Your cows cover their feed. Your banker’s calm. So why are the sharpest producers culling now? Because they see what’s coming.

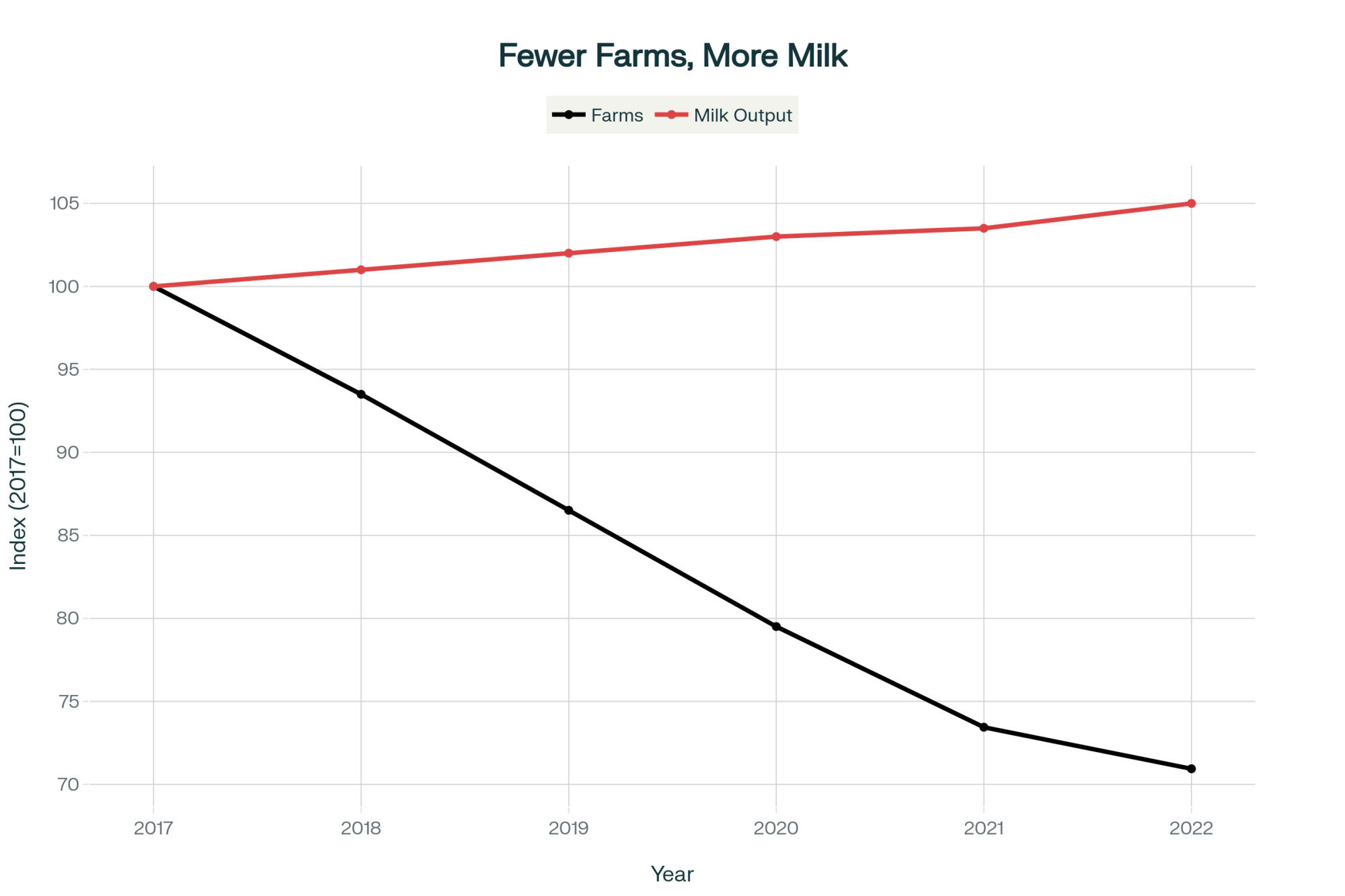

EXECUTIVE SUMMARY: Dairy farmers worldwide are caught in a trap: record milk production, collapsing wholesale prices, yet on-farm economics that make every cow look like she’s paying her way. AHDB’s December 2025 forecast puts UK output at “uncharted levels”—13.05 billion litres, up 4.9%—while USDA projects US production hitting 229.1 billion pounds in 2026. Three factors are blocking the market’s usual self-correction: milk-to-feed ratios near 20-year highs, strong cull values that encourage waiting, and contract structures that delay price pain for weeks. The 2015-16 EU crisis offers a hard lesson—farms that survived prioritized margin over volume, kept fixed costs lean, and acted early. Those that waited often lost their operations. This feature delivers a three-step culling framework, worked financial examples, and the critical questions to ask your banker and nutritionist before the exit window closes.

Looking at global dairy markets right now, the most striking thing isn’t just that milk is plentiful—it’s how long production is holding up despite softer prices.

