71% of AI breedings now use genomic bulls under 2 years old. Your conception problems? Probably not the bull’s fault.

EXECUTIVE SUMMARY: Look, here’s what I’ve learned talking to producers across the Midwest: blaming bulls for fertility problems is costing you serious cash and missing the real issues. We’re talking $5 per day for every cow that takes an extra 10 days to breed—that’s $25,000 walking out the gate on a 500-cow operation. The genomic revolution means today’s bulls are vetted harder than ever, with less than 10% failing quality checks after intense pre-selection. Meanwhile, the real fertility killers are hiding in plain sight: cows slipping into negative energy balance, heat stress knocking 15-20% off conception rates, and AI technicians whose skills can swing results by 10 percentage points. Smart producers are shifting focus to body condition scoring, environmental controls, and timed AI protocols that actually move the needle. With feed costs high and weather getting more extreme in 2025, you can’t afford to keep chasing the wrong problems.

KEY TAKEAWAYS

- Save $25K annually by preventing breeding delays — Start weekly body condition scoring to catch cows dropping below 3.0 BCS before they hit negative energy balance. With current feed prices, keeping cows in proper condition is your best ROI move for 2025.

- Boost conception rates 1.5% with better semen handling — Train your AI techs on precise thawing protocols (95-98°F for exactly 45 seconds) and invest in calibrated thermometers. As genomic sires flood the market, proper cryopreservation handling is non-negotiable.

