Is your silage field silently leaking carbon? Discover how soil management could make-or break-your dairy’s climate goals and bottom line.

As the US dairy industry charges ahead with ambitious plans to achieve net-zero greenhouse gas (GHG) emissions by 2050, a critical piece of the sustainability puzzle remains hidden in plain sight, right beneath your feet. While we’re busy counting methane emissions from cow burps and monitoring electricity usage in milking parlors, the carbon cycling through your farm’s soils represents one of the industry’s biggest climate challenges and potentially its greatest opportunity.

Over the past five decades, dairy farmers have made remarkable progress, reducing the GHG intensity per unit of milk by 42%. Production efficiencies have soared, with average milk output per cow climbing from about 9,700 pounds in the 1970s to over 23,000 pounds today. But let’s be brutally honest: are these efficiency gains really as impressive as they seem if they’re coming at the expense of our soil’s carbon bank account?

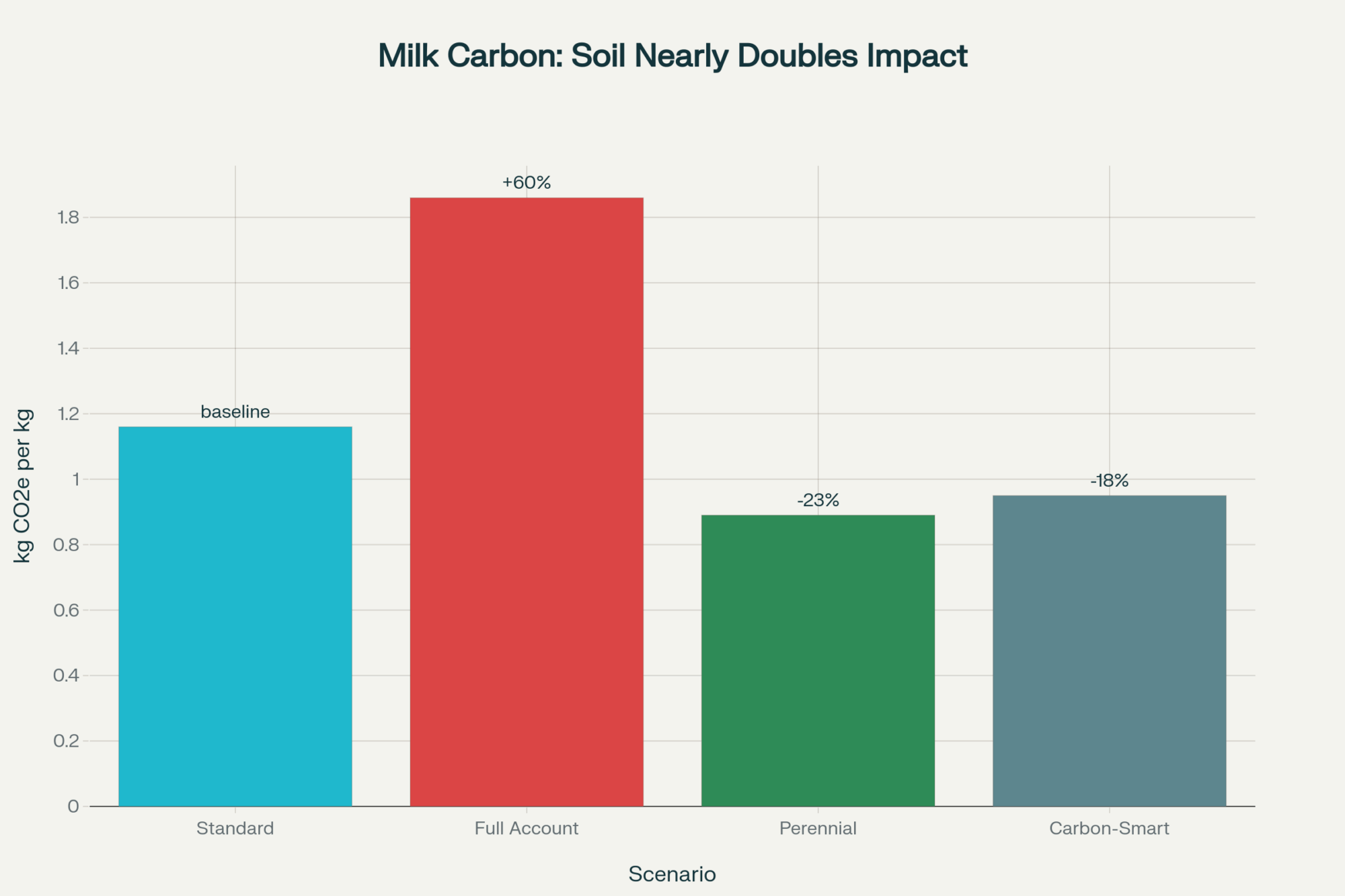

“The carbon balance on your farm is like your herd’s reproductive efficiency; you can’t manage what you don’t measure,” says Dr. Matthew Ruark, Professor of Soil Science at the University of Wisconsin-Madison. “When we include soil carbon losses in our calculations, the carbon footprint of milk can increase nearly twofold. This represents a significant challenge to meeting net-zero goals but also points to an incredible opportunity if we can reverse these losses through improved management.”