Great Britain’s latest milk forecast tells the story pretty clearly. AHDB’s December update has 2025/26 output reaching a record 13.05 billion litres, up about 4.9% on the previous milk year, with April–November deliveries already running 5.5% ahead of last season. Those are significant numbers for a mature market.

At the same time, AHDB’s November wholesale data paint a sobering picture: UK butter averaging £4,290 per tonne—down nearly £1,870 since June. Bulk cream is now worth almost half what it was in September 2024. And mild Cheddar has broken below £3,000 per tonne for the first time since July 2021.

What farmers are finding—in Britain, across the EU, in the US and down in Oceania—is that this doesn’t feel like a short, sharp price dip that will quietly self-correct. The usual brakes we’re used to seeing (high feed costs, weak cull prices, big government buying programmes) aren’t in the same place they were ten years ago.

Now, weather swings, animal disease, or policy shifts could certainly change the picture faster than any forecast suggests. But the smart bet right now is to plan as if this is a phase, not a quick bounce.

This feature takes a farmer-first look at the data, the history, and the on-farm decisions that matter most over the next 12–18 months.

Global Milk Production: Multiple Exporters Expanding at Once

Here’s what makes this particular cycle different: several major exporters are expanding at once, rather than one region growing while another pulls back.

In Great Britain, AHDB’s December forecast describes the situation as “uncharted levels”—their words, not mine. Strong grass growth and better yields per cow are driving those record volumes. Meanwhile, US data mirrors this saturation: USDA’s July WASDE report raised the 2025 forecast to 228.3 billion pounds and the 2026 forecast to 229.1 billion pounds—that’s 900 million pounds higher than they projected just a month earlier. Modest herd growth and continued gains in milk per cow are doing the work on both sides of the Atlantic.

Producers across the UK report experiences similar to those of their American counterparts—favorable conditions pushing rolling averages up significantly, with milk flowing whether the market wants it or not.

Across the wider EU, the picture is a bit more nuanced. While overall production for 2025 was initially forecast marginally below 2024 levels according to the USDA’s December 2024 outlook, conditions in the second half of the year have supported stronger-than-expected output in several key exporting regions. AHDB’s October review noted European milk production “roaring back to life in Germany and France,” helped by milder weather and those lower feed costs we’re all noticing.

Down in Oceania, New Zealand’s pasture-based sector has recovered from recent weather challenges. USDA and CLAL data show that from January to June 2025, New Zealand milk yields totaled 8.71 million tonnes—a 1.4% increase compared to 2024 —and June’s figures exceeded previous records thanks to favorable weather and early calving.

And then there’s the demand side—this is where it gets particularly interesting. China, which for years acted as the pressure valve for global skim and whole milk powder, is in a very different phase. Domestic raw milk output has increased while per-capita dairy consumption growth has slowed. Multiple industry analyses indicate that China’s stronger domestic production is constraining import demand for Oceania powders compared with earlier years.

Why does this matter? Because we don’t have the classic offset we’ve seen in other cycles. There isn’t a major drought knocking one exporter back, or a sudden demand boom somewhere else to soak up the surplus. From a farm-gate perspective, that’s worth careful consideration.

Three Reasons the Market Isn’t Self-Correcting

In the old pattern many of us remember—and I’ve watched a few of these cycles now—milk prices slid, feed stayed expensive, margins got squeezed, and the response was fairly quick: more culling, fewer fresh heifers, supply eased, prices stabilised in 9–12 months.

This time, three features are slowing that self-correction.

The Three Reasons at a Glance:

- Cheap feed is softening the blow—milk-to-feed ratios near 20-year highs

- Strong cull values create a false sense of “I can always sell later.”

- Contract structures delay price signals by weeks or months

Cheap feed is softening the blow

First up is feed. In many regions, it’s simply cheaper than milk has been for some time.

AHDB market commentary and UK advisory notes for 2025 show the milk-to-feed price ratio near multi-year highs. As AHDB analyst Susie Stannard noted in a June Dairy Reporter piece, feed costs are reasonable enough that the milk-to-feed ratio is at an almost 20-year high. AHDB’s Q2 review confirmed that although the ratio has declined very slightly, it remains near that 20-year peak.

In the US, the Dairy Margin Coverage programme’s income-over-feed margin has often sat just above the main payout triggers—not because milk prices have been spectacular, but because corn, alfalfa, and soybean meal backed off their 2022 peaks. Wisconsin and California producers report the same thing: feed’s cheap, so the cow still pencils out on paper.

