One Midwest herd just banked $30K cutting antibiotics by 78%—while their neighbors still treat every cow the old way.

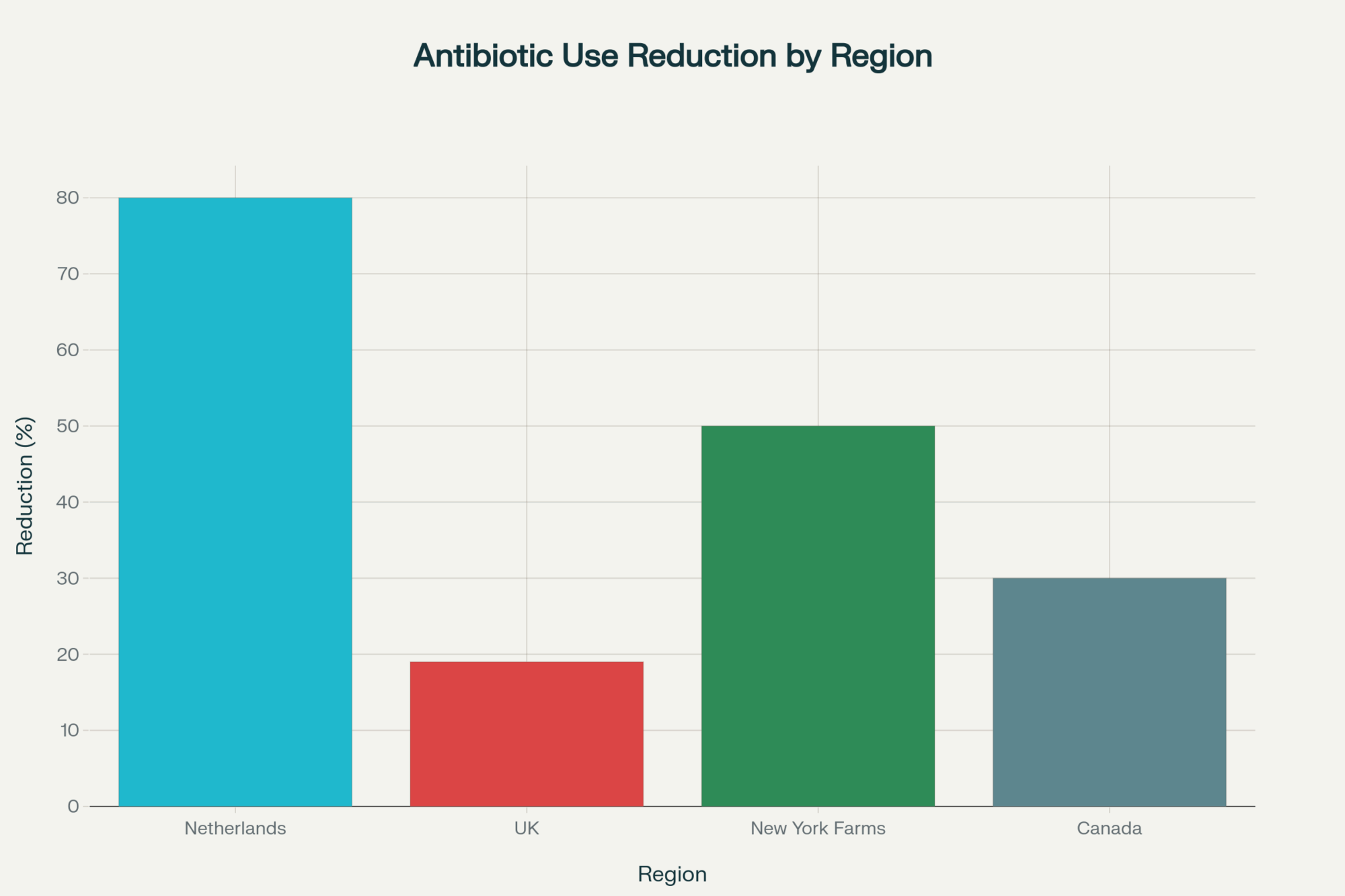

EXECUTIVE SUMMARY: Look, I’ve been digging into this selective dry cow therapy thing, and honestly? Most of us are throwing money away treating perfectly healthy cows. Wisconsin researchers tracked 37 herds and found producers saved $5.37 per cow when they switched to data-driven protocols instead of blanket treatments. That’s real money—not company marketing fluff. The Dutch have already figured this out, cutting antibiotic use by 80% while keeping their herds healthier than ever. Here’s the kicker: it only works if your bulk tank SCC stays under 250,000 and your dry cow housing doesn’t suck. But if you’ve got those basics down? The economics work, especially for bigger operations. It’s time to stop guessing and start using the data right in front of you.

KEY TAKEAWAYS

- Scale determines success — Operations over 1,000 cows see payback in 12-18 months with $2.12 net benefit per cow, while herds under 500 struggle to break even on testing costs

- Timing is everything — Launch your selective protocols in March-May when environmental pressure is lowest; summer heat and winter mud will crush your success rates if you’re not careful

- SCC threshold isn’t gospel — That 200,000 cutoff everyone talks about? University of Georgia found too many false positives, so adjust seasonally and watch your individual cow patterns

- Regulatory pressure building — FDA ramped up antibiotic oversight in 2023, and processors are starting to reward documented reduction programs with premium payments

- Start small, measure everything — Pilot selective treatment on 25% of your dry-offs first, track every dollar, and make sure your vet’s on board before going all-in

Let’s be honest. Most of us have been drying off cows the same way our dads did—antibiotics for every cow, every time. But agriculture’s moving fast, and that approach might be costing you.

