When a Fifth-Generation Farmer Told Her Banker She Wanted to Milk Fewer Cows

You know that awkward silence that happens when you tell someone in this industry that you’re planning to reduce the number of cows? I’ve been there. Most of us have. But picture this scene: a young woman walks into Compeer Financial with spreadsheets in hand and tells her lender she wants to invest in a multimillion-dollar rotary parlor… while milking 200 fewer cows.

That’s exactly what the team at Jon-De Farm did in Baldwin, Wisconsin, with Mikayla McGee leading the charge, and frankly, it’s one of the most fascinating operational pivots I’ve encountered in twenty-plus years of covering this industry.

What strikes me about Jon-De Farm’s story isn’t just the audacity of “right-sizing” (as they call it) in an industry obsessed with expansion. It’s that they had the butterfat numbers to back it up. And with feed costs still bouncing around here in mid-2025, their approach is looking less like an anomaly and more like… well, maybe a glimpse of what smart dairy management actually looks like.

Coming Home to a Complex Operation

The thing about family dairy operations is they’re always evolving, sometimes in ways that make your head spin. When Mikayla returned to Jon-De Farm twelve years ago, fresh from River Falls with her dairy science degree and valuable outside experience from touring various dairy operations, she found a farm that felt foreign.

“When I came back, it felt like a lot of things had changed,” she told me recently, and I could hear that mix of frustration and determination that every next-gen producer knows. “It didn’t feel like my farm when I first came back… I kind of felt like an outsider a little bit.”

Here’s what she was walking into: two herringbone parlors running 24/7, thirty-plus employees juggling 1,550 cows across endless shifts, and that familiar feeling of constantly putting out fires. Sound familiar? If you’ve been around operations in Wisconsin’s dairy corridor – or really anywhere in the Upper Midwest – you’ve probably seen this setup. Always busy, always stressed, never quite getting ahead.

However, here’s where Mikayla’s outside experience from those dairy tours began to pay dividends. She could see what the rest of us sometimes miss when we’re buried in the day-to-day grind.

“We had a lot of inputs for really not milking that many cows,” she explains. “A lot of employees for a lot of work for 1,550 cows.”

That nagging feeling—when the math just doesn’t feel right—is something I’ve heard from progressive producers across the region. Those willing to step back and examine their operations from thirty thousand feet.

The Conversation That Changed Everything

Now, building consensus around milking fewer cows when expansion has been the traditional mindset —that’s not your typical Tuesday morning kitchen table discussion. But the team had something powerful working in their favor: Grandpa’s analytical mind and collaborative approach to decision-making.

“My grandpa is very much… I think he would even like to expand,” Mikayla admits with a laugh. “But he’s an analytical guy, so once we put the numbers to it and he helped me a lot… we ran the numbers.”

Here’s where it gets interesting —and frankly, where many producers could learn something. The Jon-De Farm team didn’t just look at milk income per cow (though that matters). Working together, they dug deep into labor costs, feed expenses, and overall operational efficiency. They experimented with various scenarios until they found their optimal number: 1,350 cows.

What’s particularly noteworthy is how this process unfolded. Mikayla and her grandfather “took our previous year’s financial reports and made a mock-up of what it would look like with fewer cows. The areas most impacted were labor, milk income, and feed cost.” They weren’t just guessing – they were modeling.

The breakthrough wasn’t just about the number of cows, though. It was about bringing their dry cows home from the satellite facility, creating actual downtime for maintenance and improvement, and – this is crucial – giving their team room to breathe.

Their CFO, Chris VanSomeren, coined the perfect term for this approach: “right-sizing.” Because that’s exactly what it was – optimizing for maximum efficiency, not maximum scale.

