Cows avoiding water? Nervous in the parlor? Production dropping? You’re not imagining it—20% of dairies have stray voltage that utilities can’t detect.

You know, I spoke with a producer from Minnesota who shared something that many of us might recognize: her best cow had died unexpectedly after a completely normal 70-pound milking. Every consultant she’d brought in confirmed her management was exemplary. Yet cows kept declining, and nobody could explain why.

This was Jill Nelson from Olmar Farms in Sleepy Eye, and her eight-year journey to discover what was affecting her elite registered Holstein herd reveals an issue that—honestly—deserves more attention than it gets. After installing an isolated transformer to separate her farm from utility electrical infrastructure (we’re talking about an investment approaching $100,000 here), production increased by nearly 20 pounds per cow per day. And this happened during summer 2017, when most of us are just trying to maintain production through heat stress.

What’s particularly noteworthy is that Nelson’s experience aligns with estimates from that old USDA Agriculture Handbook 696—you might have seen it referenced—suggesting that up to 20% of dairy operations may encounter some level of stray voltage issues. While the data is still developing on the exact prevalence, this potential scope… well, it merits serious consideration as we evaluate those unexplained herd health and production challenges we all see from time to time.

Here’s what’s interesting from an economics standpoint: With a 20-pound daily increase on 150 cows at current milk prices, Nelson’s investment paid for itself in approximately six months. Not many farm improvements deliver that kind of return, right?

Understanding the Technical Challenge

So here’s where things get a bit complicated—but stick with me because this matters.

The complexity of stray-voltage diagnosis begins with how we measure it. Standard utility testing protocols use a 500-ohm resistor to simulate your cow’s electrical resistance. This standard, believe it or not, was established in that 1991 USDA handbook I mentioned. And it’s still what utilities use when they come out to test your farm today.

What makes this significant? Well, field research from agricultural electrical consultants has documented dairy cattle with actual body resistance ranging from approximately 100 to 400 ohms—substantially lower than what the testing standard assumes. Dr. Richard Norell, who’s the Extension dairy specialist up at the University of Idaho, has examined electrical resistance in dairy cattle as part of broader agricultural electrical research, and his work contributes to our understanding of this variation.

The practical implications… they deserve consideration. You probably remember Ohm’s Law from somewhere—current equals voltage divided by resistance, right? Well, if the testing equipment assumes 500 ohms but the actual cow resistance is closer to 200 ohms, the measured current significantly underestimates what your animals actually experience. It’s somewhat like calibrating feed measurements with equipment that doesn’t account for actual dry matter intake—the numbers look fine, but reality’s telling a different story.

When utilities measure, say, 1.0 volts using standard protocols, they calculate approximately two milliamperes of current flow—within accepted guidelines, according to veterinary references such as the Merck Manual. But here’s the thing: cattle with lower resistance are experiencing higher current levels proportionally. Norell’s research and data collected at UW–Madison showed cows reacted to current at the lowest tested levels—just 0.25 milliAmps, which is eight times lower than the standard utilities use to define possible harm to cattle. In fact, 25% of cows in those studies showed behavioral responses at only 0.25 mA, much lower than the traditional 2 mA threshold long reported in the industry.You can see the problem here.

Learning from Progressive Operations

What I find valuable about the Olmar Farms case is that they followed best management practices—and still got hammered.

Their operation, which received Holstein Association USA’s Elite Breeder Award in 2017, maintained a rolling herd average of 26,192 pounds before encountering these challenges. They’d invested in modern facilities, including equipotential planes (you know, those conductive grid systems designed to prevent electrical differentials), tunnel ventilation, sand-bedded freestalls—basically everything we’re told makes a difference.

Nelson brought in respected consultants. Dr. Tom Oldberg analyzed nutrition. Dr. Reid evaluated the milking systems. Dr. Gary Neubauer, a well-known dairy veterinarian, was also part of the diagnostic team. Each one confirmed management met or exceeded industry standards. As many of us have experienced, sometimes you can do everything right and still have problems.

Yet the herd exhibited concerning behavioral changes. Previously calm animals became difficult to handle during milking. Some cows required leg restraints for safe milking—and that’s unusual for well-managed herds, wouldn’t you say? Mastitis incidence increased despite proper protocols. Water consumption patterns changed dramatically, with cows hesitating at troughs or displaying unusual lapping behaviors rather than normal drinking.