This article explores how your forage management choices directly impact soil carbon, what this means for dairy’s climate goals, and most importantly, what practical pathways exist for transforming this challenge into an opportunity for both environmental and economic sustainability on your operation.

The Surprising Carbon Cost of Modern Dairy Forage Systems

Why Your Silage Fields Might Be Carbon Leakers

Modern dairy farms have gravitated toward corn silage as a cornerstone of their feeding programs, and for good reasons. Corn silage delivers high yields, excellent energy content, and is relatively easy to harvest and preserve. For decades, these agronomic and nutritional advantages made it the undisputed king of forage, driving dairy efficiency in an era before the full carbon cost to our soils was widely understood or accounted for. But at what cost to our soils.

WHAT THIS MEANS FOR YOUR BOTTOM LINE: Think about soil carbon depletion as a hidden withdrawal from your farm’s long-term asset account. Each year of intensive silage production without carbon replacement is like skipping maintenance on your milking equipment; the bill will eventually come due.

Here’s the catch rarely discussed at nutrition conferences or industry meetings. When harvested for silage, most of the corn plant’s above-ground biomass is removed, leaving minimal crop residue to return to the soil. This creates a fundamental imbalance in the carbon cycle, with far more carbon being extracted than returned, like continuously drawing down your herd’s genetics without reinvesting in superior breeding stock.

“Think of soil carbon like your farm’s bank account,” explains dairy nutritionist Dr. Mary Beth Hall. “When you remove more carbon through harvest than you deposit through residues and roots, you’re making withdrawals from an account with a limited balance. Eventually, the soil carbon account becomes depleted.”

