78% accuracy catching mastitis 2 days early? European farms are making us look like ancient relics.

EXECUTIVE SUMMARY: Look, I’ve been tracking what’s happening across the pond, and European dairy farms are absolutely crushing disease management while we’re still playing catch-up. They’re spotting mastitis 48 hours before you’d even notice anything’s wrong—with nearly 80% accuracy—and cutting antibiotic use by more than 60% without losing udder health. That translates to fewer vet bills, healthier cows, and more milk hitting your tank. We’re talking about a $65 billion global problem that they’re actually solving while our farmers wait days for lab results and sometimes years for crisis support. When bird flu struck Italy, European farms received compensation in months, not the typical multi-year wait we see here. Bottom line? If you want to boost profits and keep your herd healthier, it’s time to stop working harder and start working smarter.

KEY TAKEAWAYS

- Cut your antibiotic costs up to 60% with selective dry cow therapy—start testing individual cows this dry period instead of blanket treating the whole herd.

- Catch mastitis 48 hours early using thermal imaging technology—many farms see ROI within 18-24 months through faster treatment and less milk loss.

- Team up with neighbors for vet coverage—coordinate emergency response and tap into those USDA loan forgiveness programs to get more vets in your area.

- Make biosecurity your daily routine—simple stuff like visitor logs and footbaths can slash disease transmission without breaking the bank.

- Invest smart in prevention tech—with current grants and incentives, most operations see payback within two years while competitors scramble to catch up.

You know that gut feeling when you’re walking through the barn at dawn and something just doesn’t sit right? Maybe it’s how that fresh heifer is hanging back from the feed bunk, or the way she’s standing with her back humped just slightly. Most of us have learned to trust that instinct over the years—it’s probably saved more cows than we’ll ever count.

But here’s what’s been eating at me lately. While we’re still relying on those morning walks and waiting three days for lab results, European dairy operations have systems that would make your head spin. I’m talking thermal cameras that catch mastitis two days before you’d ever notice swelling, veterinary networks that respond faster than most fire departments, and—this one really gets me—crisis support that actually reaches farms in weeks, not years.

I spent the better part of last year visiting operations across the Netherlands, Germany, and France, as well as analyzing data from Nordic countries that deal with brutal six-month winters. What I found isn’t just impressive technology, though some of it feels straight out of science fiction. It’s how their entire system works together in ways ours… well, frankly, doesn’t.

Quick terminology check (because we all know these acronyms get confusing):

- SDCT: Selective Dry Cow Therapy—testing individual cows instead of blanket antibiotic treatments

- Thermal Imaging: Camera systems spotting temperature spikes 24-48 hours before clinical signs show

- EU Animal Health Law: Disease response protocols that actually work across 27 countries

- PCR Testing: Pathogen identification in hours instead of our usual three-day wait

Why One Playbook Changes Everything

Here’s what really struck me about European coordination. Back in April 2021, the EU rolled out its Animal Health Law—basically the same disease response playbook for all 27 member countries. So when foot-and-mouth hits a farm in Bavaria, they’re following identical protocols to what they’d use in Brittany or Copenhagen.

Now, it’s not perfect—smaller countries and regions with tighter budgets still face implementation challenges. But think about this for a minute: cross from Minnesota into Wisconsin and you’re suddenly dealing with completely different testing requirements, response times, quarantine procedures. It’s like each state decided to play by different rules in the same game.

The coordination works because they hammered out the details during calm periods, not in the middle of a crisis. During Europe’s avian influenza outbreak in 2022-2023, these coordinated protocols demonstrated system-wide resilience, preventing broader market panic—a stark contrast to the state-by-state rollercoaster we often see here when a major animal disease strikes.

What’s interesting is how this plays out in real time. A German producer I interviewed (who asked to remain anonymous due to regional sensitivities around the recent bluetongue outbreak) described getting lab confirmation within 48 hours and having a coordinated response team on his farm the next day. Compare that to what happened to my neighbor in Wisconsin when HPAI hit—three weeks of uncertainty while different agencies tried to figure out who was in charge.

Tech That Actually Sees Around Corners

The technology side is where things get really fascinating. During my travels, I kept hearing similar stories from operations across different countries—not just the Netherlands, though they’re definitely leading adoption.

In Bavaria, I visited a 450-cow operation where thermal imaging systems consistently flag mastitis cases two full days before clinical symptoms appear. That’s backed by solid research published this year, showing accuracy rates of 78-85%. However, what really caught my attention is that the same technology is being used in French cooperatives dealing with various housing systems and in Danish operations managing longer confinement periods.