⚠️ Warning Signs We Should All Watch For:

- Cows hesitating or “dancing” at water troughs

- Unusual lapping instead of normal drinking

- Parlor nervousness is developing in previously calm animals

- Drinking from puddles while avoiding standard waterers

- Multiple health issues appearing simultaneously without a clear cause

- High producers are dying unexpectedly without an obvious illness

Standard utility testing repeatedly showed “acceptable” voltage levels. The graphs looked normal, measurements within guidelines. This continued for eight years—eight years!—until 2016, when Nelson connected with an electrical specialist with specific experience in agricultural applications. Using equipment capable of millisecond-resolution recording (typically from manufacturers such as Fluke or Dranetz) and testing with more representative resistance values, this specialist documented electrical issues throughout the facility, including outdoor water systems.

Court records from July 2019 confirm the operation converted to three-phase power with an isolated transformer installation on May 1, 2017. There was a reported an 18-pound increase in production during the subsequent summer months, with current production exceeding 30,318 pounds rolling herd average as of March 2025. That’s quite a turnaround.

The Biological Response to Chronic Electrical Exposure

Here’s something that really fascinates me about this whole issue—the biology behind it.

Research from institutions like the University of Wisconsin-Madison helps explain what’s happening at the biological level. Doug Reinemann and co-researcher Dr. Louis Sheffield, both with Wisconsin’s biological systems engineering department, have published on how electrical stress affects dairy cattle biology. And what he’s found… it’s eye-opening.

This research shows that repeated low-level electrical exposure triggers cortisol release—the primary stress hormone. While acute stress responses serve important biological functions (we’ve all seen how a fresh cow reacts to a single stressor during transition), chronic exposure can maintain elevated baseline cortisol levels, which can affect multiple body systems. This builds on what we’ve learned about other chronic stressors in dairy production.

The cascade effects are fascinating… and concerning. We’re talking suppressed immune function, with reduced T-cell production and weakened antibody responses. This explains the varied symptoms Nelson observed: treatment-resistant mastitis in some cows, reproductive failures in others, sudden production crashes or unexpected mortality in high producers.

As Nelson put it—and I think this really captures the frustration—”It looked like we were failing at everything simultaneously. Nutrition problems AND health problems AND reproduction problems AND behavior problems all at once.” Makes perfect sense when you understand it’s all coming from the same electrical source, doesn’t it?

Research in veterinary literature also documents transgenerational effects, with calves from electrically stressed dams showing reduced immune competence, impaired vaccine responses, and various developmental issues. Nelson reported observing congenital disabilities and cardiac abnormalities during the most challenging period. That’s something that really makes you think about the long-term implications for your replacement program.

Distinguishing Source and Responsibility

Alright, so here’s where things get complicated—and expensive. The source of electrical issues fundamentally determines resolution approaches and costs.

