Master the 90-second milking rule that’s earning smart dairies $126,000—no robot needed.

So I was walking the aisles at World Dairy Expo last month, and what really got me was how nearly every booth was pushing some kind of automation as the solution to all our problems.

That same trip, I stopped by a 250-cow operation near Fond du Lac. The milkers were rushing through prep in maybe 45 seconds—when we all know biology needs closer to 90. Meanwhile, the owner’s shopping for robots while potentially leaving $126,000 in annual production sitting right there in the parlor.

What’s interesting is that Cornell just released its 2024 Dairy Farm Business Summary, which backs up something I’ve been noticing for a while now. The gap between farms that are making it and those that aren’t? It’s not really about who has the newest equipment.

The Numbers That Tell the Real Story

Cornell’s latest data is eye-opening. Top farms in New York are running at $15.79 per hundredweight in operating costs. The bottom ones? They’re hitting $22.32.

That’s a $6.35 gap between similar-sized operations with pretty much the same technology.

You’ve got 500 cows producing 25,000 pounds annually? That efficiency gap is worth about $79,000. Not from buying new equipment—just from doing what you’re already doing better.

Brazilian researchers looked at 378 dairy farms adopting precision technology—published their findings in the Animals journal back in 2021. About a large share of adopters reported limited realized benefits, underscoring that adoption alone didn’t guarantee performance gains. But you know what? The farms that just focused on nailing their basic protocols? They saw returns right away without spending anything on new gear.

I’ve been talking with producers out in California lately, and down in Georgia too, and they’re telling me the same story—dropped hundreds of thousands on cooling systems or new facilities before realizing the real problem was inconsistent feeding schedules. Different climate, same underlying issue.

And you know what’s interesting? Even operations in New Zealand—where they’re dealing with completely different grazing systems—are finding the same thing. It’s not about the technology. It’s about the execution.

“Farmers think they’re buying free time. They’re really just buying different obligations.”

Five Questions Before Writing That Technology Check

□ Have we actually put a dollar figure on what our problems are costing us right now?

□ Are we in the top 25% for how well we’re doing what we’re already doing?

□ Is this technology going to help us stand out in the market, or just make us slightly better at commodity production?

□ Do we have people who can actually run this stuff, or are we hoping to find unicorns?

□ Can we hit 15% returns and still have money in the bank for when things go sideways?

Why Those 90 Seconds Matter More Than You Think

You know how crazy it gets during second cutting—everybody’s rushing. But here’s the thing: oxytocin doesn’t wait for us.

UW–Madison tracked 16 farms and found and what he found shouldn’t surprise anyone who’s been around cows. Farms that hit that sweet spot—60 to 90 seconds between first touch and unit attachment—they’re getting 4-6% more milk.

Not from better genetics. Not from fancy supplements. Just from timing it right.

And here’s something else—it matters whether you’re milking Holsteins or Jerseys. Jerseys tend to let down a bit quicker, maybe 10-15 seconds faster on average. But the principle’s the same.

THE GOLDEN WINDOW: Your 90-Second Milking Protocol

What’s all this worth? Well, let me walk you through the math.

On 500 cows averaging 75 pounds daily, even a conservative 5% bump from proper timing gets you about 1,875 extra pounds per day. The current Base Class I price was $18.21/cwt, according to the USDA’s latest market report.

Do the math—that’s about $126,000 a year. From timing. Not technology.

Beyond volume, research shows proper stimulation timing can lift butterfat percentages and lower SCC—quality bonuses most dairies leave on the table.

Penn State Extension has been looking at training on farms, and in most operations they’ve studied, formal training is pretty sparse. Workers are mostly learning from whoever was there before them. It’s like a game of telephone where everybody loses.

What’s worse is that during planting and harvest—protocol drift accelerates when everybody’s pulled in different directions.

Two Roads Diverged in a Dairy Farm

Extension folks across the Midwest have been tracking different approaches to technology adoption, and the patterns they’re seeing are crystal clear. Let me share what they’ve found—these are representative cases, not specific farms, but the numbers are real.

