You paid half a million for the robots. The data they collect? That belongs to someone else.

Executive Summary: You paid $500,000 for robots, but the vendor owns your data—and wants $30,000 to give it back when you retire. This is the hidden crisis hitting Canadian dairy: producers discovering they don’t control the breeding records, health data, or management protocols they’ve built over decades. While the technology works brilliantly (saving 5+ hours weekly, catching mastitis days earlier), contracts grant vendors permanent rights to aggregate and sell your information back to feed companies and consultants. Mid-size farms (200-500 cows) face the worst squeeze—too big for simple systems, too small for automation economics, locked into 8-10 year paybacks they can’t escape. Before signing anything, get written answers on three things: exit costs, data access rights, and succession provisions. Your breeding data is generational wealth—don’t let fine print hold it hostage.

You know that moment when a producer realizes they’re not just passing a farm to their kids, but also a ransom note from their software provider? That’s what’s happening across Canada right now. The cost to unlock 20 years of breeding data for succession? I’ve heard figures as high as $28,000.

That’s not a typo. According to ag lending specialists at Farm Credit Canada and other major banks I’ve spoken with, data migration costs during farm transitions now range from $5,000 for basic exports to over $25,000 for complex system conversions. And when quota’s already at $24,000 per kilogram in Ontario, according to the November 2024 DFO Markets Report—with Western Milk Pool values creating massive barriers for young farmers out west—well, these unexpected data transfer costs really sting.

When Digital Integration Works (And When It Doesn’t)

Here’s the thing about the International Dairy Data Exchange Network, launched in late 2020 with Lactanet leading the charge. According to iDDEN’s own reporting, they’ve now got over 200,000 herds across fifteen countries connected. And you know what? The technology actually works pretty well.

University extension research consistently shows that we’re saving several hours per week on data management. Health monitoring systems? They’re catching issues days earlier than we’d spot them manually—especially mastitis, which anyone who’s dealt with knows is worth catching early. Farm management specialists in Western Canada have noted that producers using fully integrated platforms report significant time savings and substantial reductions in treatment costs based on 2024 Western Canadian veterinary fee schedules.

The system creates this common language so your DeLaval VMS can talk directly to Lactanet’s genetic evaluation system, which shares with your nutritionist’s software. According to industry announcements, the major equipment companies all formalized their iDDEN connections between late 2022 and 2023—DeLaval in March 2023, GEA in December 2022, and Lely in September 2023.

But here’s what gives me pause. DataGene mentioned in their recent documentation that consent management trials are still being evaluated through mid-2025. Think about that… we’re five years in, and they’re still figuring out how we control who sees our data.

The Brutal Math of Scale

You probably already sense this, but the economics vary dramatically with herd size. The USDA Economic Research Service’s 2024 report shows precision dairy technology adoption at 72% for farms with 1,000 or more cows, 48% for farms with 200-999 cows, and just 31% for farms with fewer than 200 cows.

What I’m seeing in Eastern Ontario matches this exactly. Take a typical 650-cow operation investing $1.3 million in four robots plus automated feeding. First-year benefits? Around $400,000-450,000 when you add up labor redeployment, extra milk from more frequent milking, reduced vet bills, and feed efficiency improvements. They’re looking at five-year payback, maybe less if milk prices hold.

But a 350-cow operation making similar proportional investments—two robots for around half a million? The per-cow benefit drops significantly. Based on OMAFRA business analyses I’ve reviewed, these operations are looking at eight to ten years before seeing black ink. That’s a tough pill to swallow.

Agricultural economists have long warned of what they call the “technology trap”—farms between 200-500 cows that are too big for simple systems but too small for full automation economics. And that’s a lot of Canadian dairy farms right there.

The Fine Print Nobody Reads Until It’s Too Late

What agricultural law experts reviewing dairy technology contracts have found is pretty concerning. The vast majority—we’re talking close to 90%—grant vendors what they call “perpetual, irrevocable, worldwide rights” to aggregate and analyze farm data, even after you’ve ended your contract.

Consider this typical scenario from Oxford County. A producer discovers their nutritionist has incredibly specific recommendations about metabolic issues in fresh cows in a particular barn. How’s an outside consultant know about location-specific problems? Well, it turns out that robotic milking data is aggregated by manufacturers, packaged with thousands of other farms’ data, and sold as “market intelligence” to feed companies. When producers try to limit third-party access through their system settings, they often find that it disables critical features like heat-detection alerts or even voids their service warranty.

