Your selenium strategy is obsolete. New research reveals 60-80% of supplement content is wasted while costing you $700/cow in mastitis and reproductive losses.

Here’s a number that should make every dairy operator sit up and take notice: selenium deficiency-related health issues can cost producers between $325-457 per case of mastitis and $389 per case of retained placenta, according to research published in the Journal of Dairy Science. When these complications cascade—as they often do—total costs can exceed $700 per affected cow. Yet most producers are unknowingly using selenium supplements that deliver as little as 18% of their labeled active ingredient, based on advanced analytical studies published in peer-reviewed journals.

Imagine walking into your feed room and discovering that 60-80% of what you’re paying for in your mineral program is essentially worthless. That’s exactly what’s happening with selenium supplementation across the dairy industry, and it’s time we had an honest conversation about why your current approach might be bleeding money instead of building immunity.

But here’s the uncomfortable truth the feed industry doesn’t want you to know: Recent analytical breakthroughs have exposed the dirty secret of selenium yeast: its selenomethionine content can vary from as low as 18% to 71.8%, with an average of just 55.8%, according to advanced speciation analysis published in livestock science journals. The rest? Often inactive elemental selenium that provides zero biological benefit.

Why Your Current Selenium Strategy Is Probably Failing You

Let’s start with a question that challenges everything you think you know about selenium: If selenium yeast is so effective, why do farms using premium organic selenium sources still struggle with elevated somatic cell counts and reproductive failures?

The answer lies in a fundamental misunderstanding about what “organic selenium” actually means. According to research from the University of California San Diego, genuine selenium yeast should contain 90% or more of its selenium as selenomethionine. However, independent analytical studies using high-performance liquid chromatography reveal that commercial selenium yeast products routinely fail to meet this standard.

The Modern Dairy Dilemma: Genetic Potential vs. Physiological Reality

Today’s dairy cows represent the Formula 1 race cars of agriculture—genetically engineered for maximum performance but operating at the absolute edge of their metabolic capacity. These elite animals process 150-200 pounds of dry matter intake daily, converting it into 100+ pounds of milk while their mitochondria work overtime, generating massive quantities of free radicals through normal cellular respiration.

