Early adopters of pair housing are building a competitive advantage that latecomers won’t be able to match

Executive Summary: Here’s what most dairy producers don’t realize: the 2031 pair housing mandate isn’t a burden—it’s creating the industry’s biggest competitive opportunity in decades. Research shows pair-housed calves produce $50,000 more in annual revenue through superior brain development, yielding 850-1,113 kg extra milk in the first lactation alone. But here’s the catch: mastering group management takes 18-36 months, meaning producers who start now will have six years of operational excellence when their neighbors are still figuring out the basics. While 60% of farms stay paralyzed by solvable concerns about cross-sucking and capital costs, early adopters are quietly building advantages that compound annually—better disease detection, 9-hour labor savings per calf, and premium market positioning. The brutal truth? Producers waiting until 2030 won’t just be late to comply—they’ll be permanently behind, missing profits they can never recover. Every quarter you delay is another group of superior replacements your competition is raising while you’re still deciding.

You walk through dairy operations across North America today, and those familiar rows of individual calf hutches still dominate the landscape. They’ve been our standard for good reason—biosecurity, individual monitoring, controlled feeding. But here’s what I’m seeing: something significant is shifting in how progressive producers approach calf rearing, and honestly, the implications go way beyond what most of us initially thought.

The catalyst is Canada’s requirement for pair or group housing by 2031. That’s in the revised Code of Practice that Dairy Farmers of Canada released in March 2023. What’s really catching my attention, though, is how early adopters are discovering benefits that go far beyond just checking off a regulatory box.

I was digging through research from Dr. Marina von Keyserlingk’s team at the University of British Columbia—fascinating work they published in PLOS ONE back in 2014. They documented something many experienced calf managers have suspected for years: calves raised together demonstrate remarkably superior cognitive flexibility. Get this—pair-housed calves adapt to environmental changes 35% faster and ultimately produce between 850 and 1,113 kilograms more milk in their first lactation compared to individually housed counterparts.

“This isn’t theoretical yield potential, folks. This is actual milk production, documented across multiple commercial operations.”

