You can pour money into feed, genetics, or equipment—but every day, poor communication leaves profit in the parlor.

You know, when you talk with producers from Wisconsin to Idaho, there’s always a familiar story. Most will tell you they’ve fine-tuned their feeding program, upgraded their genetics, and modernized their parlor. Yet, even with all that, something still drags performance down. What’s interesting is that it’s rarely a feed issue or cow comfort problem anymore—it’s communication.

More dairies are realizing that human communication—not sensors, not software—is becoming one of their most powerful management tools. You can have the best feed efficiency in the county, but if the team’s not hearing the same message, you’re going to lose consistency and, eventually, money.

| Impact Metric | Industry Average | High-Turnover Farms | Cost Impact |

|---|---|---|---|

| Annual Turnover Rate | 38.8% | 45-60% | $93K-$140K/year |

| Milk Production Loss | Baseline | -1.8% per point | -$18K per 100 cows |

| Calf Loss Increase | Baseline | +1.7% | +$5K-$8K annually |

| Cow Mortality Increase | Baseline | +1.6% | +$12K-$15K annually |

| Total Annual Impact | — | Cumulative | $128K-$181K |

The Economics Behind Miscommunication

Here’s what the research shows. Michigan State University Extension reports that replacing just one employee can cost between $15,000 and $25,000, once you include recruitment, onboarding, lost productivity, and training time. Multiply that across a crew of twelve, and the real price of inconsistency starts to add up fast.

Add language barriers to that, and you see why communication is quietly shaping productivity. Studies from New Mexico State University Extension show roughly 60% of U.S. dairy employees speak limited English, and in some Southwestern regions, up to a third speak K’iché, a Mayan dialect that’s often not translated in training materials.

As Dr. Robert Hagevoort from NMSU likes to put it, “Every time someone does the right job the wrong way, the farm pays tuition.” And he’s right. Bad communication doesn’t always create visible failure—sometimes it just creates smaller, daily inefficiencies that chip away at margins.

