Stop chasing genomic indexes. A 1960s dairy farmer’s breeding strategy beat today’s averages—here’s his $75K crisis management playbook.

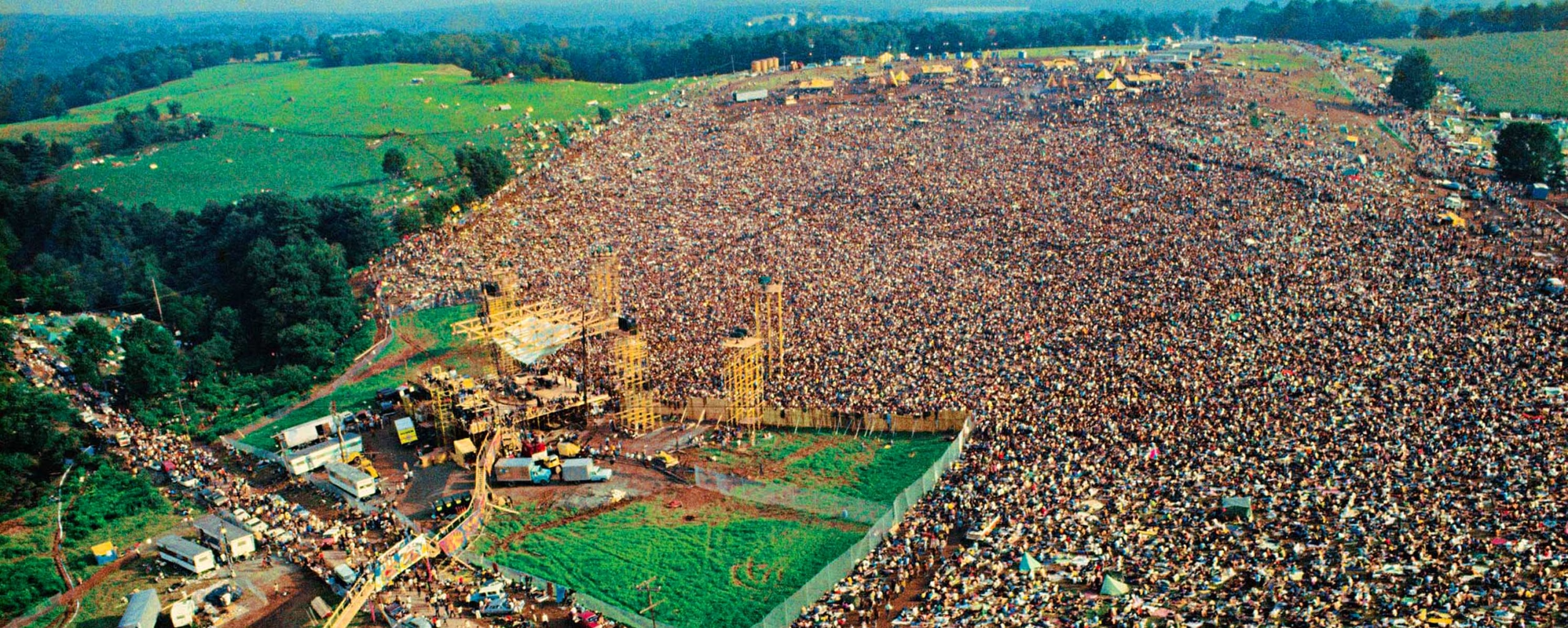

The same conservative Republican dairy farmer who rented his pasture to 460,000 counterculture rebels also revolutionized Holstein and Guernsey genetics and vertical integration decades before Silicon Valley discovered the concept. Max Yasgur’s ,000 Woodstock windfall was just the tip of an agricultural iceberg that modern dairy operations desperately need to understand.

The Festival That Fed the Farm (And What It Teaches About Modern Asset Optimization)

What if the secret to surviving today’s volatile dairy markets isn’t found in the latest genomic technology but in the business playbook of the man who made Woodstock possible? Max Yasgur didn’t just host “perhaps the most important cultural event of the twentieth century”—he demonstrated principles of strategic breeding, vertical integration, and asset diversification that modern dairy farmers are still trying to master.

The handshake that sealed the deal was missing two fingers. Michael Lang, the young promoter of what would become the Woodstock Music and Art Festival, felt a jolt of recognition as he grasped Max Yasgur’s weathered hand on that fateful Sunday afternoon in 1969. “Holy smokes,” Lang thought to himself, “He’s built this place with his own hands.”

What Lang didn’t fully comprehend was that he wasn’t just meeting the future host of the largest music festival in history—he was encountering one of Sullivan County’s most successful agribusiness pioneers, a man whose 650-head dairy operation and 2,000-acre empire represented exactly the kind of strategic thinking that separates millionaire dairy farmers from those barely breaking even.

The “Angel of Woodstock” Was Actually a Genetic Genius

While 460,000 hippies danced in his fields between August 15-18, 1969, Yasgur was quietly revolutionizing breeding with a precision that would make today’s genomic specialists jealous. His approach wasn’t about chasing the latest trends but about concentrated excellence that created lasting wealth.