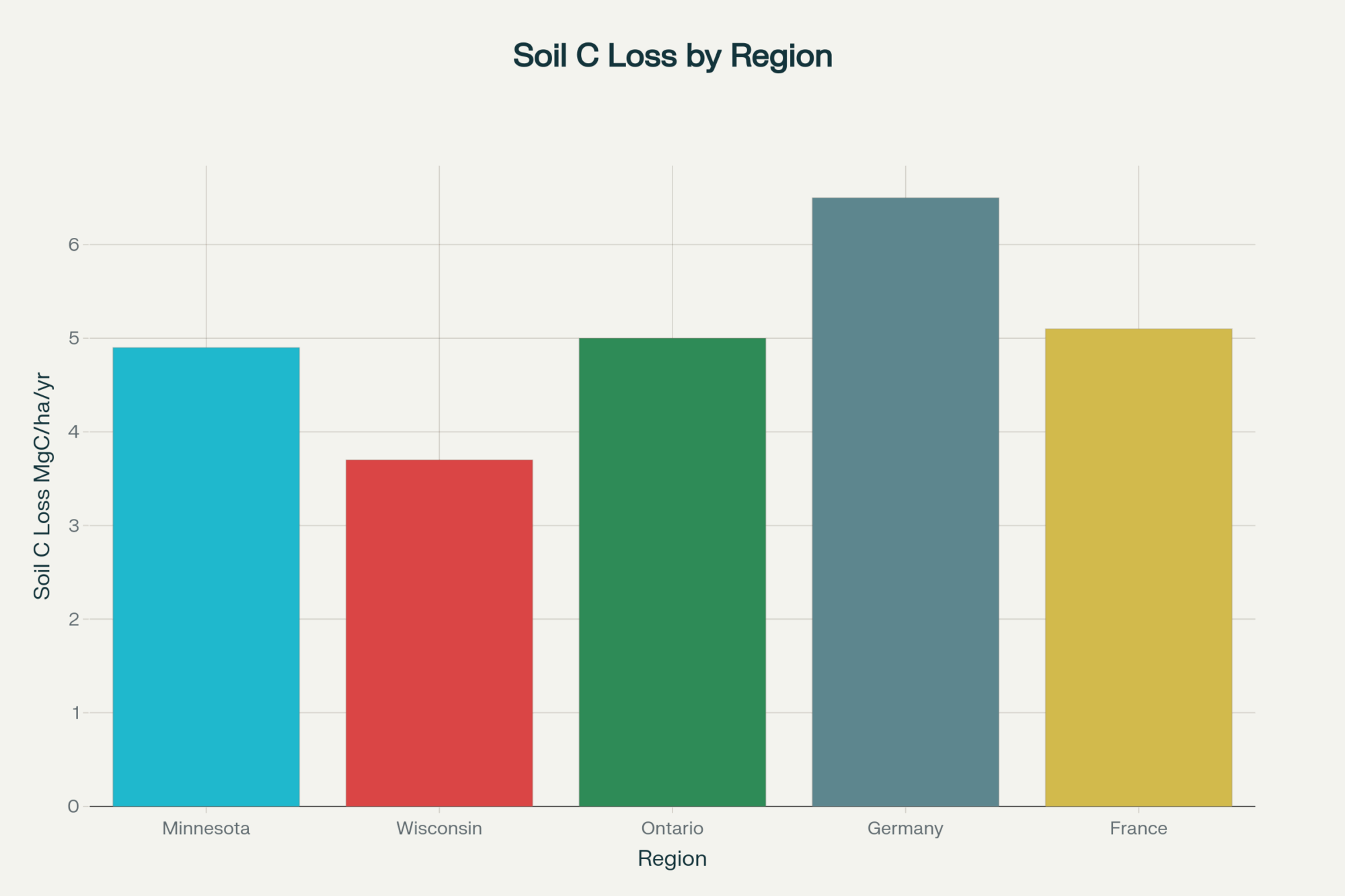

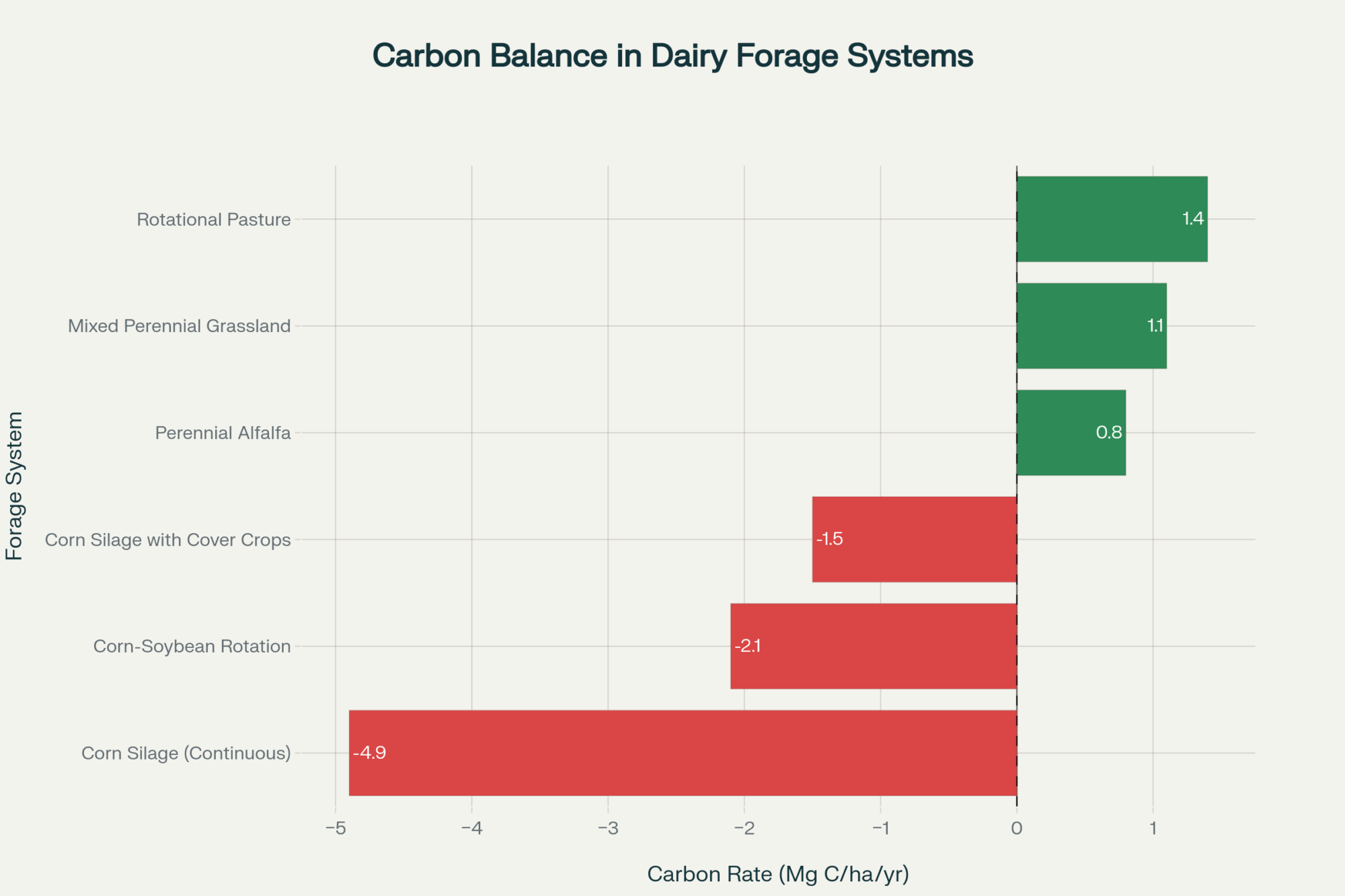

Studies using direct measurement techniques have documented substantial carbon losses across North America and Europe under corn silage systems, ranging from 13.5 to 25.6 Mg CO₂ per hectare annually. In Minnesota, researchers monitored an 8-year crop rotation of 5 years of silage corn and 3 years of alfalfa, finding net carbon losses of 13.9 Mg CO₂ per hectare annually, with most losses (17.9 Mg CO₂ per hectare) occurring during corn years.

What’s even more troubling? You’ll likely never see these losses on your farm’s climate impact statement.

The Accounting Gap That Changes Everything

Here’s what should concern every dairy farmer committed to sustainability: these substantial soil carbon losses typically aren’t included in the carbon footprint of milk.

When researchers at the University of Wisconsin included soil carbon losses in their accounting for a representative 5,000-cow dairy operation in the Midwest, they found the GHG footprint of milk increased by 60% to 93%, rising from the standard 0.75-1.16 kg CO₂e per kg of fat-and-protein-corrected milk (FPCM) to 1.45-1.86 kg CO₂e per kg FPCM.

