When satisfaction rates soar but profitability plummets, the dairy industry’s automation revolution reveals uncomfortable truths about who really wins

You know, that 4 a.m. alarm clock is becoming a thing of the past on more and more dairy farms. I’ve been tracking this transformation pretty closely, and what’s fascinating is where we’re at in 2025—the robotic milking market has grown to about $3.39 billion globally according to Future Market Insights, with projections suggesting we’ll hit $19.5 billion by 2035.

Big numbers, right? But here’s what’s interesting…

When you dig beneath all those impressive adoption statistics, there’s a more complicated story that I think every farmer considering robots really needs to hear. The University of Calgary followed 217 Canadian dairy producers through their robotic transitions—published the whole thing in the Journal of Dairy Science back in 2018—and what they found, combined with research from around the world, reveals some surprising patterns.

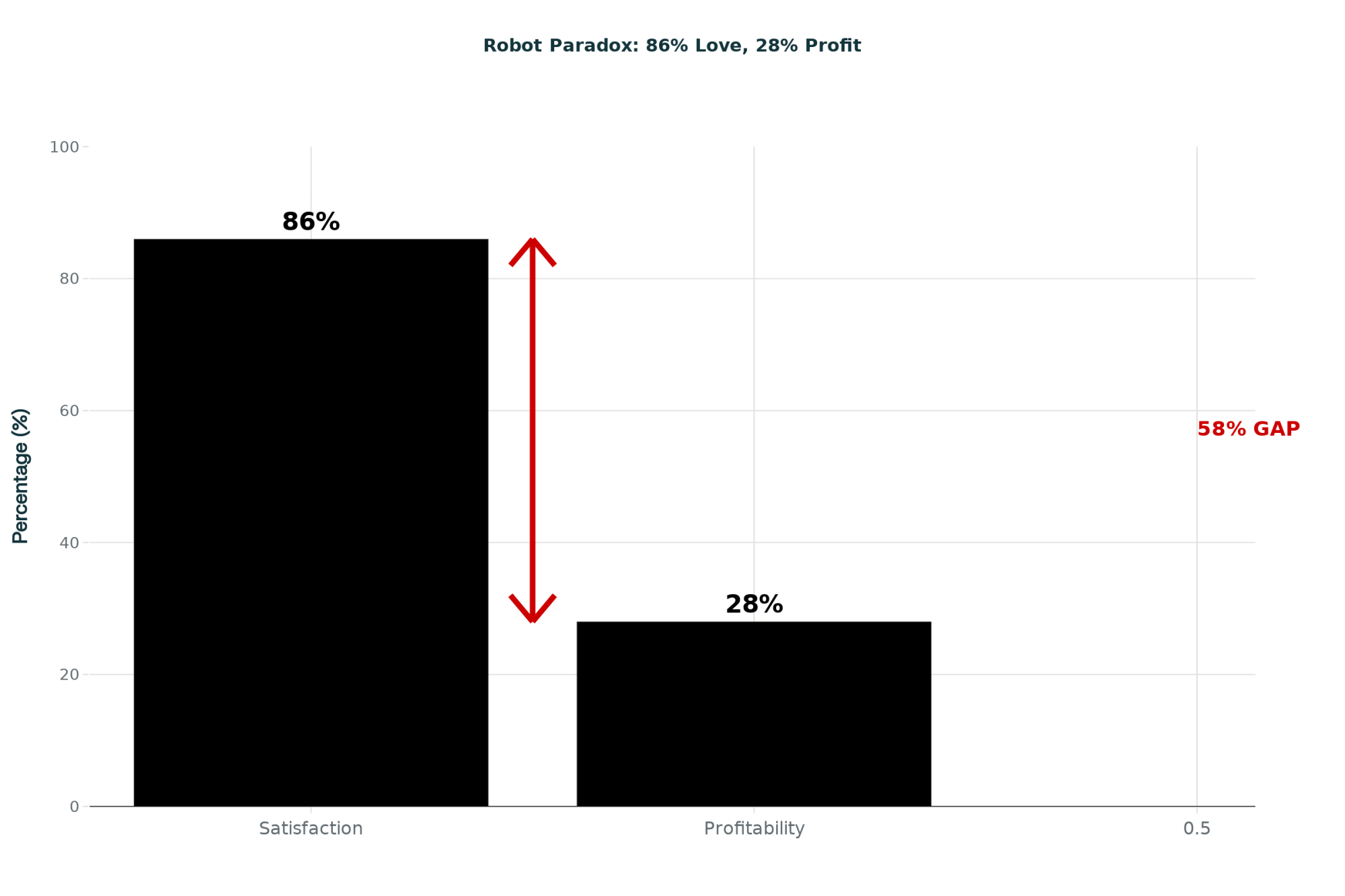

So yes, 86% of farmers who’ve installed robots would recommend them to others. That’s genuine satisfaction. But here’s the interesting part: only about 28% are actually achieving the production increases needed for clear profitability, based on the University of Minnesota’s economic modeling this year.

That gap? Well, it tells you something important about what’s really happening out there.

Why Farmers Love Robots Even When the Numbers Don’t Always Work

You probably know someone who’s installed robots and can’t stop talking about how it’s changed their life. A fifth-generation Prince Edward Island farmer told me recently, “I haven’t missed one of my kids’ events since we installed the robots.” And honestly, I hear this all the time.

This quality-of-life transformation—it’s real, and it explains why satisfaction rates stay high even when the economics get challenging.

