Progressive business owners know that if a business is not planning and moving forward then it will soon be average or behind.

Dairy farmers experience that reality in multiple areas – facilities, genetics, inputs, technology, labor efficiency, …. to name a few. The challenge to remain competitive is a matter that every manager must continually have on their mind.

Suntor Openly Shares

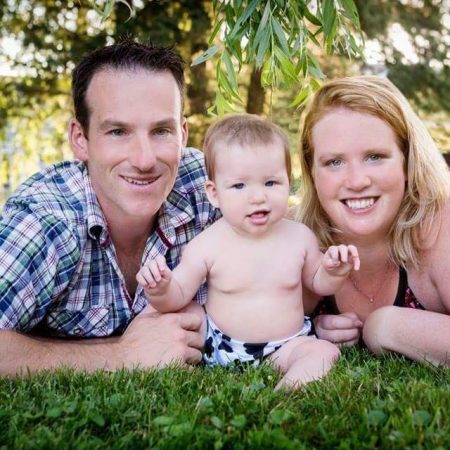

Suntor Holsteins, located in South-West Quebec, recently shared with The Bullvine some of the very positive results that they have experienced by their move to new animal housing and the use of milking robots for their high production and elite genetics Holstein herd. After reading details that Kevin and Amanda Sundborg posted on Facebook, The Bullvine decided to interview this progressive couple and share their story with our readers. The fact is that they shared so many details, we decided to make it into two articles. This one will consider facilities and another one, to follow, will highlight their thoughts and plans for their breeding program.

Suntor Background

Kevin and Amanda are very thankful for the encouragement their parents gave them to seek higher education and in thinking progressively when it comes to dairy farming.

Until January 30th, 2017 the Suntor herd had been housed in a fifty-one tie stall barn. Cow care was always important and many awards for high production had been received. But the work was labor intensive and required long hours.

A New Generation at Suntor

2015 was a big year for Kevin and Amanda. In mid-year Suntor Holsteins was transferred from Kevin’s parents to Kevin and Amanda immediately joined in. To top off this very busy year they welcomed their daughter Saydie in December. Saydie will welcome a sibling in April. At the time of purchase the herd consisted of 51 cows in milk, 10 dry cows and 60 heifers with the cows producing, on 2X, 40 kgs (88 lbs) 4.3%F and 3.4%P.

Kevin and Amanda have a love for dairy farming. Both are farm management and technology graduates from Macdonald-McGill, and have worked and/or traveled off the farm. Once the farm and cattle were theirs, they immediately set about to take Suntor to new heights.

Big Picture Goals

Kevin and Amanda shared with The Bullvine the following thoughts that formed the basis on which they built their plans:

- Lifestyle: Family is important and spending the time from 4:30 am to 8 pm in the barn, every day, is detrimental to family, friends and community time.

- Managing staff: They prefer to work directly with their animals and not have to manage staff.

- Get out of tie stalls: They found housing in tie stalls to be labor intensive and wearing on the body.

- Use new technology: They want to know, hourly to annually, the facts about their cows and operation, so having new technology to do more of the work and capture the data was a must have. Their ten-year plan was to have double the daily milk shipments without any extra labor.

- Happy and Comfortable Workers (aka cows) are a Must Have: Amanda in her off-farm worked (nutritionist and robot specialist) had seen the great results that other dairy farmers were achieving from cows that were comfortable in their environment, able to be milked on demand and that were fed high quality forage diets.

- Efficiency – a key to a successful operation: Although gross output has advanced the bottom line for dairy farms over the past half century, Kevin and Amanda foresee the need for a successful dairy farm in the future to be driven by efficiency and net returns. Cutting out or reducing daily cow expense is, they feel, an incorrect and risky decision. Their plan is produce more milk with the same expenses.

Planning, Planning, Planning

Over a five-month period, Amanda and Kevin investigated every viable alternative available for dairy facilities in Canada. They talked with mentors, engineers and consultants and visited numerous farms that had recently built new with and without robots. Much was learned from asking critical questions.

Kevin and Amanda planned based on – ”How do you want to be milking cows for the next twenty years?”.

At the end of the five months they had a detailed plan complete with a budget that put milk income at 90% of current Canadian industry level, milk production level on par with their tie stall level, costs at 5% over historic operational costs and capital costs based on 4% interest. Upon presentation of their building, operation and financial plans to their financial institution, Kevin and Amanda were told that their plans were excellent and they were approved. They had thought, for sure, that they would be told that they needed to adjust their dreams, for an ultra-modern farm, downwards. What a relief that was!

Some of the building and start up decisions Kevin and Amanda made include:

- They hired a top-notch engineer who costed out every detail for the new operation. They then identified areas for cost saving. Side note here from Amanda – “Always, always be prepared for meetings or suggested changes. Being prepared worked great for us.”

- They built large enough with a twenty-year horizon on their projected herd size and production level.

- They made the jobs of fetching and separating cows easy and quick. “Routes to the robot need to be direct. Have it so one person, operating alone, can handle the animals”.

- A fresh and special care pen, with access to a robot, needs to be fully equipped with support materials. Most definitely include a fresh and special care pen and foot baths in the building plan.