Understanding the Cognitive Advantage

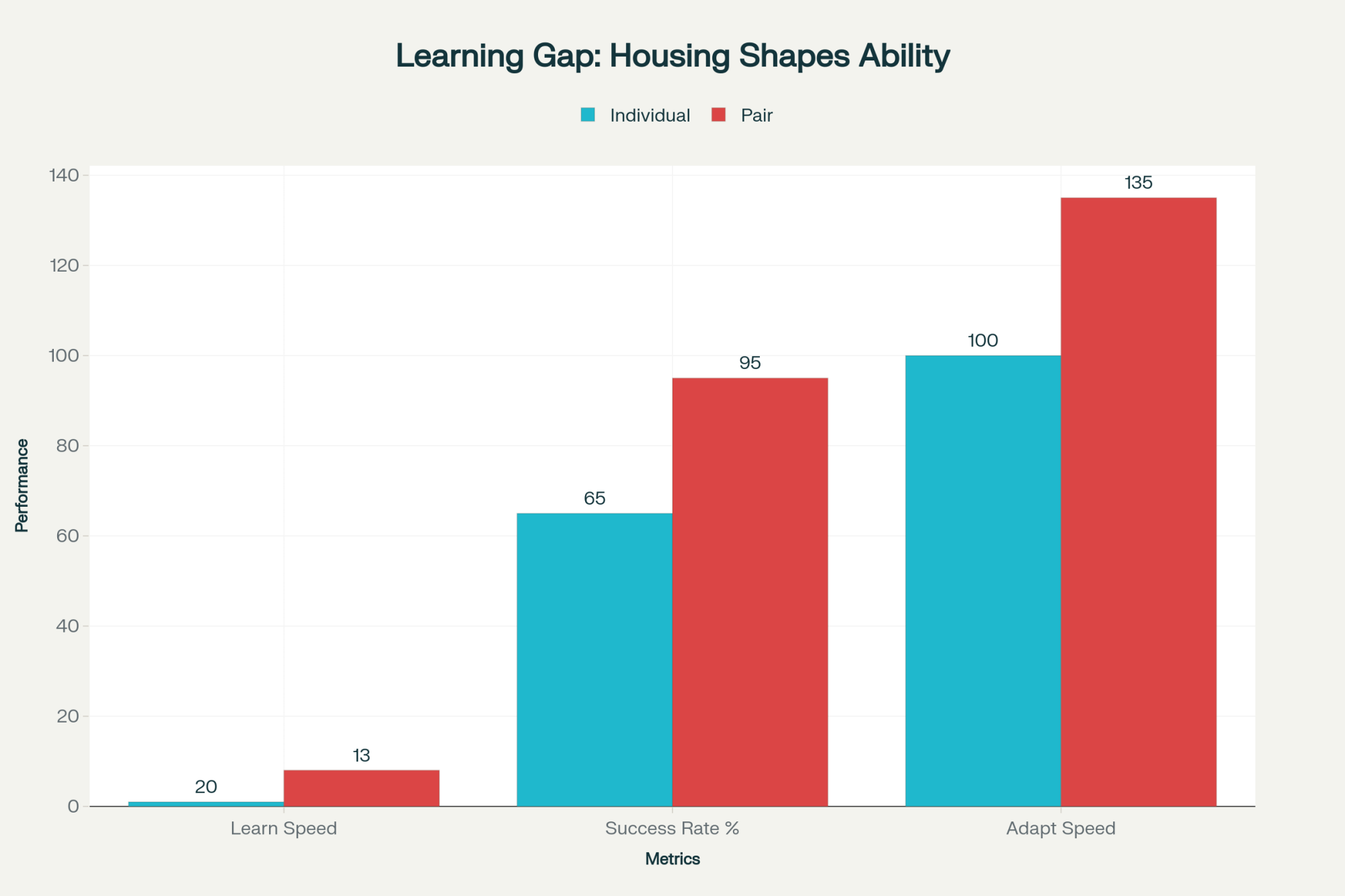

The UBC research used a Y-maze reversal learning test. Basically, they teach calves which path leads to their milk reward, then switch the rules to see how quickly they adapt. Pair-housed calves? They figured out the change in 13 trials. Individually housed calves needed 20 trials, and here’s the kicker—some never mastered the reversal at all.

Dr. Jennifer Van Os, who’s an Assistant Professor of Animal Welfare at the University of Wisconsin-Madison, puts it perfectly: “Modern dairy animals face constant learning challenges—new parlor routines, automated feeding systems, ration adjustments, social dynamics. If we’re not developing their capacity to learn from day one, we’re limiting their lifetime potential.”

What farmers are finding is that this resonates with real-world experience. Wisconsin Extension specialists have documented that operations transitioning to robotic milking systems consistently see younger animals adapting more readily than older cows. The difference? Many of those younger animals experienced social housing during their critical early development period. Food for thought, isn’t it?

The Economics Tell a Compelling Story

Looking at the numbers from Dr. Mike Van Amburgh’s comprehensive meta-analysis at Cornell University, which tracked 1,868 heifers across commercial operations, the production correlations are clear. Every kilogram increase in preweaning average daily gain translates to 850 to 1,113 kilograms of additional first-lactation milk production.

Let me break this down practically. Pair-housed calves, through what researchers call “social facilitation of feeding”plus reduced isolation stress, typically achieve 0.1 to 0.2 kilograms better daily gain during the preweaning period.

For a 500-cow operation raising 200 replacements annually:

- Improving preweaning ADG from 0.6 to 0.8 kg/day

- Generates approximately 124,200 kg of additional first-lactation milk

- At current DFO pool prices (October 2025): roughly $0.41 per kilogram

- That’s over $50,000 in additional revenue from a single cohort

And that’s just the first lactation.

What really gets interesting is research from Dr. Alex Bach’s team at IRTA in Spain. They published work in the Journal of Dairy Science showing these effects don’t diminish—they actually compound. Each kilogram of improved preweaning ADG correlates with 2,280 kilograms of additional lifetime production. The metabolic programming you establish in those first eight weeks? It sticks with them their entire productive life.