Why This Matters for Your Operation: The Italian Holstein Case Study

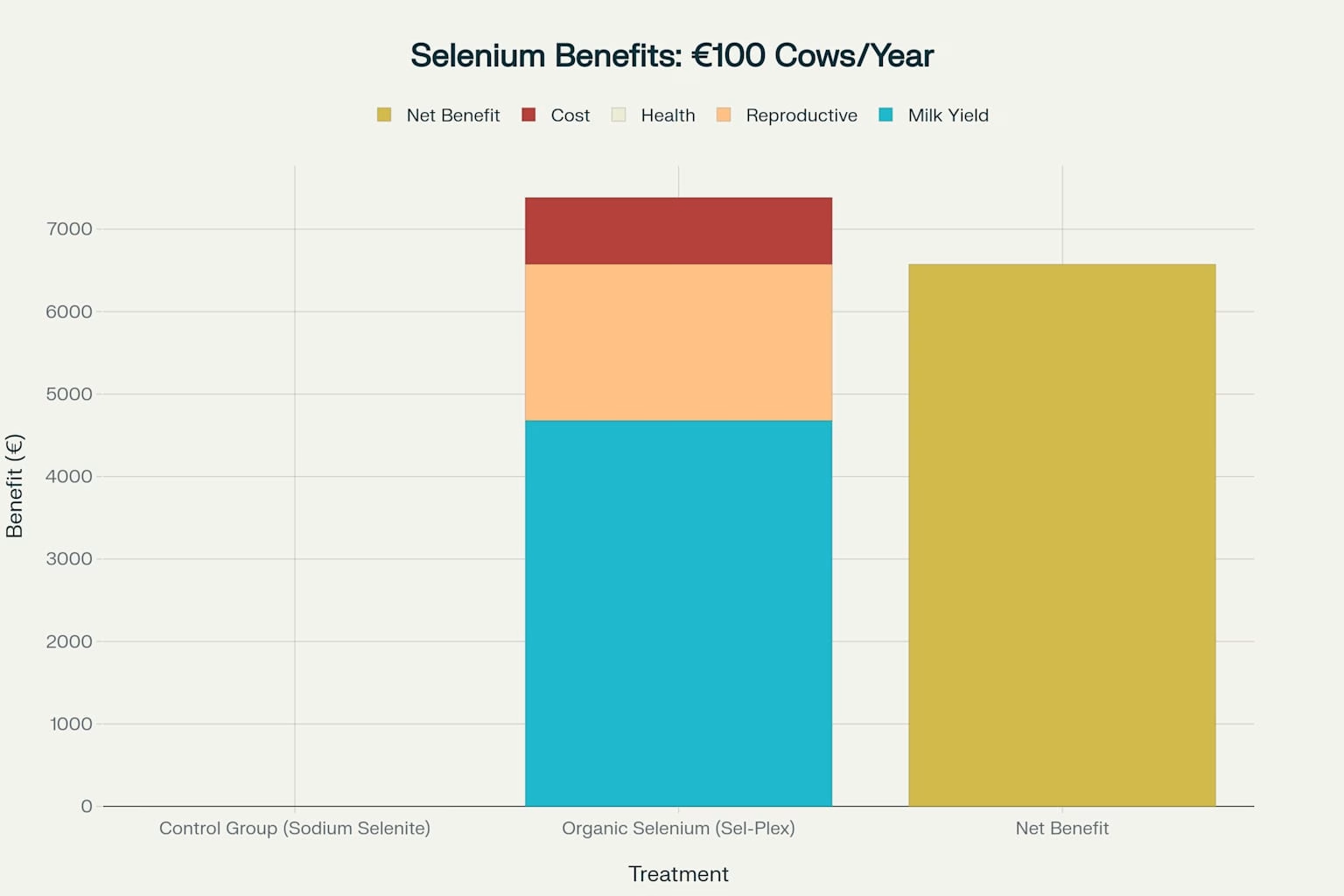

Real-world evidence comes from a landmark study conducted at Ballottino Farm in Cremona, Italy, involving 100 Italian Holstein dairy cows. Research published by Alltech demonstrated the dramatic impact of optimized selenium nutrition.

Mario Agovino from Alltech Italy led the study comparing sodium selenite (control group, n=48) versus organic selenium supplementation (Sel-Plex group, n=52). The results were compelling:

- Milk selenium content doubled: 0.058 mg/L with organic selenium versus 0.029 mg/L with inorganic selenium

- Increased milk yield: 37.9 kg/day versus 36.5 kg/day (1.4 kg/day increase)

- Reduced somatic cell counts: 272,000/mL versus 320,000/mL

- Improved reproductive performance: 83% confirmed pregnancy rate versus 67%

Let’s do the math: That extra 1.4 kg (3.08 lbs) daily translates to approximately $0.64 additional revenue per cow per day at current milk prices—or $234 annually per cow. For a 100-cow herd, that’s $23,400 in additional revenue.

The Geography of Deficiency: A Global Challenge Supported by Meta-Analysis

| Health Issue | Cost per Case/Cow ($) | Frequency | Potential Annual Cost (100-cow herd) |

| Clinical Mastitis | 128-444 | 25 cases per 100 cows | $3,200-$11,100 |

| Subclinical Mastitis | 110 (annual) | Per cow annually | $11,000 |

| Retained Placenta | 300-389 | 5-10% of calvings | $1,500-$3,890 |

| Combined Annual Impact | Variable | Cumulative | $15,700-$25,990 |

Here’s a sobering question: Did you know that selenium deficiency affects an estimated one billion people globally, and livestock in the same regions face identical challenges?

A comprehensive meta-analysis published in the Journal of Dairy Science examined 42 studies conducted between 1977 and 2007 across multiple continents. The research, led by Knowles et al., found that “soils in many regions of the world have a low Se content. Consequently, forages and crops grown on these soils may provide inadequate dietary Se for humans and grazing animals”.

The meta-analysis revealed significant geographical variations in selenium supplementation effectiveness, with American cows supplemented with selenium yeast showing greater milk selenium concentrations (approximately 0.37 micromol/L) compared to those receiving inorganic forms.

