Breeding 14,000 kg Holsteins but milking them in a 9,000 kg barn? Your genetics can’t outrun bad concrete.

Executive Summary: Canadian tie‑stall herds are heading into the 2027 Dairy Code with a brutal choice: spend roughly $480K on a retrofit or about $1.48M on a new robot barn for 60 cows. The article shows why the cheapest quote often isn’t the best bet once you price in cow‑flow, ventilation, fetch time, and mid‑life “correction” projects that can add $75,000–$100,000 back onto a tight retrofit. Using current Canadian Holstein averages — 11,364 kg in 305 days at 4.15% fat and 3.36% protein — it walks through how even a 5% drop in performance and an extra 275 hours of fetching per robot per year can erase a $200K saving over 15 years. Producers get three clear paths: minimal Code‑compliant upgrades to buy time, a serious long‑term retrofit for barns with good bones, or a full new robot barn for growth‑minded, multi‑generation herds. Along the way, it ties barn design back to labour, succession, and the ability to actually express the 14–15,000 kg Holstein genetics many Canadian breeders are already paying for. The core takeaway is simple: start your AMS decision with the building and your 15‑year horizon, or risk locking your robots—and your genetics—into bad concrete.

Here’s the picture. It’s a cold January morning in an older 60‑cow tie‑stall. The pipeline’s humming, the concrete’s polished from years of hooves and boots, and you’ve got a robotic milking quote on the table that says you can “go automated” for about $17,000 less per cow if you retrofit instead of building new. On paper, that looks like the easy choice.