“This isn’t just an academic exercise in carbon accounting,” explains Dr. Randy Jackson, grassland ecologist at the University of Wisconsin-Madison. “These carbon losses represent the mining of a finite resource, soil organic matter that took centuries to accumulate. When we lose soil carbon, we lose long-term productivity and resilience, just like pushing your cows too hard can compromise future lactation performance.”

In other words, the carbon efficiency gains in milk production that the industry celebrates may have come partly at the expense of soil carbon stocks. Instead of soils serving as carbon sinks to offset emissions, many dairy forage systems create a carbon liability that increases the challenge of reaching net-zero emissions.

Rethinking Forage Systems for Climate-Smart Dairy

The Power of Perennials

One of the most effective strategies for reversing soil carbon losses is increasing the role of perennial forages in your rotation. Are we overlooking our most powerful climate tool by relegating perennials to marginal land while devoting our best acres to corn silage?

Perennial systems offer fundamental advantages for carbon sequestration:

- Continuous living cover protects soil from erosion and temperature extremes

- Extensive root systems deliver carbon deep into the soil profile

- Minimal soil disturbance preserves soil structure and existing carbon stocks

- Year-round photosynthesis captures more atmospheric carbon

“There’s a stark contrast between what happens under perennial systems versus annual crops like corn silage,” says Dr. Sarah Goslee, research ecologist with the USDA Agricultural Research Service. “Perennial pastures managed with rotational grazing have demonstrated significantly greater accumulation of stable forms of soil carbon than even the most sustainable annual cropping systems.”

Research comparing various forage systems found that perennial pastures accumulated substantially more total soil organic carbon and, importantly, more mineral-associated organic matter (MAOM-C), a more stable carbon pool, compared to annual cropping systems, even those implementing conservation practices like no-till, diversified rotations, and cover crops.

This doesn’t mean eliminating corn silage but reimagining rotations to include longer periods under perennial forages. Options include:

- Grass-legume hay mixtures (orchardgrass, tall fescue, timothy paired with alfalfa or clovers)

- Multi-species pastures for grazing

- Emerging dual-purpose crops like Kernza intermediate wheatgrass that provide both forage and grain

WHAT THIS MEANS FOR YOUR BOTTOM LINE: Extending your perennial forage phases can reduce annual seed, fuel, and equipment costs while building soil fertility. Research from the University of Turin shows that farms incorporating more perennials have significantly lower land occupation impacts per kg of milk, making more milk on less land.

Many Italian dairy operations producing Parmigiano-Reggiano cheese have maintained this balance for generations, with research showing that farms growing higher proportions of forage on-farm and incorporating more perennials have significantly lower land occupation impacts per kg of milk. According to researchers at the University of Torino, “The LO [land occupation] per unit of production can be reduced by increasing on-farm feed production, particularly protein components, and to a lesser extent by valorizing byproducts.”

Filling the Winter Gap

In temperate regions, winter represents a period of carbon loss, as soil microbial activity continues to decompose organic matter while plant photosynthesis has ceased. Why allow our fields to leak carbon for months when we could be capturing it? Winter annual crops offer a strategic opportunity to reverse these carbon losses while diversifying the forage supply.

Options like winter rye, winter barley, field pennycress, or winter camelina can:

- Capture carbon during otherwise dormant periods

- Protect the soil from erosion

- Scavenge nutrients that might otherwise leach

- Provide additional forage or grain revenue streams

“Winter covers are like hiring a workforce that works for free during the off-season,” explains dairy nutritionist Dr. Mary Beth Hall. “They’re photosynthesizing when your fields would otherwise be bare, building soil organic matter, and can provide valuable supplemental feed.”

Research in the Midwest has shown that integrating these winter annual crops into corn silage systems can substantially reduce the carbon deficit while providing additional forage or grain, like how strategic dry cow management improves transition cow performance and prevents metabolic disorders without adding excessive costs.

Beyond the Species: Management Makes the Difference

While what you grow matters tremendously, how you manage your forages is equally important:

Conservation tillage: Reducing soil disturbance through no-till or strip-till practices helps preserve soil structure and existing carbon stocks. Studies show this can be particularly beneficial when transitioning from one forage to another, like how minimizing stress during cow transitions improves performance.