When “The System” Walks Out the Door

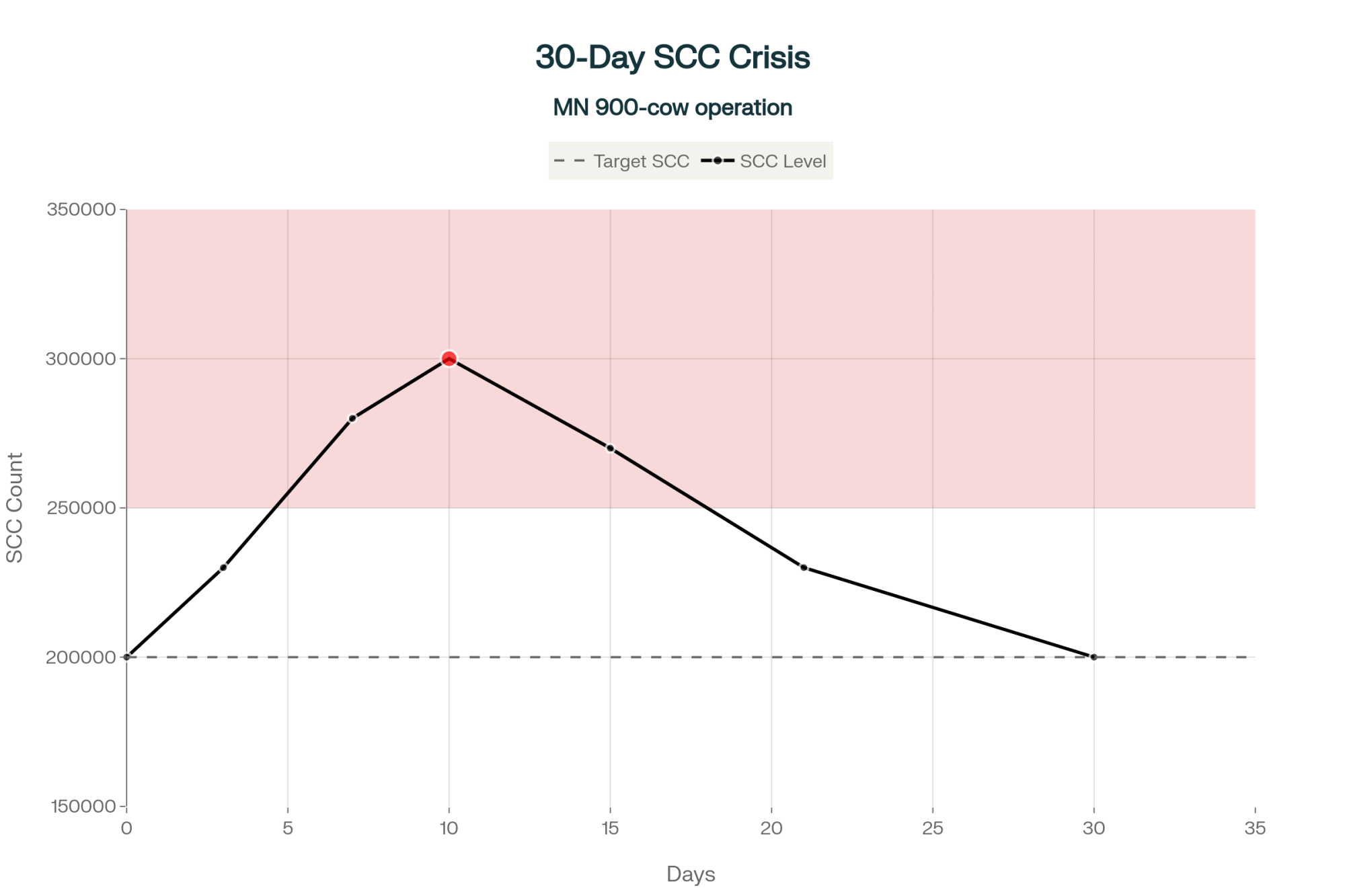

In many dairies, managers don’t realize how dependent their success is on one translator or crew leader until that person is gone. Take a 900-cow operation in Minnesota that lost its bilingual milker. Within days, the somatic cell count passed 300,000, and shifts started running nearly an hour longer.

Through the help of the University of Wisconsin–Madison Extension, the farm rebuilt its communication foundation with bilingual photo SOPs, clear shift checklists, and 10-minute morning meetings. Within 30 days, SCC was back below 200,000. More importantly, turnover slowed because work instructions no longer depended on memory or one individual.

Farms using structured check-ins are seeing consistent success. Cornell’s PRO‑DAIRY program tracked farms that began short daily huddles and found turnover fell by 30–50%. In other words, clarity does what pay raises often can’t—it builds team stability.

The Power of One Question

If there’s one thing many producers overlook, it’s how to start these improvements. You don’t need a big system overhaul. Tomorrow morning, ask your longest-standing employee a simple question:

“If someone new started tomorrow, what’s the hardest thing for them to learn?”

Then, just listen. That one question often exposes the real gaps between what’s expected and what’s taught.