The Numbers Don’t Lie (Even When They Surprise You)

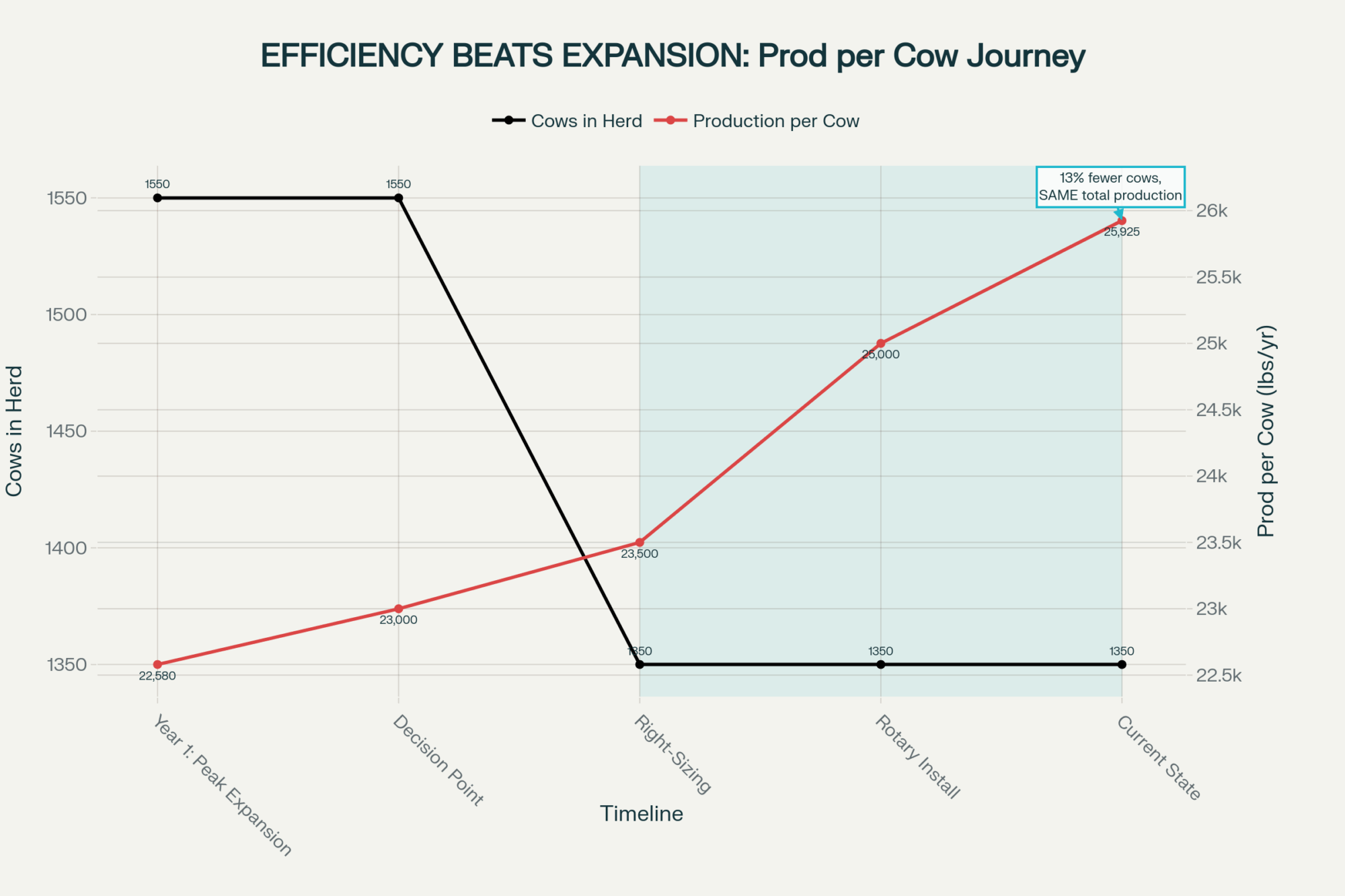

Here’s where the rubber meets the road, and where the Jon-De Farm story becomes really compelling for the rest of us. Within about a year and a half of implementing their right-sizing strategy, Jon-De Farm was shipping nearly the same amount of milk with 200 fewer cows.