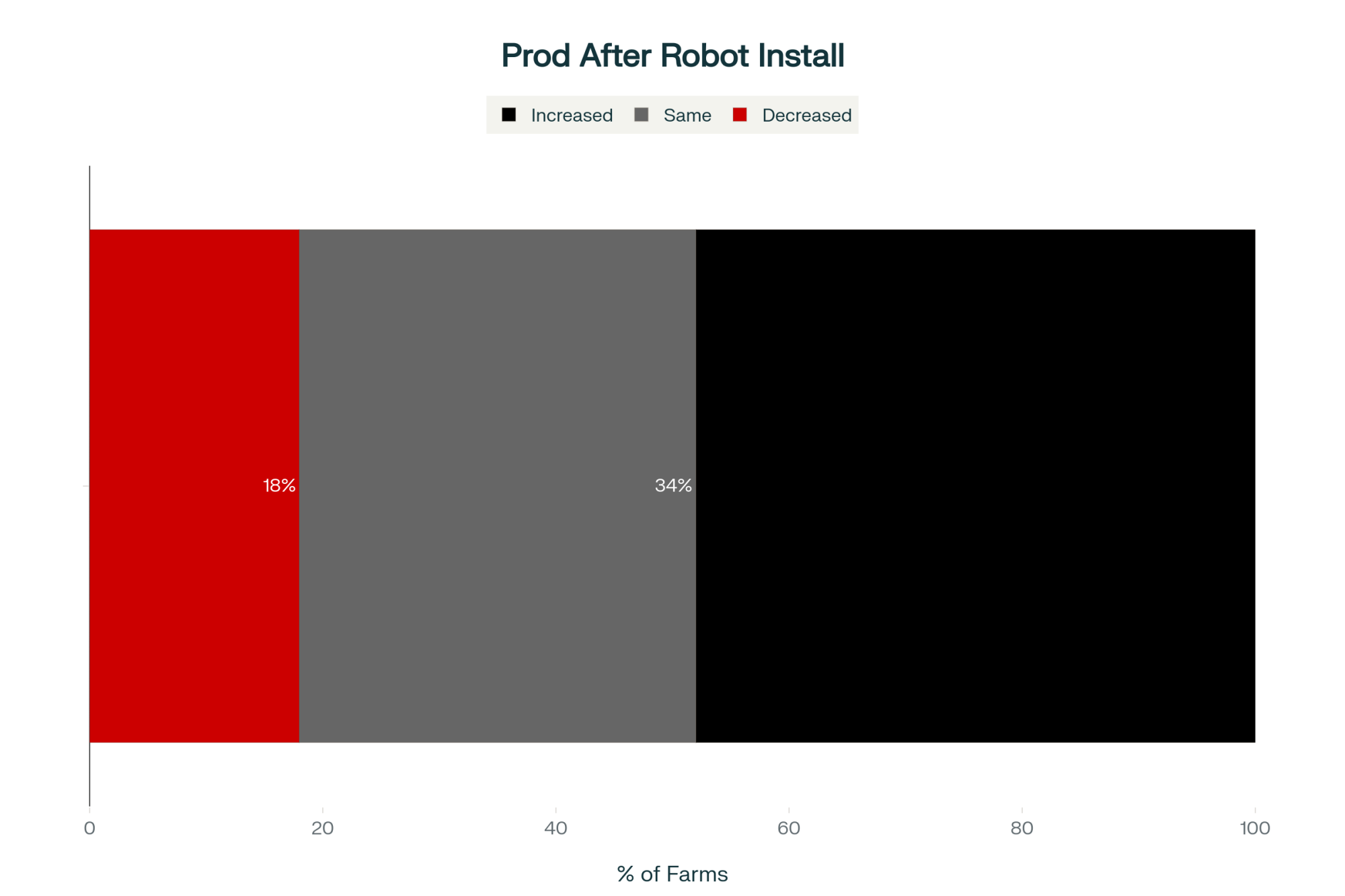

Looking more closely at that Calgary data, some interesting patterns emerge. About 58% of farms report increased milk production, which sounds good. But these range from tiny 2-pound gains all the way up to exceptional 10-pound improvements. Meanwhile, 34% maintain exactly the same production levels despite dropping serious money on robots. And here’s what really stands out—18% actually see production go down. Makes profitability pretty much impossible when that happens.

As Trevor DeVries from University of Guelph recently explained, “What producers are discovering is that robotic milking success depends on having the right combination of factors. The technology changes the nature and flexibility of labor rather than simply reducing hours.”

When More Milk Doesn’t Mean More Money

A Kansas dairy farmer shared something with me that really stuck: “We tried to save money by retrofitting our existing barn—big mistake. Cow traffic issues cost us at least 10 pounds of milk per cow until we finally redesigned the entire layout a year later. Do it right the first time.”

His experience aligns with research from multiple countries. Yes, 58% of farms report some production increases according to that Calgary study. But this year, the Minnesota Extension discovered that you need gains of at least 5 pounds per day to overcome the technology’s cost structure.

Most farms are getting just 2-3 pound increases? They’re stuck in what researchers call the “marginal profitability zone”—where success depends on milk prices staying strong and everything else going perfectly.

The Numbers That Matter

The Minnesota team uncovered specific thresholds that determine success, and honestly, these are sobering:

If your production increases just 2 pounds per day, robots need to last longer than 10 years to be more profitable than your old parlor. If production stays flat—and remember, that’s a third of farms—you’re looking at robots needing 13 to 17 years just to break even. And if production actually decreases? Well, robots are never going to be as profitable as what you had before.

