Think robots run the dairy game? Think again. The real power’s in your data and feed.

EXECUTIVE SUMMARY: Hey, here’s the scoop from down the road. Dairy farming isn’t what it used to be — and that’s actually good news for your wallet. The real money now comes from software that weaves together genomic info, feed data, and health insights — not just fancy robots. Farms trimming feed waste by just 10% are saving about $200 per cow annually and adding more than 300 lbs of milk per cow. We’re talking about a market that has already surpassed $7 billion globally and is growing rapidly. Smart farms are using AI to identify mastitis days in advance and link genetic testing with actual production records. If you want to stay ahead of the pack instead of playing catch-up, start blending genomics with smarter feeding programs today — your bank account will thank you.

KEY TAKEAWAYS:

- Cut feed waste by 10% — track your forage quality weekly and tweak rations accordingly. Small steps, but we’re talking real cash savings that add up fast.

- Don’t wait on genomic testing — get it done early and link it with your milk records to unlock your herd’s true potential. Call your vet or advisor this week.

- Leverage AI-powered health monitoring to catch issues like mastitis 2-3 days earlier, cutting treatment costs by hundreds per case and preventing lost milk.

- Choose software that integrates with everything — your robots, feeders, and health monitors — so you see the complete picture instead of juggling multiple systems.

- Roll out tech in stages with clear ROI tracking — invest in proper training and gradual implementation. That’s the playbook winners are using right now.

Walk through any major dairy expo and you’ll be bombarded by shiny new gadgets — robots humming, sensors monitoring, and apps promising insight. But here’s the truth the savvy farmers already know: the real payoff isn’t in the machinery itself. It’s in how you tame the deluge of data those tools generate.

The precision livestock farming market is experiencing significant growth, with a recent valuation of approximately $5.6 billion in 2025, and projections indicating a rise to nearly $7.9 billion by 2029. Growth rates remain impressively in the double digits, signaling clear momentum. Yet, hardware still accounts for the majority of upfront spending, while the true engine of profit lies in software’s ability to extract meaning from raw data.

Let’s pull up a chair in the barn and explore three software strategies that are shaping dairy profitability worldwide — and how each fits different farm ambitions.

The Digital Frontier: Why Software Strategy Defines Success

Across the dairy industry, data-savvy farms are outperforming their peers by 15–25%, with the overall market projected to climb toward $9.7 billion by 2032.

Three strategic archetypes dominate:

- Universal Integrators: Platforms connecting diverse systems into seamless workflows

- Specialized Analysts: Tools digging deep into critical cost centers, especially feed

- Hardware-Enabled AI Ecosystems: Proprietary sensor networks powering predictive intervention

Choosing the right path hinges on your farm’s size, resources, and current technological maturity.

Strategy 1: Universal Integration Platforms — Orchestrating the Digital Symphony

Imagine your barn tech as a complex orchestra, each instrument playing a different tune. Universal integration platforms like UNIFORM Agri, with over 17,000 farms on board, act as the conductor, bringing harmony to the different data streams without forcing you to swap out your favorite instruments.

Consider this: your morning routine could begin with a single dashboard that summarizes all critical alerts — including health flags, reproduction status, and milk yield trends. Picture a manager starting their day at the milk parlor, scanning through UNIFORM’s consolidated morning report to quickly identify which specific cows need attention today. Instead of juggling multiple systems and clipboards, everything is streamlined through a single interface.

This isn’t just about seeing data. These platforms empower farms to embed custom protocols — such as drying off schedules, hoof health checks, or early lactation monitoring routines — ensuring that consistent, repeatable management actions are triggered and tracked digitally. No more relying on memory or hoping the weekend crew remembers the special protocols.

What sets UNIFORM apart is their philosophy of practical service built by experienced ag personnel who speak the farmer’s language and understand daily rhythms, making technology approachable rather than intimidating. As their leadership puts it, it’s easier to teach computer systems to agriculture people than to teach IT specialists the nuances of animal husbandry.

Strategic partnerships also enhance the platform’s capabilities; for instance, integrating with Zoetis enables farms to combine genetic potential data with real-world performance tracking, thereby accelerating breeding progress informed by comprehensive data.