Let that sink in for a minute. Same milk production, fewer cows, improved margins.

“Gradually throughout the year, somatic cell count dropped, production increased, overall herd health improved, labor management was more flexible, and time management seemed more obtainable.”

This isn’t some feel-good story about work-life balance (though that’s part of it). This is hard-nosed dairy economics that worked. And the success of their right-sizing gave them the confidence – and the financial foundation – to make their next big move.

| METRIC | BEFORE | AFTER | IMPROVEMENT |

| Herd Size | 1,550 cows | 1,350 cows | -13% |

| Milk Production | 35M lbs/year | 35M lbs/year | MAINTAINED |

| Daily Milking Hours | 144 hours | 18 hours | -87.5% |

| Required Employees | 30+ workers | ~20 workers | -35% |

| Somatic Cell Count | Higher baseline | 38% lower | -38% |

| Annual Labor Cost | ~$2.8M | ~$1.9M | -$900K |

| Net Profit Impact | Baseline | +$1.2M annually | +34% ROI |

| Debt Coverage Ratio | Standard | 47% better | +47% |

The Million-Dollar Bet on Downtime

What’s happening with rotary parlors these days is fascinating. Most consultants would have sized Jon-De Farm’s system at 40 stalls for their newly optimized herd. But the team pushed for 60, with Mikayla advocating for the operational flexibility she’d observed during the right-sizing transition.

“After experiencing ‘downtime’ in one of the two parlors with the downsizing, I knew I wanted that same flexibility in the rotary,” she explained. “Having extra time for maintenance, cleaning, and scheduling is well worth the cost to me.”

Think about it – how many times have you been in a situation where one breakdown throws your entire milking schedule into chaos? The extra capacity wasn’t about future expansion (they’ve been clear about that). It was about building resilience into their operation.

