One infected visitor can cost you $128,250 (H5N1). Boot stations cost $820. Every major dairy that installed them reports zero outbreaks since. Facts.

Executive Summary: Boot wash stations deliver the dairy industry’s best-kept secret: 2,795% ROI for just $820, preventing $96,000+ in disease losses that Penn State, Michigan State, and UC-Davis have meticulously documented. While farms invest $250,000 in robots returning 30% over a decade, bacteria on contaminated boots survive 24 hours, travel 400 feet, and devastate herds—yet three simple steps (scrape, wash, disinfect) stop them cold. Wisconsin producers with stations report 60% fewer calf deaths and haven’t had major outbreaks in 18+ months. The math is embarrassingly clear: two-month payback versus eight years for that robot. Yet most dairies still lack this basic protection, choosing complex technology over proven prevention. The question isn’t whether boot stations work—it’s why you don’t already have them.

You know how it is at industry meetings—everyone’s talking about the latest technology. Last month at the Wisconsin Dairy Expo, I got into this fascinating conversation with a group of producers comparing notes on recent investments. Robotic milkers, automated calf feeders, precision nutrition systems… the usual suspects. Then someone mentioned they’d just put in boot wash stations, and honestly, the whole conversation shifted.

What’s interesting is how this matches a pattern I’ve been noticing across the industry. Here we are, investing heavily in automation—which makes sense, don’t get me wrong—but some of the best returns are coming from the simplest investments. And when I started digging into the numbers… well, they surprised even me.

“The payback for preventing just one Salmonella outbreak? About two months.”

The Investment Gap Nobody Talks About

So here’s what got me thinking. I’ve been looking at disease prevention data from Penn State Extension, Michigan State’s veterinary economics team, and the Canadian Dairy Network. When you compare the cost of a single boot wash station—about $820 installed—against the disease losses it prevents, the returns are extraordinary. Scale that up to three stations for comprehensive coverage at $2,460, and you’re looking at returns between 719% and 2,795% over five years. Meanwhile, that quarter-million-dollar robot we all admire? Generally delivers returns of 20-30% over a decade.

| Disease Name | Annual Cost Per Farm ($) | Boot Station Cost ($) | ROI Multiple (X times) |

| Salmonella D. | $13,860 | $820 | 17x |

| Cryptosporid. | $9,214 | $820 | 11x |

| Johne’s Dis. | $18,000 | $820 | 22x |

| Digital Derm. | $20,000 | $820 | 24x |

| H5N1 (Single) | $128,250 | $820 | 156x |

Now, that raises an obvious question, doesn’t it? Why are we hesitating on something this profitable?

During my farm visits this season, I’ve been asking producers about their biosecurity priorities, and the responses have been… enlightening. You know, UC-Davis researchers—Pires and his team published this fascinating work in the Journal of Dairy Science—showed that bacteria in manure can survive on boot surfaces for up to 24 hours. They tracked pathogen movement nearly 400 feet across plastic surfaces. About 150 feet on concrete.

Just think about that for a minute. Your hoof trimmer shows up at dawn, and he was at another farm yesterday. Your nutritionist stops by after visiting three other dairies this morning. The milk hauler who’s been in every parlor in the region… Each one represents a potential disease introduction, yet we rarely think about it the same way we analyze, say, feed efficiency or genetic improvements.

What Disease Actually Costs

Let me share what the extension services and university research teams have documented—and these aren’t worst-case scenarios, they’re documented averages for a typical 450-cow operation.

Quick Disease Cost Reality Check:

| Disease | Annual Cost | Preventable? |

| Salmonella Dublin | $13,860/outbreak | Yes, via boot hygiene |

| Cryptosporidium | $9,214/year | Yes, major route |

| Johne’s Disease | $18,000/year | Yes, if kept out |

| Digital Dermatitis | $15,000-25,000 | Yes, trimmer transmission |

| H5N1 | $128,250+ | Yes, documented boot spread |

Penn State Extension’s 2024 analysis shows a Salmonella Dublin outbreak runs about $13,860 in direct losses. Michigan State’s research puts the cost of endemic cryptosporidium at $9,214 annually. The Canadian Dairy Network documents $18,000 yearly for Johne ‘s-infected herds—with no cure available.