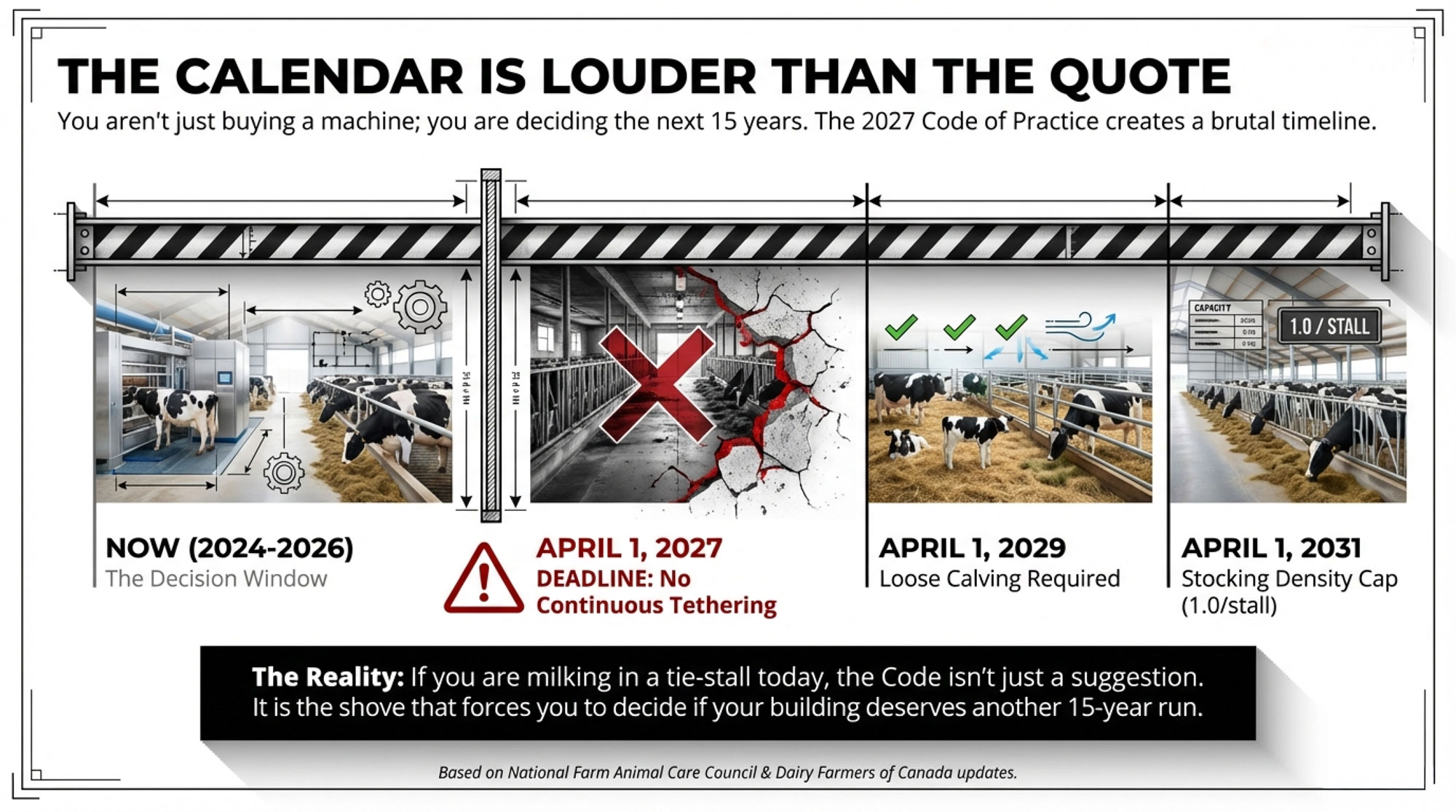

But the calendar is louder than the quote. As of April 1, 2027, Canada’s updated Dairy Code of Practice says cows in existing barns can’t be tethered continuously through their production cycle anymore. Not long after that, new rules land for loose calving and stocking density, all while you’re staring at a seven‑figure gap between the cheapest retrofit and a purpose‑built robot barn — plus your own body, your family’s future, and your quota investment. If you’re milking in a Canadian tie‑stall in 2024–2026 and thinking about robots, you’re not just buying a machine. You’re deciding what kind of barn — and what kind of life — you want for the next 15 to 20 years.

The New Code, Real Money, and Real Cows

Recent Canadian analysis of automated milking system (AMS) costs after tie‑stalls pegs a green‑site robotic facility at about $24,718 per cow once you factor in everything. That breaks down to roughly $6,800 per cow for the milking equipment and $10,700 per cow for the barn and core infrastructure, plus handling, feed storage, and manure systems. For a 60‑cow herd, you’re looking at roughly $1.48 million tied up in that project.

In a retrofit, the robot cost doesn’t change much. A single box typically runs in the $150,000–$220,000 range and realistically serves about 55–60 cows, with a working life of 7-15 years, depending on usage and maintenance. The savings show up when you reuse concrete and steel that are already in the ground. In some Canadian retrofit case studies, the total invested cost is closer to $8,000–$14,000 per cow once you upgrade floors, ventilation, and electrical systems, while keeping the shell. On a 60‑cow herd, that’s roughly $480,000–$840,000.

Now add the Code pressure. The 2023 Dairy Code of Practice update — released by the National Farm Animal Care Council and rolled into Dairy Farmers of Canada’s timelines — lays out three big structural dates:

- By April 1, 2027, cows in existing barns must not be tethered continuously throughout their production cycle.

- By April 1, 2029, all calving must take place in loose housing that allows cows to turn around — pens, yards, or pasture — not in a tie‑stall.

- By April 1, 2031, stocking density in freestall systems must not normally exceed 1.0 cow per stall, stepping down from earlier allowances of 1.2 then 1.1 cows per stall.

At the same time, reporting around the Code notes that nearly two‑thirds of Canadian dairy farms still use tie‑stall housing. Some of those barns already provide turnout or loose housing that help meet the new “freedom of movement” requirement, but there’s no national count of how many. If your barn is tired, your body’s tired, and you’re looking at robots anyway, the Code isn’t just a welfare document — it’s the shove that forces you to decide whether that building really deserves another 15‑year run.

You’re not just weighing a robot quote. You’re deciding whether to bolt a complicated, very expensive piece of automation onto something that might already be past its best‑before date — and how much that’s going to cost you in labour, milk, and sanity down the road.

Same Robot, Two Very Different Barns

What producers keep finding is pretty simple: the robot almost never lets you down. The barn design does.

Think about one of the better retrofits you’ve toured.

You walk into the old tie‑stall, and the first thing you notice is space. The family bit the bullet, dropped from 90 milking cows to around 60, and made the building fit one robot instead of trying to squeeze two into a footprint that couldn’t handle it. They tore out a row of stalls to carve out 15 to 20 feet of open approach in front of the robot, gave cows a clean exit lane that leads straight past fresh water, and built a small but functional separation pen for fresh, lame, and “special” cows.