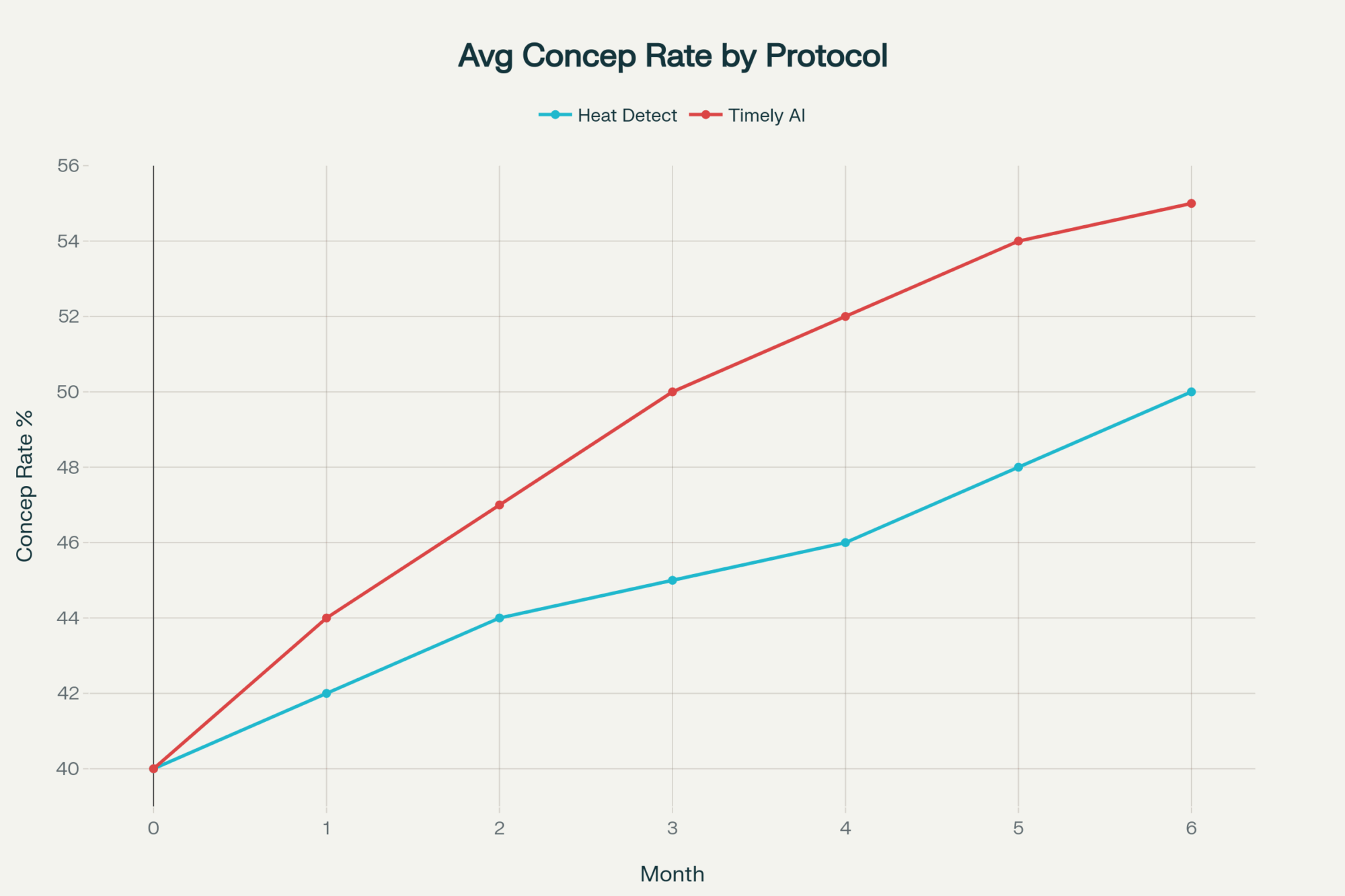

- Combat heat stress cutting fertility up to 20% — Upgrade cooling systems and shift feeding to cooler hours. Monitor your Temperature Humidity Index daily and consider Timed AI protocols to work around weather challenges hitting dairy regions harder each year.

- Close the sexed semen fertility gap (now 85-90% of conventional) — Use TAI protocols specifically designed for sexed semen timing. With producers demanding more heifer calves and beef crosses, mastering sexed semen management is becoming essential for profitability.

You know that moment when you’re standing around the coffee pot at a dairy conference and someone starts venting about their conception rates? Last month, I had exactly that conversation with a Wisconsin producer running about 500 head. His numbers had dropped 15 percentage points over six months, and his first instinct was to point fingers at the AI company.

“Must be the bulls,” he said, shaking his head. “Quality’s just not what it used to be.”

Here’s the thing that’s got me fired up—that knee-jerk reaction to blame the bull isn’t just outdated thinking, it’s costing dairy operations serious money. And honestly, after digging into the latest research and talking with folks across the industry, I think it’s time we had a blunt conversation about where fertility failures actually originate.

Because here’s the brutal math: every cow that takes an extra 10 days to get bred costs you roughly $5 per day after 100 days in milk. On a 500-cow dairy running 65% conception rates instead of 75%? That’s $25,000 walking out your gate annually. And that’s before you factor in additional semen costs, vet bills, and the compounding effect of delayed rebreeding.

The Bull Factor: More Bulletproof Than Ever

Let me start with something that might surprise you. By 2021, a staggering 71% of all AI breedings in U.S. dairy herds were using genomic young sires—bulls that didn’t even have milking daughters yet[1]. But here’s what that actually means inside the AI stud, and why it changes everything.

Industry insiders will tell you that twenty years ago, the typical collection bull was a mature powerhouse, often over 4 years old, producing between 800 to 1,000 doses per collection. Today? The median age has dropped dramatically to under 2 years, which means we’re shifting from relying on a few high-output older bulls to many younger bulls, each producing fewer doses — typically 300 to 500 per collection — but boasting superior genetics.

This shift goes hand in hand with unprecedented early-life control over these bulls. Leading AI studs don’t just scout for promising prospects at a few months old; they nurture their best genetics from birth. Many bull calves are brought into AI facilities around 6 weeks of age, while still on milk, enabling precise management of nutrition and health — a level of care unimaginable a generation ago. By the time that semen straw hits your farm tank, it’s the survivor of an elimination process that literally starts moments after birth.

What strikes me about this shift is how it’s fundamentally changed the reliability equation. Instead of waiting 4-7 years to figure out if a bull’s any good, AI companies can now analyze tens of thousands of DNA markers right after birth and pick the genetic elite early. The competition is so fierce that most major AI studs are now screening out 10-20 genetically inferior bull calves for every single one that makes it into their collection program.