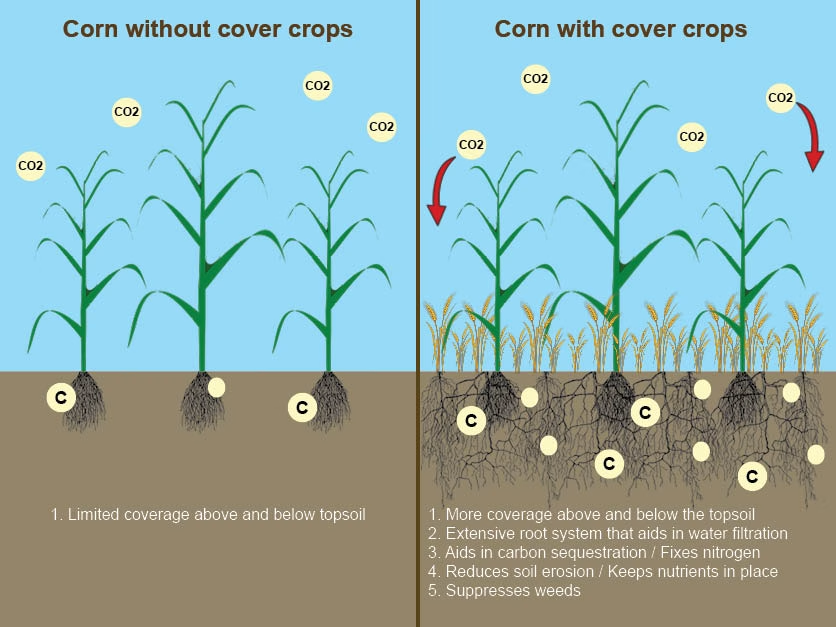

Cover cropping: Implementing cover crops between main forage harvests adds biomass to the soil and protects the surface from erosion. Different cover crops offer complementary benefits:

- Non-legumes (cereals, brassicas) scavenge leftover nutrients and produce substantial biomass

- Legumes (clovers, vetches) fix atmospheric nitrogen and often create more stable forms of soil carbon

- Mixes provide multiple benefits simultaneously, like a properly balanced TMR, which delivers multiple nutrients

Strategic grazing: Well-managed rotational grazing promotes uniform nutrient distribution, allows for rest and regrowth periods that enhance root development, and can improve species composition over time. This precision approach to grazing mirrors the principles of precision dairy nutrition, where feed efficiency improves with strategic management.

Manure management: Field application of dairy manure returns photosynthetic carbon to the soil, but how manure is handled before application significantly affects its carbon contribution. Recent research published in the Journal of Dairy Science shows that anaerobic digestion reduces slurry dry matter by 55% compared to raw manure, from 76 g/kg to 34 g/kg, which affects the carbon available for soil building. Raw slurry or solid manure typically delivers more carbon than digested or separated slurry.

As the University of Wisconsin’s Dr. Jessica Gutknecht puts it: “The carbon balance of a dairy farm is fundamentally about how much carbon you’re putting into the soil versus how much is being removed or lost. Every management decision tip that balances one way or another, like your feeding program, affects your components and bulk tank averages.”

Practical Pathways: Making the Transition Work for Your Farm

Transforming your forage system to enhance soil carbon requires a strategic approach tailored to your specific farm conditions. Here are practical steps to consider:

1. Assess Your Current Carbon Balance

Before making changes, understand your starting point. When did you last measure your soil organic matter levels across your fields? Consider:

- What proportion of your land is in annual versus perennial forages?

- How long are your current crop rotations?

- What is your typical tillage intensity?

- How much crop residue remains after harvest?

- What type and quantity of manure are you returning to your fields?

This assessment provides a baseline for measuring progress and identifying your biggest opportunities for improvement, like how you’d evaluate your herd’s current production metrics before implementing genetic or management changes.

2. Extend Rotations with Perennials

Look for opportunities to extend the perennial phase of your rotation:

- Instead of 1-2 years of alfalfa followed by 3-4 years of corn silage, consider 3-4 years of alfalfa or mixed hay followed by 2-3 years of corn

- Evaluate marginal cropland that might be more profitable and environmentally sound as permanent pasture

- Consider dedicating 10-15% of your land to strategic perennial plantings, especially on erosion-prone or less productive areas

A study from the University of Turin in Italy demonstrated that dairy farms with a higher percentage of permanent grasslands showed better land occupation efficiency per kg of fat- and protein-corrected milk (FPCM), with extensive farms producing more milk on their utilized agricultural area than on their off-farm land occupation.

3. Implement Winter Covers Strategically

Target your winter cover crop investments where they’ll provide the greatest return:

- Fields with early corn silage harvest offer an ideal window for establishing winter covers

- Choose species based on your specific goals (soil building, forage production, nitrogen fixation)

- Consider interseeding cover crops into standing corn to get a head start on establishment

4. Optimize Your Manure Strategy

Manure represents recycled carbon that can help close your farm’s carbon loop:

- Consider solid-liquid separation to strategically direct carbon-rich solids to fields with the greatest carbon deficit

- Time applications to maximize nutrient use efficiency and minimize losses

- Pair manure applications with cover crops that can capture and utilize nutrients

Recent research from Penn State University demonstrated how strategic applications of manure with cover crops enhanced soil carbon and improved nutrient retention in the soil profile, mitigating potential environmental impacts.

5. Reduce Tillage Intensity

While complete no-till may not be practical in all forage systems, reducing tillage intensity can help preserve soil carbon:

- Consider strip-till for corn planting after perennials

- Minimize the number of tillage passes when establishment is necessary

- Use no-till drills for cover crop establishment whenever possible

6. Focus on Soil Health Monitoring

Regular soil testing with a focus on organic matter can help track your progress:

- Establish baseline measurements of soil organic matter at consistent depths

- Consider more advanced soil health tests that measure active carbon fractions

- Photo-document soil structure and residue cover to track visual changes

WHAT THIS MEANS FOR YOUR BOTTOM LINE: Every 1% increase in soil organic matter can hold approximately 20,000 more gallons of water per acre, reducing irrigation costs and improving drought resilience, that’s money in the bank during dry years.

