October through March, that real-time adjustment capability becomes crucial for maintaining consistent milk components. However, I’ve also spoken with California producers who claim that their consistent TMR quality yields different benefits—mainly increased labor efficiency and improved documentation for their sustainability programs.

And if you’re running robotic milking systems—which seems to be happening in a lot of new barns these days—this precision becomes even more critical. Work from the University of Saskatchewan shows that individually targeted diets can boost milk yield by 3.3 kg per cow while maintaining the same dry matter intake. That’s improved efficiency without higher feed costs, which is exactly what we need with current market conditions.

Getting Your Team on Board

You probably know this already, but transitioning experienced operators from intuitive mixing to screen-guided precision takes some finesse. The key is positioning technology as backup support rather than skill replacement—because good feed operators have pride in their accuracy, and rightfully so.

What I’ve found works best is hands-on training where operators mix real rations alongside tech support. When veteran mixers discover their “feel” weights are actually off by pounds of grain, skepticism usually turns to curiosity pretty quickly. Dr. Marcia Endres at the University of Minnesota has studied this transition across 52 farms in Minnesota and Wisconsin, noting that successful adoption almost always involves a gradual process of trust building.

This builds on what we’ve seen with other farm technologies… you can’t just flip the switch overnight. Many operations run mobile apps alongside paper logs for a couple of weeks, letting operators maintain familiar routines while building confidence. Generally, by week three or so, paper becomes obsolete—not because management mandated it, but because operators prefer the precision and immediate feedback.

What’s worth noting is that resistance often comes from operators who’ve built their reputation on mixing accuracy. They see screens as questioning their skills rather than validating them—so you’ve got to frame it right from the start. Make it about helping them be even better at what they’re already good at.

How This Changes Your Nutritionist Relationship

Here’s something that’s caught my attention… real-time feed data is fundamentally changing how nutritionists work with farms. Monthly reviews are evolving from historical post-mortems to continuous collaborative management.

What’s particularly noteworthy is how this is reshaping the role of a nutritionist entirely. Instead of spending half their time driving farm to farm, many consultants are analyzing data patterns across multiple operations. Rather than waiting for lab results to tell them what happened last week, they can access live dashboards showing daily nutrient drift, automated alerts for unusual events, and historical overlays connecting mix deviations to milk components 24 hours later.

This shift requires some service agreements to be restructured. Rather than flat monthly fees, some nutritionists are moving toward more flexible arrangements—base dashboard access for ongoing monitoring, performance incentives tied to income over feed cost improvements, and consultation blocks for real-time scenario testing.

Based on producer discussions and industry reports, nutritionist costs might tick up slightly with these new arrangements—maybe 10-15% in many cases—but the precision enables more profitable recommendations that typically pay for the additional investment several times over. It’s one of those situations where spending a bit more actually saves you money, assuming you’re working with the right consultant.

What’s interesting here is how this technology is creating opportunities for smaller operations to access higher-level nutrition expertise. A consultant can monitor multiple farms remotely and provide more frequent guidance than the old once-a-month visit model allowed.

The Technical Side That Nobody Talks About

And here’s something that often catches many operations off guard: connecting feed management systems with herd management systems can create unexpected challenges. The issue isn’t data compatibility but timing mismatches.

Herd systems typically update pen movements on their own schedule while feed apps track in real time, which can create situations where you’re trying to mix rations for pens that have changed composition since morning. It’s like trying to hit a moving target—particularly during busy periods with lots of fresh cow management or pen moves.

From what I understand, the better systems have found ways to smooth this out—they’ll coordinate data updates and make sure both systems agree before any mix starts. But it’s worth knowing going in that you’ll probably need some patience while everything learns to talk to each other.

Multiple producers report that integration typically takes longer than vendors initially estimate—sometimes several weeks longer than promised—but once it’s working properly, it eliminates a significant amount of the manual pen count adjustments that used to consume time every morning. The key is having realistic expectations and good vendor support during the setup process.

When you’re evaluating systems, ask specifically about:

- How they handle real-time data synchronization with your existing herd management software

- What happens when systems go offline or lose connectivity (because it will happen)

- How long does integration typically take for operations similar to yours

- What level of ongoing tech support is included versus additional cost

- Whether you can export your data if you decide to switch systems later

- How they handle system updates and whether those might disrupt daily operations

I’ve noticed that the farms with the smoothest rollouts are usually the ones that budget extra time for integration and have clear backup plans for when technology hiccups occur.