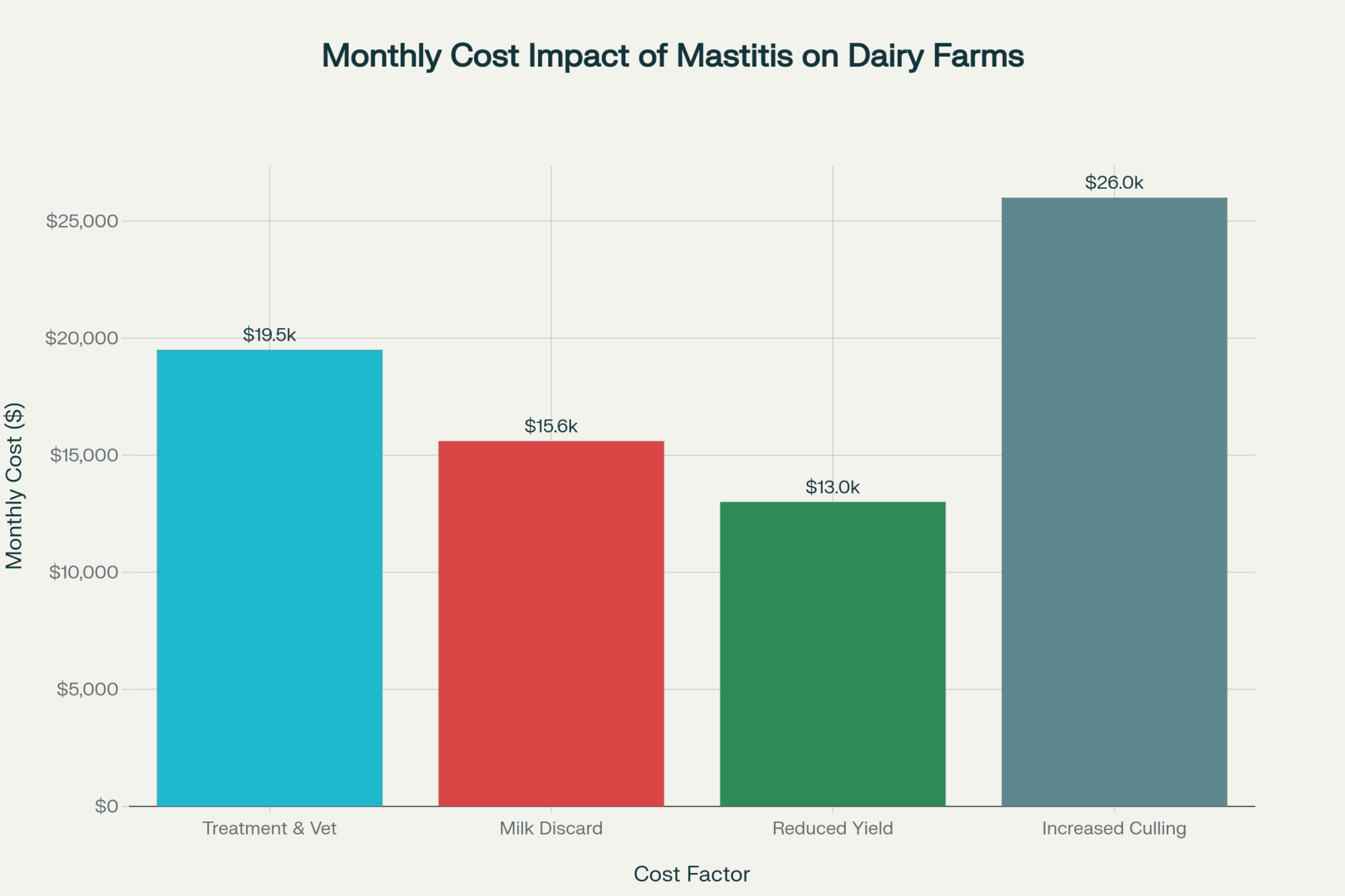

A recent HerdHQ case study found a large Midwest herd cut antibiotic use by 78%, saving nearly $30,000 annually. Now, that’s company data and not independently reviewed, so keep your skepticism. University research gives more modest but reliable numbers—$2 to $8 saved per cow when selective dry cow therapy (SDCT) replaces blanket treatment.

One thing’s clear: the old ways won’t cut it much longer.

What’s Working in the Midwest Barnyard

University of Wisconsin research covering 37 herds that switched to SDCT found that producers saved an average of $5.37 per cow. But here’s the no-nonsense reality: savings usually come only from herds with bulk tank Somatic Cell Counts (SCC) below 250,000 cells/mL, good dry cow housing, and well-trained staff.

Consider the case of a producer in rural Minnesota who initiated SDCT during a harsh winter. “Mud and frozen water lines made our old SCC thresholds useless,” the producer recalls. “We adjusted protocols for the cold, keeping infections in check.” This demonstrates that facilities and management are just as important as any technology.

The Science Backing SDCT

Dr. Simon Dufour’s meta-analysis found a 66% reduction in antibiotic use when teat sealants were applied properly, with no increase in the incidence of mastitis.

While a 200,000 SCC cutoff is a useful guideline, University of Georgia specialists warn it’s not perfect. False positives can occur, so producers should adjust thresholds seasonally and based on their herd’s history.

Experts from Minnesota Extension agree: stay flexible and watch how your cows respond to changing conditions.

Size Matters: Financial Viability of SDCT

Here’s the tough talk: Your herd size directly impacts the financial viability of SDCT. The following table breaks down estimated costs and payback periods:

| Herd Size (Cows) | Testing Cost/Cow | Avg. Savings/Cow/Year | Net Benefit/Cow/Year | Payback Time |

| Under 300 | $8.50 | $5.37 | -$3.13 | Not viable |

| 300-500 | $6.25 | $5.37 | -$0.88 | Marginal |

| 500-1,000 | $4.75 | $5.37 | +$0.62 | 36-48 months |

| Over 1,000 | $3.25 | $5.37 | +$2.12 | 12-18 months |

*Payback time represents the estimated months to recoup costs of testing and training.

If you milk fewer than 500 cows, focus first on housing improvements and consider cooperative testing with neighbors to reduce costs.