The “All-In” Approach

Farms facing typical challenges—about 30% turnover, $21/cwt costs, 220,000 somatic cells—often buy everything. Based on what dealers are charging these days:

- Robotic system: $495,000

- Barn retrofit: $75,000

- Automated feeding: $52,000

- Health monitoring: $38,000

Total: $660,000

But here’s what Minnesota’s research tracking these systems shows: you don’t eliminate labor—you change it. Instead of paying $15/hour for milkers, you’re paying $25-30/hour for technicians. And good luck finding them.

Production gains? University studies show 2-3% is realistic, not the 7% dealers promise.

Annual debt service: $30,00 to $100,000

Actual benefits: $65,000 to $100,000

Net result: $35,000

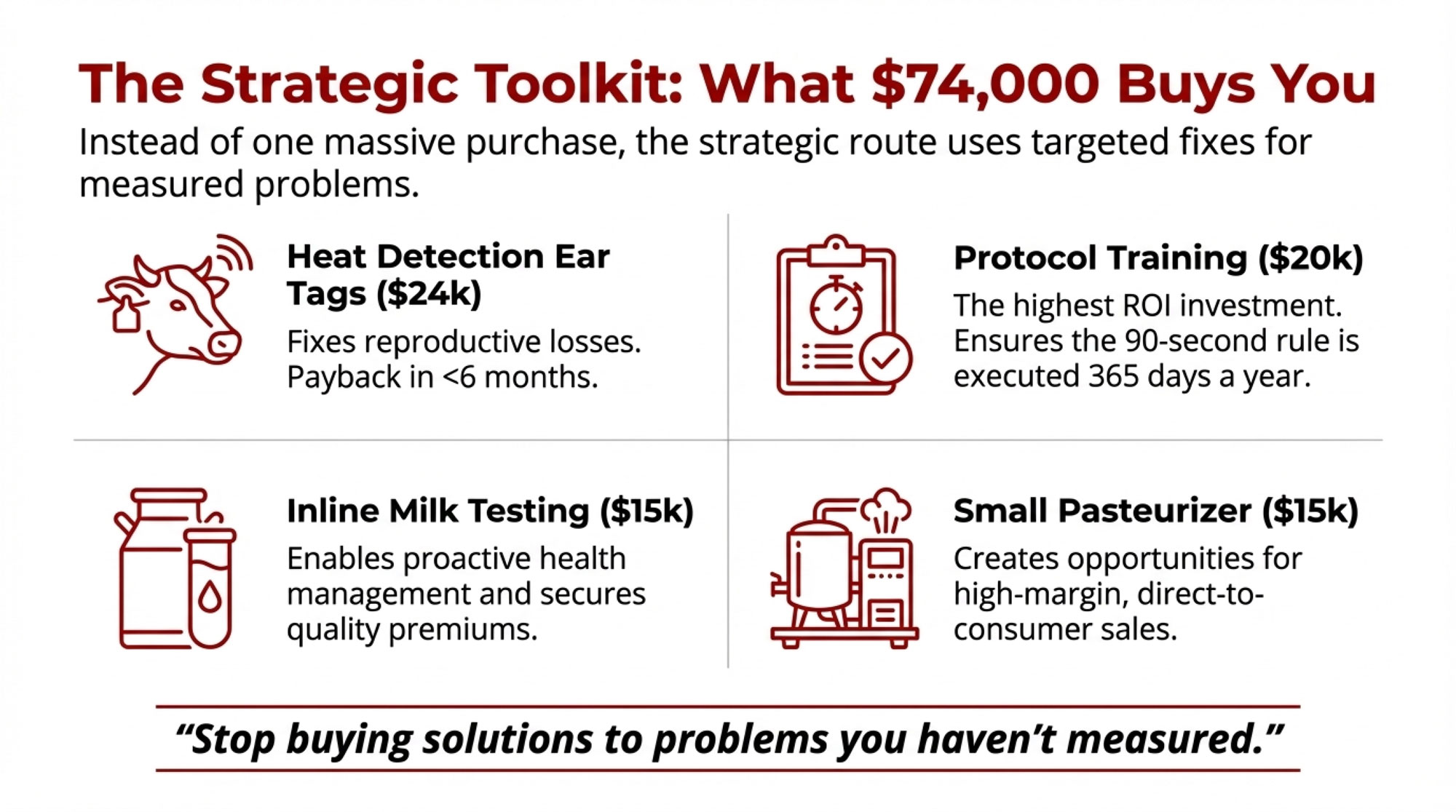

The Strategic Route

Now, I’ve seen farms take a different approach. Same problems, but they ask, “What’s actually costing us money?”