Labor Efficiency Surprises Everyone

Here’s an aspect that even experienced producers can get caught off guard by. Research from the University of Guelph and Wisconsin Extension field trials documents dramatic labor differences:

- Individual hutch systems: 10.6 hours of labor per calf (birth to weaning)

- Pair housing with automated feeding: 1.4 hours per calf

- Labor reduction: 9.2 hours per calf

Minnesota Extension documented a 450-cow operation that reduced labor needs by two and a half positions after transitioning. But the manager told researchers the bigger win was performance—they went from one pound of daily gain to consistently achieving two pounds.

“Not hauling milk to hutches when it’s minus-30 doesn’t just save time—it helps them keep good employees who might otherwise look for easier work come February.”

Addressing the Adoption Gap

Despite all this compelling evidence, Lactanet’s 2024 dairy housing survey shows approximately 60% of Canadian dairy farms still use individual housing systems. We see similar patterns across the United States. So what’s holding folks back?

The Comfort of Familiar Systems

I understand the hesitation. Many producers with well-functioning individual housing face a tough decision. Their current approach delivers acceptable results—calves survive, reach target weights, and transition successfully to group housing post-weaning.

Quebec producers commonly express this in Extension workshops: “My individual system gives me certainty. I know each calf’s intake, health status, and growth rate. Group housing introduces variables I’m still learning to manage.”

This makes perfect sense. Change carries risk, especially when your current system meets baseline performance standards.

Cross-Sucking Remains a Primary Concern

Research published in 2025 by the University of Calgary identified fear of cross-sucking as the leading barrier to adoption. Every producer who’s dealt with a blind quarter on a fresh heifer remembers that frustration—I certainly do.

But here’s what’s encouraging: Dr. Cassandra Tucker’s work at UC Davis, done in collaboration with Penn State Extension, demonstrates that cross-sucking is entirely preventable through proper management:

- Adequate milk allowance: minimum 7 liters daily for Holstein calves

- Nipple feeding rather than buckets

- Gradual weaning over 7 to 10 days

Follow these protocols, and cross-sucking essentially disappears.

Capital Investment Realities

Let’s talk dollars. Michigan State Extension’s 2024 calculations place infrastructure investment at approximately $127 per calf, with complete system implementation costing $15,000 to $25,000 for a 200-replacement operation.

Dr. Marcia Endres at the University of Minnesota documents returns of 269% to 312% on this investment, but what is that upfront capital requirement? It’s a real challenge when you’re managing tight margins.

What’s working for some producers is starting with pilot programs using temporary infrastructure. Prove the concept before making the major capital commitment.

Learning From Early Implementation

Extension specialists working with transitioning farms report remarkably consistent patterns through the first 90 days. Wisconsin Extension Bulletin A4154 clearly documents these phases.

Weeks 1-2: Resisting the Urge to Intervene

Ontario Extension case studies consistently show the biggest challenge is stepping back. Every instinct tells you to help calves find the nipple, guide them through feeding. But they need to learn independently and from each other. Too much intervention creates dependence rather than competence.

Successful protocols involve:

- Backgrounding calves individually for 10-14 days before grouping

- Establishing strong suckling reflexes

- Health screening before mixing

Dr. Dave Renaud’s research at Guelph, published in Preventive Veterinary Medicine back in 2023, confirms this approach reduces health events by 40%.

Weeks 3-4: Managing Cross-Sucking Effectively

This critical period determines whether producers persist or revert. Extension field trials documented in the 2024 Wisconsin Dairy Management Guide show that increasing milk concentration while maintaining frequent feeding opportunities stops cross-sucking behavior cold.

The target remains consistent across all research: minimum 7 liters daily through nipples, with gradual 10-day weaning transitions. Get this right, and cross-sucking becomes a non-issue.

Weeks 5-8: Ventilation Becomes Critical

Dr. Ken Nordlund from Wisconsin’s School of Veterinary Medicine emphasizes in their 2024 facility design guidelines: “Poor health management in individual housing becomes amplified in group settings.”

Calves don’t generate enough body heat for natural convection ventilation to work. You need mechanical systems—positive pressure tubes or continuous airflow fans. Operations that underestimate ventilation requirements face respiratory challenges that can derail the entire transition.

