Pasture is a very high quality, balanced feed, unless you mismanage it by leaving high post-grazing residuals.

In reviewing old research for a history paper I am writing, I came across two quotes that I thought made for as interesting a discussion today as they did 70-80 years ago when they were first uttered.

The first, from the United States in 1936, states that “if a cow will eat enough immature grass to provide the required digestible nutrients and if this grass has a normal content of minerals, her ration is not likely to be deficient in any of the essential food constituents” – Woodward, 1936 .

In other words, ‘immature’ or vegetative pasture was known to be a well-balanced feed 80 years ago and the factor most limiting milk production on pasture was dry matter intake.

Dr John Roche is principal scientist for animal science at DairyNZ.

Despite this revelation, many did not believe that pasture, growing ‘wild in the field’, could be as good for a dairy cow as the intensively selected cereal grains that fattened pigs and chickens.

This leads me to what Dr Campbell McMeekan, as superintendent of Ruakura at the time, said, when questioning the rationale of feeding anything other than pasture: “From the qualitative angle, it is often assumed and frequently stated that pasture is not capable of supplying the needs of a high producing dairy cow and ideally needs to be supplemented with suitable concentrates” – McMeekan, 1947 .

It’s 70 years since McMeekan’s presentation at the New Zealand Society of Animal Production, but his commentary is as relevant today as it was then.

Many people still believe that pasture is not a wholly balanced feed ingredient for cows, highlighting its lack of sugars (or starch) relative to cereal grains, the excess of protein, relative to a cow’s requirement, and the high milk yields of cows in dairy systems feeding grains relative to those achieved by cows ‘forced’ to live on pasture alone.

Is pasture a good feed for dairy cows?

In a word, YES!

In fact, our perennial ryegrass and white clover-based pasture in New Zealand is, arguably, the most balanced feed a dairy cow could eat.

· It contains the same energy density as wheat or maize, although the energy comes from the fermentation of fibre instead of grain.

· The composition of the protein is ideal to maximize milk production; there are no amino acids deficient, unless the cow is supplemented with a large amount of a low protein grain, palm kernel, or maize silage.

· The vitamin and mineral composition is also pretty well-balanced, although supplementation with calcium straight after calving, and magnesium and some trace elements is advised through calving and early lactation.

Decades of research in New Zealand confirm that cows consuming the same amount of metabolisable energy from pasture, or pasture plus a supplement (eg sugars, grains or silages) produce the same amount of milksolids (Carruthers et al., 1997; Roche et al., 2010) .

In fact, at a system level, the amount of milksolids produced from 100MJ pasture, 100MJ of maize grain, or 100MJ of maize silage is the same (Roche et al., 2010; Macdonald et al., 2017) . This is because in a grazing system, intake of metabolisable energy is the factor that limits milk production. So, it stands to reason that 100MJ from any feed would result in the same production response.

Considering the historical introduction to this article, it is important to point out that this is, also, not new.

Gustav Kuhn and his co-workers in Germany proved this in the 1880s – 130 years ago.

Yet, even in 2017, some people still refuse to accept that the microorganisms fermenting feed in the cow’s rumen do not care if they eat Brussels sprouts or chocolate; they merely care about the metabolisable energy the feed contains.

It is this fact and nearly 13 decades of research work that leads us to point out that milk production, body condition score and reproduction responses to supplements are very small when cows are reasonably well fed on pasture.

As a result, supplementary feeds should only be used when cows do not have enough pasture (ie grazing residuals are less than 3.5cm – 7 clicks on the plate meter).

But, what about the excess of protein – doesn’t this cost energy and reduce fertility?

As with most of the mythology I hear regarding feeding dairy cows, there is a degree of truth in this, and a whole pile of nonsense.

When cows consume protein in excess of their requirements, it is converted to urea in the liver and either returned to the rumen or excreted in urine. As the process of creating urea requires energy, it was once believed (and obviously still is by many) that there is a significant energy and protein cost to excreting excess protein.

However, more recent research has highlighted that this depends on the type of protein and is largely untrue for the type of protein in pasture. There isn’t a large cost to excreting surplus protein that is degraded in the rumen and this is the main type of protein in pasture.