The Woodstock Generation vs. The Genetic Generation

The same weekend that Jimi Hendrix played guitar with his teeth on Yasgur’s makeshift stage, the farm’s barns housed some of America’s most strategically bred cattle. Yasgur’s herd included 90 daughters of Harden Farms King Pontiac and 30 daughters of Cashman Thunderbolt, all tracing back to the elite Dunloggin bloodlines that cost Harden Farms $25,500 in the 1940s.

Dr. E.S. Harrison, manager of the prestigious Harden Farms, wrote: “Few breeders have followed a more definite breeding program than Max Yasgur.” This wasn’t casual praise but professional recognition from one of the industry’s most respected authorities, acknowledging Yasgur’s systematic approach to genetic improvement.

From City Kid to Dairy King: The Making of an Empire

Born December 15, 1919, in New York City to Russian immigrants, Samuel and Bella Yasgur, Max’s journey to dairy farming began early when his family moved to a dairy farm in Maplewood, New York, ninety miles north of the city. The farm doubled as a boarding house, catering to summer guests—an early lesson in revenue diversification that would serve him well decades later.

When his father died during Max’s teenage years, he assumed the role of family head. Though he briefly studied real estate law at New York University, “his dream was to go back to the farm.” This wasn’t a default choice but a calculated decision that revealed an entrepreneurial vision most farmers never achieve.

Yasgur’s ambition extended far beyond typical dairy farming. He wanted to build a milk processing plant and to sustain it, he needed scale. With methodical precision, he began acquiring neighboring farms, constructing barns, and expanding his herd. He built a pasteurization plant and refrigeration complex, installed bottling machines, and developed comprehensive door-to-door delivery routes.

The result was Yasgur Dairy—”the largest milk producer in Sullivan County” with a herd that peaked at 650 head and encompassed “ten farms comprising two thousand acres of land.” This wasn’t just farming—it was agricultural technology that captured value at every stage while competitors sold commodity milk.

The $75,000 Woodstock Deal: Master Class in Crisis Monetization

The year 1969 had been unusually wet, damaging Yasgur’s hay crop and threatening feed costs for his massive herd. When Lang and Roberts initially offered to rent a field for three days to accommodate “10,000 to 15,000 people,” Yasgur showed them several suitable options. But then came the revelation that changed everything.

The Tenfold Price Increase Strategy

The promoters revealed they were actually expecting “50,000 people and that they would have another 50,000 who would try to get in without paying,” bringing the total to a staggering 100,000. This disclosure prompted Yasgur’s immediate reconsideration: “Wait a minute… You’re now at 100,000 people. That’s a lot of people,” he said. “I will really have to think whether or not I want to be involved in something that large.”

Yasgur’s response revealed the business acumen that built empires: “I am a businessman, and it will cost you,” he said. “But I’ll go to bat for you”. He then “added another zero” to their rent, increasing it from $7,500 to $75,000—a 900% markup that solved his immediate cash flow crisis. Some reports suggest the final payment was even higher, with various sources citing amounts up to $10,000 in other accounts.

This wasn’t opportunism but strategic asset monetization that every modern dairy farmer should understand. Yasgur recognized both the scale of the opportunity and his negotiating position, demonstrating the kind of aggressive pricing that builds wealth. As he told himself afterward: “His cows wouldn’t go hungry this year.”

Modern Applications:

- Agritourism Revenue: Yasgur proved that agricultural land can generate substantial non-dairy income

- Event Hosting: From weddings to corporate retreats, many dairy farms sit on underutilized event venues

- Crisis Management: Using unexpected opportunities to offset operational challenges

The Conservative Republican Who Defended Hippie Rights

Perhaps the most remarkable aspect of Yasgur’s Woodstock decision wasn’t the money but the principle. Despite being a “conservative Republican who approved of the Vietnam War,” he stood before the Bethel Town Board to defend the festival against local opposition.

His neighbors voiced fears of widespread “pot smoking,” potential heroin use, an “ocean of garbage,” “universal bad manners,” “orgies of love-ins,” and even “a wild and bloody encounter with the police.” Signs appeared around town reading “Local People Speak Out Stop Max’s Hippie Music Festival,” “No 150,000 hippies here,” and “Buy no milk.”

Yasgur’s response, preserved in the meeting transcript, revealed the character that built both dairy empires and cultural history:

“I hear you are considering changing the zoning law to prevent the festival. I hear you don’t like the looks of the kids who are working at the site. I hear you don’t like their lifestyle. I hear you don’t like they are against the war and that they say so very loudly. I don’t particularly like the looks of some of those kids, either. I don’t particularly like their lifestyle, especially the drugs and free love. And I don’t like what some of them are saying about our government. However, if I know my American history, tens of thousands of Americans in uniform gave their lives in war after war just so those kids would have the freedom to do exactly what they are doing. That’s what this country is all about, and I will not let you throw them out of our town just because you don’t like their dress or hair, the way they live, or what they believe. This is America, and they are going to have their festival”.