Now, the financial reality gets even tougher when farmers discover that operational costs are running 300 to 400% higher than dealers projected. Teagasc in Ireland documented electricity costs that were nearly three times higher than those of conventional systems back in 2011. New Zealand farmers have told researchers their electricity bills doubled after installation. One farmer showed me maintenance invoices that hit six figures in the first year—the dealer told him to expect five to nine thousand.

The Scale Problem Nobody Expected

Turkish researchers published something in 2020 that really challenges what we’ve assumed about farm modernization. They looked at robot economics across different herd sizes, and what they found… well, it surprised me.

Small operations with 10 to 60 cows saw profit increases of 355% with robots. Operations with 121 or more cows? Generally profitable with proper execution. But here’s the kicker—farms with 61 to 120 cows actually saw decreased profitability.

Now, this Turkish study reveals a pattern that, if it holds true for North America, has profound implications. That middle group represents about 40-50% of North American dairy farms. We’re potentially talking about what economists call the “missing middle”—too large for the simplicity benefits of small-scale operations, but too small for the economies of scale that make it work for bigger dairies.

Looking at different regions, the pattern seems to align. Wisconsin farms averaging 90 cows? They’re right in what could be this danger zone. Vermont’s typical 125-cow operations sit just above the profitability threshold. California’s larger operations generally do fine. But those traditional Midwest family farms in that 80 to 100 cow range… if this Turkish research applies here, they really need to think this through carefully.

Down in the Southwest, where operations tend to be larger, the economics often work better. But what about Southeast producers with their typically smaller herds and higher humidity challenges? That’s a whole different calculation. And up in Canada—where that Calgary study originated—producers in Ontario versus those in Alberta face completely different economics, based on quota systems and herd-size restrictions.