What the Numbers Really Show

Research on feed efficiency continues to become more compelling. Recent studies show that highly efficient cows produce less methane than low-efficiency cows, even at the same milk yield. A 20-point gain in feed efficiency can reduce methane emissions by approximately 22 tons per year on a 2,500-cow dairy—which matters as environmental programs become more common across different regions.

This aligns with work from Viking Genetics showing that breeding for better feed efficiency can save up to 200kg of dry matter per lactation without compromising production, health, or reproduction. But technology provides immediate improvements while genetic gains accumulate over generations—which is why smart producers are pursuing both strategies.

The environmental piece is becoming more important, too, especially for operations in areas with stricter regulations or those participating in carbon credit programs. Better feed efficiency directly impacts sustainability metrics, and it’s nice when doing the right thing for your bottom line also helps with regulatory compliance and potentially generates additional revenue.

Looking at this from a broader perspective, feed efficiency improvements of just 0.1 units—say from 1.5 to 1.6—typically translate to $60-80 per cow annually in reduced feed costs, depending on your local feed prices and ration complexity. That might not sound like much, but on a 500-cow operation, that’s $30,000-40,000 annually. Real money.

Regional Differences Worth Considering

What I’ve noticed is that results vary quite a bit by region and operation size. In the upper Midwest, where seasonal forage quality changes can be dramatic, the real-time adjustment capability becomes particularly valuable for maintaining consistent butterfat performance through challenging periods.

During Vermont’s recent drought, several farms reported that mobile feed management systems helped them track forage inventory more accurately and adjust rations quickly as feed quality deteriorated. That kind of agility can mean the difference between maintaining production and facing a costly feed crisis.

But operations with more consistent feed ingredients—like some California dairies with year-round access to similar quality forages, or operations in the Southeast with more stable growing conditions—may see different benefits. For them, it’s mainly labor efficiency, better documentation for sustainability programs, and tighter cost control during volatile feed markets.

For extensive grazing operations—and I’m thinking of some of the farms I’ve visited in Missouri, Kentucky, and other regions with significant pasture-based systems—the core benefits remain, but they may find basic tracking sufficient rather than full integration platforms. The late Dr. Robert James from Virginia Tech, who passed away this past August after decades of studying automated feeding systems across multiple production systems, always emphasized that successful implementation depends more on management protocols than technology sophistication.

Current feed price volatility seems to be accelerating adoption in many areas. With corn, soybean meal, and other inputs swinging like they have been this year, several vendors report that real-time ingredient cost tracking alone is justifying investments for many producers who want better visibility into their largest expense category.

Making Sense of the Investment

So what’s this actually going to cost you? Based on vendor discussions and industry reports, basic mobile feed management systems typically run somewhere in the range of $3,000 to $8,000 annually for a mid-size operation, though this varies considerably depending on features, herd size, and integration complexity.

To put that in perspective, let’s do some quick math. If you’re running 200 cows and spending $250,000 annually on purchased feed (which isn’t unusual these days), and the system helps you reduce waste by even 2%, you’re looking at $5,000 in annual savings. That more than pays for most basic systems.

Most farms report seeing payback relatively quickly—often within six to twelve months—though this varies significantly based on current feed waste levels, number of operators, and existing management practices. The operations with the fastest payback are usually those dealing with multiple operators or frequent mixing errors.

Here’s a simple calculation you can do to estimate your potential return: Track your current feed waste percentage (if you don’t know it, industry estimates suggest 3-8% is typical). Multiply your annual feed cost by your estimated waste percentage. If that number is larger than the system cost, you’ve probably got a business case.

The key seems to be matching technology sophistication to your specific operational needs. Basic systems that track batching accuracy and delivery times can provide immediate value for smaller operations or those just getting started. Larger farms or those with complex ration management often benefit from full integration with herd management systems and advanced analytics.

But look, I’m not saying every operation needs to rush into this tomorrow. The question becomes whether the investment makes sense for your specific situation, current pain points, and long-term goals.

Decision Framework for Your Operation

When does mobile feed management make sense? Generally, when specific pain points create measurable losses or inefficiencies. These typically include frequent mixing errors, inventory surprises, communication gaps between shifts, difficulty tracking the source of nutritional problems, or simply wanting better visibility into your largest cost center.

If you’re evaluating this technology, here’s what I’d consider:

- Operations with documented feed waste above 3%, frequent butterfat or protein swings, or multiple mixer operators usually see the biggest immediate benefits and fastest payback

- Farms with stable performance seeking efficiency gains or environmental compliance improvements might find it worthwhile for the long-term advantages, even if payback takes longer

- Very small operations (under 100 cows) with single operators and stable performance metrics might want to wait and see how costs develop, unless they’re planning expansion or facing specific challenges

What’s your current feed waste level? Do you have consistent mixing between different operators? How often do you deal with ingredient shortages or quality issues that require ration adjustments? Are you participating in any environmental programs that require detailed documentation? These questions can help determine whether you’re likely to see quick returns on investment.