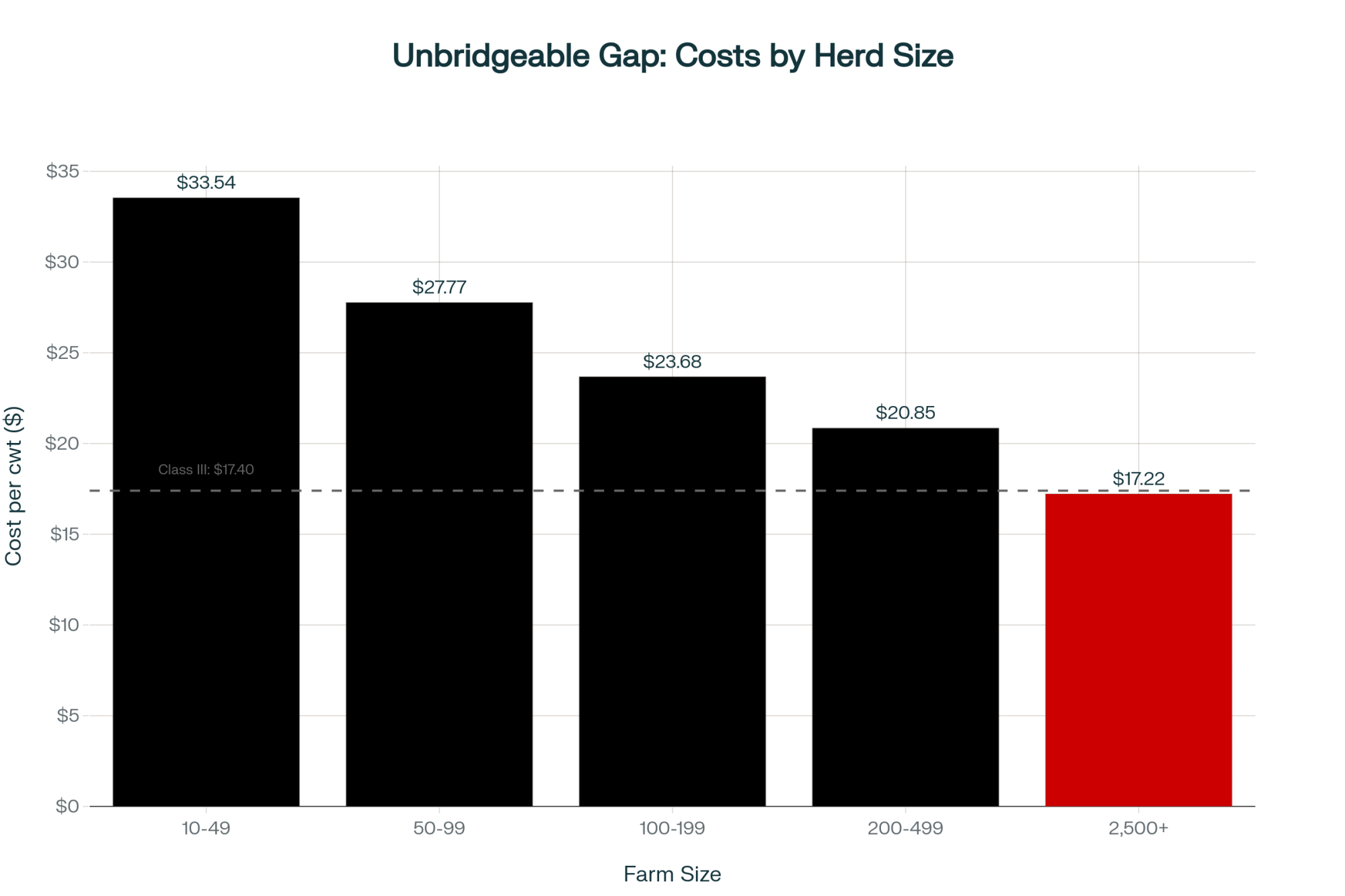

Here’s the thing, though. Extension economists at Wisconsin and other land-grant universities have pointed out something worth considering: this can make individual cows look better on paper than the whole business feels. A fresh cow might more than cover her ration and transition costs, but the farm still has to pay labour, power, interest, and machinery from a tighter cheque.

On many spreadsheets, the conclusion becomes, “The cow is paying her way, so we’ll keep her.” The risk? That spreadsheet is looking at feed, not the full cost of keeping that stall filled.