“Making these transitions doesn’t have to happen all at once,” advises Dr. Randy Jackson. “Start with pilot areas, learn what works on your farm, and expand gradually. Some of the biggest gains can come from relatively small changes applied consistently over time, similar to how small tweaks in your transition cow program can lead to significant improvements in lactation performance.”

Beyond Carbon: The Multiple Benefits of Carbon-Smart Forage Systems

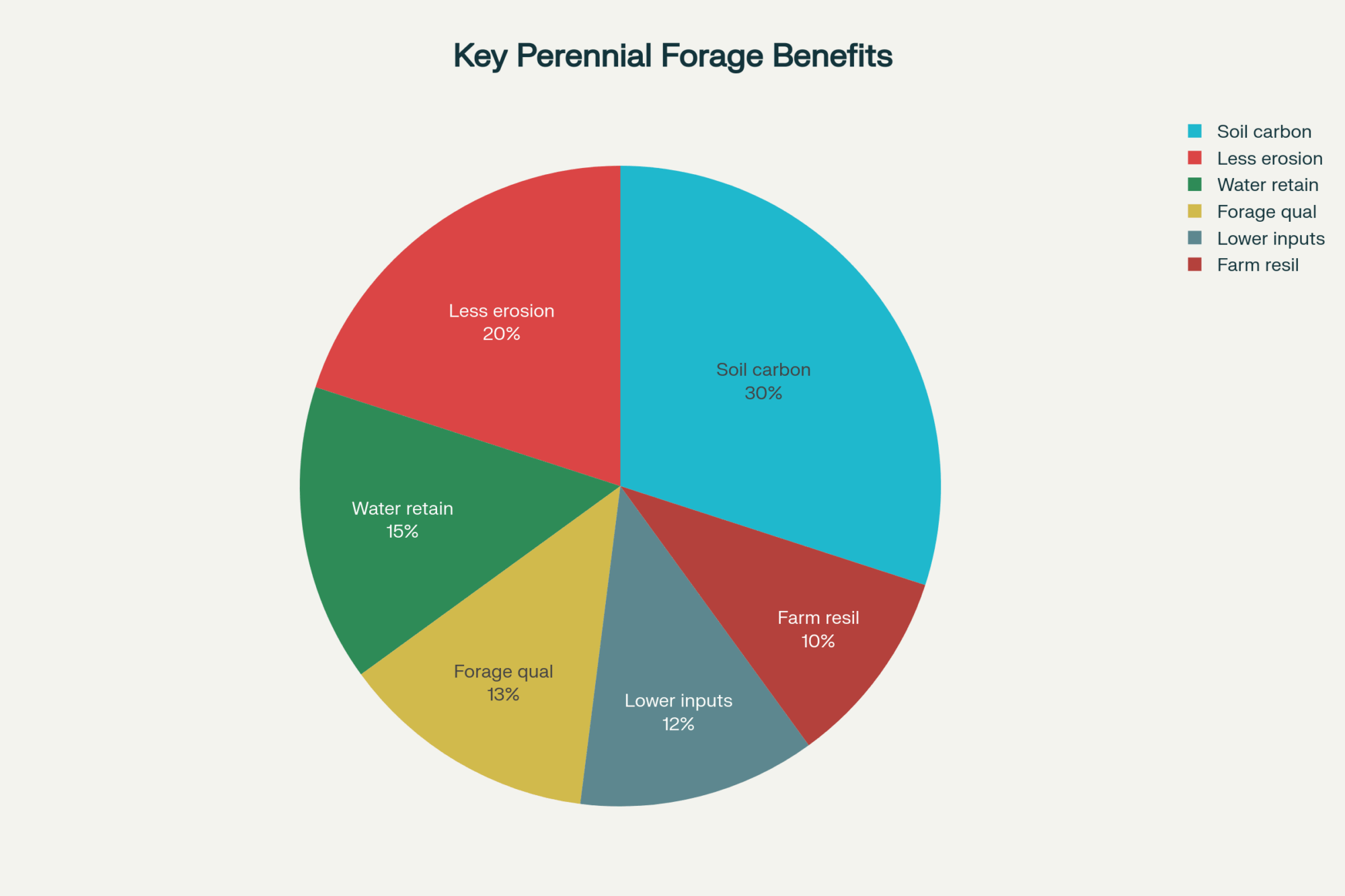

While reducing greenhouse gas emissions is a worthy goal, the benefits of enhancing soil carbon extend far beyond climate mitigation. These “co-benefits” often provide more immediate and tangible value to dairy operations:

Improved Drought Resilience

Soil organic matter acts like a sponge, dramatically increasing the water-holding capacity of soils. Research shows that for every 1% increase in soil organic matter, soils can hold approximately 20,000 more gallons of water per acre. This translates to greater drought resilience and potentially reduced irrigation needs.

“In the 2012 drought, we saw dramatic differences in forage production between farms with high and low soil organic matter,” notes Dr. Christine Jones, an internationally recognized soil ecologist. “The farms that had built their soil carbon had a buffer against the drought stress that devastated other operations, much like how a properly conditioned cow handles the stress of calving better than one that enters the dry period too thin or too fat.”

Enhanced Nutrient Cycling and Efficiency

Carbon-rich soils support more diverse and active soil microbial communities that help cycle nutrients more efficiently. This can reduce fertilizer requirements and associated costs while improving water quality by reducing nutrient runoff and leaching.