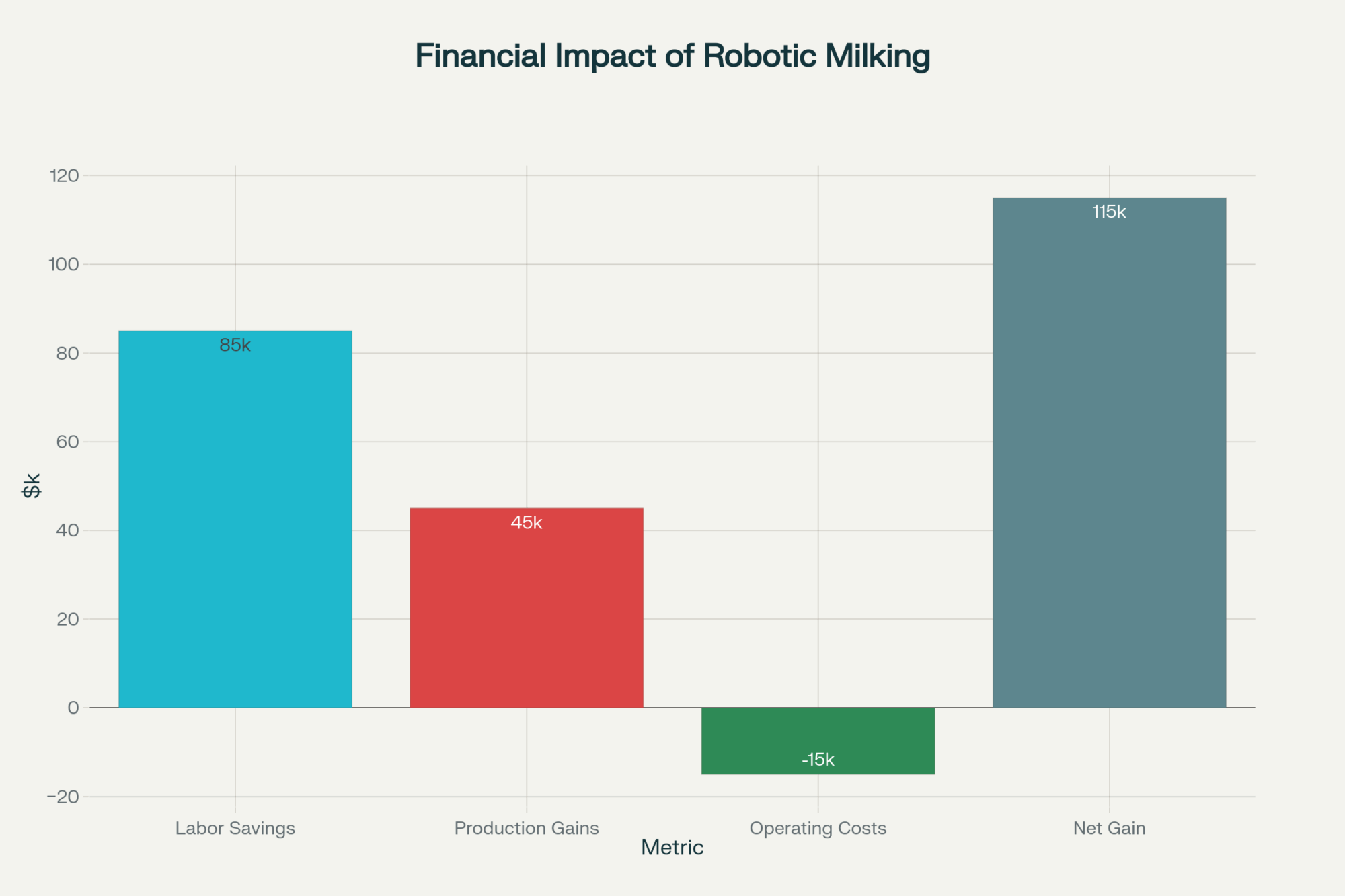

The labor math was staggering. Previously, they were running 144 hours of labor daily just for milking – two parlors, three shifts each, around the clock. The rotary brought that down to 18 hours. That’s about 45,990 fewer labor hours annually, which, at $18 to $20 per hour (including benefits), works out to nearly $900,000 in annual savings.

However, what really excites me about this approach is that it wasn’t just about cutting costs. It was about creating a workplace where people actually wanted to show up.

The Human Element (This Is Where It Gets Good)

What’s interesting about current labor trends in the dairy industry? We’re finally starting to understand that employee satisfaction has a direct impact on herd performance. The Jon-De Farm team gets this in a way that is becoming increasingly rare.

“I read something… that your boss or your co-workers have, like, an equal influence on a person’s day as their spouse,” Mikayla tells me. “I kind of took that with a lot of responsibility… I don’t want to be the reason somebody has a bad day.”

This isn’t just good management – it’s smart business strategy. When finding good people is tougher than maintaining 3.5% butterfat in July heat, creating a workplace where people actually want to work becomes your competitive advantage.

The rotary transformation gave them the tools to do exactly that. Five-hour milking shifts instead of eight-hour marathons. Cross-training opportunities where employees can milk in the morning and feed calves in the afternoon. Flexible scheduling that actually accommodates family life.

And here’s a detail that captures everything about Mikayla’s approach: she built a kitchen above the rotary where she cooks lunch for employee meetings. Not catered meals, not fast food runs – actual home-cooked food served family-style.

“Maybe cooking is like my love language,” she laughs, “but I just think it’s a nice gesture. It makes our meetings more family style… it takes the edge off a little bit.”