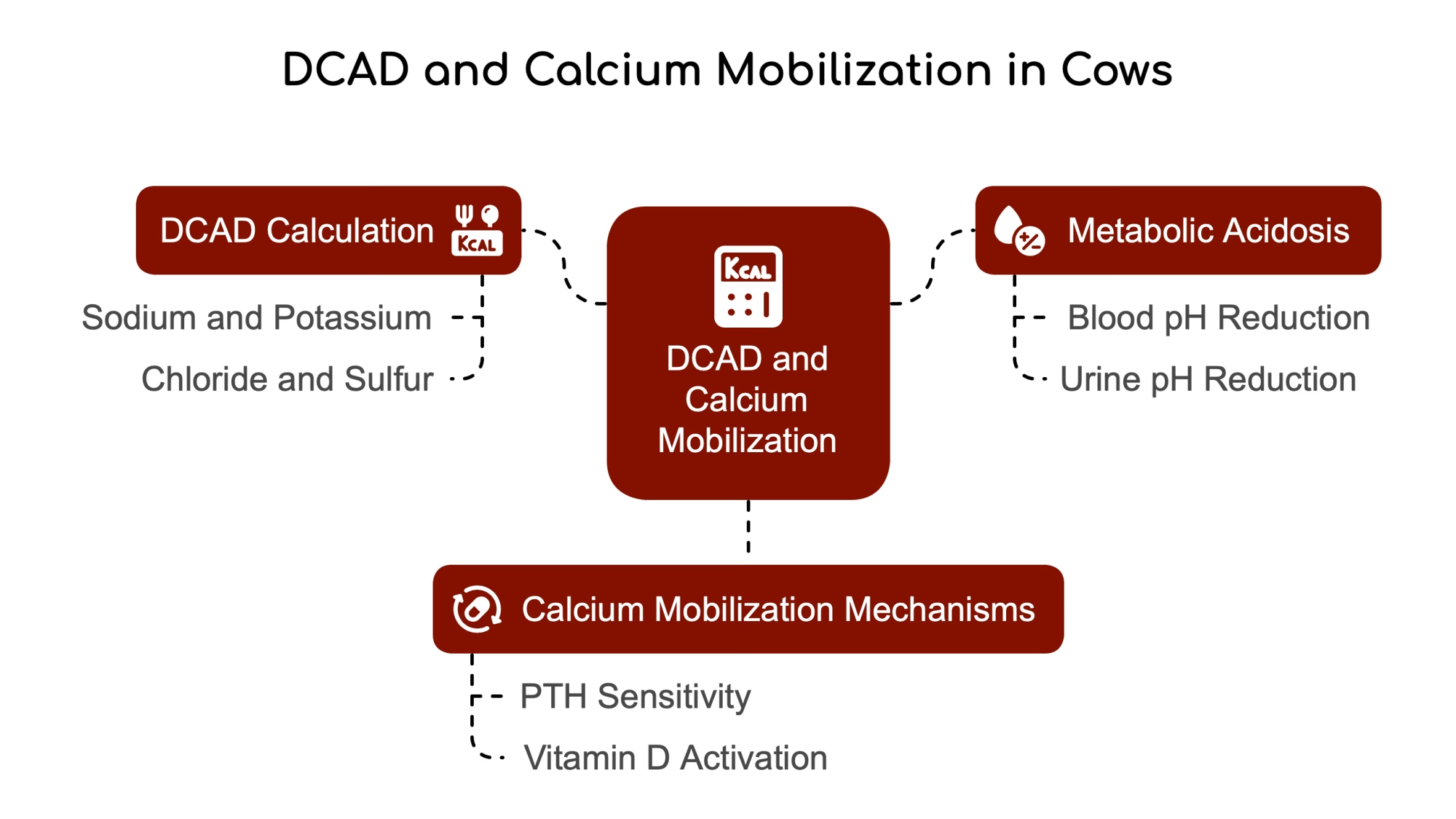

The Sulfur Antagonism Problem

Modern agriculture has inadvertently exacerbated selenium deficiency by using sulfur-containing fertilizers. Research confirms that sulfur and selenium compete for the same plant uptake mechanisms, with sulfur’s higher application rates consistently winning this biological battle.

Challenging the Conventional Wisdom: Recent Research Findings

Here’s where we need to challenge a fundamental assumption that’s costing the industry millions: A 2024 study published in the Journal of Dairy Science by Cruickshank et al. revealed surprising findings that contradicted conventional wisdom about selenium supplementation.

The study, involving multiparous Holstein cows, found that “regardless of whether selenium came from organic or inorganic sources, it did not affect the cows’ absorption of the mineral, their selenium levels, or their overall performance.” However, the researchers noted a critical distinction: “organic selenium resulted in higher selenium levels in milk, with less being excreted through urine.”

The Heat Stress Research Breakthrough

More compelling evidence comes from research published in the Journal of Dairy Science examining hydroxy-selenomethionine (HMSeBA) under heat stress conditions. The study, conducted by researchers using environmental chambers, compared inorganic selenium (sodium selenite) with HMSeBA supplementation in mid-lactation Holstein cows.