The Genetic Timeline That Changes Everything

Here’s something that doesn’t get nearly enough attention—it takes 5 to 8 years to breed a herd that’s actually optimized for robotic milking. I’m not kidding.

Research published in the Journal of Dairy Science last year analyzed over 5 million milking records from about 4,500 Holstein cows. What they found is that udder conformation traits crucial for robot efficiency are moderately to highly heritable—we’re talking 0.40 to 0.79. So yes, you can breed for robot success. But man, it takes time.

A Wisconsin farmer discovered this the hard way two years after installing his robots. “I sold three of my highest producers six months after installation,” he told me. “They were production champions but robot time hogs. After replacing them with more efficient cows, my output actually increased even though individual cow averages decreased slightly.”

Think about that—higher total output with lower individual averages. It’s all about efficiency.

CRV and other breeding organizations showed in 2023 that farmers using bulls specifically selected for robot-friendly traits ultimately get about 350,000 pounds more milk per robot annually. For a three-robot operation, that’s over $200,000 in additional revenue. But—and this is crucial—only after 5 to 8 years of strategic breeding.

The Efficiency Gap That Makes or Breaks You

What really blew my mind: individual cow efficiency in robotic systems varies by nearly 300%. Same production levels, wildly different robot utilization.

Lactanet did this fascinating comparison in 2023—two cows with almost identical daily production, 48 kilos versus 49.5 kilos. But one produced her milk nearly three times more efficiently in terms of robot time. Just think about the implications…

And here’s where genetics meets economics in ways we’re just beginning to understand…

This explains why manufacturer recommendations about running 60 to 70 cows per robot produce such different results from farm to farm. High-efficiency operations can profitably run 68 cows per robot, sometimes more. Low-efficiency farms struggle with just 45 cows on the same equipment.

The Facility Mistakes That Haunt Farmers

The Calgary study found something that should give everyone pause: 68% of farmers would do something differently during installation, with facility modifications topping the list of regrets.

We’re not talking minor tweaks here. These are fundamental design decisions that compound into permanent profitability problems.

A Michigan producer took a different approach worth noting: “We visited fifteen robotic dairies before finalizing our facility design. The three most successful operations all emphasized the same point—cow flow is everything.”

Three Design Elements That Can Make or Break Your Operation

Feed Space—The Hidden Killer

The Dairyland Initiative in Wisconsin has repeatedly shown that retrofitting four-row barns—where everyone tries to save money—creates permanent bottlenecks.

These facilities typically give you 12 to 18 inches of feed space per cow when you need 24 inches minimum. What happens? Subordinate cows see their feed intake drop 15 to 25%. Your fetching requirements jump from a manageable 5% to 20% of the herd. And lameness rates climb from a typical 20% to a devastating 35-45%.

I’ve seen this mistake too many times. Farmers think they can make that old four-row barn work. It rarely does.

Traffic Flow—More Than Philosophy

The choice between free and guided traffic isn’t just a matter of management philosophy—it’s economics.

Farms trying to save 40 to 60 thousand on selection gates often discover that their “savings” create massive waiting times. Research in Animal Welfare Science from 2022 showed that this reduces lying time from the required 12 to 14 hours to just 9 to 11 hours. You know what happens when cows don’t get enough rest—lameness goes up, production goes down.

Backup Capacity—The Insurance You Hope You’ll Never Need

Despite dealer assurances that all cows will adapt, the Calgary research shows that 2% of herds need culling because they won’t work with robots. Plus, fresh cow management requires special protocols.

An experienced farmer put it bluntly: “You can’t avoid having some backup milking capacity. The cull rate’s too high if you require everyone to be robot-trained.”

Who Actually Benefits from Automation

The industry often talks about labor savings driving automation, but the challenges are real. USDA data from this year shows immigrant workers make up 51% of the dairy workforce while producing 79% of U.S. milk. With 38.8% annual turnover creating measurable production losses, something’s gotta give.

But here’s what I’ve learned—successful automation requires specific labor economics.

Minnesota’s breakeven analysis this year shows that robots become competitive when labor costs range from $22 to $32 per hour (depending on production gains), or when turnover exceeds 50% annually. Ideally, you have both.

For farms with stable workforces at $18 to $20 per hour—common in many rural areas—the economics often don’t support automation regardless of other factors. As one Nebraska farmer explained, “We have great employees who’ve been with us 10-plus years. Robots would’ve solved a problem we don’t have.”