Studies in the Northeast have shown that dairy farms implementing perennial-based rotations with cover crops have reduced nitrogen fertilizer needs by 30-50% while maintaining or improving yields, enhancing farm profitability like how strategic feeding of bypass proteins can reduce total protein requirements while maintaining milk production.

Reduced Erosion and Improved Water Quality

The soil structure improvements associated with higher organic matter dramatically reduce erosion potential. This keeps your valuable topsoil in place while preventing sediment and nutrients from impacting waterways.

“Soil health and water quality are two sides of the same coin,” explains Dr. Matt Ruark. “The practices that build soil carbon also tend to be the ones that protect water resources.”

Greater Farm Resilience

Diversifying forage systems creates natural insurance against weather extremes, disease and pest pressures, and market volatility. If one crop struggles, others may thrive under the same conditions.

“Resilience is about having options,” says dairy farmer Ron Holter from Jefferson, Maryland, who transitioned to a perennial pasture-based system. “When you’re working with a diverse, carbon-building system, you’re not putting all your eggs in one basket, just like you wouldn’t want a herd susceptible to the same genetic weaknesses or all at the same stage of lactation.”

The Economics: Does Carbon-Smart Farming Pay?

The ultimate question for many dairy farmers considering changes to their forage systems is: Will it pay? The economics of carbon-smart forage management include both potential costs and benefits:

Potential Costs and Investments

- Equipment modifications or purchases (e.g., no-till drills, roller crimpers)

- Learning curve associated with new practices

- Potential short-term yield adjustments during transition periods

- Additional management complexity

- Higher seed costs for cover crops or diverse forage mixes

Potential Benefits and Returns

- Reduced fuel, labor, and machinery maintenance costs from less tillage

- Lower fertilizer requirements due to improved nutrient cycling

- Reduced irrigation needs from improved water retention

- Potential premium markets for low-carbon dairy products

- More stable yields under weather extremes

- Potential carbon credit revenue

The Carbon Market Opportunity

Emerging carbon markets represent a potential new revenue stream for dairy farmers implementing practices that increase soil carbon or reduce methane emissions. While still developing, these markets are gaining momentum:

- Carbon credits from agricultural soil projects currently range from $15 to $ 45 per metric ton of CO₂ equivalent

- Projects typically require verified changes in management and measured or modeled carbon gains

- Credits can come from soil carbon increases, methane reductions (e.g., manure digestion), or both

“The carbon market is still maturing, but forward-thinking dairy farms are positioning themselves to benefit,” explains Dr. Debbie Reed, Executive Director of the Ecosystem Services Market Consortium. “The farms with good data and documented practice changes will be best positioned to participate as these markets develop, similar to how farms that were early adopters of robotic milking or precision feeding technology often gained market advantages.”

Real-World Economics

Perhaps most compelling are the experiences of dairy farms that have already made transitions to more carbon-friendly systems:

Rettland Farm (Pennsylvania) transitioned from a corn silage-based confinement operation to a managed grazing system with diverse perennial pastures. While milk production per cow decreased slightly, the farm eliminated silage production costs, reduced grain purchases by 30%, and improved herd health, resulting in net profitability gains of $800 per cow annually.

Grazeway Dairy (Wisconsin) implemented a partial system where 40% of the forage comes from perennial pasture and 60% from harvested feed. They’ve documented a 35% reduction in machinery and fuel costs while maintaining comparable milk production. Soil organic matter on their pastures has increased from 3.2% to 5.7% over 12 years.

Blue Spruce Farm (Vermont) maintained its corn silage system but added winter cover crops, reduced tillage, and incorporated manure injection. While spending approximately $30 per acre more on seeds and management, they’ve reduced fertilizer costs by $45 per acre and documented yield increases worth $65-90 per acre in their subsequent corn crops.

As fifth-generation dairy farmer Jon Gilbert puts it: “There’s a cost to changing, but there’s also a cost to not changing. When I look at what we’re spending on fertilizer, fuel, and equipment repairs in our conventional system versus our transition fields, the numbers increasingly favor the carbon-building approach; it’s like comparing the economics of preventing metabolic disease versus treating it.”

Taking Action: Where to Start on Your Farm

Ready to explore how carbon-smart forage management might work on your dairy? Here are the practical next steps:

1. Start with Knowledge Building

- Attend field days where carbon-friendly practices are being demonstrated

- Connect with your local extension office about soil health programs

- Join farmer networks focused on regenerative agriculture and soil health

- Consider a soil health assessment to establish your baseline

2. Experiment on a Small Scale

- Choose a field or portion of a field for trying new approaches

- Consider side-by-side comparisons of your current system versus alternatives

- Document what you observe, including operational aspects and visual soil changes

- Be patient, soil carbon changes happen over years, not months, like genetic improvements in your herd

3. Seek Technical Assistance and Incentives

- NRCS (Natural Resources Conservation Service) offers technical assistance and cost-sharing for many carbon-enhancing practices

- State departments of agriculture often have specific programs for dairy conservation

- Some milk processors and cooperatives are developing sustainability incentive programs

- Carbon market project developers can help assess your operation’s potential for credit generation

4. Connect with Peers Who Have Made Similar Transitions

- Farmer-to-farmer learning is consistently rated as the most valuable information source

- Look for progressive dairy discussion groups in your region

- Consider visiting farms that have successfully implemented practices you’re interested in

5. Take a Whole-Farm Systems Approach

- Consider how forage changes might integrate with other sustainability efforts (e.g., renewable energy, manure management)

- Think about potential synergies across your operation

- Involve your nutritionist, crop advisor, and other team members in planning

Looking Forward: Dairy’s Carbon-Smart Future

The dairy industry stands at a pivotal moment. The path to net-zero emissions requires addressing all sources of greenhouse gases, including those from the soils that grow dairy feeds. While this challenges conventional forage systems, it also creates tremendous opportunities for innovation and leadership.