Weeks 9-12: Systems Integration

Producers who navigate that initial learning curve consistently report dramatic improvements around month three. Multiple Extension case studies from 2024-2025 document this pattern:

- Feed efficiency improves

- Health events decline

- Growth rates accelerate

Fraser Valley producers dealing with higher humidity than Prairie provinces really emphasize moisture management alongside ventilation. British Columbia Extension specialists report in their 2024 regional guide that once environmental controls are optimized, preweaning mortality typically drops from 7% to under 3%.

Data-Driven Management Revolutionizes Calf Rearing

| Health Indicator | Days Early Detection | Visual Observation Accuracy | Automated System Accuracy | Improvement |

|---|---|---|---|---|

| Milk Intake Drop (15-25%) | 5 | 40% | 78% | +38% |

| Drinking Speed Reduction | 4 | 35% | 72% | +37% |

| Unrewarded Feeder Visits ↑ | 3 | 45% | 80% | +35% |

| Combined Metric Analysis | 5 | 50% | 82% | +32% |

This transition from visual observation during feeding to continuous behavioral monitoring? It’s a fundamental shift in how we think about calf management.

Dr. David Renaud’s research, published back in November 2023 in the Journal of Dairy Science, reveals that automated systems detect illness indicators 3 to 5 days before you’d see visual symptoms.

Key metrics for early disease detection:

- Milk intake declining 15-25% → 5 days before clinical illness

- Drinking speed reduction → 4 days before visible symptoms

- Unrewarded feeder visits tripling → Calf feels unwell but can’t finish meals

- Meal duration increasing → While actual consumption decreases

Dr. Melissa Cantor at Penn State found—and published in the Journal of Dairy Science earlier this year—that combining these metrics achieves 75-80% disease-detection sensitivity, compared to just 40-50% with single indicators. This early detection capability? It transforms treatment outcomes and reduces both medication costs and production losses.

Building Competitive Advantage for 2031 and Beyond

The mandated transition creates an industry-wide baseline. Everyone has to comply. But here’s what I think many are missing: competitive advantage comes from operational excellence developed through early adoption.

“Producers transitioning in 2025 will have six annual cohorts of cognitively enhanced replacements by 2031. Late adopters starting in 2030? They begin with zero such animals.”

Consider the arithmetic:

- 180 to 360 animals with cognitive advantages in your herd

- 187 to 491 additional pounds of milk per lactation

- Worth $34 to $88 per cow annually (Cornell longitudinal studies)

Dr. Jessica McArt’s research at Cornell’s College of Veterinary Medicine, published in Preventive Veterinary Medicine in 2024, demonstrates that disease prediction algorithms need 18 to 24 months of calibration to achieve optimal sensitivity. Early adopters will be preventing disease, while late adopters are still figuring out which buttons to push.

Market dynamics are shifting, too. Dr. Beth Ventura’s research at the University of Minnesota documents consumer willingness to pay 4-6% premiums for milk from enhanced welfare systems. Trade publications like Dairy Foods and Progressive Dairy suggest processors, including Agropur and Saputo, are exploring differentiated supply chains—though specific program details are still emerging. Early adopters with documented performance histories? They’re positioning themselves for opportunities that won’t be available to last-minute converts.

A Practical Implementation Framework

Based on Extension specialist experiences documented across multiple regions, here’s what consistently works:

Start with a 12-calf pilot program. Not to validate the science—that’s been done—but to develop expertise specific to your facility without risking your entire replacement program.

Foundation Phase (Months 1-3)

- Get passive transfer rates above 90% (Dr. Sandra Godden at Minnesota recommends serum total protein >5.5 g/dL)

- Establish 20% body weight milk feeding minimums

- Develop cross-sucking prevention protocols for your specific setup

Skill Development (Months 4-6)

- Learn to interpret behavioral data

- Recognize that 20% intake drop that signals illness

- Identify weaning readiness (Dr. Mike Steele at Alberta: look for 1.4 kg daily starter intake for three consecutive days)

- Document equipment performance patterns

Protocol Optimization (Months 7-9)

- Refine feeding algorithms for your genetics

- Balance welfare with facility constraints

- Align health protocols with actual disease pressure

Team Integration (Months 10-12)

- Train every team member who touches calves

- Ensure understanding of behavioral indicators

- Establish report interpretation protocols

- Define intervention thresholds

“This phase gets skipped too often, and it comes back to bite you.”