Compare that to boot station costs: $820 for your highest-risk entry point, or $2,460 for three-station comprehensive coverage, plus about $1,850 annually for disinfectant and maintenance. The payback for preventing just one Salmonella outbreak? About two months.

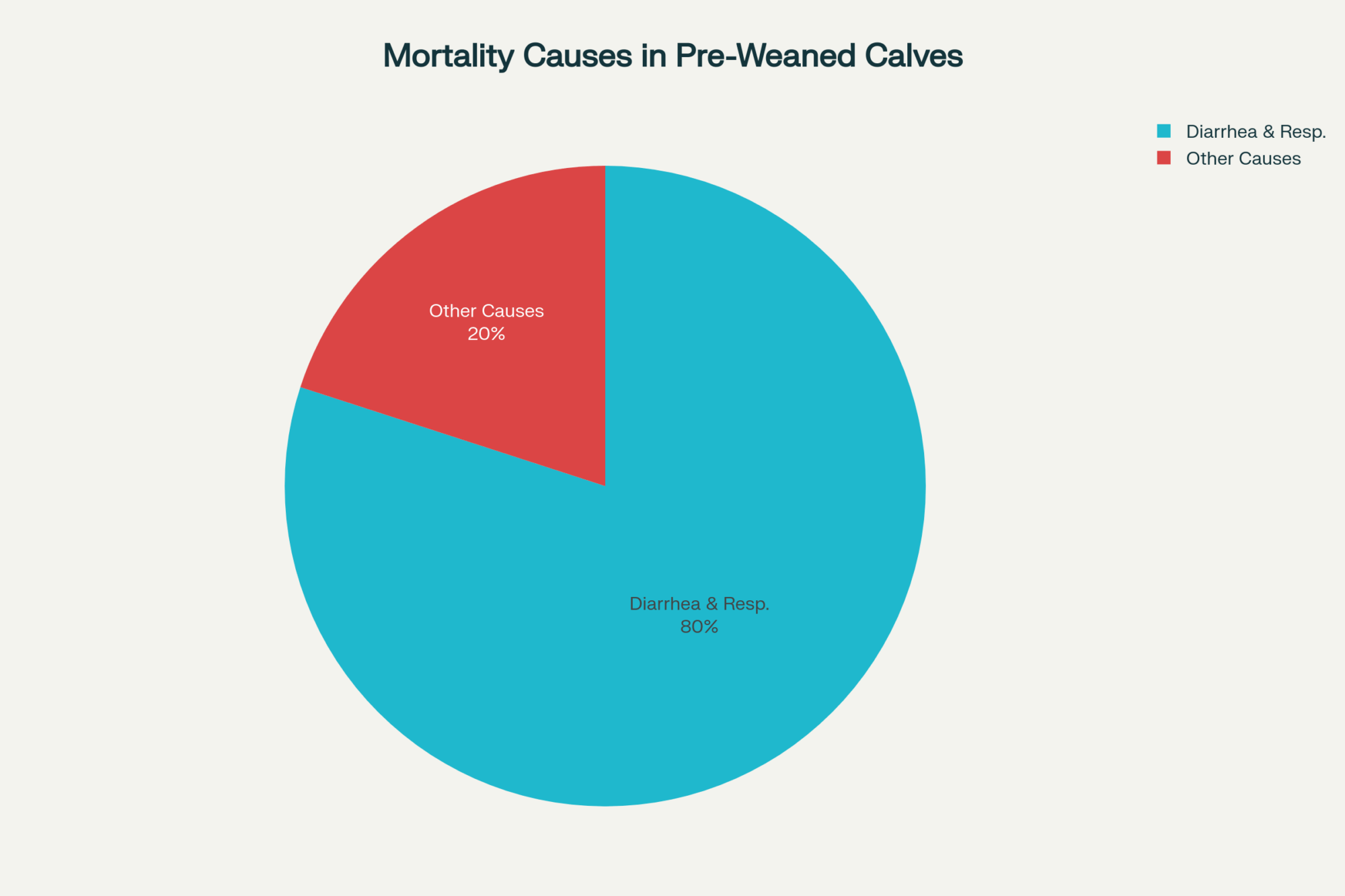

Why Calves Are Ground Zero

Dr. Jennifer Bentley at Wisconsin’s vet school has this way of putting it that really resonates: “Calves under 30 days represent your operation’s highest disease risk, period.”

The vulnerability facts are sobering:

- Newborn calves operate at 20-50% of adult immune capacity

- Maternal antibodies are half depleted by day 28 (Cornell QMPS data)

- Enhanced biosecurity reduces calf mortality from 5.9% to under 4% (Estonian research, 118 herds)

- External biosecurity ranks in the top five factors affecting calf survival

I keep hearing the same thing from California producers: excellent genetics, premium milk replacer, perfect ventilation—none of it matters if someone tracks crypto into your calf barn on dirty boots.

The Three-Step Process That Actually Works

Here’s something Purdue University’s research revealed that really challenges our assumptions: disinfectant type becomes completely irrelevant if you don’t remove organic matter first. They proved definitively that stepping through even the most expensive disinfectant with manure-caked boots provides zero effective pathogen control.

The only sequence that works:

- Mechanical scraping – Remove visible contamination

- Washing with brushes and water – Eliminate residual material

- Chemical disinfection – Only effective on clean boots

Skip any step and you’re operating on faith rather than science.

Strategic Placement: The 13-Fold Compliance Difference

Canadian RFID monitoring research (Frontiers in Veterinary Science) documented something remarkable. Placement impacts compliance by a factor of thirteen. A well-positioned station gets 90% usage. A poorly placed one? Seven percent.