The genetic screening is so ruthless that the idea of a bull just “not being fertile” is almost off the table. What is the failure rate for young bulls entering the system? Less than 10% don’t make the grade—because the genetic duds have already been identified and removed from the pipeline.

The scientific side has evolved dramatically as well. Yeah, cryopreservation still kills about 40-50% of sperm cells—that’s just the brutal reality of freezing and thawing. But modern extenders aren’t your grandfather’s egg yolk mixture. Today’s formulations are packed with antioxidants, including glutathione, resveratrol, and vitamins, that actively protect sperm DNA and membranes during the freeze-thaw cycle.

And here’s something concrete: the industry’s shift from 0.5cc to 0.25cc straws isn’t just about convenience. The smaller diameter allows for more uniform cooling and heating, resulting in a measurable 1.5% improvement in conception rates. Not earth-shattering, but in a business where every percentage point matters, it makes a significant difference.

Quality control has become ruthlessly objective. Computer-assisted sperm analysis (CASA) systems track hundreds of individual sperm cells, measuring parameters such as progressive motility (minimum 30%) and morphology (minimum 70% normal). Leading studs go even further with DNA fragmentation testing and flow cytometry to identify subtle issues that could impact fertility in the future. They’re even analyzing why a bull might produce great conventional semen but struggle to make a high-fertility sexed product, or vice versa. That’s the level of microscopic detail they’re managing before a single straw is cleared for sale.

Where the Real Action Is: The Cow’s Metabolic Tightrope

This is where things get complicated—and honestly, where I see the biggest opportunities for improvement. The modern dairy cow is performing an almost impossible balancing act, especially during the critical weeks leading up to calving.

Picture this: your fresh cow is producing 80+ pounds of milk while recovering from calving, regaining her reproductive system, and maintaining her body condition. It’s like asking someone to run a marathon while doing calculus. Something’s got to give, and usually, it’s fertility.

Negative Energy Balance (NEB) is the technical term, but what it really means is your cow is burning more calories than she’s consuming. This isn’t just about looking thin—it’s about hormonal chaos. When a cow slips into deep NEB, her hypothalamic-pituitary-ovarian axis basically hits the pause button.

The most practical way to monitor this? Body Condition Scoring. Research consistently shows that cows with a BCS below 3.0 at first breeding have significantly lower conception rates compared to those at 3.0 or higher. I’ve seen herds where getting serious about BCS management—really serious, not just eyeballing it—improved first-service conception by 8-12 points.

But here’s what keeps me up at night: the cascade effect of postpartum health problems. A difficult calving isn’t just a bad day—it’s the starting gun for weeks or months of reproductive challenges. Metritis alone can knock 20% off your first-service conception rate, while dystocia and retained placentas typically cost you 4-10%.

Then you add heat stress to the mix… and that’s a fertility killer if there ever was one. We’re seeing 15-20% drops in conception rates during hot summer months across much of the country. Texas, Arizona, and even parts of Wisconsin and New York during heatwaves—it doesn’t discriminate by geography.

And then there’s lameness—the silent fertility assassin. Lame cows have elevated cortisol levels that actively suppress reproductive hormones. I’ve walked through barns where 15-20% of the cows had some degree of lameness, and the owners couldn’t figure out why their conception rates were in the tank.

The Human Element: Where Small Mistakes Make Big Differences

Even with perfect genetics and healthy cows, poor management can torpedo your conception rates faster than you can say “heat detection.”

That semen straw is stored in liquid nitrogen at -196°C. At this temperature, all biological processes stop—but damage from ice recrystallization starts at just -130°C. That means even brief exposure to the warmer temperatures in your tank’s neck can be cumulative and irreversible.

The thawing protocol isn’t negotiable: a 95-98°F water bath for a minimum of 45 seconds, using a calibrated thermometer and timer. No pocket thawing, no “warming it up in the cow,” no shortcuts.