Therefore, in most day to day situations, dealing with excess protein is an insignificant detail to the grazing dairy cow.

When milk companies began presenting milk urea results on the milk docket, many farmers began asking what this meant. There was plenty of advice from ‘nutritionists’ that the levels in grazing cows were very high. Pasture was labelled as ‘poison’ and needed to be supplemented with a low protein feed, like cereal grains or maize silage. If you didn’t do this, your cows wouldn’t get pregnant.

This is utter nonsense. Although there was limited evidence in the US that high protein diets reduce the chances that a cow will get pregnant (Canfield et al., 1990; Butler, 1998) , the only information available for grazing dairy cows suggests that fertility improves with increasing blood and milk urea nitrogen (Roche et al., 2011) . This evidence comes both from experiments and from testing bulk milk from real farms.

If pasture is such a good feed, why do New Zealand cows produce less milk than cows in the US?

The difference in milk yield between cows grazing pasture or fed a ration in a barn is primarily due to a difference in dry matter intake (Kolver and Muller, 1998) . Simply put, grazing cows have to work for their feed, while cows fed indoors can consume their daily feed requirement with little or no effort.

However, not many cows are fed rations in barns in New Zealand. Instead, when they are offered supplementary feeds, they still have to graze pasture and ‘work for their supper’.

In this situation, when cows are fed a supplement they refuse to work hard. They reduce both their time spent grazing and their bite rate, so their intake of pasture declines. This is referred to as substitution – cows refuse pasture when offered a supplementary feed.

Substitution is as much a biological fact as the apple falling from the tree was a physical fact in Isaac Newton’s story about gravity.

As humans, we’re the same; if someone fed you cake before dinner, you are less likely to eat all your vegetables. This isn’t because your stomach is full. It is because your stomach and intestines produce hormones that tell your brain that you have eaten a calorie-loaded meal. We have measured these hormones in dairy cows and have found that cows are less hungry after eating supplementary feeds (Roche et al., 2007, 2008) . It doesn’t matter if they’re fed in the shed, the feed-pad or in the paddock, or if they’re fed grains, silage or complex rations.

It’s quite simple, if cows are fed a supplement they refuse pasture.

The main factor that influences how much pasture a cow refuses when she eats a supplement is her pasture intake before she was offered the supplement (Stockdale, 2000) ; the more pasture a cow is eating, the more pasture she will waste when she is fed a supplementary feed. Because of this, we recommend that cows should not be supplemented unless the post-grazing residual is less than 3.5 cm (7 clicks on the rising plate meter).

By following this simple rule, the cow will be well-fed, substitution rate will be low (i.e., very little pasture is wasted), and the milk production response to the supplementary feed will be greater.

But can’t we just get that pasture next time?

No you can’t. As a farmer mentor of mine says, “use it or lose it”. In fact, the effect is much worse than just wasting pasture. If supplements are offered when cows are not hungry, substitution will be high and post-grazing residuals will rise. This will result in poor quality pasture in the following grazing and a drop in milk production because of this.

People sometimes associate this drop in production with removing supplements when, in fact, it is because supplements were offered earlier and when they weren’t needed.

Conclusions and implications

Pasture is a very high quality, balanced feed, unless you mismanage it by leaving high post-grazing residuals. It is energy dense and has very high protein quality; but, because cows have to work to eat their fill, they are limited by dry matter intake. This limitation is overcome by making sure that the stocking rate for the farm is correct and that the dry matter intake/ha optimises pasture utilisation.

If someone tells you that pasture is not a good feed and needs another feed to complement it or ‘balance it’ for some deficiency, my suggestion is that you should probably stop listening at that point; the next piece of information is likely to cost you money.

Take the myths out of feeding cows. The marginal cost and benefit from offering supplements in a feed deficit situation and under different milk prices can be predicted using DairyNZ’s Supplement Price Calculator: https://www.dairynz.co.nz/feed/supplements/supplement-price-calculator/).

Source: Stuff

Bovine somatotopin is a peptide hormone produced by cows’ pituitary glands. It is produced in small quantities and is used in regulating the metabolic process. During the 1970s, pharmaceutical companies discovered and patented expertise to synthesise the hormone using recombinant DNA technology to create recombinant bovine somatotropin (rBST).