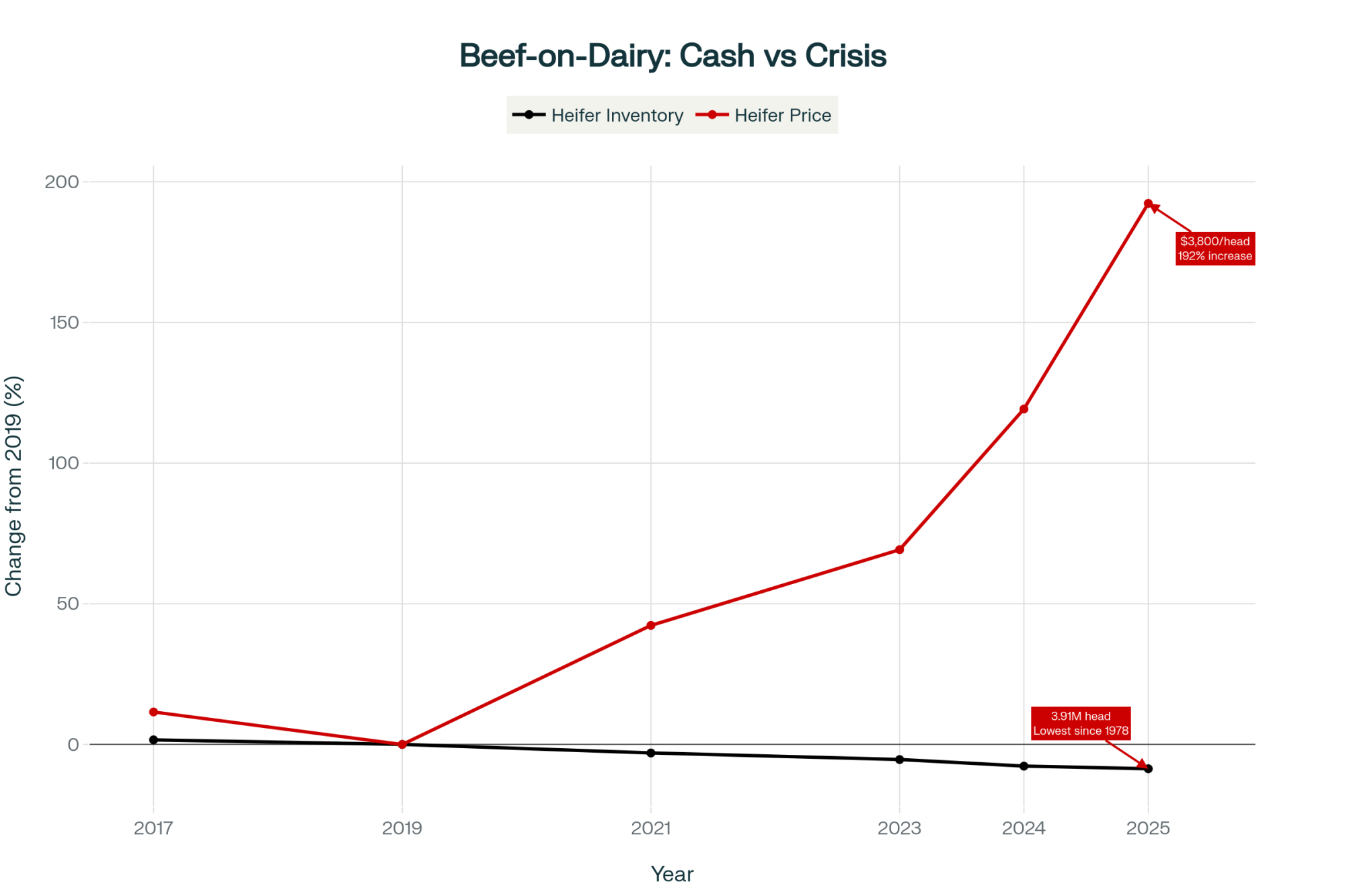

Strong cull prices create a false sense of security

The second feature is cull value—and this one cuts both ways.

UK beef and cull reports for 2025 show deadweight cow prices averaging around 420–450p/kg for much of the year. That’s well above long-term norms. North American reports tell a similar story: tight beef supplies and solid cattle prices have supported cull values through 2024 and into 2025.

Penn State Extension educator Michael Lunak made an interesting observation in a Dairy Herd article last autumn: the more a dairy can shift its culling from involuntary (injury, disease, breakdowns) to voluntary (strategic removal of low producers or problem cows), the more likely it is to be successful. As he put it, “Culling cows from the bottom of the herd makes room for more profitable cows.” He noted that typical overall cull rates around 35–37% aren’t inherently bad if more of those are strategic choices rather than forced exits.

From one angle, this environment makes culling a valuable financial tool. Every “passenger” cow you move today can generate more cash for feed bills, repairs, or debt reduction than she would have three or four years ago.

But there’s another side to consider: strong cull values can quietly encourage a mindset of, “If things really get bad, I can always sell a bunch of cows later.” If many producers end up thinking the same thing and time that “later” together, the exit door can get crowded quickly—and cull values can soften faster than anyone expects.

Contract structures delay price signals

The third factor lives in the milk contract—and this is something that’s evolved significantly over the past decade.