Optimal placement priorities:

- Calf barn entrances – Highest vulnerability point

- Maternity pen access – Protect those critical first hours

- Hospital pen entry/exit – Bidirectional protection essential

- Age group transitions – Prevent adult-to-youngstock transmission

Your Implementation Roadmap

Based on what’s working for successful producers:

Month 1: Start With One Station ($820)

- Install at your highest-risk location (typically calf barn)

- Establish protocols and culture

- Track baseline health metrics

Months 2-3: Build Momentum

- Add maternity pen coverage

- Implement visitor protocols (boot covers: $0.50 each)

- Train on the critical three-step process

Months 4-6: Complete Coverage ($2,460 total)

- Install hospital pen stations

- Integrate with broader biosecurity

- Establish maintenance responsibilities

The Technology Partnership

What’s particularly encouraging is seeing operations recognize that technology and biosecurity aren’t competing investments—they’re synergistic.

Take automated calf feeders. Great technology. But I’ve seen operations where one infected calf deposits crypto on shared nipples, efficiently delivering pathogens to everyone. Compare that to Wisconsin operations using identical feeders but with boot hygiene preventing crypto introduction. The technology performs as designed because the disease isn’t undermining it.

This pattern repeats everywhere:

- Robotic milkers achieve potential when herds stay mastitis-free

- Activity monitors catch problems that escape good biosecurity

- Genetic programs deliver when calves survive to production

Common Implementation Challenges

Winter Operations:

- Install stations inside doorways when possible

- Use heated water lines or warm water buckets

- Switch to cold-weather disinfectants (Virkon S works near freezing)

- Have a plan before temperatures drop

Low Compliance After Installation:

- Check placement first—is it in the natural flow of traffic?

- Examine time allocation—are employees too rushed?