Ceiling height is 10–12 feet instead of a tight 8. The foundation and posts checked out structurally, and there’s enough sidewall height to hang curtains and install big fans without blowing air into the beams instead of the cows. They didn’t try to force guided cow traffic into a shoebox. They went with free‑flow, grooved and leveled the floors so cows weren’t skating, and gave cows reasons to walk past the robot on their own — feed, water, and an easy path.

Startup was still messy — every AMS startup is. But once cows and people settled, fetch time landed in the “normal” range you see out of AMS field data: roughly 45–60 minutes per robot per day, depending on stage of lactation and season. Fetching is still work, but it feels like the system is on your side.

Now picture another barn you’ve walked into, where the quote looked great and the robot “fit” on paper.

The box is shoved into an end wall because that’s where it was easiest to cut concrete. There’s one narrow alley, maybe 8 feet wide, leading to it with a sharp corner around a post. Dominant cows love to stand there, blocking timid heifers and fresh cows. There’s no real waiting area and no proper separation pen because no one wanted to give up stalls. It technically fits. Practically? It’s a choke point.

Research on automatic milking systems has documented fetch time per robot anywhere from 5 minutes to 120 minutes per day, heavily influenced by barn layout, stocking density, and cow traffic design. In herds with bottlenecks like that second barn, the fetch list never really shrinks. In at least one AMS cow‑traffic study, increasing stocking density by just over ten percentage points made cows roughly one‑and‑a‑half times more likely to end up on the fetch list. That’s the difference between a quick pass through the barn and another hour and a half of “come on girl, let’s go.”

Ventilation amplifies it. When robots and robot rooms are tucked into sidewalls without thinking about inlets and outlets, they can block the main curtain area. Work using Canadian Holstein data and climate records has shown that heat stress hits production and components well before cows are visibly panting, especially in barns with weak air movement. In a retrofit where the robot approach is the hottest, stalest air in the barn, you’re literally asking cows to walk into a sauna to get milked. They’re not going to volunteer.

| Component | Good Ventilation (Well-Designed) | Weak Ventilation (Compromised Retrofit) | Difference |

|---|---|---|---|

| Butterfat % | 4.15% | 4.00% | −0.15% |

| Protein % | 3.36% | 3.26% | −0.10% |

Same robot. Two very different barns. And completely different lives for the cows and people inside them.

| Metric | Good Layout | Compromised Layout | Difference |

|---|---|---|---|

| Daily fetch time per robot | 45 min | 90 min | +45 min |

| Annual fetch hours per robot | 274 hrs | 549 hrs | +275 hrs |

| Labour cost per hour (loaded) | $30 | $30 | — |

| Annual fetch labour cost | $8,220 | $16,470 | +$8,250 |

| 15-year cumulative labour cost | $123,300 | $247,050 | +$123,750 |

The Barn‑Design Math You Don’t See on the Quote

Here’s where the “cheapest option” can quietly turn into the most expensive barn you own.

For a 60‑cow herd, using the Canadian cost work above as a guide, the three basic options look like this:

- Full new robotic build: About $24,718 per cow in total → roughly $1.48 million. Clean‑sheet layout, designed cow flow, new manure and ventilation systems.

- Strategic retrofit with proper upgrades: Around $14,000 per cow → roughly $840,000. Serious spend on floors, air, robot area, and separation, but within the old shell.

- Minimal retrofit (robot dropped into existing layout): As low as $8,000 per cow → roughly $480,000. Robot, basic wiring and plumbing, but little to no change to alleys or ventilation.

If you stop there, minimal retrofit wins every time. That’s why so many kitchen‑table conversations end at the quote.

But AMS economics don’t end at installation. They run for over 10–15 years.

AMS comparisons from several North American and European extension projects have reported labour savings of roughly 10–29%, depending on herd and system, when cow flow and stocking match the robot’s capacity. That’s the upside.

On the downside, the gap between a barn fetching 45–60 minutes per robot per day and one fetching 90–120 minutes per robot per day is enormous. If your retrofit ends up on the wrong side of that line, you’ve effectively given yourself a permanent labour tax:

- Roughly 275 extra hours per robot per year of fetch time when you jump from 45 to 90 minutes a day.

- At roughly $25–$35 per hour for fully loaded labour on many dairy farms today, that’s about $6,875–$9,625 per robot per year just to drag cows to the box.

