GEA Farm Technologies recently hosted its 2013 Innovation Dairy Tour. Dairy producers from 12 states attended the two-day event to see industry-leading technologies in action on five innovative dairies, including an automatic teat dipping system, a robotic milking system and several other new industry innovations.

Photo left: The recent Innovation Dairy Tour allowed producers from across the country to network with one another and industry experts about new technologies. On-farm tours helped the group to see innovative technologies in action.

“The goal of the Innovation Dairy Tour was to bring producers from across the country onto dairies to see how their peers are operating efficient and profitable dairies,” said Matt Daley, president and chief executive officer of GEA Farm Technologies. “By networking with other dairy producers and the GEA Farm Technologies team, producers learned first-hand how to improve parlor efficiency, milk quality and overall herd performance.”

Visiting producers traveled throughout western Michigan to tour a pocket of dairy operations during the tour. “We chose this group of dairies because they represent new thinking and a variety of new technologies,” said Jerry Quellhorst, sales consultant for GEA Farm Technologies who works with each of the five host dairy producers. Quellhorst explained that these managers are getting more cows through the parlor per hour with fewer employees, are raising calves more efficiently and are better able to reallocate labor resources. “Overall, these operations are more efficient because of the technologies they’ve implemented.”

Photo right: Cow comfort and parlor efficiency were key themes of the Innovation Dairy Tour, hosted by GEA Farm Technologies. Industry experts in attendance credited technological advancements for helping the industry move forward.

Quellhorst added that the variety of dairies visited during the tour gave the producers a look into several management strategies and technology options. Producers attending the tour appreciated the hands-on approach of the event, saying that the tour allowed them to have an open dialog with each other and the host dairies about the installation process of the new technologies and discuss tips for implementing the technologies on-farm.

Dairies visited on the tour and the technologies showcased are as follows:

Gingrich Meadows Dairy, Leroy, Mich.: Owned by Amy Martin and Shawn Gingrich, this new facility was built in April 2012 and now milks 320 Holsteins with two MIone four-box robotic milking systems. Amy Martin shared that the cows have transitioned into the system easily and that they have been able to reallocate labor resources to other areas of the operation.

Photo right: Dairy producers from 12 states recently attended the Innovation Dairy Tour in Michigan. The producers toured Gingrich Meadows Dairy in Leroy, Mich., where they heard from owner Amy Martin on her experiences with the MIone robotic milking system. Martin told the group that the system allows cows to enter and be milked up to five times per day, creating a calm efficiency in the parlor.

“The cows are more calm and content than ever before and our employees have more time to manage cows and spend time monitoring the herd,” she said, explaining that cows enter the robotic system routinely to be milked up to five times per day. “This is a new way of managing our farm that’s made our cows more content and helped our kids become interested in returning to the farm.”

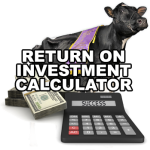

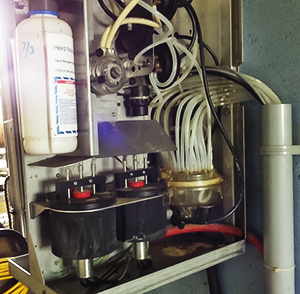

Hillhaven Farms, Edmore, Mich.: This facility started in 1998 by Mike Rasmussen. At the time, the producers built a 2 x 16 Magnum 40 Herringbone Parlor, and later upgraded to DemaTron 70 detachers. With the goal of improved milk quality and parlor efficiency, the owners recently added the ApolloTM MilkSystem and FutureCowTM Prep System.

Photo left: During the Innovation Dairy Tour, hosted by GEA Farm Technologies, producers toured Hill Haven Farms in Edmore, Mich. Owner, Mike Rasmussen told the group of his success with the ApolloTM MilkSystem and FutureCow™ Prep System in terms of improved milk quality through consistent udder prep and post-dip.

“The combination of Apollo and FutureCow is helping each cow to be prepped and post-dipped the same way every time they enter the parlor,” Rasmussen said. “Milk quality begins with preventing new infections; this new system helps with that by minimizing employee error. The system is set to do the job right each time.”

Photo right: The addition of the FutureCow™ Prep System has helped employees at Hill Haven Farms to consistently and efficiently prep each cow prior to milking. This new technology was showcased to producers during the recent Innovation Dairy Tour in Michigan.

Son Rise Farm, Westphalia, Mich.: John and Debbie Feldpausch began this calf facility in February 2010. Today, these calf growers raise about 200 calves in individual calf hutches and 350 calves on four DairyFeed Automated Quattro Calf Feeders. They also utilize a UV Pure, which uses ultraviolet light to purify calf milk – killing harmful bacteria while maintaining the vital nutrients naturally found in the milk. The growers credit the automated feeding system as a more efficient option for calf raising.