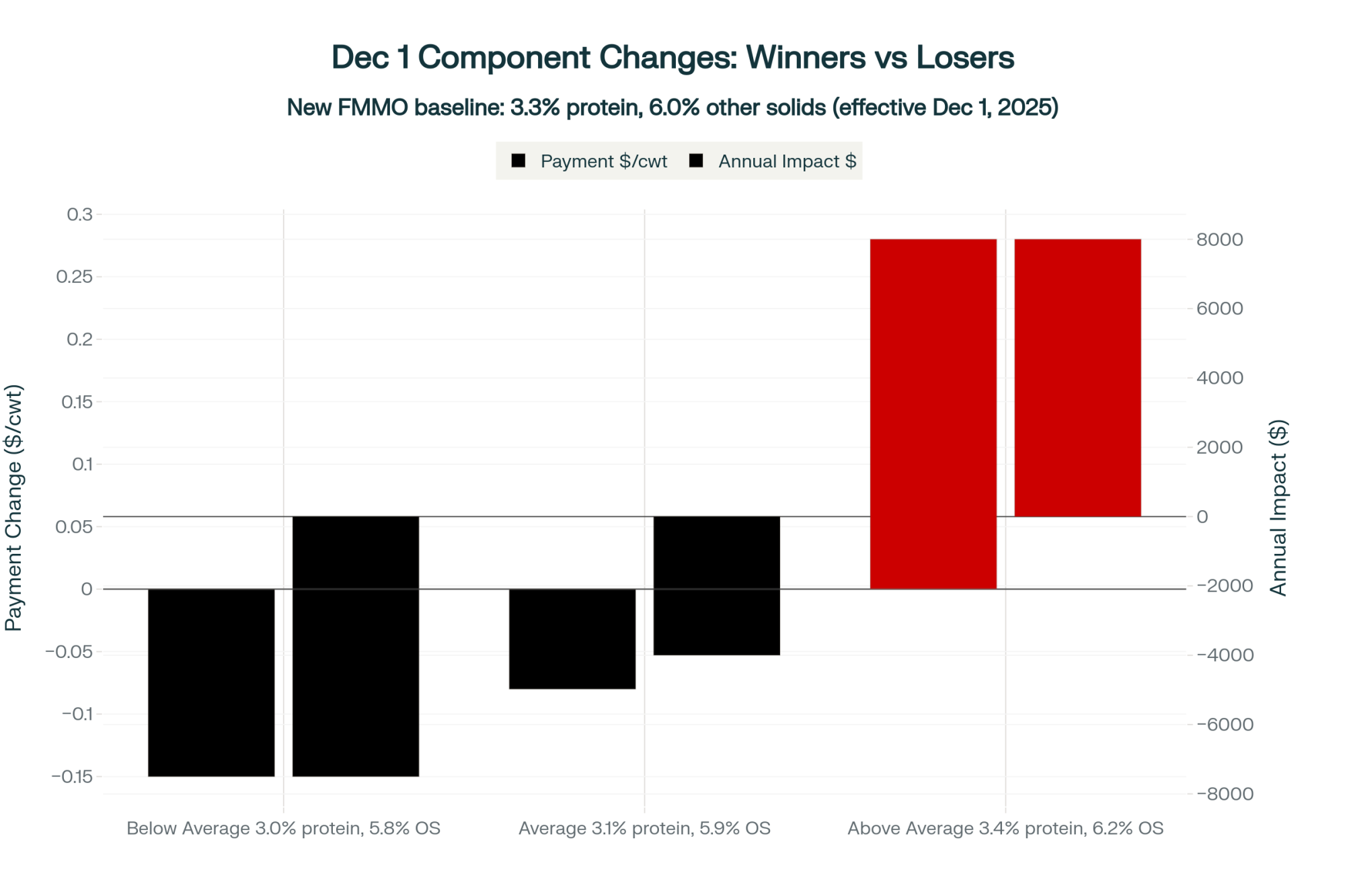

We’ve seen more UK and EU buyers move to deals that blend retail-aligned or cost-of-production-style pricing for a base volume, with A/B or similar structures for extra litres (where A is paid at the headline price and B is tied more closely to commodity returns).

Defra’s fair dealing rules and AHDB explainers go into how these contracts are meant to balance risk between buyer and producer while giving processors tools to manage surplus. In principle, that’s reasonable. In practice, it creates some timing challenges.

When markets are tight, B-litres can be a useful outlet. When butter, cream, and powder are under pressure, they can drop well below the cost of production. Farmers in GB and Ireland have reported that, in late 2025, B-milk, particularly powder, has at times been priced far below their overall costings—even while their A-price looked stable on paper.

The twist is timing. You make feeding, breeding, and fresh cow stocking decisions today; the milk cheque that fully reveals the effect of low-priced B-milk arrives weeks later.

A 2023 study on UK dairy price transmission, published in the journal Commodities, found that shocks at the farm level don’t always pass cleanly downstream, and that movements in one part of the chain often lag those in another. This builds on what researchers have observed for years: dairy supply is genuinely difficult to stabilise because of all these small delays and signals that don’t line up neatly.

Putting this all together, cheap feed, strong culls, and delayed contract signals go a long way toward explaining why barns are still full, even as global price indicators are flashing amber.

Lessons from the 2015–16 Dairy Crisis

To get a better handle on what might come next, it helps to look back at the 2015–16 EU milk crisis, when the end of quotas, steady supply growth, and weaker demand combined into a tough 18-month stretch for European producers.

Several independent studies and farm-business reviews have since examined which operations were more likely to come through that period intact. The patterns are fairly consistent—and they offer some useful guidance for today.

More milk from forage, less from the feed wagon

Research in agricultural economics journals found that European herds that got a larger share of their production from home-grown grass and silage tended to have lower and more resilient production costs.

Those farms could trim concentrate levels or push grazing and forage utilisation harder when prices dropped, without their output collapsing. By contrast, high-yield units where an extra 3,000–4,000 litres per cow were driven primarily by bought-in concentrates were more exposed. When milk prices dipped below the marginal value of that extra feed, the economics quickly stopped working.