Production is the other quiet killer. Recent Canadian Dairy Information Centre data show Holsteins averaging 11,364 kg in 305 days, 4.15% fat, and 3.36% protein in 2024. If a compromised layout and heat load cost you even 5% of that potential, you’re giving up around 570 kg of milk per cow per year, plus components. On 60 cows, that’s over 34,000 kg of milk a year gone.

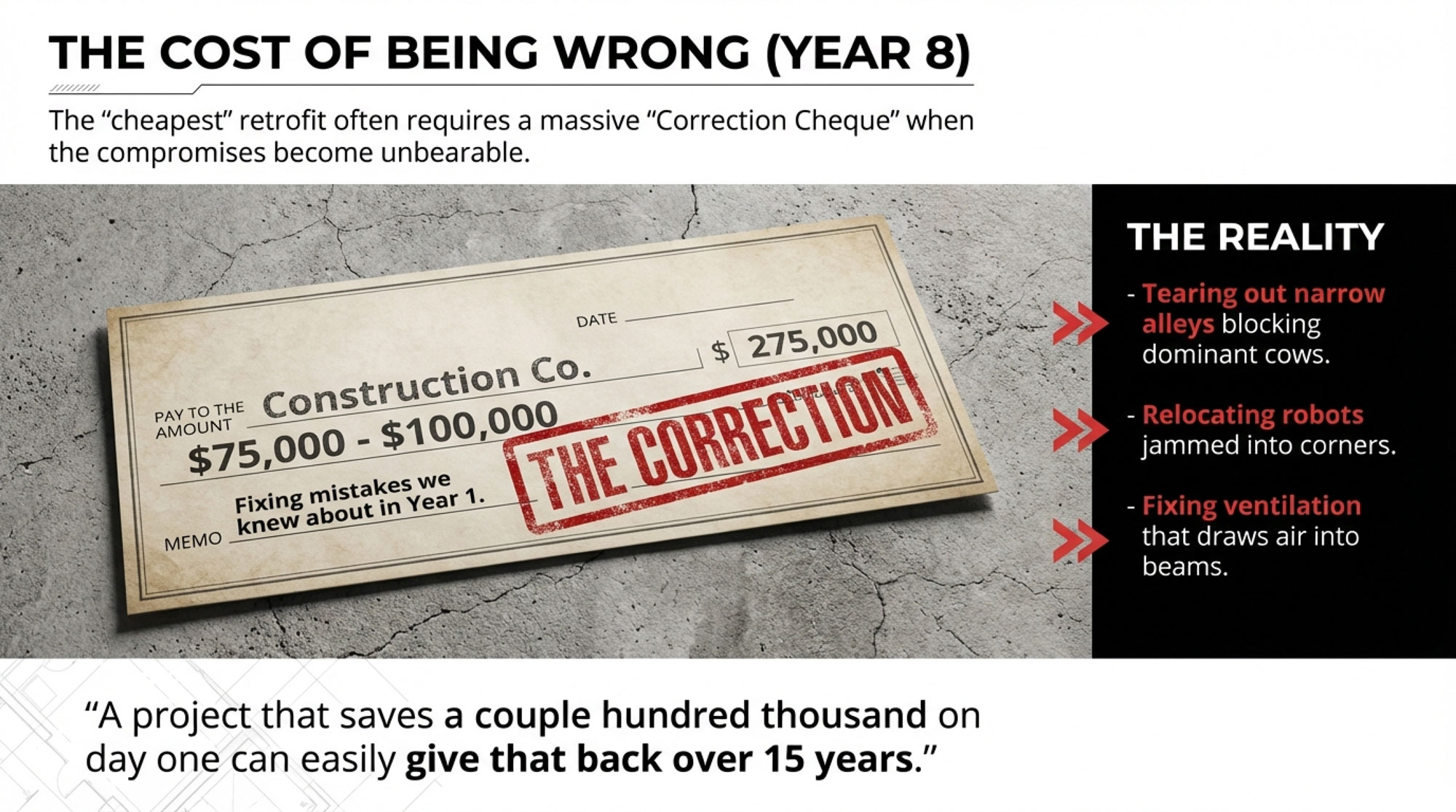

Stretch that over a 15‑year robot life, and the real cost of that “cheap” retrofit starts to show itself. A project that saves a couple hundred thousand dollars on day one can easily give that back — and more over 15 years — through extra labour, lost milk, and the kind of “year eight correction” AMS designers warn about.