It’s essentially holding your own operational data hostage.

What the Nordic Countries Got Right

Now this is interesting. Danish farmer cooperatives don’t just use their digital infrastructure—they own it outright. When Danish farmers share data through their systems, it flows through organizations where farmers hold the majority of board seats. That’s a completely different power dynamic.

EU Data Act vs Canada Dairy Rights

| Criteria | EU (2024 Data Act) | Canada (Current) |

| Data portability | 30-day mandatory, by law | Export only if vendor agrees |

| Deletion rights | Guaranteed, enforced | No legal guarantee |

| Consent for new uses | Explicit, must be granted | Vendor controls consent |

| Succession protections | Legal transfer to new owner | Not specified, risky |

| Vendor override ability | Disallowed | Allowed, vendor can override contract |

With the EU’s Data Act, which took effect January 11, 2024—not September, as some have reported—farmers there gained enforceable rights that override contract terms. The legislation guarantees data portability within 30 days, deletion rights that vendors must honor, and requires explicit consent for any new data uses. Plus, their cooperative structure means any revenue from data monetization flows back to member farms through dividends.

What’s particularly clever about their timing is that Nordic cattle exchanges began developing in 2013, before all the commercial fragmentation occurred. They set up farmer-favorable governance when nobody really knew how valuable this data would become.

Meanwhile, here in Canada? Bill C-27—our Digital Charter Implementation Act—just died on the order paper when Parliament was prorogued on January 6, 2025. That leaves us with PIPEDA rules from 2000 that never contemplated precision agriculture. As one MP on the Standing Committee on Agriculture put it to me, we’re essentially trying to regulate smartphones with rules written for rotary phones.

Fair enough—though it’s worth noting that some vendors are beginning to recognize these concerns. Several equipment manufacturers have recently introduced improved data portability features, though implementation varies widely and often still involves CSV export limitations.

The Succession Planning Nightmare

Here’s where it gets really challenging for farm families. I’ve been hearing similar stories across the country. Farms using software systems for 15-20 years accumulate incredibly detailed records—breeding decisions, health patterns, management protocols. When the next generation wants to use different technology, the costs are staggering.

One family I spoke with near New Hamburg had used the same herd management software for eighteen years, building detailed records on 450 cows. The son wanted to switch to a different system for better smartphone integration. The quote to export their historical data? Nearly $5,000. Converting it to work in the new system? Another $8,000-10,000. Training and setup? Add another few thousand. We’re talking $15,000-20,000 just to keep using their own information.

Ag lenders from TD, RBC, and FCC have all told me they now specifically assess software dependencies when reviewing succession financing. Several deals were delayed this year by data transfer complications, resulting in an average of over $20,000 in unexpected costs.

Data Migration Costs by Farm Size

| Cost Category | Small Farm (under 200 cows) | Mid-Size (200-500 cows) | Large (500+ cows) |

| Export Fee | $3,000 | $5,000 | $7,000 |

| Conversion Fee | $5,000 | $10,000 | $18,000 |

| Training/Onboarding | $2,000 | $5,000 | $8,000 |

| Total Estimated Cost | $10,000 | $20,000 | $33,000 |

Out in Manitoba, producers at the fall dairy meeting were discussing similar challenges. One mentioned that data conversion alone would cost more than good used equipment. These aren’t small expenses when you’re already dealing with all the other succession costs.

Three Questions That Save Your Farm

Before you sign anything, get these answers in writing:

First, nail down exit costs: “If we change systems in three years, what’s the total cost—data export, format conversion, transition support?” If you get vague responses about “reasonable fees,” that’s a red flag. Get specific numbers.

Second, understand who accesses your data: “Which organizations see our operational data? For what purposes? How do we modify permissions?” Watch especially for words like “perpetual” and “irrevocable.”

Third, address ownership transitions upfront: “How does this contract handle business succession, merger, or if your company discontinues the system?”

Agricultural lawyers specializing in these contracts typically charge $800- $ 1,500 for a review. That’s nothing compared to discovering you can’t access your own data when you’re trying to retire.