Practical Considerations for Your Operation

Looking at all the evidence, several principles stand out:

Early implementation with modest scale beats last-minute scrambling with your entire calf crop. That learning curve takes 18 to 36 months, no matter when you start.

Management excellence, not equipment sophistication, determines your outcomes. You can have the fanciest automated feeder on the market, but without skilled interpretation of its data, you’ve bought yourself an expensive milk dispenser.

Your foundation protocols have to be solid. If you’re running sub-90% passive transfer rates or marginal ventilation, group housing will amplify those problems rather than solve them.

Expect the learning curve. Embrace it, even. Those initial challenges? That’s education, not failure.

Document everything meticulously. This data validates your investment decisions and supports premium market positioning down the road.

Looking Forward

We’re witnessing one of those generational transitions that reshapes how we do things. Producers who view this 2031 requirement as an opportunity for systematic improvement? They’ll capture lasting competitive advantages. Those approaching it as just another compliance burden will perpetually lag behind early adopters who’ve already optimized their systems.

The parallel to previous industry evolutions is pretty clear. Consider free-stall adoption, TMR implementation, and genomic selection. Early, thoughtful adopters consistently emerged stronger.

What I’ve noticed across other major transitions is that success doesn’t come from the technology itself. It comes from the operational excellence you develop through implementation. Pair housing represents another one of those opportunities—it challenges our assumptions, rewards innovation, and ultimately advances both animal welfare and farm profitability.

The timeline is set. The science is clear. The economics are compelling. What remains is the decision each operation needs to make: lead this transition or follow those who do.

Six years gives you adequate time for thoughtful implementation. But it disappears quickly if you keep putting it off. The question isn’t whether to transition—that decision’s been made for us. The question is when to start capturing the advantages of early adoption.

Your move.

KEY TAKEAWAYS

- Start with 12 calves, not 200: Master the learning curve on a pilot scale where mistakes won’t sink you—but start NOW because the 18-month expertise gap between early and late adopters becomes permanent

- $50,000 isn’t the ceiling, it’s the floor: First-lactation gains of 850-1,113 kg are just the beginning—these calves produce 2,280 kg more lifetime milk because early brain development programs permanent metabolic advantages

- Stop fearing cross-sucking, start fearing the competition: While 60% of producers avoid pair housing over a completely preventable issue, early adopters are banking profits you’ll never catch up to

- The 2031 deadline creates winners and losers: Producers with 6 years of experience will be preventing disease while you’re reading instruction manuals, capturing premium markets while you’re proving compliance

Complete references and supporting documentation are available upon request by contacting the editorial team at editor@thebullvine.com.

Learn More:

- The Ultimate Guide to Colostrum Management: Securing the Future of Your Herd – This article provides the critical tactical foundation the main piece says is non-negotiable. It offers a step-by-step masterclass on perfecting passive transfer to ensure calves have the robust immunity required to thrive in a group housing environment.

- Beyond the Bulk Tank: How Top Producers Are Turning Sustainability into Their Next Major Profit Center – This piece validates the main article’s strategic vision by detailing how leading operations are monetizing enhanced welfare and environmental practices. It demonstrates how pair housing fits into the larger, profitable trend of creating differentiated, premium-worthy products for processors and consumers.

- Genomics 3.0: Are You Prepared for the Next Leap in Dairy Herd Advancement? – While the main article shows how to maximize a calf’s developmental potential, this piece explains how to ensure you’re starting with the best genetic potential. It reveals strategies for leveraging genomics to multiply the ROI of superior calf-rearing investments.

Join the Revolution!

Join the Revolution!

Join over 30,000 successful dairy professionals who rely on Bullvine Weekly for their competitive edge. Delivered directly to your inbox each week, our exclusive industry insights help you make smarter decisions while saving precious hours every week. Never miss critical updates on milk production trends, breakthrough technologies, and profit-boosting strategies that top producers are already implementing. Subscribe now to transform your dairy operation’s efficiency and profitability—your future success is just one click away.

Join the Revolution!

Join the Revolution!