When Everything Goes Right: A Success Story

Let me share what success looks like based on several Vermont operations I’ve worked with that represent that successful 28%.

One particular farm began in 2021, selecting for robot traits while still milking in their double-8 parlor. “We genomic tested every animal and started culling hard for robot efficiency traits,” they explained.

By the time they installed four DeLaval robots in 2023, 40% of their 240-cow herd already had favorable genetics. They built a new freestall barn explicitly designed for robots—about a $1.7 million investment that hurt, but they had the capital reserves.

“We could’ve retrofitted for $800,000,” they noted, “but after visiting twelve robot farms, we saw how facility compromises created permanent problems.”

Today, successful operations like these are achieving 90 to 95 pounds per day, with robots running at 2.0 to 2.2 kilos per minute. Many report annual labor cost reductions of 40-50%. But what really matters to these families—they’re coaching youth hockey, returning to off-farm careers part-time, actually having a life outside the barn.

“This technology transformed our operation,” one farmer told me. “But I tell neighbors straight up—if you can’t absorb significant losses for three years and invest in genetics and facilities, wait. This isn’t for everyone.”

The Questions That Predict Success or Failure

After analyzing hundreds of operations, researchers have identified the key diagnostic question that predicts success with remarkable accuracy:

Can you comfortably absorb $100,000 in annual losses for three consecutive years while investing an additional $150,000 in facility corrections and genetic improvements—without threatening your farm’s survival?

If you can’t confidently say yes, the research suggests waiting or exploring alternatives. This single question brings together every critical factor: scale, capital reserves, commitment to the timeline, and strategic thinking capacity.

There’s also the temperament piece. Ask yourself: Am I comfortable with data-driven decision making rather than hands-on control? Can I wait 24 to 48 hours for technical support instead of fixing things immediately? Will I accept that 5-8% of cows will always need fetching?

That last one’s important—perfectionism becomes a liability with robots.

Dutch research from 2020 found something surprising: farmers who quit robotic milking actually scored higher on conscientiousness scales than those who successfully adopted robotic milking. The characteristics that make excellent conventional dairy farmers—disciplined, hard-working, hands-on—can work against you with systems requiring indirect management.

Making Sense of It All: Who Should Actually Buy Robots

Based on everything we’re seeing, clear patterns emerge for different situations.

You’re a Strong Candidate (about 28 to 40% of farms) If You Have:

- 121 or more cows with plans to maintain or expand

- High-wage labor markets ($24+ per hour) or severe turnover (over 50%)

- Capital reserves to absorb $250,000 to $400,000 in losses and corrections over three years

- Already started genetic selection for robot traits at least two years before installation

- Willingness to build new or invest in proper retrofits ($1.2 million plus)

- Comfort with systems thinking and data-driven management

Proceed with Extreme Caution (about 40 to 50% of farms) If You Have:

- 60 to 120 cows—remember, scale economics work against this group

- Moderate labor costs ($18 to $22 per hour) with manageable turnover

- Limited capital requiring minimal facility retrofits

- Haven’t begun genetic selection for robot efficiency

- Need profitability within 2 to 3 years

- Preference for hands-on problem solving over remote management

Consider Alternatives (about 20 to 30% of farms) If You Have:

- Under 60 cows without expansion plans

- Stable, affordable labor force

- Existing facilities requiring extensive modification

- Management style strongly favoring direct control

- Can’t absorb three years of potential losses

The Bottom Line

What we’re learning about robotic milking challenges many of the assumptions we’ve held for years.

Quality-of-life improvements? They’re absolutely real and valuable. That 86% recommendation rate reflects genuine lifestyle benefits. But—and this is important—quality of life doesn’t automatically translate to profitability. I’ve seen too many farms discover this the hard way.

The 72% profitability gap is sobering but manageable if you understand what you’re getting into. Only 28% achieve the 5-plus-pound daily gains needed for clear profitability, according to Minnesota’s analysis. But understanding the specific requirements lets you make an informed decision rather than just hoping for the best.

Timeline expectations need radical adjustment, too. Full optimization takes 5 to 8 years, not the 1 to 2 years dealers suggest. Start genetic selection 2 to 3 years before installation and expect marginal performance for the first couple of years of operation. This isn’t pessimism—it’s realism based on what farmers have actually experienced.