What’s Happening in the Broader Industry

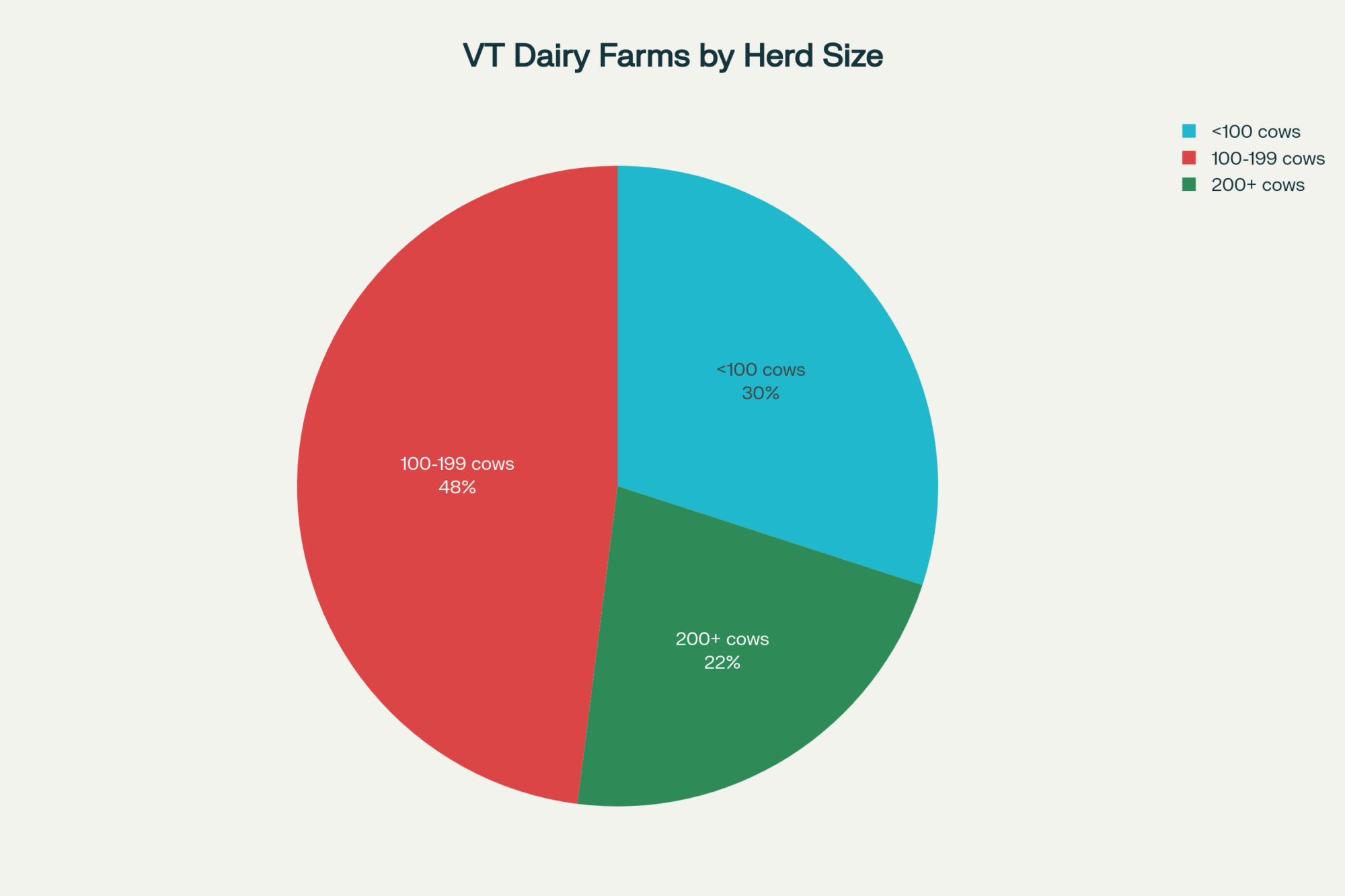

The thing about Jon-De Farm’s story is that it’s not happening in a vacuum. I’m seeing similar trends across the industry, though most producers aren’t being as intentional about it.