Strategy 2: Specialized Analytics — Illuminating the Feed-to-Milk Nexus

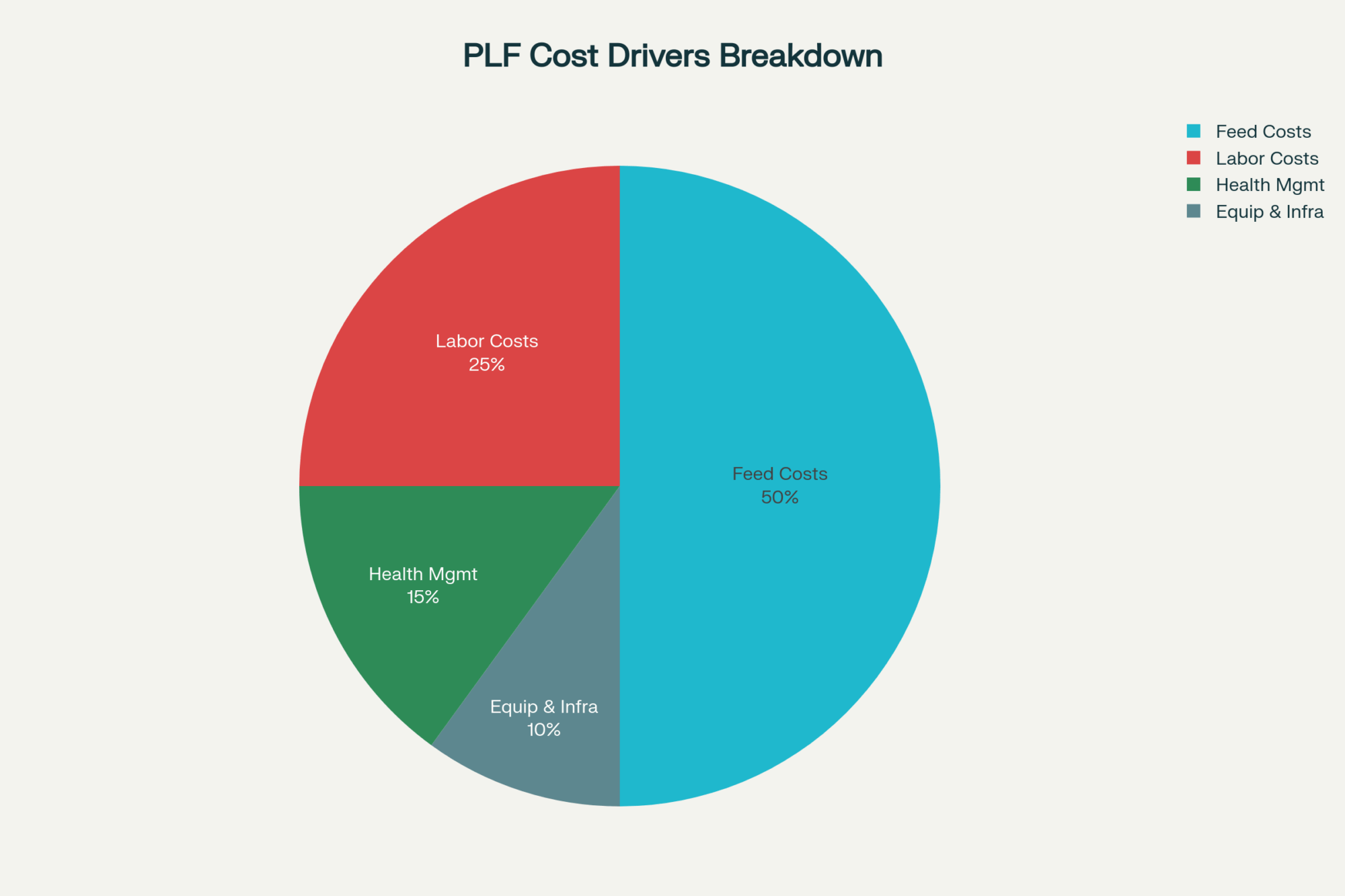

Feed dominates your cost sheet, accounting for 50–70% of expenses, and peeling back the layers to find inefficiencies is a challenge that generic platforms often overlook.

Enter MyDairyS, which boasts a fascinating origin story that lends credibility to its brand. Born from a nutrition company’s internal quest to understand better the direct connections between feed adjustments and herd performance, what started as an internal tool evolved into a sophisticated platform that makes complex feed-to-milk relationships crystal clear.

The platform excels as a collaborative tool across your advisory team. Feed consultants use it to graphically demonstrate the impact of their ration recommendations, while veterinarians can analyze health trends and metabolic patterns without needing deep nutrition expertise themselves. It bridges the gap between different specialists working with your herd.

By linking ration changes, forage quality analyses, and milk component data in intuitive visualizations, it transforms complexity into actionable insight. A farm that optimizes feed efficiency by just 7–10% reclaims significant margins — tens of thousands of dollars on larger operations — a crucial leverage in today’s volatile input markets.

Strategy 3: Hardware-Enhanced AI — The Sensor Inside the Cow

The cutting edge? Hardware and AI fused intimately.

smaXtec‘s small ingestible sensor nests in the cow’s reticulum, delivering real-time data on body temperature, rumination, water intake, and optional rumen pH for up to five years with precision few external devices can match.

Behind the scenes, their AI engine — TruAdvice™ — represents a continuously learning system that gets smarter over time. Rather than static programming, it constantly refines its disease detection algorithms by analyzing millions of new data points and incorporating feedback from veterinarians and scientists across their network. This means that the system you install today will become more accurate and valuable over time.

But smaXtec’s philosophy goes beyond impressive technology. They position themselves as a genuine partner in the barn, not just another complex gadget. Their approach focuses on delivering concrete, actionable recommendations that benefit farm staff of all experience levels — from seasoned managers to newer team members who might not have years of animal health expertise. This addresses the real-world challenge of empowering your entire crew to make better decisions.