That correction cheque usually shows up when the compromises you thought you could live with stop being tolerable: tearing out and re‑pouring the main alley, moving a robot that was jammed into the wrong corner, cutting new curtain openings, or finally building the separation pens you knew you needed from day one. In some retrofits, those correction projects can easily reach $75,000–$100,000.

So you’re not really choosing between a $480,000 retrofit and a $1.48 million new barn. You’re choosing between:

- A cheaper‑to‑build, potentially more expensive‑to‑operate barn that could lock you into chronic labour and production penalties.

- A more expensive‑to‑build facility that, if designed right, is cheaper and saner to live with for the next 15–20 years.

| Year | Minimal Retrofit | Strategic Retrofit | New Robot Barn |

|---|---|---|---|

| 0 | $480,000 | $840,000 | $1,480,000 |

| 5 | $590,000 | $920,000 | $1,520,000 |

| 10 | $730,000 | $1,020,000 | $1,570,000 |

| 15 | $900,000 | $1,140,000 | $1,630,000 |

New construction isn’t automatically “right.” For some herds, the capital hit and land base requirements make it a non‑starter. But if you’re only looking at the quote and not the 15‑year picture, you’re flying blind.

Quick Comparison: Retrofit vs New Robot Barn

A lot of this comes down to how much risk you’re willing to carry — and for how long.

| Path | Typical Investment (60 cows) | Labour Relief | Best For | Biggest Risk |

| Minimal Compliance(No Robot) | $50K–$150K(loose pens, ventilation, turnout) | None | <10 yrs to retirement, no successor, tight capital, already offer turnout | You buy time, not relief—body still breaks down |

| Strategic Retrofit(One Robot, Long-Term) | $840K (serious upgrades, good cow-flow) | Moderate to High (if done right) | 15-yr plan, solid structure, realistic stocking, stable herd size | Cutting corners on air/flow turns it into a bridge you never leave |

| Bridge Retrofit(Robot Now, New Barn Later) | $480K–$600K(clean one-robot setup) | Moderate(temporary) | Next generation committed, need relief now, capital for Phase 2 coming | Bridge quietly becomes destination—Phase 2 never happens |

| Purpose-Built Robot Barn | $1.48M (clean-sheet design) | High (best layout) | Growth-minded, multi-generation, want 15–20 yrs of good cow-flow | Highest upfront cost—requires strong balance sheet and land base |

Three Realistic Paths Between Now and 2027

If your tie‑stall barn still has decent bones, you’re not stuck between “retrofit now” and “build new now.” In practice, most serious Canadian producers are landing in one of three lanes.

Path A: Minimal Compliance, Maximum Optionality

This lane says, “I’ll get Code‑compliant by 2027, but I’m not ready to bet six or seven figures on robots yet.”

It fits when you already give cows turnout or pasture, or have loose pens for dry and close‑up cows, so you’re not continuous tethering today. It also fits when there’s no clear successor, or you’re within 10–12 years of stepping back. And it fits when debt capacity is tight, and a $500,000–$1 million project would stretch things uncomfortably.

On this path, you focus on making freedom‑of‑movement time real and defensible, upgrading or adding loose maternity pens well before the April 2029 deadline, and fixing obvious stall, bedding, and ventilation issues within your tie‑stall footprint to protect comfort and longevity. You watch AMS tech and neighbour experience, so when you do make a move, it’s on your terms—not because you panicked.

The trade‑off is straightforward: you guard flexibility and your balance sheet, but you don’t ease the daily labour grind much. If your body’s already telling you you’re done with twice‑a‑day pipeline milking, this path buys time — not relief.

Path B: Strategic Retrofit as Your Long‑Term Barn

Path B is for when you look at your barn and honestly say, “She’s got another 15 years in her — if we don’t cut corners.”

It fits when a structural engineer has reviewed the foundation, posts, and roof and given you the green light for robot pads and ventilation upgrades. You can carve out 15–20 feet of clear approach in front of the robot, plus a clean exit lane and at least one functional separation pen. Ceiling height is closer to 10–12 feet than 8, or you’re committed to opening up low loft space to gain headroom. Once you’ve made room for cow flow and separation, your stall count still matches realistic robot capacity — about 60 cows per box, not 80 or 90 forced through. And you don’t see yourself doubling cow numbers in the next decade.

Here’s where it gets uncomfortable: you may have to drop from 90 cows to 60. That means less quota in the main string and, on paper, less milk shipped. But if those 60 cows are closer to their genetic potential in a barn that flows, with a robot that isn’t choking on overstocking, your dollars per cow and dollars per labour hour can look a lot better than fighting 90 in a compromised setup. Run the margins both ways before you decide.