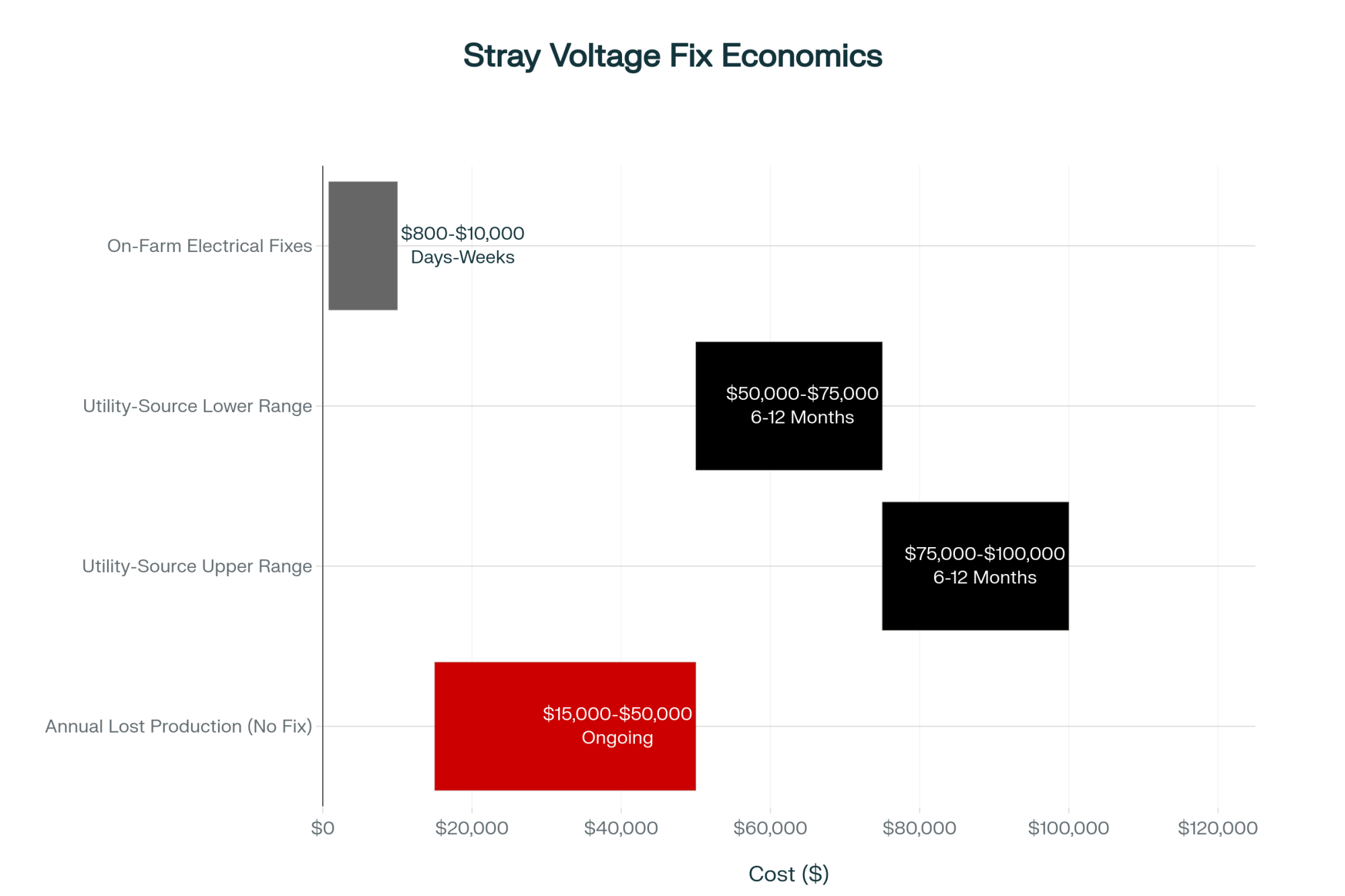

On-farm sources (damaged motor insulation, corroded connections, inadequate grounding) typically cost between $800 and $10,000 to address, depending on scope. Any qualified agricultural electrician can handle these repairs. That’s manageable for most operations.

But utility-source issues? That’s a different story altogether.

Every North American farm connects to multi-grounded neutral systems—the National Electrical Safety Code requires it. The utility-neutral conductor is repeatedly grounded between the substation and your farm, with your farm’s electrical systems bonded to this neutral at the transformer. You probably know this already, but it’s worth reviewing.

Under ideal conditions, this system works well. But when utility neutrals can’t adequately carry return current—maybe due to undersized conductors for modern loads, deteriorated connections from age, or phase imbalances—that current seeks alternate paths through earth ground. And since your farm’s grounding system is bonded to theirs… well, that current can flow right through your agricultural facilities.

The primary solution is to install isolated transformers to create electrical separation between the farm and utility systems. Based on documented cases, these installations can cost $50,000 to $100,000 or more. The Nelson operation’s investment approached $100,000, including a three-phase power installation located more than 100 yards from the buildings. And despite the problem originating from utility infrastructure, farms often bear these costs themselves. That still frustrates me when I think about it.

What about insurance? Most standard farm policies generally don’t specifically address stray voltage losses, though some carriers now offer specialized riders. I always tell producers: verify coverage with your agent rather than assuming protection exists. Better to know before you need it.

Best Practices from Affected Operations

Looking at successful resolutions, I’m seeing consistent patterns that are worth sharing.

Documentation proves crucial. Producers who achieve resolution create comprehensive evidence before engaging utilities or consultants. This includes video documentation of behavioral changes—hesitation at water sources, unusual drinking patterns, and parlor nervousness. They maintain detailed production records showing systematic changes despite consistent management. Health events, treatments, mortality patterns—it all merits careful tracking.