What’s Happening Beyond Our Fences

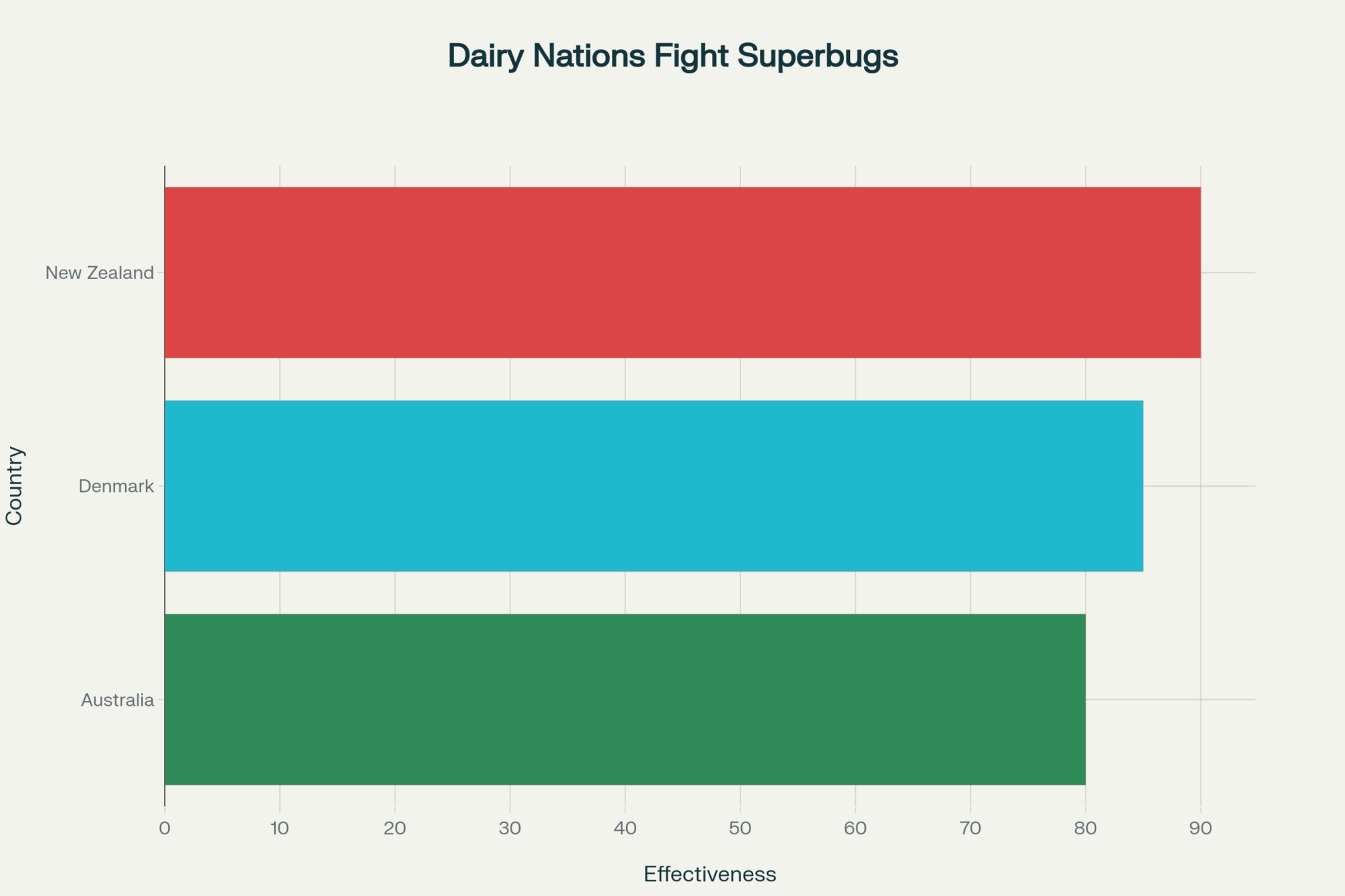

The Dutch government pushed hard for antibiotic cuts, slashing antimicrobial use by over 80% in a decade. In the UK, dairy farms have reduced antibiotic use by 19% since 2020 through targeted, selective treatments, while maintaining milk quality and herd health.

