Unable to find enough workers to carry out the painstaking tasks of milk production, dairy producers in South Dakota hope to tap into a different labor force: unemployed residents of Puerto Rico.

Unable to find enough workers to carry out the painstaking tasks of milk production, dairy producers in South Dakota hope to tap into a different labor force: unemployed residents of Puerto Rico.

It could be a tonic both for dairy operators and Puerto Rico, where the jobless rate stands at 12 percent but workers are far freer to travel to the U.S. for jobs than immigrants due to the island’s status as a U.S. territory.

South Dakota dairy farms produced 209 million pounds of milk in 2016, according to the National Agricultural Statistics Service. That’s far less than the more commonly known milk-producing states of California and Wisconsin, but the state’s pilot project to find another labor source is gaining attention.

“If this is successful, this would be a significant success for the U.S. dairy industry, certainly South Dakota’s industry,” said Jaime Castaneda, senior vice president of the National Milk Producers Federation. “So, we are watching it. We are looking at what happens.”

Certain agricultural industries are allowed to hire foreign-born workers seasonally under a visa category, but dairy farms do not qualify because they operate year-round. A study commissioned by the National Milk Producers Federation released in June 2015 concluded immigrant labor accounts for 51 percent of all dairy labor in the U.S.

The proposal from a team of agriculture experts to recruit a labor force from the Caribbean island to work on South Dakota’s dairies would eliminate the need for a visa because Puerto Ricans are U.S. citizens. Experts from the South Dakota State University Extension hope to bring about 20 workers by September.

They hosted recruiting sessions in November and December in three Puerto Rican communities that are home to dairies and addressed topics such as the farm routine, weather and cost of living. Of the 28 people who attended the sessions, half had an agricultural background. Others were electricians, nurses and construction workers. More sessions are planned for May.

The team is focused on developing a program that would help the workers adjust to life in the Great Plains. Karla Hernandez, an SDSU Extension forage field specialist, said producers in South Dakota, Minnesota and Wisconsin who have hired Puerto Ricans have seen them last only short periods on the job after realizing the demands, pay and the stark differences between the two places.

“Say you have a person from Mexico who gets here, that person will stick around because he has a need to provide for himself and for his family back in Mexico. Now if you get a Puerto Rican and he doesn’t like the job, he can go home very easily because he doesn’t need to wait for any visa or passport,” Hernandez said.

It’s no secret that immigrant labor is crucial at many agricultural enterprises in the U.S. The American Farm Bureau Federation estimates that about 80 percent of the agricultural labor force is foreign born and over half is unauthorized to work in the U.S.

Castaneda said his organization is not speculating about what the incoming Trump administration might do in terms of immigration. But he said the group will continue to pressure Congress and the administration to approve changes that would allow immigrant dairy workers to stay in the U.S. for at least three years with the option of reapplying after a stay in their home countries.

For those who doubt the need of foreign-born workers on dairy farms, Walt Bones, part owner of the Turner County Dairy and former South Dakota secretary of agriculture, has a succinct answer: U.S.-born workers don’t want to work that hard.

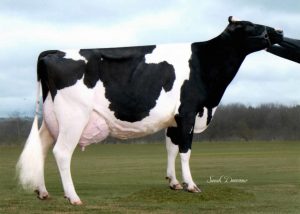

“They’re not hungry enough to improve themselves that they don’t want to work that hard. I think it’s that simple,” said Bones, whose dairy farm has 1,600 cows that are milked three times a day. “It’s not easy work. It’s repetitive, but at the same time, it’s not bad work.”

Gerson Cardona, a Guatemala native, began working on a dairy farm in South Dakota 15 years ago at the age of 15 by milking and washing cows. These days, he cares for days-old calves.

“If one enjoys the job, one can persevere,” Cardona said in Spanish during a break. “If one enjoys working with the animals, then that’s what motivates one to learn more and stay in one place. This (job) is a good source to be able to do something with one’s life.”