Facility design really does determine destiny. Those 68% who regret their installation decisions teach us a powerful lesson: cutting corners on facility design creates permanent barriers to profitability. Proper design typically requires $1.2 to $2.2 million for most operations. If that number makes you uncomfortable… well, that’s valuable self-knowledge.

And scale economics aren’t what we thought. That 61 to 120 cow “dead zone” where robots actually decrease profitability challenges everything we’ve assumed about modernization improving economics. This has profound implications for mid-sized family farms—the backbone of our industry in many regions.

The dairy industry’s at an interesting crossroads. Technology adoption is accelerating even as economic pressures intensify. Robotic milking represents a genuine transformation for the 28 to 40% of operations that have the right combination of scale, capital, management style, and long-term commitment. For these farms, the technology really does deliver.

But for the majority—those who lack critical success factors at 60 to 72%—the technology might create more challenges than solutions. When you look at industry projections suggesting growth from $3.39 billion to $19.5 billion by 2035, those numbers require adoption rates that probably exceed the population of farms that are actually good candidates.

The lesson isn’t that robotic milking is good or bad. It’s that complex agricultural technologies require an honest assessment of your individual situation rather than following narratives about what’s “inevitable.”

The farmers succeeding with robots aren’t just early adopters or tech enthusiasts. They’re operations whose specific circumstances align perfectly with the technology’s requirements.

As that Vermont farmer put it perfectly: “This technology is amazing—for the right farm, at the right scale, with the right preparation. The challenge is being honest about whether you’re that farm.”

And honestly? That’s the conversation we all need to be having.

KEY TAKEAWAYS:

- The One Question That Matters: Can you lose $100K/year for 3 years? If no, skip robots. Only 28% ever see profit.

- The Scale Trap: 60-120 cows = robot dead zone (you’ll lose money). Under 60 or over 120 = potential profit.

- The Timeline Nobody Tells You: Year 1-3: Losses. Year 4-5: Breakeven. Year 5-8: Maybe profit. Plan accordingly.

- Your Best Cows Are Your Biggest Problem: High producers often fail at robots. Efficiency beats volume every time.

- The Real Math: Dealers say $9K/year costs. Reality: $30-45K. Triple everything, including disappointment.

EXECUTIVE SUMMARY:

The robot revolution has a secret: it’s only working for 28% of dairy farms. After tracking 217 operations, researchers discovered a brutal truth—farms with 60-120 cows (nearly half of U.S. dairies) actually lose money with robots, while those below 60 or above 120 can profit. Success demands crushing requirements: 0,000 in loss tolerance, 5-8 years of genetic prep, and willingness to cull your best producers for efficiency. Yet 86% of farmers still recommend robots, creating false confidence that drives unsuitable operations toward financial disaster. The industry needs these failures to hit its $19 billion target by 2035. One question predicts your fate: Can you bleed $100,000 a year for 3 years and survive?

Complete references and supporting documentation are available upon request by contacting the editorial team at editor@thebullvine.com.

Learn More:

- 42% Heritability: The Milking Speed Breakthrough That Fixes Your Labor Problem – Reveals how to leverage new sensor data to breed for milking speed—a trait with 42% heritability—allowing you to maximize robot box time and increase throughput without compromising udder health.

- Robotic Milking Revolution: Why Modern Dairy Farms Are Choosing Automation in 2025 – Analyzes the global shift toward automation amidst severe labor shortages, providing a strategic reality check on why 14% market growth is occurring despite the strict profitability requirements for mid-sized farms.

- Holstein’s Automated Classification Cameras: Why They’ll Work for 500-Cow Dairies but Maybe Not Yours – Demonstrates how emerging automated scoring technology creates competitive advantages for large herds while presenting a dangerous ROI trap for operations under 200 cows, reinforcing the critical importance of scale.

Join the Revolution!

Join the Revolution!

Join over 30,000 successful dairy professionals who rely on Bullvine Weekly for their competitive edge. Delivered directly to your inbox each week, our exclusive industry insights help you make smarter decisions while saving precious hours every week. Never miss critical updates on milk production trends, breakthrough technologies, and profit-boosting strategies that top producers are already implementing. Subscribe now to transform your dairy operation’s efficiency and profitability—your future success is just one click away.

Join the Revolution!

Join the Revolution!