Austrian company smaXtec is now serving over 8,000 farms globally, generating more than 300,000 health alerts monthly through continuous monitoring. The technology isn’t just about early detection—it’s about pattern recognition that most of us couldn’t spot without help.

A French cooperative manager told me something that really stuck: “The system doesn’t replace good stockmanship—it makes good stockmen better. I still walk through twice daily, but now I know which animals need closer attention before problems become obvious.”

Technology Investment Reality Check

| System Package | Initial Investment | Monthly Operating | Early Detection | Payback Range |

| Basic Thermal Setup | $12,000-18,000 | $200-350 | 24-48 hours | 18-30 months |

| Individual Cow Sensors | $8,000-15,000 | $5-8 per cow | 48-72 hours | 12-24 months |

| Integrated AI Platform | $25,000-40,000 | $800-1,200 | 72+ hours | 15-25 months |

Note: Payback varies dramatically with baseline herd health, management competency, milk pricing, and local market conditions

The catch? (There’s always a catch, right?) These systems need proper setup and training. European farms report 3-6 month learning curves before hitting optimal results. That’s challenging when you’re already doing three jobs and working 70-hour weeks.

But here’s what nobody talks about enough—the technology is only as good as your ability to get veterinary support when you need it.

The Veterinary Desert We’re Living In

Let’s be honest about something that’s keeping a lot of us up at night. According to the American Veterinary Medical Association’s latest workforce study, 43% of rural dairy counties don’t have a resident large animal veterinarian. The Canadian numbers are similarly brutal—emergency response times over four hours in many rural areas.

I’ve talked to producers in Montana who are six hours from the nearest large animal vet. Think about that. Six hours. By the time help arrives, you’re often looking at damage control instead of treatment.