The results demonstrated that “HMSeBA supplementation decreases some parameters of HS-induced oxidative stress” and showed:

- Increased selenium concentrations in serum and milk during heat stress

- Maintained glutathione peroxidase activity while it declined in control cows

- Increased total antioxidant capacity

- Decreased oxidative stress markers (malondialdehyde, hydrogen peroxide, nitric oxide)

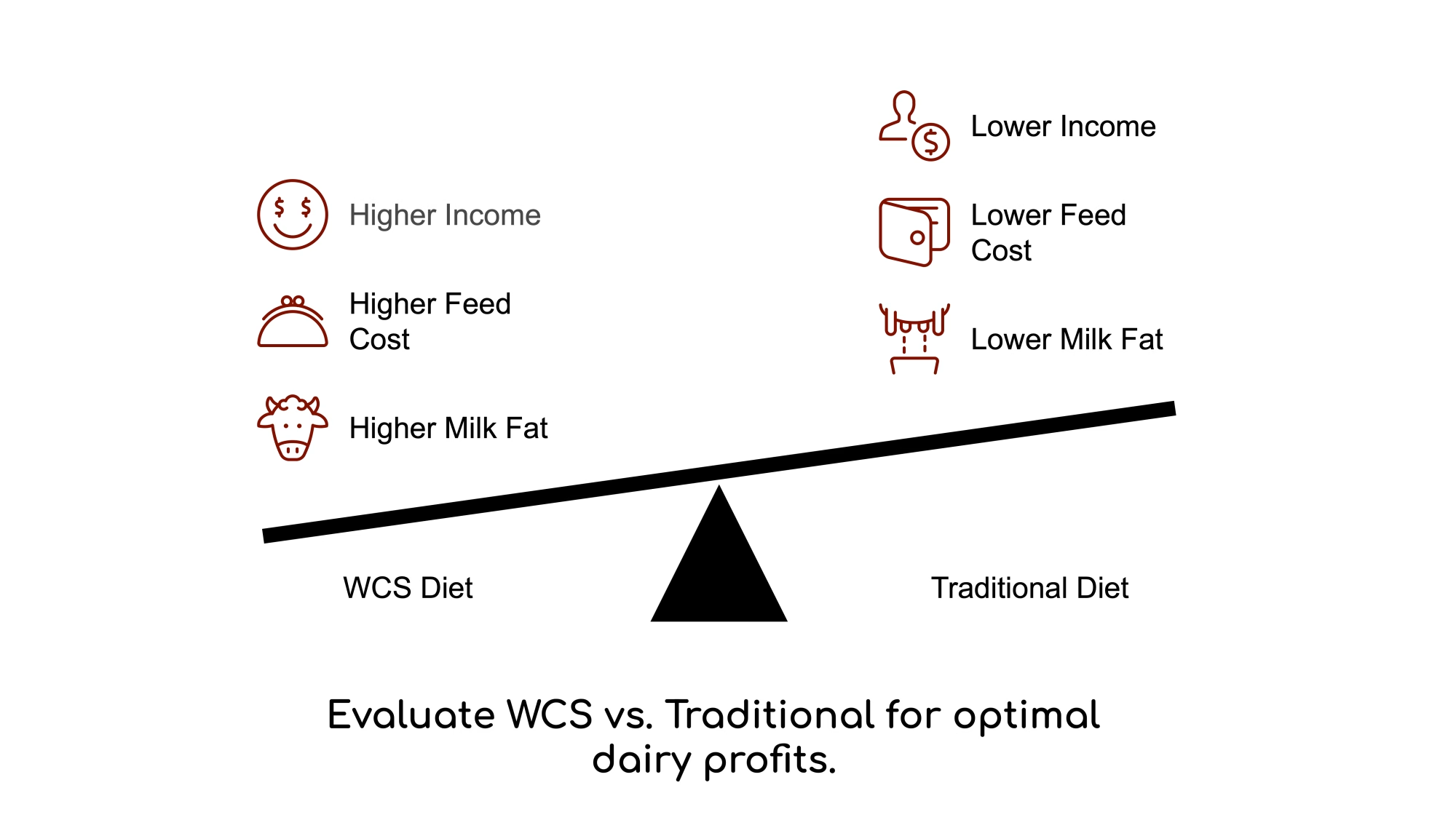

- Tendency to increase milk yield while decreasing milk fat percentage

The Three Generations: Why Technology Evolution Matters

First Generation: The Obsolete Technology Still Widely Used

Despite overwhelming scientific evidence of poor bioavailability, many operations use sodium selenite. Studies consistently show absorption rates of just 10-30% for inorganic selenium in ruminants due to reduction by rumen microbiota.