When you’re talking to vendors, don’t just focus on features—ask about their track record with farms similar to yours, what ongoing support looks like, and whether you can talk to other producers who’ve been using their system for at least a year. Get references from operations in your region if possible, because local conditions matter.

Implementation Reality Check

Let me be honest with you… I’ve talked to some operations that struggled with these systems initially. Usually, it comes down to not having realistic expectations about the learning curve, trying to implement too much too fast, or not getting adequate vendor support during rollout.

One producer in Pennsylvania told me they had to dial back their expectations during the first few months. “We thought it would solve all our feed management problems immediately,” he said. “What we found is that it gave us better information to make decisions, but we still had to make the decisions and adjust our management.”

Common first-year challenges include adapting to new workflows, occasional connectivity issues, learning to interpret data effectively, and coordinating system updates with daily operations. Most of these are temporary, but knowing they’re coming helps set realistic expectations.

The successful implementations I’ve seen typically involve starting with basic features and gradually adding complexity as the team gets comfortable. Don’t try to revolutionize your entire feed management system in the first month.

The Bottom Line

What’s happening in feed management really reflects a fundamental shift from reactive to proactive farm management. The farms making this transition first—and doing it well—are positioning themselves not just for today’s challenges, but for whatever comes next in terms of market conditions, environmental regulations, and labor availability.

And based on what I’m seeing across different regions and operation sizes, that practical advantage is becoming harder to ignore. As input costs stay volatile and margins remain tight, farms embracing data-driven precision are gaining advantages that build on themselves over time.

The question isn’t really whether digital feed management will become standard—it’s whether individual operations can afford to wait while others capture these efficiency gains. Because when you’re looking at potential savings of tens of thousands of dollars annually, plus better positioning for future challenges… well, that math becomes pretty hard to ignore.

But remember, technology is just a tool. It won’t address poor management practices or resolve fundamental nutritional issues. What it will do is help good managers be even better at what they’re already doing—and in today’s competitive environment, that edge might be exactly what you need.

KEY TAKEAWAYS

- Quantified waste reduction: Operations typically discover 3-8% feed shrink they weren’t tracking, translating to $30,000-80,000 annual savings for mid-size dairies when systems cost $3,000-8,000 annually

- Integration advantages: Farms connecting feed and herd management systems eliminate manual pen count adjustments while enabling nutritionists to provide remote monitoring and real-time ration adjustments during volatile markets

- Regional adaptation strategies: Wisconsin and Minnesota operations find real-time adjustments crucial for seasonal forage quality changes, while California dairies focus on labor efficiency and sustainability documentation requirements

- Implementation realities: Most successful rollouts involve 2-3 week parallel operation periods, gradual feature adoption, and realistic expectations about 6-12 month learning curves with vendor support

- Decision framework: Operations with multiple operators, documented feed waste above 3%, or frequent component swings see the fastest payback, while smaller farms with consistent single operators may benefit from waiting as technology costs decline

Complete references and supporting documentation are available upon request by contacting the editorial team at editor@thebullvine.com.

Learn More:

- The Numbers That Actually Tell the Story – This article moves beyond feed management to show how data-driven decisions in genetics and nutrition can boost butterfat and protein. It provides a strategic view on how component premiums and risk management are becoming more valuable than volume, offering a holistic approach to profitability.

- June Milk Numbers Tell a Story Markets Don’t Want to Hear – This piece provides a critical economic perspective on market shifts. It analyzes how factors like regional production growth and feed costs are influencing milk prices, revealing why locking in feed prices and focusing on agility are essential strategies for navigating volatility and protecting your bottom line.

- Danone vs. Lifeway: How a $307M Standoff Proves Grit is the New Milk Check – While not about feed, this article provides a powerful lesson in innovation and speed. It demonstrates how nimble companies are outperforming corporate giants, inspiring producers to rethink their own operations and embrace rapid decision-making to survive and thrive in a fast-changing industry.

Join the Revolution!

Join the Revolution!

Join over 30,000 successful dairy professionals who rely on Bullvine Weekly for their competitive edge. Delivered directly to your inbox each week, our exclusive industry insights help you make smarter decisions while saving precious hours every week. Never miss critical updates on milk production trends, breakthrough technologies, and profit-boosting strategies that top producers are already implementing. Subscribe now to transform your dairy operation’s efficiency and profitability—your future success is just one click away.

Join the Revolution!

Join the Revolution!