If you choose this lane, you have to mean it. Floors, air, cow‑flow, and separation are the engine room of your AMS system. If that’s where you decide to save money, you’re setting your future self up to write that correction cheque and wonder why you didn’t do it right the first time.

Here’s a rough rule of thumb barn planners talk about: if your strategic retrofit budget is climbing past about half of what a new barn would cost and you’re still compromising on cow flow and air, that’s your cue to run full‑build numbers side by side seriously.

Path C: Retrofit as a Bridge to the Next Barn

This lane is for families where the next generation is coming home, but the timing and capital for a full new build aren’t there yet.

It works when the current operator needs physical relief now — backs, knees, and shoulders are sore from tie‑stall milking. The next generation is committed to staying in dairy and sees future growth in cow numbers or robots. The existing tie‑stall can be turned into a solid one‑robot, 60‑cow barn with honest upgrades, but everyone agrees it’s not the 2040 barn.

Here, you retrofit cleanly for one robot and about 60 cows with good cow flow and air, knowing this is Phase 1. You use this barn as your AMS training ground — learning how your cows behave in free‑flow, how to manage data, feed tables, and alarms. You start planning the new build right away: land base, manure storage, feed layout, number of robots, and cow capacity. And you put a real-time frame on Phase 2 (even if it’s a range like 2030–2033) and build your capital plan around it.

The risk? The bridge quietly becomes the destination. A few years in, payments feel normal, the worst of the old problems are gone, and the push for a purpose‑built barn fades. That’s how you end up a decade later, still in a building you meant to use “for a while,” staring again at the same cow‑flow and expansion walls.

What This Means for Your Operation

Start with the building, not the robot.

Before you call a single dealer, get a structural engineer and a barn/AMS designer to walk your place. If your foundation is suspect, ceiling height is under 9 feet across most of the barn, or you can’t find 15–20 feet of clear approach space for a robot, you’re not choosing between two good options. You’re choosing between a new barn and an AMS retrofit that may never work right.

Run 15‑year numbers, not 15‑month paybacks.

Sit down with your lender or advisor and build three cash‑flow models—minimal compliance, strategic retrofit, and new build—out 15 years. Use realistic labour assumptions (including fetch time at $25–$35/hour) and plug in current Canadian Holstein production as a baseline, then model what happens if you’re 5% under that due to layout and air. The spreadsheet might tell a very different story than the quote.

Be brutally honest about herd size and quota.

If a workable robot layout means dropping from 90 cows to 60, are you actually going to do it? Or are you planning to sneak cows back in until the barn is overstocked again? Be honest about how many cows your footprint can truly handle and how that lines up with robot capacity.

Use fetch time as a barn‑health metric.

If you’re regularly spending more than about 90 minutes per robot per day fetching cows once the system is “broken in,” treat that as a warning sign. It’s not just a bad day — it’s your layout, stocking density, or air telling you something.

Separate “Code‑compliant” from “livable.”

You may be able to meet the 2027 tethering rule with turnout, exercise yards, or loose housing for some groups without robots. That might be the right move if capital’s tight and you can still physically handle the pipeline. But if your body is already done, that’s just postponing the real decision.

Match your path to your horizon.

If you’re a decade from retirement and no one’s stepping in behind you, a smart retrofit or even minimal compliance might be perfect. If your kids are already talking about 120 cows and two robots, your plan should focus on where you want to be in 2035, not just how to squeeze one more trick out of a 1970s barn.

Check if your barn matches your genetics.

If your breeding decisions and proofs say 14–15,000 kg Holsteins and strong component genetics, ask yourself honestly whether your barn is built for that — or whether the concrete and air in front of your robot are still a 9,000‑kg design. Genetics can’t outrun a barn that holds them back.

| Scenario | Realized Milk (kg/year) | Lost to Layout/Heat (kg/year) | Genetic Potential (kg/year) |

|---|---|---|---|

| Good Layout (New Barn) | 11,364 | 0 | 11,364 |

| Moderate Retrofit | 10,796 | 568 | 11,364 |

| Compromised Layout | 10,296 | 1,068 | 11,364 |

Talk it through before you call the dealer.