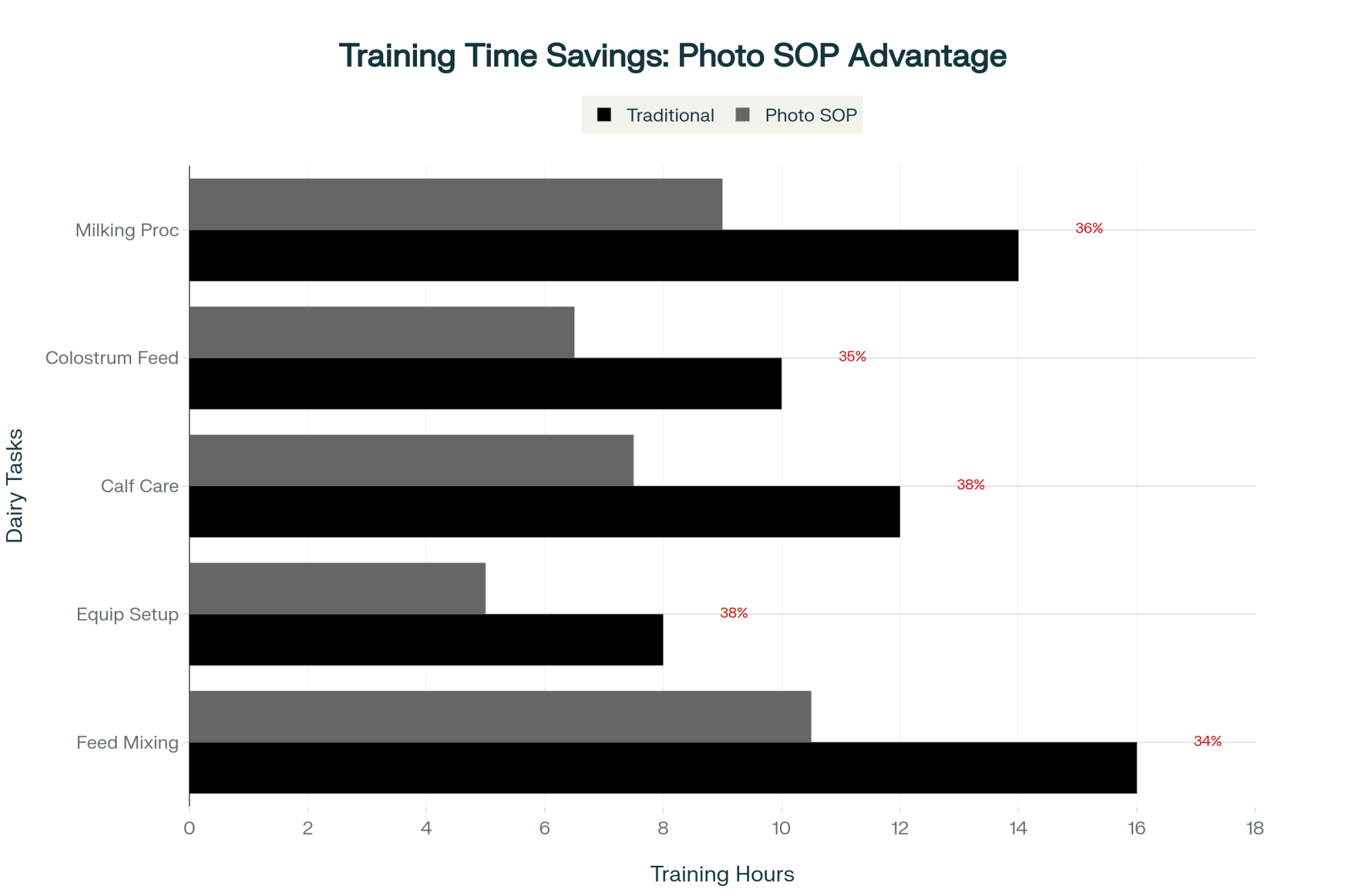

Penn State Extension research has found that farms documenting even five key tasks—feeding order, colostrum prep, milking procedures, machinery setup, and calf care—report 25–40% faster training times within six months.

What’s encouraging is that asking questions like this builds trust. Workers realize their knowledge matters, and managers finally see where assumptions replaced structure.

Turning Words into Pictures

More and more dairies are swapping old binders for laminated photo SOPs. The idea sounds simple, but the payoff can be huge.

Research from Iowa State University Extension and the University of Illinois Dairy Extension confirms that visual direction significantly improves retention, especially on multilingual crews.

Here’s a proven step-by-step approach:

- Photograph each task exactly the way you want it done—using real employees and your own equipment.

- Write short, clear captions—one line per photo.

- Translate into every primary crew language (your Extension office can help).

- Hang the cards exactly where the work happens.

One Wisconsin dairy shared that this approach reduced their parlor changeover time by nearly 20%. And what’s fascinating is that the same process strengthened morale. When everyone knows the expectations, the blame game disappears.

Keep It from Getting Dusty

Now, even the best materials lose their spark if they’re not refreshed. Cornell University’s PRO‑DAIRY Workforce Development specialists recommend short, quarterly “protocol walks.”

These aren’t long meetings—just 10 or 15 minutes walking the barn with the team, asking if anything has changed. Maybe the layout’s different, or a new sanitizer replaced the old one. The key is showing that management updates protocols with the team, not to the team.

It’s a small act that keeps everyone engaged and avoids compliance fatigue.

Why “Teach‑Back” Works Better Than “Do You Understand?”

We’ve all said it—“Do you understand?”—and seen the nods that don’t always mean yes. The teach‑back methodreplaces guesswork with demonstration. Instead of asking if an employee understands a procedure, you ask them to show it back to you.

Studies by Michigan State University, the University of Guelph, and Cornell confirm that using teach‑back reduces repeated errors and improves training retention.

When University of Wisconsin researchers applied this system to calf feeding protocols, they found 50–70% fewer scours treatments thanks to consistent colostrum handling.

One Ontario herdsman told me, “When you ask me to show you, I pay attention differently.” It’s a method that not only teaches but also strengthens respect both ways.