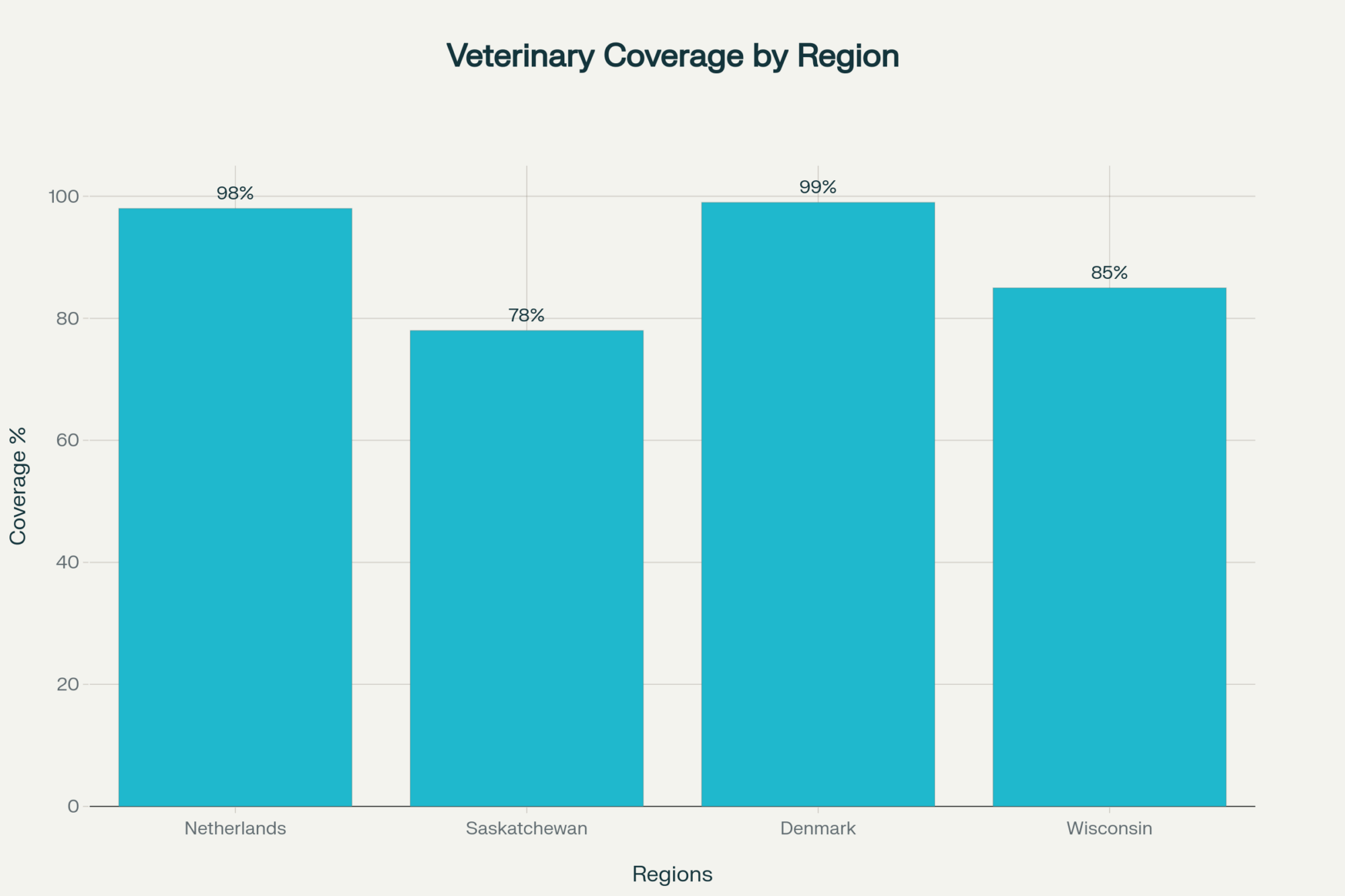

European countries tackled this head-on. Finland guarantees rural coverage through municipal contracts that supplement private practice. France runs mentorship programs pairing experienced vets with new graduates, backed by financial incentives that actually work. The Federation of Veterinarians of Europe documents average emergency response times under two hours across participating countries.The data clearly shows coordinated approaches work better while maintaining professional independence. What gives me hope are existing federal initiatives, such as the USDA’s Veterinary Medicine Loan Repayment Program and the Veterinary Services Grant Program, which offer loan forgiveness and grants to encourage veterinarians to serve in high-need rural areas. As we’ve covered extensively, it’s a start, though the scale of the problem shows we need to do much more.

Nowhere is the Gap More Obvious—or the Opportunity Greater—Than in Mastitis Management

Europe’s shift to Selective Dry Cow Therapy represents the biggest mastitis management change in decades, driven by European Medicines Agency regulations restricting prophylactic antibiotic use.

The Netherlands pioneered SDCT in 2012, but it has since spread across different systems and countries. Wageningen University research shows Dutch farms implementing SDCT achieved antibiotic use reductions of 60-65% while maintaining comparable somatic cell counts.

But it’s not just the Dutch. German operations report similar reductions. French cooperatives note improved cure rates. Nordic producers dealing with long housing periods find it especially valuable for managing confined herds.

Multiple producer interviews illustrate the economics: “SDCT seemed expensive until we calculated the real costs. Blanket therapy was masking chronic infections that were costing us 400 kilograms per cow annually. Now we treat fewer animals but cure more problems.”

SDCT Economics: Real Numbers for Different Operations

| System Type | Diagnostic Investment | Antibiotic Savings | Net Annual Benefit |

| Confinement (300+ cows) | $15-25 per cow | $30-40 per cow | $15-25 per cow |

| Seasonal Grazing (100-300 cows) | $20-30 per cow | $25-35 per cow | $5-15 per cow |

| Organic Systems | $25-35 per cow | $60-80 per cow | $25-45 per cow |

These numbers assume stable milk prices above $18/cwt and baseline SCC under 250,000. When prices drop below $15/cwt, payback can extend to 36+ months

What makes it work is accurate diagnostics and proper timing. European farms use culture-based or PCR testing to identify specific pathogens before treatment selection. The key insight—you’re not just reducing antibiotics, you’re improving outcomes.

Crisis Support That Actually Shows Up

When Italy’s avian influenza hit, the European Commission approved €46.7 million in compensation distributed within 90 days. Ninety days.

Compare that to what we typically see here—12-24 month timelines for similar support, if you’re lucky enough to qualify.

Economic research shows every euro invested in rapid crisis response generates 3.5-4.2 euros in prevented losses through maintained market stability. It’s not just a generous policy—it’s economically strategic. Disease outbreaks create market failures that private insurance can’t handle due to correlated regional risks.

Crisis Response Speed: European vs. North American Reality

| Support Element | EU Approach | US/Canada Average |

| Emergency Assessment | 24-48 hours | 2-4 weeks |

| Funding Approval | 30-60 days | 6-18 months |

| Payment Distribution | 60-90 days | 12-24 months |

| Market Stabilization | Coordinated EU-wide | State/provincial variation |

The difference this makes on actual farms is profound. European producers can focus on recovery and prevention instead of survival and debt management.

Biosecurity That’s Actually Practical

European biosecurity succeeds through systematic integration rather than isolated measures. Based on visits across France, Germany, and the Netherlands, producers consistently describe it as “doing the same good thing every day.”

Research shows substantial reductions in disease transmission, although effectiveness varies significantly. Recent studies have suggested results ranging from a 20% improvement in respiratory disease transmission on some confinement dairies to a 50% reduction in specific bacterial infections in well-managed systems—it depends on the pathogen type, farm design, and how well protocols are followed.