Second Generation: The Inconsistent Promise of Selenium Yeast

Advanced analytical techniques have exposed serious quality control issues that the feed industry has largely ignored. Recent research using state-of-the-art speciation analysis reveals that commercial selenium yeast products contain highly variable selenomethionine levels.

Third Generation: The Precision Solution

Recent research from 2025 published in the journal Animals examined the effects of organic selenium supplementation in late lactation dairy cows. The study found that “supplementation of organic zinc and selenium in late lactation dairy cows, in the form of chelated zinc amino acid and selenium amino acid complex, had positive effects on immunity and antioxidant activity.”

The Economic Reality: Verified ROI from Italian Research

| Metric | Control (Sodium Selenite) | Organic Selenium (Sel-Plex) | Improvement |

| Milk Yield (kg/day) | 36.5 | 37.9 | +1.4 kg (+3.8%) |

| Somatic Cell Count (cells/mL) | 320000.0 | 272000.0 | -48,000 (-15%) |

| Confirmed Pregnancy Rate (%) | 67.0 | 83.0 | +16% points |

| Retained Placenta Cases (per 100 cows) | 10.0 | 6.0 | -4 cases (-40%) |

| Days to Confirmed Pregnancy | 139.0 | 130.0 | -9 days |

| Services per Conception | 1.81 | 1.63 | -0.18 |

| Annual Cost (€ per 100 cows) | 0.0 | 810.0 | +€810 |

| Annual Benefits (€ per 100 cows) | 0.0 | 7380.0 | +€7,380 |

| Net ROI (€ per 100 cows) | 0.0 | 6570.0 | 9:1 ROI |

The Italian Holstein study provides concrete ROI analysis that challenges the assumption that premium selenium supplements are “too expensive.” The research calculated specific economic benefits:

The Italian Holstein ROI Analysis Breakdown:

- The added cost of organic selenium (Sel-Plex): €810 annually for a 100-cow herd

- Documented benefits: €7,380 annually

- Net benefit: €6,570 ($7,000+) annually

- Return on investment: 9:1

The study documented specific improvements:

- 9 fewer open days per cow annually (€2,700 total value)

- 1.3 L/day/cow increased production (€4,680 total value)

- Reduced retained placenta cases (6 versus 10 cases per 100 cows)

- Lower days to confirmed pregnancy (130 versus 139 days)

- Improved services per conception (1.63 versus 1.81)