New York farms are proving the concept works. Of the 24 dairies that tried SDCT, nearly all continued the practice, resulting in a 50% or more reduction in antibiotic use.

Canada’s veterinary-led programs confirm health and financial wins from SDCT implementation.

This global momentum demonstrates that the model is effective, but success ultimately depends on adapting these principles to local farm conditions.

Regulatory pressure is mounting, too. The FDA increased veterinary oversight for medically important antibiotics in 2023, signaling that prudent antibiotic use isn’t just good business—it’s becoming a required practice.

Stay Sharp: Use Technology, Not Just Buzz

HerdHQ is popular, but recent research indicates that machine learning has not yet outperformed tried-and-true rule-based SDCT decisions.

Bottom line: master the basics first—clean housing, solid protocols, and veterinary backing.

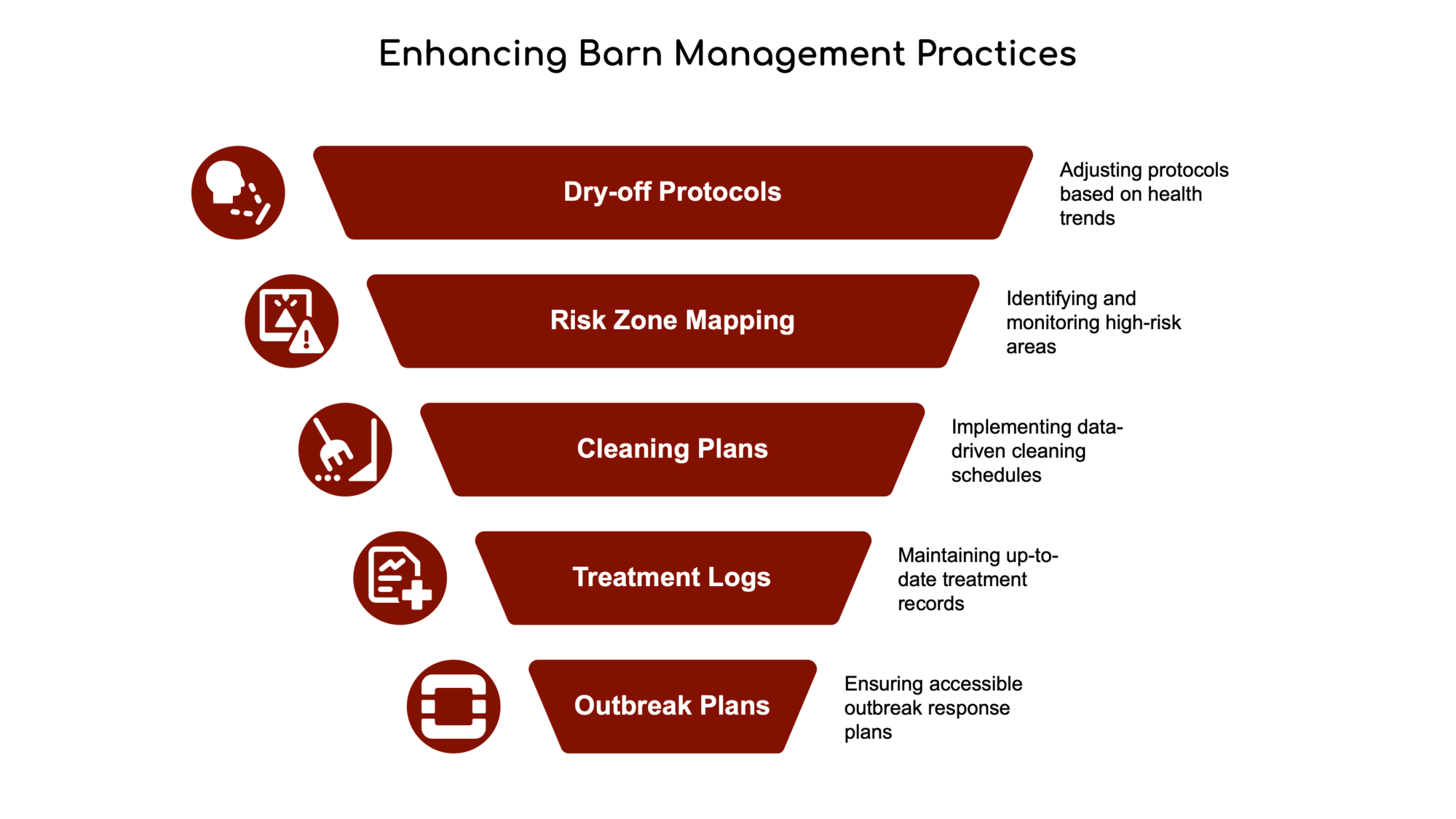

The Blueprint for SDCT Success

Here’s what Midwest producers and vets say you need:

Prerequisites for Success:

- Maintain bulk tank SCC under 250,000 cells/mL for six months

- Keep dry cow housing clean, dry, and comfortable

- Train your staff on the proper steps for dry-off

- Build a trusted relationship with your vet

Timing Matters: The optimal time for initiating selective dry cow treatment tends to be spring (March through May). Summer heat triggers mastitis, while winters call for careful adjustments.

“Trying to go it alone with selective therapy usually ends in frustration.”

—A New York dairy veterinarian, from a 2021 Journal of Dairy Science study¹³

Your SDCT Action Plan by Herd Size

For herds of 1,000 cows and up:

- Schedule a vet consultation to design an SDCT program

- Audit your dry cow treatment expenses

- Pilot selective therapy on 25% of dry-offs

For 300 to 1,000-cow herds:

- Prioritize dry cow housing upgrades

- Explore testing cooperatives with neighbors

- Work closely with your vet to tailor protocols

For herds under 300 cows:

- SDCT savings are likely further out

- Focus on improving dry cow care fundamentals

- Explore group testing and extension support programs

Regardless of farm size, keep track of treatment costs, monitor SCCs, and collaborate with your veterinarian.