Farmers Fighting Back

What’s encouraging is that mid-size operations are finding creative solutions. I’ve heard about Manitoba producers cutting their automation investment from $680,000 to under $400,000 through selective implementation—automating only milking while keeping conventional feeding, joining multi-farm software licensing groups. They’re capturing most of the efficiency gains at a fraction of the cost.

In Quebec’s St-Hyacinthe region, producer groups have formed to negotiate collectively with vendors. With their combined purchasing power—we’re talking thousands of cows—they’ve successfully negotiated data portability clauses into contracts with major vendors. As one coordinator told me, alone, they had no leverage, but together, vendors actually listened.

Organizations are starting to pay attention too. The Canadian Dairy Network Foundation has mentioned exploring standardized data governance frameworks, and Dairy Farmers of Ontario has been discussing digital agriculture issues at recent meetings.

Making It Work for Your Operation

Looking at research from major dairy universities and what Canadian producers are experiencing, here’s how the economics generally break down:

500-plus cows: Technology typically delivers reasonable returns at current milk prices. Focus your negotiation on succession provisions and avoid those perpetual licenses. DFO has contract-review resources on its website worth checking out.

200-500 cows: This is 40-something percent of Canadian dairy farms, according to recent statistics. You’ve got to look at complete costs—not just equipment but electrical upgrades (often $40,000-50,000 according to utility companies), first-year training, annual subscriptions running $4,000-8,000, plus succession planning. Group purchasing through cooperatives can knock 15-20% off costs.

Under 200 cows: University research suggests full automation won’t pencil out at current Canadian milk prices. But targeted tools can work—heat-detection monitors offer reasonable payback periods, and automated calf feeders can significantly reduce labor while improving consistency.

The Bottom Line

Recent research has documented real benefits for integrated herds—improved feed efficiency, better pregnancy rates, and reduced treatment costs. The technology itself works brilliantly.

But the contract structures? They heavily favor vendors over producers. And you know what? That’s not surprising—vendors need returns on their innovation investments. The issue is that the balance has tilted too far.

I keep thinking about what a long-time producer said at a recent county federation meeting: “We created supply management in the 1970s when individual farmers couldn’t negotiate fair prices with processors. Today’s data situation feels awfully similar.”

He’s got a point. The next year or two will likely determine whether Canadian dairy develops producer-favorable data governance or just accepts vendor terms. Parliament’s going to be reviewing digital agriculture when they’re back in session. Provincial organizations are mobilizing. Your voice matters here.

Stop signing contracts you haven’t read. Stop letting vendors treat your data like their property. Stop accepting “that’s just how it works” as an answer.

You own the cows. You own the quota. You damn well better own the data.

Get those three questions answered in writing before you sign anything. Join or form a producer group in your area if you can. Push your provincial organization to take this seriously.

Your breeding decisions, your management insights, your operational data—that’s generational wealth being held hostage by fine print. Time to take it back.

Key Takeaways

- Lock in control: require written exit costs, specific data-access permissions, and guaranteed succession transfers before you sign.

- Budget realistically: set aside $15k–$30k for data export, conversion, and onboarding during succession or platform changes.

- Fit tech to herd size: for 200–500 cows, prioritize targeted tools with verified ROI, pilot first, and use co-op/group purchasing to trim 15–20%.

- Use proven guardrails: EU-style rights—30‑day portability, explicit consent for new uses, and deletion—are practical protections for farmers.

- Time your leverage: ask the three questions during quotes/RFPs, capture answers in the contract, and coordinate with producer groups to secure portability.

Complete references and supporting documentation are available upon request by contacting the editorial team at editor@thebullvine.com.

Learn More:

- The Tech Reality Check: Why Smart Dairy Operations Are Winning While Others Struggle – Uncovers the hidden implementation costs dealers often omit, revealing why true robotic ROI takes 3.8 to 5 years and how to budget for the 40% in “unseen” infrastructure upgrades.

- Decide or Decline: 2025 and the Future of Mid-Size Dairies – specific strategies for the “squeezed middle” (400-600 cows) to compete through precision management rather than just scale, directly addressing the economic trap mentioned in this article.

- The Hidden Cost of Waiting: Why Dairy’s 2025 Crisis Response Is Breaking Historical Patterns – Analyzes the financial impact of delaying technology decisions, demonstrating how hesitation can cost 100-cow operations over $2,500 every two weeks in lost efficiency opportunities.