Source: Associated Press

A computer programmer says there is a lot of potential for using big data in the dairy industry.

A computer programmer says there is a lot of potential for using big data in the dairy industry. At a recent event hosted on Bryn Jones’ farm near Oswestry local farmers heard how AHDB Dairy’s Mastitis Control Plan had helped him to significantly reduce the rate of new clinical mastitis cases and reduce antibiotic use across his 800-cow herd, delivering annual savings of around £57,000. This downward trend is encouraging as the livestock industry works towards achieving a long term reduction in the use of antibiotics.

At a recent event hosted on Bryn Jones’ farm near Oswestry local farmers heard how AHDB Dairy’s Mastitis Control Plan had helped him to significantly reduce the rate of new clinical mastitis cases and reduce antibiotic use across his 800-cow herd, delivering annual savings of around £57,000. This downward trend is encouraging as the livestock industry works towards achieving a long term reduction in the use of antibiotics.

Are you using an activity tracker like a Fitbit to move more in the new year? Whether you’re an intense athlete, a busy mom, a farmer, or even a cow, you’ve got to get those steps in to meet your daily goals!

Are you using an activity tracker like a Fitbit to move more in the new year? Whether you’re an intense athlete, a busy mom, a farmer, or even a cow, you’ve got to get those steps in to meet your daily goals!

The Manning Farm in Swanton, Vermont uses trackers that fit on their cow’s ankles! We also caught up with the Manning family to learn about how they track their cow’s activity.

The Manning Farm in Swanton, Vermont uses trackers that fit on their cow’s ankles! We also caught up with the Manning family to learn about how they track their cow’s activity.

DAIRYING in the subtropics at Dobies Bight, NSW, Wayne and Paul Clarke know too well the importance of keeping cows comfortable in hot and humid weather. When they installed an automatic milking system (AMS) they entered relatively unchartered territory in terms of keeping cows cool.

DAIRYING in the subtropics at Dobies Bight, NSW, Wayne and Paul Clarke know too well the importance of keeping cows comfortable in hot and humid weather. When they installed an automatic milking system (AMS) they entered relatively unchartered territory in terms of keeping cows cool. It seems producers are turning more towards robotics to help fill the gap in the agricultural workforce.

It seems producers are turning more towards robotics to help fill the gap in the agricultural workforce.

The 2016 Alltech Canada Harvest Analysis tested 45 TMR samples from across Canada, from June 1 to November 30, at the company’s ISO-accredited Alltech 37+® mycotoxin analytical services laboratory in Nicholasville, Kentucky. The report showed that only 2 percent of the samples contained no mycotoxins. Two percent of the samples contained eight to nine mycotoxins, 20 percent contained six to seven mycotoxins, 29 percent contained four to five mycotoxins, 29 percent contained two to three mycotoxins and 18 percent contained one mycotoxin. Type B trichothecene mycotoxins (including DON) were present in 80 percent of the samples, and fusaric acid was present in more than half.

The 2016 Alltech Canada Harvest Analysis tested 45 TMR samples from across Canada, from June 1 to November 30, at the company’s ISO-accredited Alltech 37+® mycotoxin analytical services laboratory in Nicholasville, Kentucky. The report showed that only 2 percent of the samples contained no mycotoxins. Two percent of the samples contained eight to nine mycotoxins, 20 percent contained six to seven mycotoxins, 29 percent contained four to five mycotoxins, 29 percent contained two to three mycotoxins and 18 percent contained one mycotoxin. Type B trichothecene mycotoxins (including DON) were present in 80 percent of the samples, and fusaric acid was present in more than half. A full potential diet and good calf management help calves fight off disease.

A full potential diet and good calf management help calves fight off disease. Weather this time of year can change in a hurry. “So how many of you as dairy producers have heeded the warning and taken the time to prepare for the upcoming winter?”