Photo below: Producers visited Son Rise Farm in Westphalia, Mich., during the recent Innovation Dairy Tour. Owner John Feldpausch discussed his experiences with automated calf feeders during the event, crediting the automated system for boosting average daily gains in his custom-raised calves.

“Our goal is to have a 2-pound average daily gain (ADG) per calf in the first 60 days,” John said. “We’re moving toward this goal with the auto-feeders, with a large percentage of calves doubling their birth weights by weaning. These calves have a greater potential to get in the parlor sooner and make more milk; it’s hard to meet these goals in the individual feeding system.”

Vanderploeg Holsteins, Ithaca, Mich.: This 72 stall AutoRotor Performer parlor was installed in October 2012 by Klaus, Mares and Tony Vanderploeg. Today, 2,250 Holsteins average 87 pounds of milk per head per day in the facility.

Photo left: This 72 stall AutoRotor Performer parlor was a highlight of the Innovation Dairy Tour in Michigan. Through the automated system, four employees are able to milk 72 cows in an eight minute time period at Vanderploeg Holsteins in Ithaca, Mich.

Farm managers at the facility say that the rotary parlor has improved efficiency and reduced the number of employees needed in the parlor. Cows enter the rotary parlor one at a time through a system of gates and are then rotated to employees who each have a designated task. Through the system, four employees are able to milk 72 cows in an eight minute span.

Rich Ro Colony, St. John’s, Mich.: Owned by Glenn and Brett Feldpausch, this dairy averages 82.4 pounds of milk per head per day on 2,735 Holsteins. The herd is milked in a 2 x 44 Magnum 90i parallel stall parlor and each cow is prepped with the FutureCow Prep System.

Photo right: Rich Ro Colony in St. John’s, Mich., was a stop on the recent Innovation Dairy Tour, hosted by GEA Farm Technologies. Co-owner Brett Feldpausch shared changes the team has implemented to stay above a production level of 80 pounds per cow per day, including consistency in the parlor.

“This is the first summer that we never dropped below 80 pounds per head per day,” said Brett. “We credit part of this to changes in our milking routine. We’re milking fresh cows four times a day, then three times a day through lactation and two times a day as cows near the dry period. To keep milk quality up, we need to be consistent at each of these milkings and the FutureCow is helping with that. It’s the same brush and the same amount of dip each time – and that’s made a difference.”

Photo left: Producers discuss the technology and implementation process of a rotary parlor during the Innovation Dairy Tour. The tour was hosted by GEA Farm Technologies.

For more information on the Innovation Dairy Tour or to connect with producers from the tour, contact GEA Farm Technologies at 1.877.973.2479.

ViaGen of Cedar Park, Texas is pleased to announce that now, progressive livestock breeders have an additional choice in DNA preservation tools. In addition to their Genetic Preservation (GP) service, ViaGen is now offering a more economical option to answer breeder’s needs to preserve all of the elite genetics in their herd, with an Express Tissue Bank (ETB).

ViaGen of Cedar Park, Texas is pleased to announce that now, progressive livestock breeders have an additional choice in DNA preservation tools. In addition to their Genetic Preservation (GP) service, ViaGen is now offering a more economical option to answer breeder’s needs to preserve all of the elite genetics in their herd, with an Express Tissue Bank (ETB).

It is clear – high tech devices are here to stay. A friend of mine was just telling me how his granddaughter was going up to his flat screen television set and attempting to use it like a touch screen on a smart phone to display something other than what they were watching. Just this morning, I was talking to a feed consultant who also illustrated how his five year old son constructs Lego creations and controls them with robotic technology. Be assured, these kids will live and work in a far different world than we know.

It is clear – high tech devices are here to stay. A friend of mine was just telling me how his granddaughter was going up to his flat screen television set and attempting to use it like a touch screen on a smart phone to display something other than what they were watching. Just this morning, I was talking to a feed consultant who also illustrated how his five year old son constructs Lego creations and controls them with robotic technology. Be assured, these kids will live and work in a far different world than we know.

![VMSFullCow[1]](https://www.thebullvine.com/wp-content/uploads/2013/07/VMSFullCow1.png) Designed as the next tool for top herds

Designed as the next tool for top herds Multi-Purpose Tool

Multi-Purpose Tool

What’s a family farm? How is technology changing farming today? While farming may evoke the picture of tractors in the field and rubber boots in the barn, the truth is that dairy farming is serious business and the investment and advancement in technology has made farms more efficient and sustainable.

What’s a family farm? How is technology changing farming today? While farming may evoke the picture of tractors in the field and rubber boots in the barn, the truth is that dairy farming is serious business and the investment and advancement in technology has made farms more efficient and sustainable.

AT THE END OF THE DAY, LOOK FOR BIG BENEFITS NOT PREVIOUSLY ACCESSIBLE

AT THE END OF THE DAY, LOOK FOR BIG BENEFITS NOT PREVIOUSLY ACCESSIBLE