Learning from Europe—Without Copying It

It’s tempting to compare our systems to Europe’s, but context is everything. Denmark and the Netherlands often operate with 100–130 cows per two to four trained employees, supported by national certification programs through SEGES Innovation and Wageningen University & Research.

Their culture and policies encourage lifelong training, but what’s useful for us is the principle: communication is built right into routine management. Dutch CowSignals training, for instance, asks every employee to identify one improvement idea weekly.

Some North American farms have adapted this idea through five-minute Friday “crew check-ins.” It may not be European apprenticeship precision, but it keeps everyone proactive instead of reactive.

Employees as Innovators

What I find most inspiring is how communication changes roles. It turns “labor” into “leadership.”

Cornell research shows that farms that let employees participate in protocol revisions see adoption rates jump by nearly one-third. The process is simple: people respect what they help create.

A producer I know in Idaho gave his milkers a dry-erase board to log claw fall‑offs. Within a month, they found a prep‑timing issue and boosted butterfat performance by 0.1–0.2 points in that string. The knowledge didn’t come from management—it came from the crew actually applying the system.

And that’s what progress really looks like—ownership at every level.

Why This Matters, Right Now

Margins are thin, and labor turnover is real. It’s becoming clear that communication isn’t a luxury; it’s infrastructure. Effective communication reduces training time, minimizes costly errors, and keeps workers engaged. It’s the backbone that supports every improvement effort, from nutrition to fresh cow management.

Dr. Jessica Pempek from The Ohio State University Department of Animal Sciences once said, “We spend months designing systems for cows. Communication is about designing systems for people.” That idea deserves to sit on every office wall.

The Bottom Line

- Start with a question. One conversation can identify your biggest knowledge gap.

- Make it visual. On multilingual crews, photos create clarity faster than manuals.

- Review quarterly. Keep your protocols alive, not laminated museum pieces.

- Teach back. “Show me” builds ownership and confidence.

- Recognize contributions. Employees protect what they help improve.

What’s interesting about this next phase in dairying is that it’s not built on new equipment or feed additives. It’s built on human systems.

As one Wisconsin producer told me over coffee, “Once people understand each other, the cows take care of the rest.”

That might just be the quiet revolution already underway in barns across the country—and it’s one every operation can afford to start tomorrow morning.

Key Takeaways:

- The best upgrade for most dairies isn’t stainless steel—it’s stronger communication between people.

- Visual SOPs and teach‑back training turn “I told them” into “they own it.”

- Quick quarterly “protocol walks” keep systems sharp and employees engaged.

- When crews help design the way work gets done, performance and retention rise together.

Executive Summary:

Clear, consistent communication is turning out to be one of the best upgrades a dairy can make—no new equipment required. Research from Michigan State and Cornell confirms that farms using simple visual SOPs, multilingual training cards, and short “teach‑back” checks cut turnover and boost consistency fast. A 15‑minute quarterly “protocol walk” is often all it takes to keep systems sharp and teams engaged. What’s interesting is how quickly results snowball: steadier milk flow, smoother training, and better retention. The dairies investing in people, not just technology, are quietly proving that communication might be the most profitable tool in the barn.

Complete references and supporting documentation are available upon request by contacting the editorial team at editor@thebullvine.com.

Learn More:

- Optimize Your Dairy Farm: Lean Processes for Cleaner, More Efficient Operations – This guide provides the next tactical step, showing how to apply “Lean” and “Kaizen” principles to systematically observe, streamline, and improve the daily parlor tasks your team already performs.

- The Labor Crisis Hidden in Plain Sight: How Dairy’s Worker Shortage Will Reshape Your Farm by 2030 – For a strategic view, this article details the hard economics and demographic shifts behind the labor shortage, framing your investment in people and training as a critical competitive advantage for 2025 and beyond.

- AI and Precision Tech: What’s Actually Changing the Game for Dairy Farms in 2025? – This piece explores the technology solution, providing ROI breakdowns for how automation, robotic milking, and AI health monitoring can directly reduce labor dependency, cut costs, and boost operational efficiency.

Join the Revolution!

Join the Revolution!

Join over 30,000 successful dairy professionals who rely on Bullvine Weekly for their competitive edge. Delivered directly to your inbox each week, our exclusive industry insights help you make smarter decisions while saving precious hours every week. Never miss critical updates on milk production trends, breakthrough technologies, and profit-boosting strategies that top producers are already implementing. Subscribe now to transform your dairy operation’s efficiency and profitability—your future success is just one click away.

Join the Revolution!

Join the Revolution!