Think higher wages solve labor problems? Wrong. Workforce stability beats pay every time—here’s proof.

EXECUTIVE SUMMARY: Look, here’s what nobody wants to talk about: Nearly 80% of American milk comes from farms staffed by immigrant workers, and that workforce is more fragile than we’d like to admit. With 40% annual turnover costing thousands per replacement and potential industry losses hitting $32 billion, this isn’t just a labor issue—it’s an existential threat to your margins. Meanwhile, European dairies are already 20% automated while we’re stuck at 5%, and states like Kansas are pulling ahead with 15.7% production growth compared to California’s decline. The math is simple: audit your workforce risk, push for policy reform through your co-op, and get serious about automation ROI—because waiting isn’t a strategy that pays bills.

KEY TAKEAWAYS

- Stop bleeding cash on turnover: Each replacement worker costs thousands in direct expenses plus lost productivity—calculate your real turnover cost using BLS data and target retention strategies that actually move the needle on your bottom line.

- Push for policy wins: The Farm Workforce Modernization Act’s year-round H-2A program could stabilize your labor costs—contact NMPF or your co-op today to support legislation that directly impacts your 2025 profitability.

- Automation isn’t just for mega-dairies: Robotic systems show 18-month paybacks for smaller herds under 260 cows—schedule that dealer consultation now while 2025 cost pressures make the ROI calculation even more compelling.

- Follow the production leaders: Kansas’s 15.7% growth versus California’s struggles show how workforce stability drives milk yield—consider operational changes that put you in the winner’s column instead of hoping things improve.

- Connect workforce to genetics: Stable employees deliver better feed efficiency and consistent genomic testing protocols—invest in retention strategies that protect your breeding program investments and maximize milk components.