- Address root causes, not symptoms

The Bottom Line Investment Analysis

| Investment | Cost | 5-Year ROI | Payback |

| One Boot Station | $820 | 400-1,500% | 2-3 months |

| Three Stations | $2,460 | 719-2,795% | 1.5-2.1 months |

| Robotic Milker | $250,000 | 20-30% | 6-8 years |

| Auto Calf Feeder | $180,000 | 15-25% | 5-7 years |

The math clearly supports boot station investment, yet adoption remains inconsistent. A Wisconsin producer captured it perfectly: “We’ll invest $5,000 in feed additives, hoping for 2% production increases while hesitating over $820 boot stations that prevent thousands in losses.”

Your Next Steps

The path forward is straightforward. Start with one boot wash station at your most vulnerable location—probably the calf barn entrance. Just $820 to protect your highest-risk animals. Implement the three-step cleaning protocol. Document your health metrics for three months.

Based on what I’m seeing from producers who’ve taken this step, you’ll likely find yourself planning stations 2 and 3 before month 4. The economics are that compelling, the results that consistent.

This isn’t about choosing between technology and biosecurity. It’s about recognizing that your sophisticated systems perform best when built on a solid foundation of disease prevention. And in an industry facing mounting disease pressure and tightening margins, that foundation—starting at just $820—might be the most important investment you make this year.

Your banker will appreciate the economics. Your employees will appreciate healthier animals. And those expensive automated systems? They’ll finally deliver what you paid for.

The choice, as always, is yours. But the math—and the growing number of success stories—suggest this is one investment decision that’s actually pretty straightforward.

Key Takeaways:

- The Math Nobody Can Argue With: $820 boot station = 2,795% ROI in 5 years. $250,000 robot = 30% ROI in 10 years. Stop choosing the wrong one.

- The Only Process That Works: Disinfectant without scraping = zero protection. You MUST do all three: scrape → wash → disinfect. Skip one step and you’re playing pretend biosecurity.

- The 13X Compliance Secret: Put stations IN doorways where people can’t avoid them (90% usage), not around corners where they will (7% usage). Physics beats willpower every time.

- What Success Actually Looks Like: 60% fewer dead calves in 3 months. 18+ months without major outbreaks. $96,000+ in prevented losses. Wisconsin farms proved it—now it’s your turn.

- Your Monday Morning Action: Order one $820 station for your calf barn entrance. Install it this week. Track calf health for 90 days. Watch what happens.

Complete references and supporting documentation are available upon request by contacting the editorial team at editor@thebullvine.com.

Learn More:

- The Biosecurity Changes That Stuck: What Dairy Producers Say Actually Works (And Pays) – This article moves beyond boot stations to reveal what producers say actually works for daily biosecurity. It details low-cost, practical traffic management and visitor control protocols you can implement this week to layer your farm’s defenses.

- H5N1 Crisis One Year Later: What Dairy Farmers Need to Know – The main article used H5N1 to prove its point; this piece provides the full strategic breakdown. It details the $700,000+ per-herd losses and $950-per-cow cost, proving why prevention is the only affordable option.

- Digital Dairy Detective: How AI-Powered Health Monitoring is Preventing $2,000 Losses Per Cow – This piece perfectly illustrates the “technology synergy” concept. It demonstrates how AI health monitoring, which detects illness days before humans, combines with foundational biosecurity to prevent catastrophic losses and deliver a 95.6% accuracy rate on disease detection.

Join the Revolution!

Join the Revolution!

Join over 30,000 successful dairy professionals who rely on Bullvine Weekly for their competitive edge. Delivered directly to your inbox each week, our exclusive industry insights help you make smarter decisions while saving precious hours every week. Never miss critical updates on milk production trends, breakthrough technologies, and profit-boosting strategies that top producers are already implementing. Subscribe now to transform your dairy operation’s efficiency and profitability—your future success is just one click away.

Join the Revolution!

Join the Revolution!