Sit down with your family and your lender, map each of these paths on paper, and make sure everyone’s aligned on which lane you’re actually in — before anyone falls in love with a shiny robot quote.

Watch your cows for a week before you draw lines on paper.

Set the notebook and the quote aside and just watch. Where do cows hesitate? Where do they bunch up? Who owns which alleys? Any robot layout that fights their natural movement will cost you in fetch time, milk, and patience for as long as that concrete is there.

Key Takeaways

- The robot is the cheap part. The expensive part is where you bolt it. If the cow flow and air are wrong, that box will spend 15 years amplifying every design mistake.

- A $17,000‑per‑cow cost gap between a retrofit and a new build can disappear over 15 years if you’re burning an extra 30–60 minutes a day on fetching at $25–$35/hour and running 5% under your herd’s production potential.

- Strategic retrofits work when the barn has genuinely good bones, your realistic future herd size lines up with about 60 cows per robot, and you’re willing to give up stalls and invest in floors, ventilation, and separation.

- Minimal‑change “compliance only” strategies can buy you time on the Code and protect your borrowing capacity, but they don’t fix labour, ergonomics, or succession pressures.

- Bridge‑style retrofits only make sense if everyone’s honest that Phase 2 — a true, purpose‑built robot barn — is coming, with a rough date and a financial plan. If that’s never going to happen, treat the retrofit as permanent and design it that way.

- A well‑designed robot barn isn’t just about labour; it’s how you actually realize the ROI on your high‑LPI and genomic investment. You can’t breed for 14,000–15,000 kg and build for 9,000 kg and expect those proofs to show up on the milk sheet.

| Cost Category | Minimal Retrofit | Strategic Retrofit | New Robot Barn |

| Initial Investment (60 cows) | $480,000 | $840,000 | $1,480,000 |

| Robot & equipment | $200,000 | $200,000 | $200,000 |

| Barn/infrastructure | $280,000 | $640,000 | $1,280,000 |

| Hidden Operating Costs (Annual) | |||

| Extra fetch labour (vs. good layout) | +$8,250/yr | +$2,000/yr | $0 |

| Lost production (5% vs. genetic potential) | +$8,500/yr | +$3,000/yr | $0 |

| Mid-Life Correction Project (Year 8) | +$85,000 | +$25,000 | $0 |

| 15-Year Total (All-In) | ~$900,000 | ~$1,140,000 | ~$1,630,000 |

| Real 15-Yr Cost Gap vs. New Barn | −$730,000 (not −$1M) | −$490,000 | Baseline |

The Bottom Line

At the end of the day, you’re not just picking a milking system — you’re designing how every single day is going to feel in that barn in 2030 and 2035. The Code, the cost of concrete and steel, and the genetics you’ve already paid for are all going to meet in that alley. Before you chase the cheapest ticket into robotic milking, ask yourself one blunt question: when you’re walking that alley with a fetch list in year eight, will this still feel like a smart move — or just the move that cost the least on paper?

Complete references and supporting documentation are available upon request by contacting the editorial team at editor@thebullvine.com.

Learn More

- Dairy Tech ROI: The Questions That Separate $50K Wins from $200K Mistakes – Gain a hard-nosed checklist for Monday morning that stops you from buying trade-show hype. This breakdown exposes the $27/hour labor threshold and armors your operation against the infrastructure failures that sink 62% of automation projects.

- More Milk, Fewer Farms, $250K at Risk: The 2026 Numbers Every Dairy Needs to Run – Secure your farm’s 2026 viability by running the five mission-critical numbers lenders are watching. It delivers a risk-management playbook that shifts you from simply watching Class III prices to proactively protecting your regional processor contract.

- 20 Generations to One: What Europe’s Gene Editing Decision Means for the Future of Your Herd – Unlock a single-generation leap in heat tolerance and disease resistance that bypasses 80 years of traditional backcrossing. This expose reveals how gene editing lets your elite Holsteins thrive through climate shifts without sacrificing production or components.

Join the Revolution!

Join the Revolution!

Join over 30,000 successful dairy professionals who rely on Bullvine Weekly for their competitive edge. Delivered directly to your inbox each week, our exclusive industry insights help you make smarter decisions while saving precious hours every week. Never miss critical updates on milk production trends, breakthrough technologies, and profit-boosting strategies that top producers are already implementing. Subscribe now to transform your dairy operation’s efficiency and profitability—your future success is just one click away.

Join the Revolution!

Join the Revolution!