Strategic investments based on Extension case studies typically look like this:

- Heat detection ear tags: $24,000 (fixes quantified reproduction losses)

- Inline milk testing: $15,000 (enables premium capture)

- Protocol training: $20,000 (the one nobody talks about)

- Small pasteurizer: $15,000 (direct sales opportunity)

Total: $74,000

What happens? Based on composite results from university tracking, conception rates jump from mid-40s to low 60s. Training delivers 4-5% more milk. Cornell and UVM data show that organic premiums add $250-$300 per cow. Direct sales can bring $70,000-85,000 from just 15% of production.

“Stop buying solutions to problems you haven’t measured.”

YOUR 4-PHASE IMPLEMENTATION ROADMAP

Phase 1 (Months 1-3): Get Brutally Honest

- Independent assessment: $5,000-8,000

- True cost of production analysis

- Problem quantification in dollars

Phase 2 (Months 4-7): Fix the Basics

- Training & protocols: $15,000-25,000

- Expected returns: 1,500% first-year ROI

- No conference sponsorships, just results

Phase 3 (Months 8-12): Pick Your Lane

- Top-25% commodity efficiency?

- Organic/specialty markets?

- Agritourism opportunities?

Phase 4 (Year 2+): Strategic Technology

- Only if problems cost more than solutions

- Only if it enables differentiation

- Only if you have the workforce

- Only if a 15% ROI is achievable

ROI COMPARISON: The 300% Difference

| Investment Approach | All-In Automation | Strategic Technology |

| Total Investment | $660,000 | $74,000 |

| Annual Returns | $65,000 | $200,000-250,000 |

| Net Annual Result | $35,000 | $150,000 |

| ROI | 9.8% | 300% |

These are representative outcomes based on Extension case studies—your results will vary

What Really Happens to Your Labor

Finnish researchers looked at this back in 2016, and Marcia Endres at Minnesota has been tracking it ever since. Yeah, milking time drops from 5 hours to 2. But you know what shows up instead?

Watching screens. Midnight alarms. Tech support holds. Being on call 24/7.

As Marcia says, “Farmers think they’re buying free time. They’re really just buying different obligations.”

You’re not replacing a $15/hour milker with nothing. You’re replacing them with a $25-30/hour technician—if you can find one who wants to live in rural Wisconsin and answer their phone at 2 AM.

The Canadian Agricultural HR Council says we’ll be 1,000 workers short by 2029, with a third of our current people ready to retire. But robots need fewer people with way more skills. So we’ve got workers who can’t do tech work and tech workers who don’t want to live where the cows are.

Any of us who’ve gotten that 2 AM robot alarm knows what I’m talking about.

Small Doesn’t Mean Dead—It Means Different

USDA tells us we lost 15,221 dairy farms between 2017 and 2022—that’s 39% gone. And when you see big farms running at $17/cwt while small farms face $33/cwt according to the USDA’s Economic Research Service, it looks pretty hopeless for the little guys.

But here’s something interesting—a small minority—maybe 10% based on ERS estimates—are actually making money despite their small size. How?

Three approaches that work:

Elite execution: I know of operations in places like Skagit County, Washington, running under 200 cows at under $18/cwt with 50+ cows per worker. It’s exhausting, but it’s possible.

Finding your niche: Cornell’s 2024 organic dairy tracking shows certified farms pulling $250-300 extra per cow. Vermont’s been watching this for a decade—100-cow organic dairies making money while their conventional neighbors go under.

Down South, producers in Georgia and Florida tell me that being the only dairy for 200 miles creates automatic premiums. Geography becomes an advantage. And operations at 5,000-8,000 cows—not quite mega-scale but bigger than most—they’re finding automation sweet spots that work at their size.

Smart technology: Not robots. Targeted fixes. $25,000 for heat detection to prevent your reproductive disaster. $15,000 on milk quality monitoring to qualify for premiums. Not $665,000 on a robot hoping to fix everything.