- Provide extra open space around robot entry and exit points. Expect cows to be both bossy and timid. Avoid sharp turns.

- At start up, they planned on a maximum of 1,800 – 2,000 kgs (4,000 – 4,400 lbs) of milk per robot per day. Based on their experience they strongly recommend not to over-fill the robot(s) at start up.

- In her experience with start-ups in other herds, Amanda recommends a maximum of 50 cows per robot at start-up.

- After cows leave the fresh pen and go into general group, Kevin takes the time to make sure those animals know where the second robot is. They have found that some cows only go to one robot, while other cows will use both robots.

Kevin and Amanda told us that they committed 100% to the process of moving from the old tie stall to the new robotic barn. “Only going half way will only get you half way there.”

Pre-Move In Steps are Important

- Hoof Care: “Trim hooves at least two months before and not any closer to the move in date. Cows need a good hoof build up when being moved onto freshly grooved cement floors.”

- Minimize Fetch Cows: “Dry off any cows who would be a waste of time to train. Those end of lactation cows giving under 20 kgs/ 44 lbs will have no need / want to go to the robot. They will end up being a fetch cow until dry off. Don’t bother making them part of start up.”

- Have DIM 150 days or lower: “Try to plan to have Days In Milk around 150 days for start-up. A stale herd takes longer to transition and your fresher cows will suffer.”

- Dry Cow Program: “Our dry cow program was one key to our success. We feed a simple dry cow TMR which consists of corn silage and a low potassium dry hay. In the pre-fresh pen, we have an automated grain feeder (Cosmix) that feeds a pre-fresh pellet. It allows us to monitor and feed the exact amount they need. It also works to train our heifers prior to their first calving. They get accustomed to going into a box to get grain and the sound is like the sound of grain falling in the robot. We find that the heifers are calm in the robot for their first milking.”

- Ration before Start-Up: “Suntor fed the robot feed to the cows as a top dress for two weeks before start-up. Cows need to know the feed when they go into the robot for the first time. Do not be afraid to drop the TMR energy at start-up. The less energy you have in the ration the faster they will go to the robot. We wanted our cows hungry, so they would go to the robot. They did drop on average 10 kg of milk per day the first week, but by 10 days 70% of the herd was going to the robot on their own. By one month, the average milk was back up to where it was when they were in the tie stalls.”

More Pertinent Details

Daily Cow Management: Amanda uses the reports generated from the T4C software, especially the health report, the expected heat report and the fetch cow report, to manage the herd on a daily basis. She noted that keen producers can also design their own reports.

Feeding Program: In the tie stall barn, cows were fed a one group TMR of 50:50 corn silage and haylage balance for 42 kgs of milk. Fresh and high producing cows were top dressed protein, fat and beet pulp. However now, based on Amanda’s five years of experience as a nutritionist and seeing how feed changes can significantly affect production, a one group TMR is still fed but it is now 75% corn silage and 25% haylage – balanced for 150 days in milk and for 6-7 kgs below herd average production. Feeding more corn silage allows for a more stable ration, given that haylage can vary greatly depending on stage, field and cut.

Six Month Results: First calf heifers have responded very well with 200 – 1,500 kgs more milk in the new system. Three (20%) of Suntor’s first lactation cows have peaked at 50 kgs and have continued to give over 40 kgs past 240 DIM. And six months in the herd was averaging 42 kgs milk, the same as when they left the tie stalls. However, given that some older cows were dried off before the move and many were just calving by six months in, the Sundborg’s are very happy with the herd average from the younger milking herd. Cows are currently being milked 3.1 times per day on average. Reproduction is excellent with a 55-60% conception rate and 9 of 10 cows pregnant at herd heath check day.

Worthy of note is that Kevin and Amanda moved the entire tie stall herd into their new facility. All cows transitioned well or extremely well. They plan to increase their herd size by growing from within.

One Year Expectations: By one year in, January 30th, 2018, Kevin and Amanda can see easily reaching 45 kgs milk per day and average days in milk will be very good at under 140-150 days. By next spring they will be milking 70 cows with no added labor required, two things that were not possible in their old tie stall barn.

Some Added Benefits: Kevin told us about some added benefits. “The expansion happened at the right time as they have been allocated or purchased 35% more quota since purchasing the farm. The robot reports help them catch any problems sooner, which helps to avoid sick cows. Having two robots, that were not used to capacity, shortens any line ups. We wondered about retaining and moving an older deeper uddered brood cow but she took to the new system like a duck to water. Using a higher percent corn silage assists by reducing the summer rush of harvesting of haylage.”

Future Operation Plans: The original plan was, in ten years, to milk 80 cows producing 140 kgs of fat per day. With more quota becoming available for purchase and the barn and robot working so well it now appears that that goal will be achieved in half the time. The higher revenue will speed up the process of implementing systems to monitor and manage calves, heifers and dry cows.

The Bullvine Bottom Line

Planning to be successful is Step #1. Carrying out the plans is Step #2. The Bullvine congratulates Kevin and Amanda Sundborg and thanks them for sharing their dreams, thoughts and information on both these steps. What cow would not want to live and be cared for at Suntor Holsteins?

Get original “Bullvine” content sent straight to your email inbox for free.