Researchers at institutions like the Swedish University of Agricultural Sciences are exploring additional technologies to reduce methane emissions, including seaweed supplements like Asparagopsis taxiformis, which has shown a 30% reduction in methane production in some trials. However, managing soil carbon through improved forage systems represents a more fundamental solution with multiple co-benefits.

“The dairy farms that will thrive in the coming decades are the ones thinking holistically about carbon, not just how to reduce emissions, but how to actively build carbon in their soils,” predicts Dr. Jed Colquhoun, Associate Dean for Extension at the University of Wisconsin-Madison.

Are you ready to be part of this transformation? By reimagining your forage systems to enhance soil carbon, you can:

- Make meaningful progress toward industry climate goals

- Build more resilient, profitable operations

- Improve environmental outcomes beyond carbon (water, biodiversity)

- Position yourself for emerging ecosystem service markets

- Tell a compelling sustainability story to consumers and processors

The transition won’t happen overnight, and there’s no one-size-fits-all solution. But by starting the journey now, testing, learning, and adapting, you can turn one of the industry’s biggest climate challenges into one of its greatest opportunities.

As we reimagine dairy forage systems for a carbon-constrained future, the focus must extend beyond yield and feed quality to include these systems’ fundamental role in the carbon cycle. The practices that build soil carbon, incorporating more perennials, reducing tillage, implementing cover crops, optimizing grazing, and refining manure management, represent climate solutions and pathways to more resilient, productive dairy farms.

The carbon that sustains us ultimately comes from the soil. By managing that carbon more thoughtfully, you can lead agricultural climate solutions while building operations that will thrive for generations. What will your farm’s carbon legacy be?

Key Takeaways

- Soil carbon losses from intensive silage corn production (3.7-7.0 Mg C/ha/yr) are significant but typically excluded from carbon footprints, dramatically increasing the true climate impact of dairy production when accounted for.

- Perennial forage integration, conservation tillage, cover cropping, and strategic grazing represent proven approaches to reverse soil carbon losses while providing drought resilience and potential economic benefits through reduced input costs.

- Every 1% increase in soil organic matter can hold approximately 20,000 more gallons of water per acre, creating natural insurance against increasingly common weather extremes.

- Farmers who have implemented carbon-smart practices report tangible benefits-from 35% reductions in machinery and fuel costs to improved herd health and drought resilience-demonstrating that environmental and economic sustainability can be aligned.

- The transition to carbon-smart forage systems doesn’t require wholesale change overnight; starting with pilot areas and scaling gradually allows farmers to learn what works best for their specific operation while building soil health and climate resilience.

Executive Summary

This compelling article reveals how conventional corn silage-based dairy systems are creating a significant but often overlooked carbon deficit in soils, potentially doubling milk’s true carbon footprint when properly accounted for. The author challenges the industry’s reliance on corn silage, presenting evidence that perennial forages, cover crops, and strategic grazing can reverse soil carbon losses while improving drought resilience, reducing input costs, and enhancing overall farm profitability. Through case studies of innovative dairy operations and expert insights, the article demonstrates that transitioning to carbon-smart forage systems offers multiple pathways to achieve both environmental sustainability and economic advantages. With practical guidance for implementation and a frank assessment of the challenges, the piece makes a persuasive case that soil carbon management represents both dairy’s biggest climate challenge and its greatest opportunity.

This article was developed based on research from the University of Wisconsin, Minnesota, Vermont, Cornell, Turin, and the Swedish University of Agricultural Sciences, as well as the USDA Agricultural Research Service and interviews with dairy farmers implementing carbon-smart practices. For more information on specific regional practices or programs, contact your local Extension office or NRCS field office.

Complete references and supporting documentation are available upon request by contacting the editorial team at editor@thebullvine.com.

Learn more:

- How Hanover Hill Holsteins Revolutionized the Dairy Breeding Industry

- Roy Ormiston: The Holstein Man’s Holstein Man Who Revolutionized Modern Breeding

- Hanoverhill Starbuck’s DNA Dynasty: The Holstein Legend Bridging 20th Century Breeding to Genomic Futures

Join the Revolution!

Join the Revolution!

Join over 30,000 successful dairy professionals who rely on Bullvine Weekly for their competitive edge. Delivered directly to your inbox each week, our exclusive industry insights help you make smarter decisions while saving precious hours every week. Never miss critical updates on milk production trends, breakthrough technologies, and profit-boosting strategies that top producers are already implementing. Subscribe now to transform your dairy operation’s efficiency and profitability—your future success is just one click away.

Join the Revolution!

Join the Revolution!