Implementation Challenges and Solutions

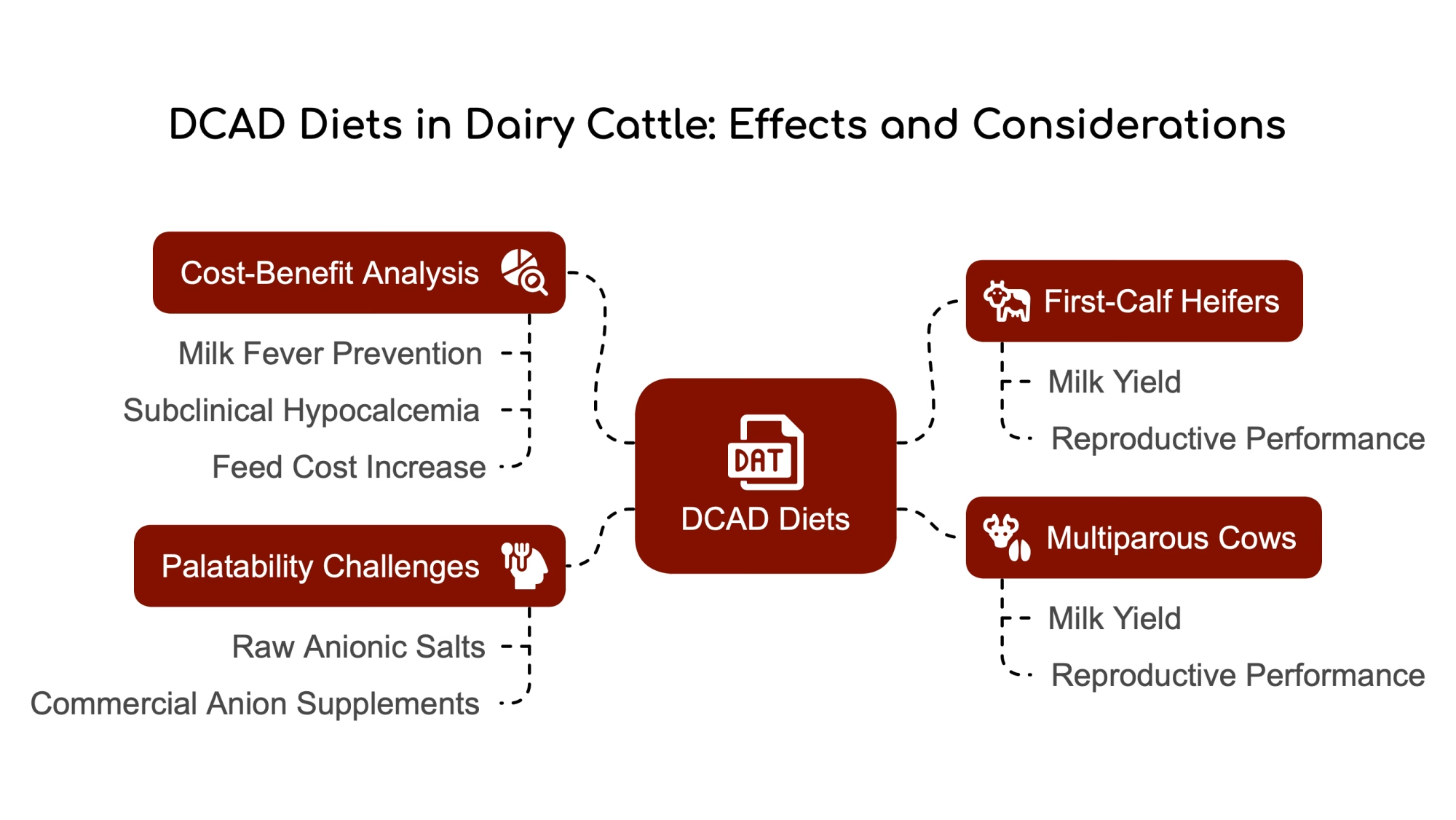

Addressing Cost Concerns

While third-generation selenium supplements cost 2-3 times more per unit than basic inorganic selenite, the bioavailability differences mean you’re getting 3-5 times more effective selenium per dollar spent. As Agovino’s research demonstrates, preventing just one case of mastitis pays for an entire herd’s annual selenium supplementation program several times over.

Quality Control Issues

The 2024 research by Cruickshank et al. highlights a critical implementation challenge: “Despite expecting differences, the study showed similar results in terms of the cows’ eating habits and milk production” between organic and inorganic sources. This suggests that product quality and consistency remain significant variables in real-world applications.

Potential Limitations

Recent research also reveals some limitations of selenium supplementation. The 2025 Animals journal study noted that “selenium supplementation induced a reduction in fat percentage” and “solids content showed a tendency to decrease.” These findings suggest that selenium optimization requires careful balance with other nutritional factors.

The One Health Opportunity: Adding Value Beyond the Farm Gate

The meta-analysis by Knowles et al. confirms that “using organic selenium could enhance the selenium content in milk, providing potential benefits for consumers or calves and reducing environmental mineral waste.” Research demonstrates that supplementing dairy cows with highly bioavailable organic selenium increases milk selenium concentration, predominantly as selenomethionine bound within milk proteins.