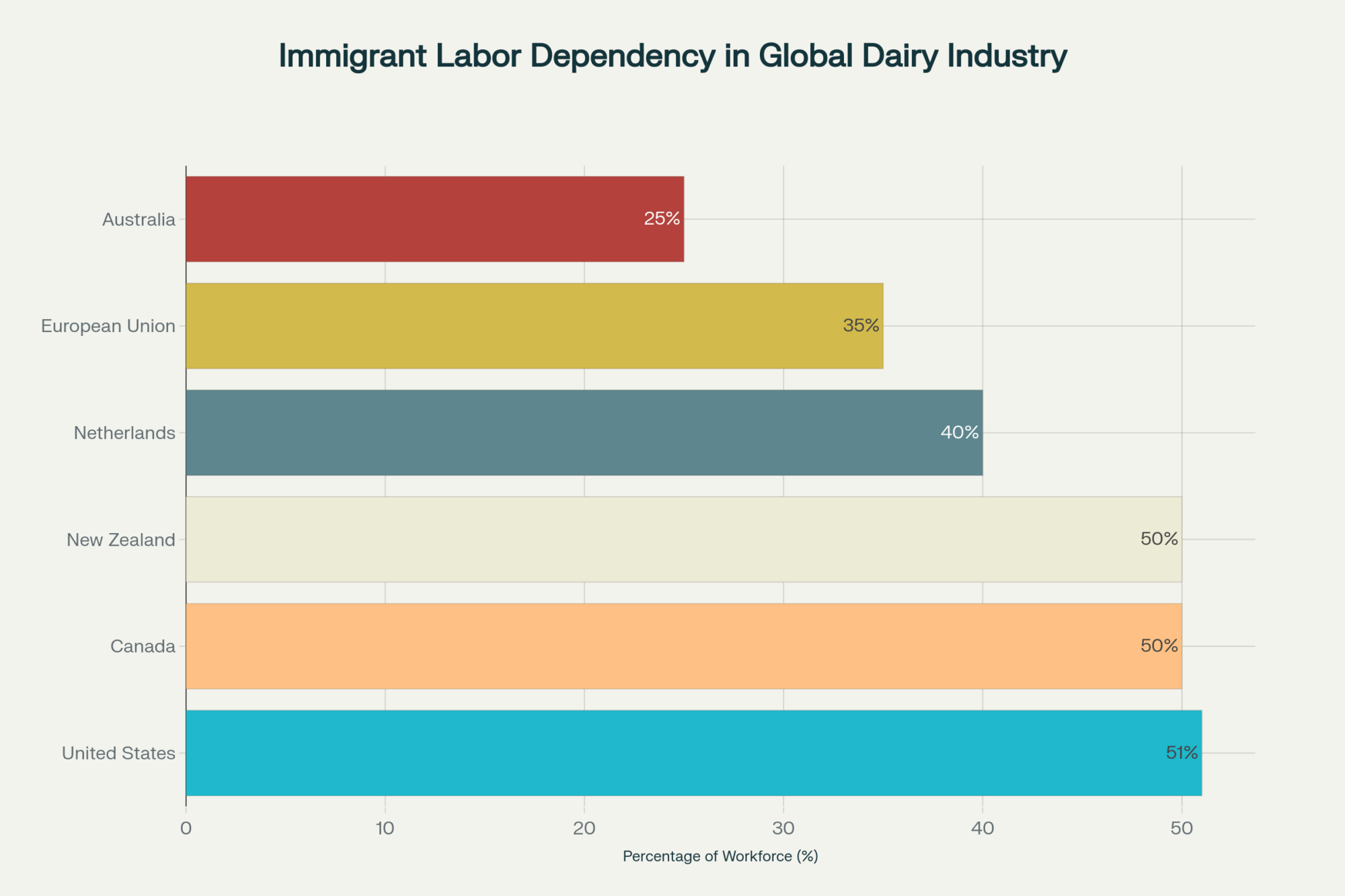

The labor situation in dairy is no longer just another box to check on a list with feed costs and milk prices. What really catches my attention: about 51% of U.S. dairy workers are immigrants, and those same workers are responsible for producing nearly 79% of our nation’s milk supply. This is the backbone of our industry.

You’ve probably observed—milk prices at around $21.30 per hundredweight in May 2025, while corn costs hover near $4.20 a bushel according to recent USDA forecasts. Those thin margins are being squeezed further by an instability most farms aren’t fully pricing in: the workforce.

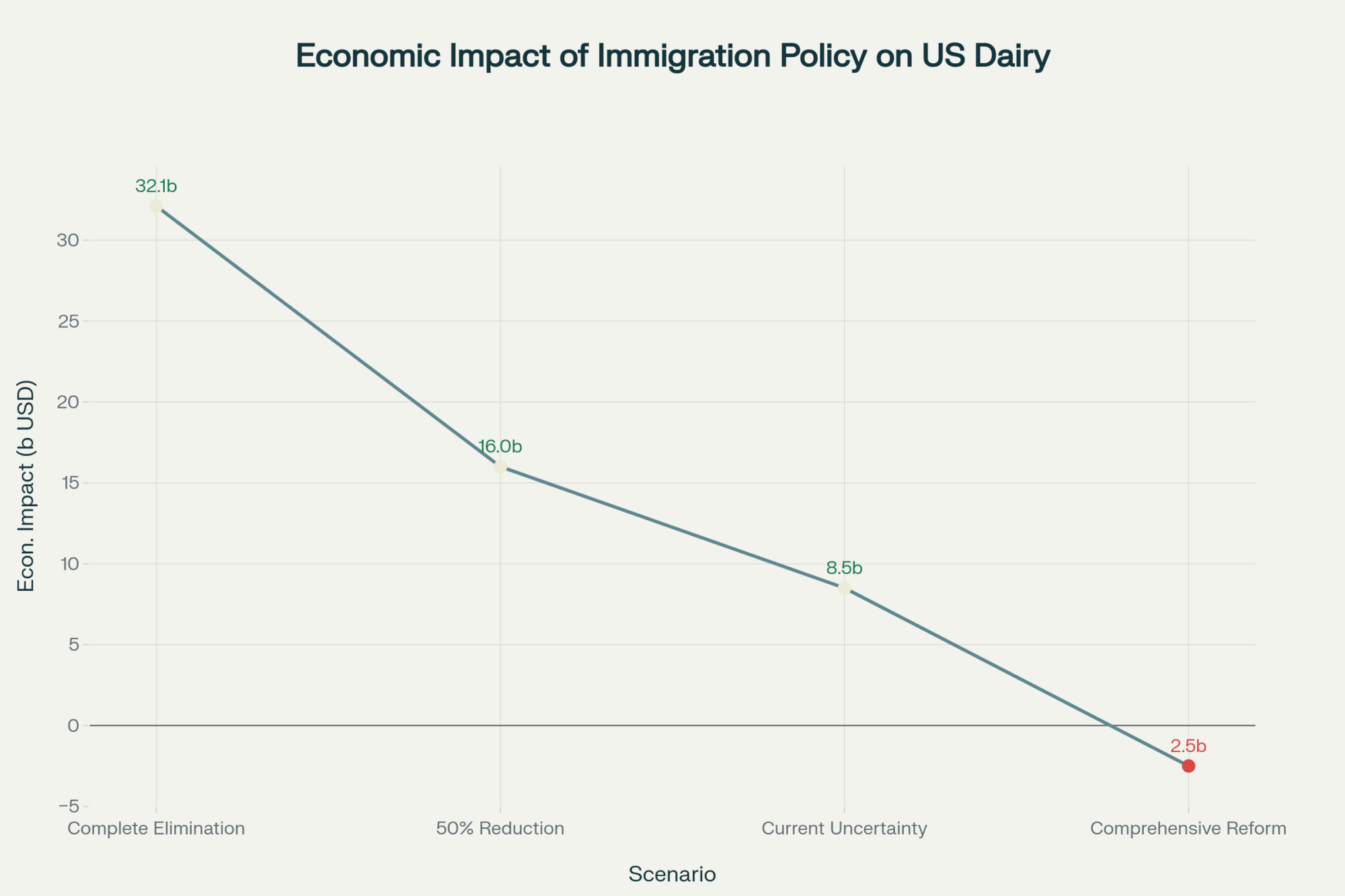

The economic modeling on this is sobering: losing this immigrant workforce could trigger up to $32 billion in industry losses, and milk prices could spike past $7.60 a gallon at retail. The ripple effects from such a shift would extend far beyond the farm gate.