The real-world impact, verified by an independent IFCN study, is a financial uplift of $210 in returns plus $190 more in income per cow annually, including a 330 kg increase in solids-corrected milk. A 2,100-cow operation reported a remarkable 7.8x ROI — over $500,000 saved primarily by reducing costly health incidents and improving reproductive efficiency.

Early mastitis detection alone justifies the investment, as clinical cases average $300 in direct costs, plus $180 in lost milk, while sensor systems typically cost $45-$ 65 per cow annually, with payback periods averaging just 2.1 years.

Bridging the Tech Divide — Overcoming Integration Challenges

More than half of dairy farmers cite incompatible technology as their primary barrier to adoption. Legacy farm networks, proprietary hardware locks, and diverse software landscapes create data silos and information overload that frustrate even tech-savvy operators.

I’ve walked through operations where managers juggle four different tablets for different systems, manually transferring data between platforms. That’s not efficiency — that’s digital chaos that undermines the value proposition of technology investment.

Emerging interoperability standards, such as ICAR ADE and open APIs, are crucial for sustainably integrating diverse systems. Hands-on support and intuitive interfaces remain paramount to drive adoption beyond early enthusiasts to mainstream farm operations.

Planning for Success — Avoiding Common Pitfalls

Implementation data reveals that unrealistically high ROI expectations account for 58% of technology failures, while inadequate training contributes to 47% of failures, with infrastructure gaps causing another 34%. The technology itself rarely fails; implementation and change management are the issues.

Successful farms follow structured rollouts with measurable milestones and dedicated user training. They start with pilot programs on portions of their operation before full deployment, maintaining realistic expectations while tracking meaningful metrics that demonstrate value.

Scaling Technology — The Role of Herd Size

Your optimal strategy depends heavily on operational scale:

- Small herds (1000 cows): Combined approaches maximize returns across multiple operational areas

- Medium herds (300-1,000 cows): Leverage integrated platforms for best ROI

- Large herds (>1,000 cows): Combine all three approaches strategically

Geographic and climate factors, such as feed price volatility, labor availability, and regional market premiums, should inform the timing and investment priorities for technology deployment.

A Glimpse Ahead — AI Evolution & Industry Consolidation

The future promises integrated animal records combining genetic data, nutritional inputs, real-time health biometrics, welfare indicators, and lifetime production history — the holy grail for precision livestock management.

Artificial intelligence will advance from current diagnostic capabilities to prescriptive decision-making and eventually automated farm operations. We’re moving from systems that tell you what happened to systems that recommend what to do next.

Industry consolidation continues to accelerate as technology leaders acquire specialized platforms to build comprehensive solutions. The acquisition of UNIFORM-Agri by DeLaval exemplifies this trend toward integrated equipment and software offerings.

Your Strategic Action Plan

The digital divide in dairy is real and growing. Data-driven operations consistently outperform traditional approaches by significant margins, and this gap is expected to widen.

Start with an honest assessment of your most expensive operational challenge. Is it feed efficiency, health management, reproductive performance, or labor productivity? Focus there with proven solutions rather than trying to solve everything simultaneously.

Match your strategy to your operational philosophy and scale, then implement systematically with realistic timelines and comprehensive training. The successful farms aren’t rushing — they’re being methodical about change management while maintaining a focus on measurable outcomes.

The Bottom Line

In this rapidly evolving digital age, the gap between technology leaders and laggards continues to widen daily. The precision livestock farming market continues expanding at double-digit rates, with software representing the fastest-growing segment.

The three software strategies — universal integration, specialized analytics, and hardware-enabled AI ecosystems — each offer proven pathways to improved profitability and operational efficiency. Success depends on matching your strategy to operational reality and implementing systematically with realistic expectations.

The digital barn isn’t coming — it’s already here. The only question is whether you’re driving the transformation or getting swept along by it.

Complete references and supporting documentation are available upon request by contacting the editorial team at editor@thebullvine.com.

Learn More:

- Key Financial Considerations Before Investing in Dairy Farm Technology – This article provides a practical financial framework for evaluating technology. It details how to calculate realistic ROI, manage cash flow during implementation, and secure financing, turning your investment strategy from a guess into a calculated business decision.

- The New Currency of Dairy: How Sustainability and Transparency are Reshaping the Market – Go beyond on-farm efficiency to understand how technology addresses consumer demands. This piece reveals how data and traceability are becoming essential for market access and premium pricing, connecting your tech investments to long-term strategic positioning.

- Beyond the Bull: How Genomic Testing is Unlocking a New Era of Dairy Profits – Explore the untapped potential of your herd’s DNA. This deep-dive demonstrates how to leverage genomic data to make more profitable breeding decisions, accelerate genetic progress, and identify elite animals, directly connecting genetic investment to your bottom line.

Join the Revolution!

Join the Revolution!

Join over 30,000 successful dairy professionals who rely on Bullvine Weekly for their competitive edge. Delivered directly to your inbox each week, our exclusive industry insights help you make smarter decisions while saving precious hours every week. Never miss critical updates on milk production trends, breakthrough technologies, and profit-boosting strategies that top producers are already implementing. Subscribe now to transform your dairy operation’s efficiency and profitability—your future success is just one click away.

Join the Revolution!

Join the Revolution!