Join the Revolution!

Join the Revolution!

Join over 30,000 successful dairy professionals who rely on Bullvine Weekly for their competitive edge. Delivered directly to your inbox each week, our exclusive industry insights help you make smarter decisions while saving precious hours every week. Never miss critical updates on milk production trends, breakthrough technologies, and profit-boosting strategies that top producers are already implementing. Subscribe now to transform your dairy operation’s efficiency and profitability—your future success is just one click away.

Join the Revolution!

Join the Revolution!

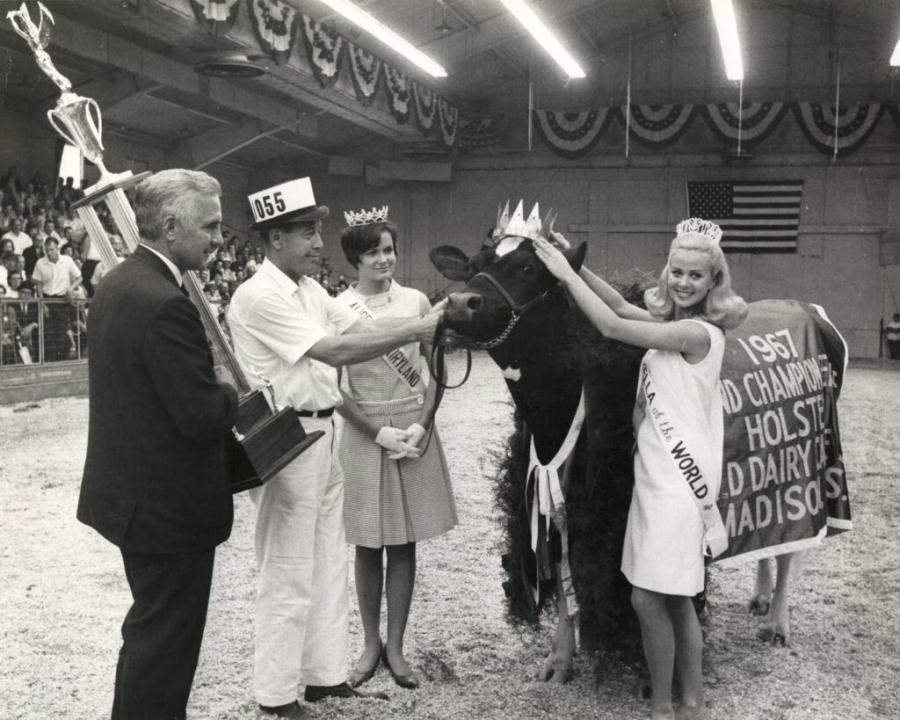

Held yearly in Madison, Wisconsin, the World Dairy Expo is the main event for those who like dairy products and attracts a varied worldwide attendance. Set for October 1–5, 2024, this five-day event turns the Alliant Energy Center into a hive of dairy innovation and legacy.

Held yearly in Madison, Wisconsin, the World Dairy Expo is the main event for those who like dairy products and attracts a varied worldwide attendance. Set for October 1–5, 2024, this five-day event turns the Alliant Energy Center into a hive of dairy innovation and legacy.

The World Dairy Expo 2024 isn’t just a showcase of dairy excellence; it’s also a launchpad for the latest efforts in sustainability and innovation within the industry. These themes resonate throughout the event, emphasizing their critical role in shaping the future of dairy farming.

The World Dairy Expo 2024 isn’t just a showcase of dairy excellence; it’s also a launchpad for the latest efforts in sustainability and innovation within the industry. These themes resonate throughout the event, emphasizing their critical role in shaping the future of dairy farming.

The World Dairy Expo is a pinnacle event for anyone passionate about dairy. There’s something for everyone, from the sprawling trade show and top-tier cattle showcases to many networking opportunities and educational sessions. The Expo brings together the best in the industry and provides a platform for learning, connecting, and innovating.

The World Dairy Expo is a pinnacle event for anyone passionate about dairy. There’s something for everyone, from the sprawling trade show and top-tier cattle showcases to many networking opportunities and educational sessions. The Expo brings together the best in the industry and provides a platform for learning, connecting, and innovating.