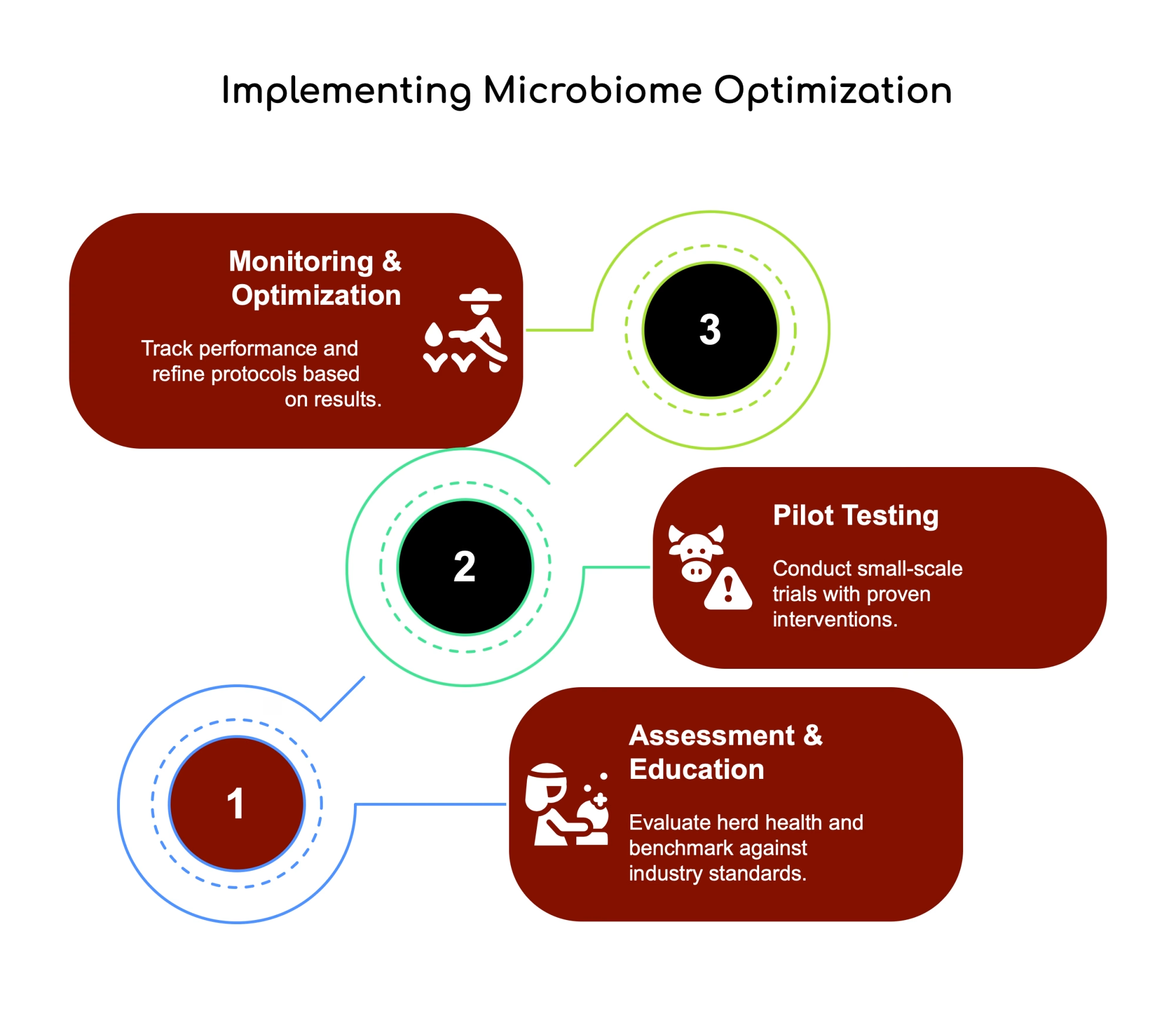

Implementation Strategy: Making the Switch Without Disruption

Phase 1: Diagnostic Assessment (Month 1) Start with comprehensive herd testing using blood selenium analysis. Target plasma levels above 80-100 µg/L, with optimal status above 100 µg/L. Cost consideration: Blood selenium testing typically runs $15-25 per sample.

Phase 2: Critical Product Evaluation (Month 1-2) Demand specific documentation from suppliers about selenium form, purity guarantees, and analytical testing results. If your supplier can’t provide selenomethionine content verification for selenium yeast products, that tells you everything you need to know about product quality.

Phase 3: Strategic Implementation (Month 2-3) Focus upgrades on critical periods: dry cow supplementation and early lactation. The Italian research demonstrates this approach provides the highest return on investment through improved health outcomes and milk production.

Phase 4: Performance Monitoring (Month 3-6) Retest selenium status 90 days post-implementation and track key performance indicators following the Italian study model:

- Somatic cell count trends (target: reduction from 320,000/mL to 272,000/mL)

- Milk yield improvements (expect: 1.4 kg/day increase)

- Reproductive performance metrics (goal: increase confirmed pregnancy rates from 67% to 83%)

The Bottom Line: Transforming Cost into Competitive Advantage

Remember that $700 per cow figure we started with? The Italian Holstein research suggests this may actually underestimate the true economic impact when you factor in the comprehensive benefits documented by Agovino and colleagues.

The Research-Backed Reality Check:

- Italian research documenting 9:1 ROI from organic selenium

- Meta-analysis of 42 studies confirming the superiority of organic sources

- Heat stress research demonstrates maintained antioxidant function

- Recent 2025 studies confirming immune and antioxidant benefits

The choice isn’t whether you can afford to upgrade your selenium program—it’s whether you can afford not to. With mastitis costs averaging $325-457 per case and retained placenta adding another $389, the Italian research proves that preventing just two cases annually pays for an entire herd’s premium selenium supplementation several times over.

Your Next Strategic Move: Contact your nutritionist this week and demand a detailed breakdown of your current selenium program’s analytical specifications. Ask specifically about selenomethionine content verification, batch consistency guarantees, and bioavailability data. If they can’t provide clear, scientifically-backed answers backed by peer-reviewed research like our cited studies, you’ve just identified why your selenium strategy might fail.