But here’s something that really gets my attention: the skill gap between AI technicians. Studies show that individual inseminator performance can create 5-10% swings in conception rates. That’s enormous in a business where 2-3% improvements can transform profitability.

The Game-Changer: Your Fertility Action Plan

Here’s where we get tactical. Instead of playing defense and reacting to problems, I want you to think offense. Here’s the systematic approach I use with operations that are serious about fertility:

Week 1: Semen Management Audit

- Calibrate your thermometer and timer

- Observe every AI technician’s thawing protocol

- Check tank nitrogen levels and straw organization

- Document any deviations from standard protocol

Week 2: Body Condition Scoring Blitz

- Score every cow in the breeding pen

- Identify cows below 3.0 BCS

- Adjust rations for thin cows immediately

- Set up a weekly BCS monitoring system

Week 3: Postpartum Health Review

- Pull health records for the last 6 months

- Calculate the incidence of metritis, retained placenta, and dystocia

- Meet with your vet to tighten prevention protocols

- Train staff on early disease detection

Week 4: Heat Detection Analysis

- Review breeding records for missed heats

- Consider activity monitors or tail paint systems

- Evaluate the timing of the current AI relative to the observed heat

- Plan transition to TAI if heat detection is inadequate

Week 5: Environmental Controls

- Install or service cooling fans and water systems

- Provide adequate shade for all holding areas

- Adjust feeding times to cooler parts of the day

- Monitor Temperature-Humidity Index daily

Week 6: Staff Training and Protocols

- Retrain all AI technicians on proper technique

- Standardize record-keeping procedures

- Establish accountability measures for conception rates

- Create an ongoing training schedule

Each week builds on the previous one. By week six, you’ve systematically addressed every major controllable factor in your fertility program.

The Bottom Line: It’s About Systems, Not Scapegoats

The evidence is crystal clear: in modern dairy reproduction, the bull is rarely the primary limiting factor. The intensive genomic selection, advanced semen processing, and rigorous quality control systems have mitigated mainly the risks associated with the male contribution.

Instead, conception success hinges on three manageable factors: cow readiness, precise management, and the strategic deployment of reproductive technologies.

The farms that get this right aren’t necessarily spending more money. They’re spending it more strategically, focusing on the factors that actually drive reproductive success rather than chasing ghosts.

So the next time someone in your area starts complaining about bull fertility, maybe suggest they look a little closer to home first. The answers are usually there—in the feed bunk, the breeding barn, and the protocols that govern how everything comes together.

Because at the end of the day, that $25,000 you’re potentially losing? It’s not walking out the gate because of the bull. It’s walking out because of decisions and systems you can actually control.

Take a stand on the things that matter. Your bottom line depends on it.

Complete references and supporting documentation are available upon request by contacting the editorial team at editor@thebullvine.com.

Learn More:

- The Dairy Producer’s Guide to Breeding Synchronization Programs – This guide offers a tactical deep-dive into implementing Timed AI. It breaks down the pros and cons of different protocols, helping you choose and execute the most cost-effective system to reduce days open and maximize pregnancy rates in your herd.

- Is Beef on Dairy the Answer to Volatile Milk Prices? – Explore the strategic economics of a “beef-on-dairy” program. This article reveals how to segment your herd to create high-value beef-cross calves from lower-genetic-merit animals, turning a reproductive decision into a powerful secondary revenue stream.

- Beyond the Pedometer: How AI is Revolutionizing Dairy Fertility – Look to the future with this analysis of precision fertility technologies. It demonstrates how AI-powered sensors are moving beyond simple activity monitoring to predict health issues and pinpoint ovulation, offering a glimpse at the next leap in reproductive efficiency.

Join the Revolution!

Join the Revolution!

Join over 30,000 successful dairy professionals who rely on Bullvine Weekly for their competitive edge. Delivered directly to your inbox each week, our exclusive industry insights help you make smarter decisions while saving precious hours every week. Never miss critical updates on milk production trends, breakthrough technologies, and profit-boosting strategies that top producers are already implementing. Subscribe now to transform your dairy operation’s efficiency and profitability—your future success is just one click away.

Join the Revolution!

Join the Revolution!