Bovine somatotopin is a peptide hormone produced by cows’ pituitary glands. It is produced in small quantities and is used in regulating the metabolic process. During the 1970s, pharmaceutical companies discovered and patented expertise to synthesise the hormone using recombinant DNA technology to create recombinant bovine somatotropin (rBST).

Fonterra is playing its part in fuelling the revolution of on-farm weather forecasting by working with MetService and BloomSky – a smart weather camera station that delivers hyperlocal weather information in real-time to any laptop, tablet or smartphone.

Fonterra is playing its part in fuelling the revolution of on-farm weather forecasting by working with MetService and BloomSky – a smart weather camera station that delivers hyperlocal weather information in real-time to any laptop, tablet or smartphone. A new advert from the Farm Safety Partnership in Northern Ireland has focused on the dangers of freshly calved cows.

A new advert from the Farm Safety Partnership in Northern Ireland has focused on the dangers of freshly calved cows. Source: Teagasc

Source: Teagasc

There are more Holstein dairy twins today than in the past – from just over 3 percent in 1975 per herd to 10 percent or more today.

There are more Holstein dairy twins today than in the past – from just over 3 percent in 1975 per herd to 10 percent or more today. “I have to admit that for the first time in my life, I felt burnt out last May. I was emotionally and physically drained,” said Sixsmith, who farms with her husband, Brian James, in Crettyard, Co. Carlow.

“I have to admit that for the first time in my life, I felt burnt out last May. I was emotionally and physically drained,” said Sixsmith, who farms with her husband, Brian James, in Crettyard, Co. Carlow. The use of injectable versus pour-on worm treatments is a subject for much debate on Irish dairy farms.

The use of injectable versus pour-on worm treatments is a subject for much debate on Irish dairy farms. Roche and DairyNZ economist Matthew Newman spoke to farmers about whether they were making money from milk or milk from money at the DairyNZ Farmers’ Forum in Wallacetown on May 4.

Roche and DairyNZ economist Matthew Newman spoke to farmers about whether they were making money from milk or milk from money at the DairyNZ Farmers’ Forum in Wallacetown on May 4.

Dr John Roche is principal scientist for animal science at DairyNZ.

Dr John Roche is principal scientist for animal science at DairyNZ.

Dairy farmers and vets should aim to stop using critically important antibiotics (CIAs) in herds by 2020 in order to prevent the increase in antimicrobial resistance, according to a leading vet.

Dairy farmers and vets should aim to stop using critically important antibiotics (CIAs) in herds by 2020 in order to prevent the increase in antimicrobial resistance, according to a leading vet. Enrique Correal knows the anxiety that foreign workers go through when they hear about deportation and new immigration policies coming out of Washington, D.C.

Enrique Correal knows the anxiety that foreign workers go through when they hear about deportation and new immigration policies coming out of Washington, D.C. Anyone can learn to use ultrasound on their dairy farm, but producers need to know their reproduction numbers to financially justify the purchase.

Anyone can learn to use ultrasound on their dairy farm, but producers need to know their reproduction numbers to financially justify the purchase. Summer’s heat seems far away. But it will be here soon and so will pesky flies. Don’t wait for flies to emerge to start your fly control program. For maximum effectiveness, now is the time to evaluate and start your fly control strategy.

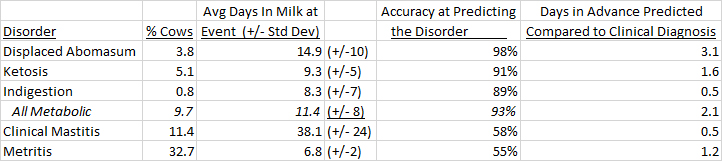

Summer’s heat seems far away. But it will be here soon and so will pesky flies. Don’t wait for flies to emerge to start your fly control program. For maximum effectiveness, now is the time to evaluate and start your fly control strategy. If producers don’t see clinical milk fever and clinical ketosis, they often think all is well with the transition cows. But that is far from the truth.

If producers don’t see clinical milk fever and clinical ketosis, they often think all is well with the transition cows. But that is far from the truth. For many farms, across all of agriculture, the returns are poor relative to the cost of production. The result is great stress among many farm families. During times like this, it is easy to lose perspective, have difficulty making decisions and to be discouraged. Here are 10 things that may be of help to any family in that situation.