Here’s what’s encouraging, though—this is something farmers can actually work on. Teagasc’s National Dairy Conference messaging in December 2025 reinforced that the strongest relationship with profitability in Irish grass-based systems isn’t milk per cow. It’s the grass utilised per hectare. About 40% of the variability in margin is explained by how much grass the farm grows and uses well.

That’s a powerful finding, and it applies beyond Ireland. Whether you’re running a grazing operation in the Southwest of England or managing a TMR system in the Midwest, the principle holds: the more of your milk that comes from home-grown feed, the more flexibility you have when prices tighten.

Lower fixed cash commitments

A second pattern was around capital structure—and this one deserves careful thought.

EU and national analysis showed that many farms which struggled the most had loaded up on new parlours, machinery, and buildings during the good years, and went into the downturn with high monthly finance payments. Those payments didn’t shrink when milk did.

Farms running older but paid-off kit (maybe with more workshop time and fewer shiny tractors) often had greater ability to cut back on non-essential spends without breaching covenants temporarily. Advisors who went through that period still talk about “machinery per litre” and “barn cost per stall” as critical resilience metrics.

I’m not suggesting anyone should avoid investment—modern facilities and equipment matter for efficiency and quality of life. But the timing and financing of those investments make a real difference when cycles turn.

Liquidity, timing, and fresh cow management

The third difference was liquidity and timing. Farms that entered the 2015–16 period with some cash on hand (or at least undrawn credit) and acted early tended to have more options.

Many of them did a “strategic shrink” in the first six months: they culled the bottom 10–15% of the herd while cull prices were still decent, used the cash to shore up their balance sheet, and ran the remaining cows harder and smarter.

Those who tried to “wait it out” with a full herd and no buffer were more likely to be forced to sell cows or land later, often at lower prices.

Producers who came through 2015–16 in good shape often note the same pattern: the cows they kept were the ones that freshened well and bred back. That wasn’t a coincidence—it was a strategy. Strong fresh cow management made every remaining stall more valuable, especially when the decision had been made to run fewer cows.

It’s worth saying: quotas and policy tools are different today, and climate rules add another layer. But the core operational lessons—milk from forage, sensible fixed costs, sound transition management, some liquidity, and willingness to adjust sooner rather than later—still apply.

Supply Chain Dynamics: Where Processors and Retailers Fit In

What farmers also notice, quite understandably, is that pain isn’t always evenly distributed along the chain.

Work on UK milk price transmission found that retail prices can be sticky on the way down. Wholesale and farm-gate prices may react more quickly to global markets than the price of a block of cheese or a pint of milk in the supermarket chiller. Similar studies on EU dairy supply chains have flagged that processor and retailer margins may widen for a time when farm-gate prices fall, until contracts and competition pull them back towards normal levels.

That can feel frustrating—and it’s a fair observation.

From a farm-level planning view, though, the practical takeaway is this: the fastest and most controllable levers are on your own side of the bulk tank.

Processors, retailers, and traders will make their adjustments, and there are legitimate pressures on them too (energy costs, labour, and environmental compliance). But those changes take time to filter back into milk prices. That’s why the rest of this piece focuses on what’s inside your control.

Strategic Herd Reduction: A Three-Step Framework

Farmers who came through previous downturns in reasonably good shape rarely talk about “chasing litres at all costs.” More often, they talk about tightening up the margin per cow and protecting cash.

In practice, that often started with a structured look at which cows were genuinely contributing and which were simply filling stalls.

The Three-Step Framework at a Glance:

- Pull the right data: DIM, pregnancy status, SCC trends, component yields, contract structure, feed costs

- Flag the passengers: Open/late cows, chronic SCC problems, repeatedly lame or problem animals

- Rank by value, not volume: Sort by fat+protein kilos, stress-test bottom 10–15% at B-milk prices

Here’s how to work through each step using your own recording data and a bit of quiet time at the kitchen table.

Step 1: Pull the right herd data

From your herd management software and milk recording, pull days in milk and pregnancy status for each cow, recent somatic cell count trends (at least the last three tests), and milk, fat, and protein kilos per cow over a consistent recent period—say the last 30 or 60 days. Also note your current contract structure, including any A/B litres and how B-milk is priced.

From your costings (AHDB’s Promar Milkminder in GB, Teagasc reports in Ireland, or university benchmarks in North America), have your latest feed cost per cow per day and an up-to-date estimate of the total cost of production.

This sounds basic, but you’d be surprised how many operations don’t have all of this in one place.

Step 2: Flag the obvious “passengers”

Next, make a first pass with clear rules that don’t require a calculator.

Look for cows that are open and late—any cow open beyond an agreed DIM threshold (say, greater than 150–200 days) with no clear breeding plan, particularly if she’s in her third or later lactation. Flag chronic SCC or mastitis cases—cows that have repeatedly tested over your bonus threshold and regularly drag the bulk tank toward penalty territory. Losing a quality bonus can be the difference between black and red ink. And note problem cows: repeatedly lame animals, three-quartered cows, dangerous or extremely slow milkers that add stress to every milking.