The key insight involves treating biosecurity as an interconnected system rather than a series of individual procedures. As we’ve detailed in our biosecurity guide, start with visitor protocols and vehicle disinfection—immediate risk reduction with minimal complexity.

Research That Gets to Barn Level Fast

European research funding prioritizes practical solutions that farms can implement within 18 months. Horizon Europe allocates approximately €9 billion annually to agricultural innovation with heavy emphasis on animal health.

This research strategy produces tangible results: mRNA vaccine platforms enabling rapid outbreak response and AI diagnostic systems providing farm-specific predictions are already reaching commercial application.

The Economics That Actually Matter

Research across European countries indicates farms implementing comprehensive disease management report improved profitability, though benefits vary significantly by operation size, baseline health, and—this is crucial—management competency.

Researchers peg global dairy disease losses at over $65 billion annually, with mastitis among the top contributors.

Investment Analysis by Operation Type

| Operation Type | Initial Investment | Annual Operating | Expected Benefits | Payback Period |

| Confinement (200-500 cows) | $15,000-25,000 | $3,000-5,000 | $12,000-18,000 | 18-24 months |

| Seasonal Grazing (100-300 cows) | $20,000-30,000 | $4,000-6,000 | $10,000-15,000 | 22-28 months |

| Intensive Systems (500+ cows) | $60,000-85,000 | $15,000-20,000 | $45,000-65,000 | 18-24 months |

These returns assume competent management, stable pricing, and baseline herd health. Poor management or market volatility can extend payback significantly

The benefits come through multiple channels—reduced veterinary costs, decreased medication expenses, improved milk quality premiums, reduced mortality, and enhanced reproductive performance.

Here’s the thing, though—for cash-constrained operations, focus on highest-impact, lowest-cost interventions first. Thermal imaging in milking facilities offers immediate detection advantages with the fastest return on investment.

What This Means for Your Operation

European dairy disease management works because it treats prevention as a profitable investment rather than a necessary expense. But you don’t need to overhaul everything overnight. Based on what I’ve seen work across different operations:

Consider starting this month: Look into basic thermal imaging for milking facilities—documented 18-24 month payback in most scenarios. Begin individual cow health monitoring for behavioral changes; this doesn’t require a major investment but provides early warning capabilities. Explore coordinated veterinary agreements with neighboring operations to improve response times.

Within six months: Work with your vet on selective dry cow therapy protocols. Start with problem groups or first-lactation animals while building confidence. Join or form regional producer groups to share veterinary resources—this is becoming increasingly common and helps address coverage gaps. Investigate rapid diagnostic capabilities for pathogen identification.

Within two years: Deploy comprehensive digital health monitoring based on proven results from initial investments. Establish farm-specific biosecurity protocols integrated with monitoring systems. Participate in regional disease surveillance networks where available.

The technology exists, the protocols are proven, and the economic benefits are documented. European systems aren’t magic—they’re just more comprehensive, treating disease management as an interconnected system of prevention. The choice isn’t if these approaches work, but how quickly you can adopt them. After seeing what’s possible across the Atlantic, it’s clear the biggest risk isn’t the investment—it’s waiting.

The European playbook isn’t rocket science—it’s just coordinated, smart farming. And honestly? We can do this too.

Complete references and supporting documentation are available upon request by contacting the editorial team at editor@thebullvine.com.

Learn More

- A Dairy Farmer’s Guide to Selective Dry Cow Therapy – This tactical guide provides a step-by-step framework for implementing SDCT on your operation. It reveals practical methods for testing, protocol development, and staff training to help you successfully cut antibiotic costs while improving udder health outcomes.

- The Trust Deficit: Why Consumers are Losing Faith in Dairy Farming and How to Win Them Back – This strategic analysis connects the on-farm practices discussed in the main article to the bigger picture of consumer trust. It demonstrates how transparent health management and reduced antibiotic use are essential for maintaining your social license and market access.

- Precision Dairy Farming: The Unseen Revolution That’s Changing Everything – For a deeper dive into innovation, this piece explores the full potential of the technologies mentioned. It showcases how integrated data from sensors and AI are creating unprecedented opportunities for proactive health management, genetic selection, and long-term profitability.

The Sunday Read Dairy Professionals Don’t Skip.

The Sunday Read Dairy Professionals Don’t Skip.

Every week, thousands of producers, breeders, and industry insiders open Bullvine Weekly for genetics insights, market shifts, and profit strategies they won’t find anywhere else. One email. Five minutes. Smarter decisions all week.

The Sunday Read Dairy Professionals Don’t Skip.

The Sunday Read Dairy Professionals Don’t Skip.