For many farms, across all of agriculture, the returns are poor relative to the cost of production. The result is great stress among many farm families. During times like this, it is easy to lose perspective, have difficulty making decisions and to be discouraged. Here are 10 things that may be of help to any family in that situation. Farmers in the UK and Austria could be among first to experiment with an automated robotic animal feed-growing machine, which its makers claim can revolutionise the way animal feed is made.

Farmers in the UK and Austria could be among first to experiment with an automated robotic animal feed-growing machine, which its makers claim can revolutionise the way animal feed is made.

A Canadian analysis of 49 such studies indicated canola meal in feed, at up to 20 percent of dietary dry matter, can increase milk production.

A Canadian analysis of 49 such studies indicated canola meal in feed, at up to 20 percent of dietary dry matter, can increase milk production. During lactation the udder is under pressure to continue producing milk after which there is a dry period during which the udder has an opportunity to recover.

During lactation the udder is under pressure to continue producing milk after which there is a dry period during which the udder has an opportunity to recover. Mitch Bruenig has been around dairy cows long enough — all his life, to be exact – to suspect something was amiss with two of his Holsteins.

Mitch Bruenig has been around dairy cows long enough — all his life, to be exact – to suspect something was amiss with two of his Holsteins. A farm expansion planner says it takes time to properly go from concept to completion. Emily Schmidt of Miller Engineers & Scientists in Sheboygan, Wisconsin helps farmers with the expansion process and says there are two time-consuming steps. “If you take the 90-days in just for the permitting process plus the time to design, I mean we usually look into a month to six months in advance before we want to break ground.”

A farm expansion planner says it takes time to properly go from concept to completion. Emily Schmidt of Miller Engineers & Scientists in Sheboygan, Wisconsin helps farmers with the expansion process and says there are two time-consuming steps. “If you take the 90-days in just for the permitting process plus the time to design, I mean we usually look into a month to six months in advance before we want to break ground.” Since the new year, I have travelled to many dairy farms across Western Canada and conducted a personal survey about lameness in dairy cattle. At each visit, I asked producers “What was their biggest cause of hoof problems?” Almost unanimously, their answer was “hairy heel warts!” This is no surprise, since multiple surveys conducted over the last few decades, mapped its spread across North American dairy farms. Fortunately, early detection, constant vigilance and prevention is the key to controlling this major hoof disease.

Since the new year, I have travelled to many dairy farms across Western Canada and conducted a personal survey about lameness in dairy cattle. At each visit, I asked producers “What was their biggest cause of hoof problems?” Almost unanimously, their answer was “hairy heel warts!” This is no surprise, since multiple surveys conducted over the last few decades, mapped its spread across North American dairy farms. Fortunately, early detection, constant vigilance and prevention is the key to controlling this major hoof disease. If you think your heifer reproduction program is on track, you may want to look again. Conception rate and percentage of heifers pregnant within three services are metrics commonly used to track performance of heifer reproduction.

If you think your heifer reproduction program is on track, you may want to look again. Conception rate and percentage of heifers pregnant within three services are metrics commonly used to track performance of heifer reproduction. Oregon has 228 family dairy farms, ranging from fewer than 100 cows being milked each day to more than 30,000. Regardless of the size of the farm, there are certain values, standards and management practices that every Oregon dairy farmer has in common.

Oregon has 228 family dairy farms, ranging from fewer than 100 cows being milked each day to more than 30,000. Regardless of the size of the farm, there are certain values, standards and management practices that every Oregon dairy farmer has in common.

Spring is in the air, and while spring-cleaning typically means deep cleaning your house, your dairy could benefit from some sprucing up, too. Whether it’s milking protocols, curtain maintenance or fine-turning vaccination programs, it’s important that no areas are missed so you can reach your Dairy Wellness goals and improve profitability.

Spring is in the air, and while spring-cleaning typically means deep cleaning your house, your dairy could benefit from some sprucing up, too. Whether it’s milking protocols, curtain maintenance or fine-turning vaccination programs, it’s important that no areas are missed so you can reach your Dairy Wellness goals and improve profitability.