Where Do We Go from Here?

So here we are. Milk costs around $20, feed eating 60% of revenues according to Penn State’s 2025 outlook, and they can’t find good help. The temptation to buy your way out is real.

But the farms thriving keep proving the same thing: doing the basics really well beats fancy equipment almost every time.

Most of us have $100,000-plus sitting right there in the parlor. It doesn’t need financing. It doesn’t need a technician from three counties away. It just needs us to do what we already know how to do, consistently.

Looking ahead, some interesting opportunities are developing. Programs like USDA’s Climate-Smart Commodities are paying $20-50 per cow for verified carbon reductions. Processors like Danone, through its “Dairy Farmers of Tomorrow” program, and Nestle, through its Net Zero Roadmap, offer select benefits as well as some offer contracts with $0.50 to $1.00/cwt sustainability premiums—though these are limited and require specific documentation.

These aren’t about technology. They’re about management and documentation—rewarding what good farmers already do.

Your cows don’t care about robots. They care about those 90 seconds before you put the milker on. They care about eating at the same time every day. They care about someone noticing when they’re in heat.

Maybe we should care about the same things.

Because with 39% of farms gone in five years, what separates survivors from statistics isn’t who bought the most technology. It’s who got the basics right first, then used technology strategically to make good even better.

The path forward isn’t in the dealer’s catalog—it’s in doing what we already know works, day after day after day.

That’s not what gets the spotlight at Expo. But when you look at who’s still milking versus who’s having an auction, it’s the story the numbers keep telling.

Key Takeaways:

- The 90-second milking rule is adding $126,000 a year to smart dairies—no robots required.

- Farms chasing automation before fixing fundamentals lose money twice—on milk and on debt.

- Precision routines and trained teams outperform half-million-dollar robots every time.

- Targeted fixes—heat detection, training, timing—average 300% ROI without new equipment.

- Dairy’s next winners aren’t high-tech—they’re high-discipline.

Executive Summary:

Dairy’s future isn’t being built by robots—it’s being rebuilt by precision. According to Cornell’s 2024 Dairy Farm Business Summary, top operations outperform neighbors not through automation, but through disciplined execution. The research is clear: a well-timed 90-second milking routine can deliver 4–6% more milk and more than $126,000 in extra revenue annually—without buying a single new machine. Meanwhile, farms chasing automation often trade labor headaches for technical ones while falling behind on fundamentals. Cornell, UW-Madison, and Penn State all point to the same truth: technology multiplies skill—it can’t replace it. In a volatile milk market, the smartest dairies in 2025 aren’t betting on gadgets. They’re doubling down on training, timing, and teamwork that pay real dividends.

Complete references and supporting documentation are available upon request by contacting the editorial team at editor@thebullvine.com.

Learn More:

- 42% Heritability: The Milking Speed Breakthrough That Fixes Your Labor Problem – Reveals how selecting for Milking Speed (MSPD) complements your parlor protocols to eliminate bottlenecks. Discover how aligning genetics with your 90-second routine can save an hour of labor daily while improving udder health.

- Decide or Decline: 2025 and the Future of Mid-Size Dairies – Provides a strategic roadmap for the “squeezed” mid-size operation. Analyzes the financial realities of 700-1,200 cow herds and details three specific survival paths—expansion, optimization, or niche marketing—that define profitability in the current market.

- Robotic Milking Revolution: Why Modern Dairy Farms Are Choosing Automation in 2025 – Examines the labor crisis driving automation and offers a realistic ROI analysis for robotic adopters. Learn how successful farms achieve a 5-7 year breakeven by treating automation as a comprehensive labor strategy rather than just a technology purchase.

Join the Revolution!

Join the Revolution!

Join over 30,000 successful dairy professionals who rely on Bullvine Weekly for their competitive edge. Delivered directly to your inbox each week, our exclusive industry insights help you make smarter decisions while saving precious hours every week. Never miss critical updates on milk production trends, breakthrough technologies, and profit-boosting strategies that top producers are already implementing. Subscribe now to transform your dairy operation’s efficiency and profitability—your future success is just one click away.

Join the Revolution!

Join the Revolution!