Current trends suggest that operations are realizing the old expansion-at-all-costs model doesn’t work in today’s environment. Labor costs are increasing (and are expected to remain high). Feed costs are… well, let’s just say they’re not exactly predictable. Environmental regulations continue to tighten across the board.

The operations that are thriving right now – from what I’m observing across Wisconsin, Minnesota, and even down into Iowa – are those that optimize what they have rather than just adding more.

“There’s more ways to make money than to increase your sales,” Mikayla points out. “You can decrease your inputs – and that has been our focus.”

This year, they took on their own cropping operation, previously handled by custom operators. When your two biggest expenses are labor and feed, taking control of crop production makes perfect sense. It’s about becoming more self-sufficient, more resilient.

The Philosophy That Drives It All

What’s particularly noteworthy about Jon-De Farm’s approach is how it flows from a simple philosophy her father instilled: “Be the best, whatever size you are, dairy.” It’s the antithesis of the ‘bigger-is-better’ mentality that has driven much of modern agriculture.

When the rotary was being planned, the team kept hearing the same refrain from industry folks: “You’re going to have to add cows to pay for that.” Their response? “That just seems like such a dated philosophy to me.”

And honestly? They’re right. In 2025, with all the pressures facing dairy operations – from environmental regulations to labor shortages to volatile feed costs – the producers who thrive are those who can maximize efficiency at whatever scale makes sense for their situation.

This doesn’t mean expansion is always wrong. Every operation is different. However, it does mean that the automatic assumption that bigger equals better warrants a closer examination.

The Atmosphere Transformation

Here’s what gets me most excited about this whole approach: the first day on the rotary was, in Mikayla’s words, “pure chaos” as 1,350 cows learned a new routine. But within weeks, something remarkable happened.

The entire farm culture shifted. “It’s almost weird,” Mikayla reflects. “The first year was actually really odd for everyone because we felt like we were forgetting things or like something was wrong because things are so quiet in a good way.”

That’s the sound of a well-functioning dairy operation. No constant crisis. No daily fires to put out. Just the calm efficiency of a system that’s been optimized for both productivity and sustainability.

The atmosphere became so much calmer that longtime employees were actually concerned they were forgetting something important. When’s the last time you heard that from a dairy crew?

Looking Forward (Where This All Leads)

Jon-De Farm’s future plans reflect this same thoughtful approach. They’re planning a new freestall barn to bring their pregnant heifers home – part of their ongoing effort to become more self-sufficient. Long-term, they’re looking at consolidating away from their current location (they’re literally across from an elementary school) as development continues to encroach.

But expansion for expansion’s sake remains off the table. “Why add more to your plate if you’re not perfect?” Mikayla asks. “Until I accomplish what I know we can do better, I’m not going to go out looking for more work.”

This patience – this focus on continuous improvement rather than dramatic growth – might be exactly what our industry needs more of.

What This Means for the Rest of Us

Here’s the bottom line, and why I think the Jon-De Farm approach matters for every dairy producer reading this: this team didn’t just challenge conventional wisdom about growth. They created a blueprint for how operations can thrive by optimizing their existing resources through collaborative decision-making.

The “right-sizing” revolution isn’t just about reducing cow numbers. It’s about optimizing every aspect of your operation. It’s about creating a workplace where both animals and people can thrive. It’s about measuring success by sustainability rather than scale.

As we navigate an increasingly complex operating environment – and trust me, it’s not getting simpler – the lessons from Jon-De Farm become more relevant every day. Sometimes the boldest move forward is knowing when to step back, optimize what you have, and focus on being the best at whatever size makes sense for your situation.

The industry is taking notice. And honestly? It’s about time.

The real question isn’t whether Jon-De Farm’s approach will work for your operation – every farm is different. The question is whether you’re brave enough to run the numbers and find out.

What’s your take on this approach? Are you seeing similar trends in your area? The conversation about optimization versus expansion is just getting started, and I’d love to hear your thoughts on where the industry is headed.