Paul Halderson’s Wisconsin operation, which prevailed in litigation against Xcel Energy, maintained decades of documentation. This record proved invaluable when addressing utility claims about management deficiencies. The lesson here is clear: document everything, even if it seems minor at the time.

Independent testing before utility engagement often proves worthwhile. Specialists familiar with agricultural electrical systems, using appropriate protocols and resistance values, typically charge $3,000 to $5,000 for a comprehensive assessment. While that’s significant, this investment can prove valuable if negotiation or—God forbid—litigation becomes necessary.

Understanding state-specific standards helps producers navigate the system. Wisconsin and Minnesota use 1-volt or 2-milliamp action thresholds. Knowing these standards—and their basis in that 500-ohm testing protocol we discussed—helps you advocate for appropriate testing when utilities respond.

Regional Variations and Current Context

The 2025 dairy economy makes hidden production losses particularly challenging, doesn’t it? While feed costs have moderated from recent peaks (thankfully), maintaining production efficiency remains crucial for profitability. A 15% production loss from undiagnosed electrical issues—not uncommon based on documented cases—that can determine operational viability.

I’ve noticed regional patterns emerging from infrastructure age and agricultural practices. Wisconsin and Minnesota operations, particularly those served by infrastructure dating back 40-50 years, report more utility-source issues as equipment struggles with modern electrical loads. Similar patterns appear in Vermont and upstate New York, especially where utility consolidation has deferred infrastructure updates.

Newer dairy regions present different challenges. Texas and Idaho operations may have more modern infrastructure, but they face issues stemming from shared distribution lines used by center pivot irrigation systems. Seasonal voltage fluctuations during peak irrigation can affect nearby dairy facilities. And Southeastern operations? They contend with how seasonal variations in ground moisture affect current flow through the soil—I heard about this recently from a Georgia producer dealing with mysterious summer production drops.

California’s large-scale operations, with their substantial electrical loads for cooling and milk processing, sometimes encounter unique challenges when utility infrastructure hasn’t kept pace with dairy consolidation and expansion. It’s a different set of problems, but the underlying issue remains the same.

Recognition and Response Strategies

Based on documented cases and producer experiences, if you’re seeing behavioral changes at water sources—hesitation, unusual lapping behaviors, complete avoidance despite obvious thirst—that’s particularly telling. Same with parlor nervousness that develops in previously calm animals, especially during milking preparation.

For producers observing these patterns, here’s what works: Begin with thorough documentation using available technology—smartphones can capture behavioral evidence effectively these days. Engage independent testing through specialists who understand agricultural applications. Eliminate on-farm sources by systematically evaluating motors, connections, and grounding systems. Only then engage utilities, preferably in writing, with documentation already assembled.

Budget considerations should include $3,000-$5,000 for comprehensive independent testing. If utility infrastructure proves problematic, resolution costs can reach $50,000 to $100,000 or more for isolated transformer installation. Yes, that’s significant. But remember Nelson’s six-month payback period. Sometimes the investment, painful as it is, makes sense.

Industry Evolution and Future Considerations

Recent legal precedents suggest evolving recognition of these challenges. The Iowa Supreme Court’s June 2024 decision upholding Vagts Dairy’s verdict against Northern Natural Gas for pipeline-related electrical issues establishes important precedent for infrastructure liability. That’s encouraging, at least.

Most producers won’t pursue lengthy litigation—and shouldn’t have to. Practical solutions matter more than legal victories. That’s why farmers like Jill Nelson are developing resources to share knowledge. Her website, strayvoltagefacts.com, provides research and guidance based on her direct experience. It’s worth checking out if you’re dealing with unexplained issues.

What’s encouraging is how the industry conversation has evolved. A decade ago, debates centered on whether stray voltage even existed. Today’s discussions focus on identification and mitigation strategies. This represents meaningful progress, even if implementation remains inconsistent.

Nelson’s operation now maintains a rolling herd average of over 30,318 pounds on twice-daily milking, according to March 2025 data. While genetics were damaged during the affected period, the operation survived and recovered. As Nelson has shared in various forums, early recognition of testing limitations and documentation requirements might have shortened their eight-year challenge considerably.

Given the substantial number of operations potentially experiencing some level of electrical issues, it is important to acknowledge that “acceptable” testing results may not ensure the safety of sensitive animals. Just as we’ve embraced precision management for nutrition and reproduction, electrical safety may require similar individualized approaches.