Weather this time of year can change in a hurry. “So how many of you as dairy producers have heeded the warning and taken the time to prepare for the upcoming winter?” Our legal expert on the insurance implications of flooding and the steps to take if you are a victim of flooding

Our legal expert on the insurance implications of flooding and the steps to take if you are a victim of flooding New resources available to help farmers develop safety plans

New resources available to help farmers develop safety plans Specialist dairy producers in Ireland have now become the most cost competitive within the EU with the lowest cash-cost per kg solids base, expert analysis of sector for 2015 has shown.

Specialist dairy producers in Ireland have now become the most cost competitive within the EU with the lowest cash-cost per kg solids base, expert analysis of sector for 2015 has shown. Farmers speak frequently about the volatility in the dairy industry and how it is affecting their profit margins, especially milk and feed price fluctuations, which have become more marked as we move into a global marketplace.

Farmers speak frequently about the volatility in the dairy industry and how it is affecting their profit margins, especially milk and feed price fluctuations, which have become more marked as we move into a global marketplace. We all have a responsibility to eliminate drug residues in milk and meat to ensure a safe, wholesome and healthy food supply. Having a drug residue prevention plan can help your dairy reduce the risk of having a violative drug residue. Consider these six tips for making drug residue avoidance a top priority on your dairy:

We all have a responsibility to eliminate drug residues in milk and meat to ensure a safe, wholesome and healthy food supply. Having a drug residue prevention plan can help your dairy reduce the risk of having a violative drug residue. Consider these six tips for making drug residue avoidance a top priority on your dairy: Unmanned aerial vehicles, autonomous tractors and other technologies will continue to emerge as producers meet world food needs in the near and distant future, according to experts.

Unmanned aerial vehicles, autonomous tractors and other technologies will continue to emerge as producers meet world food needs in the near and distant future, according to experts.

The use of deep straw bedding and calf jackets, as well as providing extra calories during cold temperatures, will result in healthier calves and improved gains.

The use of deep straw bedding and calf jackets, as well as providing extra calories during cold temperatures, will result in healthier calves and improved gains. Now that corn harvest is complete, producers hopefully can look forward to having quality silage that is stable and well protected. The next steps are to monitor and maintain the integrity of the plastic covering (or bag silos, or bale wrap) and manage feedout to prevent heating and spoilage.

Now that corn harvest is complete, producers hopefully can look forward to having quality silage that is stable and well protected. The next steps are to monitor and maintain the integrity of the plastic covering (or bag silos, or bale wrap) and manage feedout to prevent heating and spoilage. Often, during financial stress, farmers are encouraged to cut more costs, but is a there a better way to achieve relief in a tight market?

Often, during financial stress, farmers are encouraged to cut more costs, but is a there a better way to achieve relief in a tight market? Let’s face it – hiring a new team member can be an exhausting process. Spending time sorting through candidates to identify real talent vs. “half-hearted” talent is a tough process. Many managers have had to “settle” on a slightly-less-than-desired candidate due to time pressures or lack of solid candidates. So, there is never a guarantee that you will not end up getting burned after hiring a new employee.

Let’s face it – hiring a new team member can be an exhausting process. Spending time sorting through candidates to identify real talent vs. “half-hearted” talent is a tough process. Many managers have had to “settle” on a slightly-less-than-desired candidate due to time pressures or lack of solid candidates. So, there is never a guarantee that you will not end up getting burned after hiring a new employee. Agriculture is at the start of a digital revolution, and to advance it will need to embrace and understand the increasing amount of data that is being collected, writes Chris Harris.

Agriculture is at the start of a digital revolution, and to advance it will need to embrace and understand the increasing amount of data that is being collected, writes Chris Harris. Milking robots at a New South Wales Mid North Coast dairy are contributing to an increase in milk production of 25 per cent over the last 12 months, according to Manning Valley dairy farmer Adrian Drury.

Milking robots at a New South Wales Mid North Coast dairy are contributing to an increase in milk production of 25 per cent over the last 12 months, according to Manning Valley dairy farmer Adrian Drury.