This ties back to Lunak’s point from Penn State: the more you can shift culling from involuntary to voluntary—strategic removal of low producers or problem cows—the more likely you are to improve herd profitability over time.

Mark these as “review candidates.” Once you see them all on one page, there are usually more than you expect.

Step 3: Rank by milk value, not just milk volume

This is where the conversation gets interesting. Instead of just looking at litres, shift to milk solids.

Many buyers in Europe, Oceania, and North America increasingly pay on fat and protein, and even where volume is still primary, higher-solids milk often has more value once it’s into cheese, butter, or powder.

Sort the remaining cows by fat plus protein kilos per day, not just litres. Identify the bottom 10–15% on that solids basis. Often, these are cows that look “good” because of fluid yield, but when you factor in components and feed, they’re not pulling their weight.

Now ask a simple “what if?” question for that bottom slice: if this milk were effectively priced at a lower B-price or spot value, would this cow still cover her feed and variable costs?

To stress-test, some advisers suggest modelling those cows at a conservative milk price consistent with recent B-milk or spot values (especially where powder and cream have come under pressure) and subtracting your current feed cost per cow. If the margin is tiny or negative, that animal is essentially being subsidised by her herdmates.

Industry commentary in Dairy Herd Management and Hoard’s has echoed this approach, noting that when herds go through their books honestly, a bottom 10–15% group almost always emerges that can be culled with surprisingly little impact on total milk revenue—and a meaningful impact on cash and labour load.

Worked Example: What a 10% Cull Actually Looks Like

Let’s put some rough numbers around this, because the concept is easier to grasp with specifics.

Take a 200-cow, year-round calving herd in GB or the northern US. Average yield: 32 litres per cow per day, 4.0% fat, 3.3% protein. Latest costings show feed cost at about £4.00 (or roughly $5.00) per cow per day, with total cost of production around 35–36p/litre or $18–19/cwt.

Suppose that, using the framework above, the farm identifies 20 cows that are late-open, chronically high in SCC, and at the bottom of the solids ranking. If those animals average 300 kg deadweight at around 430p/kg (consistent with recent UK cull averages from AHDB cattle data), the cull cheque comes to roughly £26,000 before costs.

Daily feed costs drop by about £80, or around £2,400 per month, plus a bit of saved parlour time, bedding, and transition management overhead.

Milk sold might fall by 500–600 litres per day, but if those were mainly low-solids, higher-risk litres that were pushing the farm into B-milk, the hit to revenue can be smaller than expected. In some A/B setups, that reduction in total volume can actually improve the average milk price by keeping more litres in the better-valued A-band.

Obviously, every farm is different. Some will decide to cull more, some less, and some not at all. The point isn’t the exact number. It’s that a small, strategic shrink can unlock both immediate cash and lower monthly outgoings without undermining the core of the herd.

Conversations with Your Banker and Nutritionist

What farmers are finding is that conversations with lenders, nutritionists, and accountants go better when they’re started early and anchored in numbers rather than gut feel.

A few questions that have come up again and again in advisory meetings this season:

“If milk averaged X pence per litre (or $Y/cwt) for the next 12 months, what would that do to our cash-flow and overdraft?”

“How many months of operating costs do we currently have in working capital or undrawn credit?”

“What happens to our covenants if we reduce cow numbers by 10–15% but improve margin per cow?”

“Are there any high-cost debts we can refinance to ease monthly pressure if prices stay only average through 2026?”

These aren’t comfortable conversations. But they’re far better to have now, when you have options, than later when you don’t.

On the nutrition side, advisers are encouraging herds to look at whether they’re still feeding “for the cheque they had last year” or for the one they have now.

That might mean trimming some additives, shifting emphasis slightly from maximum litres to steadier components, or matching rations more tightly to groups (fresh cows versus late-lactation) to squeeze a bit more efficiency out of each tonne of silage and concentrate.

Strong fresh cow management—keeping transition problems, culls, and early deaths down—also shows up in the research as a major driver of both animal welfare and long-run profitability. Healthy, well-transitioned cows are far more likely to make it into that top tier of solids producers that you really want in the barn.

In Canada, supply management and quota systems buffer much of the day-to-day price volatility, but even there, Dairy Farmers of Canada and Farm Credit Canada have noted that tighter returns and changing product mixes are placing greater emphasis on cost control, milk quality, and component yield per kilogram of quota. The efficiency conversation is happening everywhere, even where prices are more stable.

Risk Management: Insurance, Not Speculation

Risk-management tools—such as fixed-price contracts, futures, and options—often spark mixed reactions. Some producers have used them for years; others have had experiences that make them cautious.

Recent guidance from university and industry economists is fairly consistent: treat these tools as insurance against very bad prices, not a way to outguess the market.

In practice, that might look like locking in or insuring a portion of expected milk at a level that, when combined with your costings, at least covers feed, routine bills, and a realistic debt payment. It means accepting that you won’t hit the exact top—the win is not being forced to sell all your milk at the bottom. And it means matching hedge volumes to your realistic production after any planned culling or stocking changes, so you aren’t over-hedged and tied to volumes you might not ship.