Bottom Line

Farmers ahead of the curve on SDCT didn’t get lucky—they got prepared. They invested in proper housing, built strong vet relationships, and understood their numbers before making the switch.

The question isn’t whether selective dry cow therapy will become standard practice. The question is whether your operation will be ready when the economics make sense for your herd size and regulatory requirements become even tighter.

Are you ready?

Complete references and supporting documentation are available upon request by contacting the editorial team at editor@thebullvine.com.

Learn More:

- The Golden Opportunity of the Dry Period – This article provides tactical strategies for optimizing dry cow management and nutrition. It reveals practical methods for reducing metabolic issues and improving udder health, directly supporting the on-farm prerequisites needed for a successful selective therapy program.

- The Future of Dairy Farming is Now: How to Stay Ahead of the Curve – Go beyond the barn with this strategic look at market trends shaping the industry. It explores how consumer demands for sustainability and antibiotic stewardship are creating new economic opportunities, positioning your prudent use of antibiotics as a market advantage.

- On-Farm Culturing: A Game Changer in Mastitis Management – This piece is a deep dive into the innovative technology that powers precision SDCT. It demonstrates how on-farm culturing provides the actionable data needed to identify specific pathogens and make confident, cost-effective treatment decisions for individual cows.

Join the Revolution!

Join the Revolution!

Join over 30,000 successful dairy professionals who rely on Bullvine Weekly for their competitive edge. Delivered directly to your inbox each week, our exclusive industry insights help you make smarter decisions while saving precious hours every week. Never miss critical updates on milk production trends, breakthrough technologies, and profit-boosting strategies that top producers are already implementing. Subscribe now to transform your dairy operation’s efficiency and profitability—your future success is just one click away.

Join the Revolution!

Join the Revolution!