The dairy industry rewards operators who make decisions based on evidence rather than tradition. Cruickshank et al. noted in their 2024 research that “using organic selenium could enhance the selenium content in milk, providing potential benefits for consumers or calves and reducing environmental mineral waste.” Your selenium strategy represents one area where peer-reviewed research clearly points toward an upgrade that pays for itself through improved herd health, reduced treatment costs, and enhanced productivity.

The research is clear. The economics are compelling. The Italian Holstein study provides a real-world roadmap for success. The remaining question is: Will you continue paying premium prices for inconsistent results or invest in proven technology that transforms selenium from a cost center into a profit driver with documented 9:1 returns?

KEY TAKEAWAYS

- Documented 9:1 ROI on selenium optimization: Italian Holstein research shows €7,380 in benefits against just €810 in costs per 100 cows annually, with specific improvements in milk yield (1.4 kg/day increase), reproductive efficiency (6 vs. 10 retained placenta cases per 100 cows), and udder health (SCC reduction from 320,000/mL to 272,000/mL).

- Traditional selenium sources are failing your herd: Inorganic selenium (sodium selenite) shows just 10-30% bioavailability in ruminants, while “organic” selenium yeast products contain highly variable active content—analysis reveals some products with as little as 18% selenomethionine and up to 51.8% unavailable elemental selenium.

- Implementation requires just a 4-phase approach: Start with strategic blood testing ($15-25 per sample) targeting 80-100 μg/L plasma levels, demand SeMet content verification from suppliers, focus supplementation during transition periods, and monitor improvements within 90 days.

- Heat stress resilience improves with optimized selenium: Research on hydroxy-selenomethionine supplementation shows maintained antioxidant function during thermal stress when conventional approaches fail—critical as climate models predict increasing heat stress challenges for dairy operations across North America in 2025.

- Beyond cow health—marketing opportunity: Selenium-optimized milk contains significantly higher selenium content in a highly bioavailable form (90% human bioavailability), creating potential premium market opportunities as consumer health awareness grows in 2025’s competitive dairy marketplace.

EXECUTIVE SUMMARY

The selenium supplementation strategy your nutritionist recommended is likely costing you hundreds of dollars per cow while delivering minimal protection. Research reveals that conventional selenium sources suffer from devastating flaws: inorganic forms are 70-90% destroyed in the rumen, while “premium” selenium yeast products contain highly variable levels of active selenomethionine—ranging from just 18% to 71.8% with an average of only 55.8%. Italian research demonstrates a remarkable 9:1 return on investment when upgrading to third-generation selenium sources, with documented benefits including 1.4 kg/day increased milk production, SCC reduction from 320,000/mL to 272,000/mL, and 9 fewer open days per cow annually. In today’s challenging dairy economy, with USDA forecasting cautious milk prices around $20.90/cwt for 2025, this hidden profit leak represents one of your highest ROI opportunities for immediate implementation. It’s time to demand verification of exactly what you’re getting in your mineral program and upgrade from minimum requirement thinking to strategic optimization.

Complete references and supporting documentation are available upon request by contacting the editorial team at editor@thebullvine.com.

Learn More:

- Retained Placentas Costing You $389 Per Case? Your Nutrition Program is Bleeding Money – Reveals practical transition cow nutrition strategies that complement selenium optimization, demonstrating how targeted vitamin E and selenium protocols during the critical 21-day transition period can eliminate retained placenta cases entirely.

- Dairy’s Bold New Frontier: How Forward-Thinking Producers Are Redefining the Industry – Explores how progressive dairy operations integrate advanced nutrition strategies with technology adoption and revenue diversification, providing strategic context for positioning selenium optimization within broader farm modernization efforts.

- Proven Strategies to Boost Milk Production and Maintain Udder Health – Demonstrates how selenium-dependent glutathione peroxidase activity directly correlates with lower somatic cell counts, offering practical implementation methods for monitoring and maintaining optimal udder health through targeted nutritional interventions.

Join the Revolution!

Join the Revolution!

Join over 30,000 successful dairy professionals who rely on Bullvine Weekly for their competitive edge. Delivered directly to your inbox each week, our exclusive industry insights help you make smarter decisions while saving precious hours every week. Never miss critical updates on milk production trends, breakthrough technologies, and profit-boosting strategies that top producers are already implementing. Subscribe now to transform your dairy operation’s efficiency and profitability—your future success is just one click away.

Join the Revolution!

Join the Revolution!