In Europe, some processors now offer fixed-price pools or index-linked contracts that can serve a similar purpose for farmers who are uncomfortable with direct futures trading. In New Zealand, Fonterra and others have rolled out fixed milk price schemes and options that are increasingly used as planning tools rather than speculation.

The common thread is using these tools deliberately, as part of a broader risk plan, not on a hunch.

What’s interesting is that when you talk with operations that have come through choppy periods in decent shape, they rarely say “hedging saved us.” They more often say “hedging helped us sleep at night while we did the real work on costs, cows, and grass.”

Wildcards: Weather, Disease, and Policy

It’s also fair to say that models and forecasts only get us so far. Weather, animal disease, and policy can all quickly tilt the board.

Recent years have reminded us how regional droughts, wet harvests, or mild winters can turn forage plans upside down and push more or less milk into the system than expected. Animal health issues—from mastitis pressure in wet housing to broader concerns like avian influenza affecting dairy operations in some regions—can affect both productivity and trade flows. Policy changes related to climate, trade, or support programmes can also alter incentives. The EU’s ongoing environmental targets are one example; Canadian quota policy and US farm bill debates are another.

All of that is a long way of saying: your plan for 2026 doesn’t need to be set in stone. It does, though, help to have a plan—and to revisit it a couple of times a year as new information comes in.

The Bottom Line

Pulling this together, a few practical lessons seem to be emerging from both the current data and the 2015–16 experience.

We’re probably in a longer phase, not a quick dip. Multiple exporters are growing at once while major buyers like China are more cautious, and outlooks from AHDB, USDA, Teagasc, and others still point to comfortable supplies into 2026. Building plans that assume a full, rapid rebound may be optimistic.

Cheap feed and good cull values are helpful but can mask underlying stress. They make it possible to carry marginal cows longer and delay decisive action—which works out fine if prices turn up quickly, but creates risk if they don’t.

Margin per cow is a better guide than litres per cow. Whether you’re on pasture-based grass systems or TMR in a freestall or dry lot, the herds that consistently earn room to reinvest tend to know their milk-from-forage numbers, watch solids, manage fresh cows carefully, and think in terms of margin rather than volume.

Liquidity and flexibility buy options. Cash in the bank, undrawn credit, and manageable fixed payments give breathing space when prices wobble or fresh cow problems crop up. It’s often the lack of liquidity—not a single bad month—that forces hard decisions.

There’s no single “right” answer. For some, the best move is to tighten the belt, trim the bottom of the herd, and ride this out. For others—especially where succession is unclear, or debt is heavy—an orderly, thought-through exit while cow and land values are still decent might be the wiser route. Either way, it’s better to make that choice on your own terms than have it made for you.

What this oversupply episode is really doing is pushing every dairy business—big or small, housed or grazing-based—to ask a simple but important question:

What do we actually want this farm to look like in five years, and what steps today move us towards that rather than away from it?

There’s no template, and there’s no shame in different answers. The common thread is taking a hard, honest look at numbers, cows, and goals—and then making changes while you still have room to manoeuvre.

KEY TAKEAWAYS

- The cheap feed trap is real: Milk-to-feed ratios near 20-year highs make every cow look profitable—masking a global oversupply that won’t self-correct

- Margin per cow beats litres per cow. Every time. Farms that survived 2015-16 knew this and acted early, before options disappeared

- Find your passengers: Late-open cows, chronic SCC cases, and low-component producers are quietly being subsidized by your best animals

- Have the hard conversations now: Model cash flow at lower prices. Stress-test your covenants. Your banker would rather hear your plan than your panic

- The exit window is open—but not for long: Today’s strong cull prices are an opportunity to act, not a reason to wait. If everyone sells later, that door closes fast

Complete references and supporting documentation are available upon request by contacting the editorial team at editor@thebullvine.com.

Learn More:

- The True Cost of Raising Heifers: Are You Raising Too Many? – Breaks down the hidden impact of heifer inventory on farm liquidity and demonstrates how reducing heifer numbers can free up working capital without sacrificing future production potential—a key tactic for the “Strategic Shrink.”

- Beef on Dairy: The Golden Ticket? – Provides a strategic analysis of the beef-on-dairy market, offering producers methods to maximize the value of their lower-ranking animals and leverage the “strong cull values” mentioned in the main article to create a second, reliable revenue stream.

- Why Genomics is the Best Investment You Can Make – Delivers the technical “how-to” for the article’s Step 3: Rank by Value, showing how to use genomic data to accurately identify the bottom 15% of the herd that drains profit, ensuring you are culling the right cows for the right reasons.

Join the Revolution!

Join the Revolution!

Join over 30,000 successful dairy professionals who rely on Bullvine Weekly for their competitive edge. Delivered directly to your inbox each week, our exclusive industry insights help you make smarter decisions while saving precious hours every week. Never miss critical updates on milk production trends, breakthrough technologies, and profit-boosting strategies that top producers are already implementing. Subscribe now to transform your dairy operation’s efficiency and profitability—your future success is just one click away.

Join the Revolution!

Join the Revolution!