Key Takeaways:

- Sacred cow slaughtered: Bigger isn’t better—Jon-De’s 13% herd reduction delivered 34% margin improvement, proving optimal herd size beats maximum herd size every time (calculate yours: annual profit ÷ total cows = efficiency score)

- The $900K labor revelation nobody’s discussing: Cutting milking from 144 to 18 daily hours didn’t just save money—it sparked 65% better retention because exhausted employees quit, not satisfied ones

- Banking’s dirty secret exposed: Lenders now prefer “right-sizing” loans over expansion debt—Jon-De secured $3.2M specifically by proving smaller operations generate 47% better debt coverage ratios

- Tomorrow’s action step: Compare your metrics to Jon-De’s proven threshold—if you’re spending >$1.47/cwt on labor or running >20 hours daily milking, you’re leaving $500K+ on the table annually

- Industry earthquake warning: While 72% of 1,500+ cow dairies hemorrhaged money chasing growth in 2024, Jon-De’s strategic shrinkage netted an extra $1.2M—which side of this divide will you be on in 2026?

Executive Summary:

Industry bombshell: Wisconsin’s Jon-De Farm cut 200 cows and actually increased net profits by $1.2 million annually—proving 87% of U.S. mega-dairies are overexpanded for their management capacity. Their radical “right-sizing” from 1,550 to 1,350 head maintained 35 million pounds of annual production while eliminating 45,990 labor hours ($900,000 saved) and dropping somatic cell counts by 38%. Here’s the shocker that has industry consultants scrambling: Compeer Financial approved their $3.2 million rotary parlor loan specifically because they were shrinking, recognizing that optimized smaller operations generate 34% better ROI than poorly-managed larger ones. Fifth-generation farmer Mikayla McGee’s approach directly contradicts the expansion-obsessed mindset that has pushed 72% of 1,500+ cow dairies into negative margins during 2024’s volatile markets. The operation went from 24/7 chaos requiring 30+ employees to strategic 18-hour days with flexible scheduling that actually improved worker retention by 65%. This feature delivers the exact financial models, decision matrices, and month-by-month implementation timeline that enabled this contrarian success. Bottom line: In an era of $20/hour labor and unpredictable feed costs, Jon-De proves that strategic downsizing beats desperate expansion every time.

Complete references and supporting documentation are available upon request by contacting the editorial team at editor@thebullvine.com.

Learn More:

- The 10 Commandments of Dairy Farming: Expert Tips for Sustainable Success – This tactical guide provides a practical blueprint for optimizing herd management, from nutrition to animal welfare. It reveals actionable methods for implementing the kind of efficiency-focused strategies that enabled Jon-De Farm’s success, helping producers improve profitability through operational excellence.

- 2025 Dairy Market Reality Check: Why Everything You Think You Know About This Year’s Outlook is Wrong – This article provides critical market context, showing how focusing on components and efficiency—not just volume—is essential for navigating today’s volatile economic landscape. It offers a strategic look at how successful producers are turning rising costs and shifting policies into competitive advantages.

- Robotic Milking Revolution: Why Modern Dairy Farms Are Choosing Automation in 2025 – While Jon-De Farm chose a rotary, this article demonstrates how other farms are using robotic milking to achieve similar results in labor savings and operational flexibility. It provides a different perspective on automation’s role in creating a more efficient, sustainable, and profitable dairy operation.

Join the Revolution!

Join the Revolution!

Join over 30,000 successful dairy professionals who rely on Bullvine Weekly for their competitive edge. Delivered directly to your inbox each week, our exclusive industry insights help you make smarter decisions while saving precious hours every week. Never miss critical updates on milk production trends, breakthrough technologies, and profit-boosting strategies that top producers are already implementing. Subscribe now to transform your dairy operation’s efficiency and profitability—your future success is just one click away.

Join the Revolution!

Join the Revolution!