What Turnover Really Costs

Look at BLS data from 2024—livestock workers earn about $17.45 an hour, but the turnover rate hovers around 40% annually according to recent labor market reviews. Each replacement costs thousands in direct expenses and lost productivity while they get up to speed.

“When your people change, your feed conversion, your cow health, your rhythm—it’s like trying to keep the groove while the beat’s changing.” — Dr. Marin Bozic, University of Minnesota

This churn shows up in production numbers too. USDA data reveals Kansas’s milk output rising by 15.7% recently, while California declined nearly 2%—a clear sign that stable labor markets support greater productivity.

On top of that, ICE enforcement actions have caused some farms to lose half their workforce almost overnight, adding real operational stress.

Legislative Hope—The Farm Workforce Modernization Act

The Farm Workforce Modernization Act, reintroduced in spring 2025, seeks to reshape the H-2A visa system by creating year-round access aligned with dairy’s demands. It dedicates 20,000 annual spots for dairy workers and offers a certified status pathway for longtime employees.

However, the current H-2A system only certified 384,900 seasonal farmworker positions in fiscal 2024. That’s an impressive number, but it overlooks a fundamental reality: we milk 365 days a year.

Automation’s Role: Partial but Growing

Robotic milking systems have grown to cover about 5% of U.S. dairy farms, with European counterparts like Denmark and the Netherlands reaching 20-25% adoption, per recent analyses. The global milking robot market is expected to hit $2.5 billion in 2025, as labor shortages and costs push more operations toward automation.

Farmers praise robots for easing labor demands and improving cow comfort, but as Dr. Rick Watters of Cal Poly observes, “Robots don’t replace labor—they change the skills you need.” Smaller herds (under 260 cows) enjoy better ROI, while larger operations still find parlors viable. Maintenance can cost up to $9,000 annually.

Your Bottom Line—What’s Next?

Here’s the thing though: continuing to hope this labor problem works itself out is a strategy that won’t cut it. Nearly 80% of American milk depends on a workforce caught in legal limbo and operational unpredictability. That’s not just a problem—it’s shaping who survives and who thrives. The regional production shifts make it clear: where labor is stable, production grows.

What strikes me about leaders in the space is they’re taking deliberate steps to blend policy advocacy with technology investments:

Audit Your Labor Risk. Truly calculate your costs from turnover—including lost milk, additional training, and potential herd health impacts.

Raise Your Voice. Work through your co-op or the NMPF to support the Farm Workforce Modernization Act.

Explore Tech Values. Even if you’re not ready to buy, get a robotic milking dealer’s cost-benefit analysis to guide future investments.

So… are you ready to lead your farm into that future, or will you be left behind?

Editor’s Note: This article is accompanied by key data visuals—a concise infographic on workforce statistics, a clear comparison of H-2A program limitations versus dairy’s labor needs, a U.S. milk production map highlighting regional shifts, plus high-resolution photos of robotic milking in action and diverse farm teams.

Learn More:

- How Top Dairies Are Solving Labor Shortages in 2025 – Reveals practical strategies for reducing 38.8% turnover rates through structured training programs, creative compensation packages, and strategic automation investments that deliver measurable ROI.

- Break Labor Crisis: New Farmworker Permits Could Save Your Dairy Operation $127,000 Annually – Demonstrates how new H-2A program expansions and permit strategies can dramatically reduce labor costs while providing workforce stability and compliance advantages for forward-thinking operations.

- When the Labor Well Runs Dry: How Smart Dairies Are Turning Crisis into Competitive Edge – Explores cutting-edge automation solutions including precision feeding and predictive health monitoring that reduce labor dependency by 20-30% while boosting productivity and profitability.

Join the Revolution!

Join the Revolution!

Join over 30,000 successful dairy professionals who rely on Bullvine Weekly for their competitive edge. Delivered directly to your inbox each week, our exclusive industry insights help you make smarter decisions while saving precious hours every week. Never miss critical updates on milk production trends, breakthrough technologies, and profit-boosting strategies that top producers are already implementing. Subscribe now to transform your dairy operation’s efficiency and profitability—your future success is just one click away.

Join the Revolution!

Join the Revolution!