This builds on what we’ve learned about variation in biological systems—what works for the average may not protect the sensitive. Until testing protocols better reflect this reality, those of us who combine careful observation with independent verification will be best positioned to protect our herds.

The Bottom Line

You know, the difference between management challenges and electrical issues can be subtle but significant. Understanding this distinction—and knowing how to investigate it properly—that’s valuable knowledge for any operation experiencing unexplained herd challenges.

Sometimes what appears to be a management problem stems from infrastructure issues that standard testing protocols weren’t designed to detect. And that’s not a failure of management—it’s a limitation of how we’ve been measuring things.

What’s your experience been with unexplained herd health or production challenges? Have you noticed behavioral changes that didn’t quite fit typical patterns? The conversation continues as we work together to understand and address the complex interactions between modern dairy operations and aging electrical infrastructure.

For more resources and to share experiences, visit strayvoltagefacts.com or reach out through The Bullvine’s producer network. Because sometimes the best solutions come from farmers sharing what they’ve learned the hard way. And that’s how we all get better at this business we’re in.

KEY TAKEAWAYS:

- If cows are hesitating at water or dying unexpectedly, it’s likely stray voltage—affecting 1 in 5 dairy farms, not management failure

- Standard utility testing misses the problem: They test at 500 ohms resistance when actual cow resistance is 200-400 ohms, underreporting exposure by half

- Your documentation strategy determines your outcome: Video behavior changes, track production/health data, get independent testing ($3-5K) BEFORE calling utilities

- Resolution costs vary wildly: On-farm electrical fixes are manageable (under $10K), but utility-source problems requiring isolated transformers can hit $100K—though payback can be swift (20 lbs/cow/day gains)

- You’re not imagining it: Courts are awarding millions in stray voltage cases, proving this hidden problem is real and fixable when properly diagnosed

EXECUTIVE SUMMARY:

Your cows avoiding water troughs and dying after perfect production days might not be a management problem—it’s likely stray voltage, a hidden electrical issue affecting up to 20% of dairy operations nationwide. The crisis stems from a fundamental testing flaw: utilities measure using 500-ohm resistance standards established in 1991, but research shows dairy cattle actually average 200-400 ohms, meaning your animals experience double the electrical current that standard tests report as “safe.” Jill Nelson’s award-winning Minnesota Holstein operation suffered eight years of mysterious losses before discovering this truth—her $100,000 investment in an isolated transformer delivered 20 pounds of milk per cow per day, paying for itself in six months. The difference between financial recovery and bankruptcy often comes down to recognizing symptoms early (behavioral changes at water sources, parlor nervousness, unexplained deaths) and getting independent testing with proper equipment. While on-farm electrical fixes typically cost under $10,000, utility-source problems can exceed $100,000, making documentation and proper diagnosis critical before accepting utility test results that miss what’s really happening to your herd.

Complete references and supporting documentation are available upon request by contacting the editorial team at editor@thebullvine.com.

Learn More:

- Mastering the Transition: A Holistic Approach to Dairy Cow Health and Productivity – Stray voltage manifests as a cascade of health failures. This article provides a tactical, holistic guide for mastering the transition period, helping you differentiate between a management gap and a hidden electrical issue.

- China’s 42 Million Tonne Milk Mountain: What Every Dairy Farmer Needs to Know About the Industry’s Biggest Shift Since Mechanical Milking – This strategic analysis details the brutal economic reality and market forces pressuring mid-size dairies. It provides the essential context for why finding and fixing a 20-pound production loss is no longer optional—it’s a matter of survival.

- The Lameness Detection Wake-Up Call: What Three-Quarters of Your Herd is Costing You – The stray voltage article highlights a massive diagnostic failure. This piece reveals how new automated detection technologies are achieving 85% accuracy in lameness, reinforcing the value of using precision tools to find costly problems your eyes are missing.

The Sunday Read Dairy Professionals Don’t Skip.

The Sunday Read Dairy Professionals Don’t Skip.

Every week, thousands of producers, breeders, and industry insiders open Bullvine Weekly for genetics insights, market shifts, and profit strategies they won’t find anywhere else. One email. Five minutes. Smarter decisions all week.

The Sunday Read Dairy Professionals Don’t Skip.

The Sunday Read Dairy Professionals Don’t Skip.