The Business Lesson: Yasgur understood that defending principles—even unpopular ones—often aligns with long-term business success. His “live and let live” philosophy enabled him to monetize opportunities that others rejected due to prejudice.

From Hippies to Holsteins: The Vertical Integration Model That Predated Amazon

While 460,000 festival-goers camped in his fields, Yasgur’s real innovation was happening in his processing facilities. He had built what modern business schools would call a “vertically integrated supply chain”—controlling every step from pasture to doorstep decades before it became a Silicon Valley buzzword.

Yasgur’s Pre-Digital Disruption:

- Pasteurization plants and refrigeration complexes

- Bottling machines and door-to-door delivery routes

- Ten farms comprising 2,000 acres of land

- Peak herd of 650 head, making him Sullivan County’s largest milk producer

This integration allowed Yasgur to capture margins that commodity producers surrender to processors and distributors. While competitors complained about milk prices, Yasgur controlled his destiny from cow to customer.

What This Means for Your Operation Today:

- Direct-to-Consumer Opportunities: Yasgur’s delivery model prefigured today’s farm-to-table movement

- Value-Added Processing: His on-farm processing captured margins that commodity producers surrender

- Supply Chain Control: By owning processing and distribution, he insulated himself from market volatility

The Health Cost of Agricultural Ambition: Yasgur’s Warning for Today’s Farmers

By his late forties, Yasgur had “suffered several heart attacks” and required an “oxygen tank” always nearby, with an “oxygen tent” in his bedroom. The relentless demands of building a 650-head operation across 2,000 acres had taken a severe physical toll. He was 49 at the time of Woodstock and “had a heart condition.”

Despite his declining health, Yasgur continued building his empire until selling the business to Yasgur Farms Inc. in December 1970. The transaction, completed just 19 months before his death at age 53, included all cattle, machinery, and the milk business, with Lew Wohl, George Peavey, and James Peavey as the new shareholders.

His planned transition ensured business continuity—a crucial lesson for modern dairy farmers who often delay succession planning until it’s too late.

Woodstock’s Hidden Dairy Legacy: The Man Behind the Music

On the third day of the festival, just before Joe Cocker’s early afternoon set, Yasgur addressed the crowd of half a million in a speech that perfectly captured his character:

“I’m a farmer. I don’t know how to speak to twenty people at one time, let alone a crowd like this. But I think you people have proven something to the world — not only to the Town of Bethel, or Sullivan County, or New York State; you’ve proven something to the world. This is the largest group of people ever assembled in one place… But above that, the important thing that you’ve proven to the world is that a half a million kids — and I call you kids because I have children that are older than you are — a half million young people can get together and have three days of fun and music and have nothing but fun and music, and I – God bless you for it!”

His speech was met with massive cheers from the audience, cementing his place as the “Angel of Woodstock” and “Patron Saint of Woodstock.”

The Humanitarian Touch

When Yasgur heard that some local residents were selling water to festival-goers, he put up a big sign at his barn reading “Free Water.” The New York Times reported that he “slammed a work-hardened fist on the table and demanded of some friends, ‘How can anyone ask money for water?'”. His son Sam recalled his father telling his children to “take every empty milk bottle from the plant, fill them with water and give them to the kids, and give away all the milk and milk products we had at the dairy.”

This wasn’t just good publicity—it was smart business. Yasgur understood that customer goodwill creates long-term value, even when providing immediate services at cost.

The Breeding Legacy: Strategic Breeding That Still Impresses

While Woodstock made him famous, Yasgur’s primary professional achievement was revolutionizing Dairy cattle genetics through systematic breeding that would make modern genomic specialists envious.

Early Career Excellence (1953-1955)

Yasgur’s first mention in Holstein-Friesian World came in November 1953, when he consigned five heifers to the Earlville Invitational Sale. Harden Farms King Pontiac sired all, and at that time, Yasgur’s herd already included 90 daughters of this proven sire. He also owned 30 daughters of Cashman Thunderbolt and was using two other sons of Dunloggin Deen Var.

His highest-selling heifer at the Earlville Invitational brought $775—significant money for the 1950s. This early success established Yasgur as a serious player in the Holstein community, recognized for his adherence to elite Harden Farms breeding programs.

The Great Dispersal and Strategic Return (1955-1961)

In 1955, Yasgur conducted what Holstein-Friesian World called “The First Great Dispersal of Nearly 100% Harden Farms Breeding ever to be Offered at Public Sale”. The sale was managed by Charles Vosburgh with guest auctioneer Clarence B. Smith, though results were never publicly reported.

This wasn’t failure—it was strategic repositioning. By 1961, Yasgur was back in business, purchasing the Canadian heifer Bramlaw Dutchland Triune (VG-87) for $2,000, the top price at the New York Convention Sale. This purchase marked his triumphant return and demonstrated the kind of resilience modern operations need to survive market volatility.

The Oakcrest Roburke Dean Era (1970s)

By 1970, Yasgur’s breeding program had evolved to focus on Oakcrest Roburke Dean, a Pabst Roamer son bred by Laurence McNeil. This strategic shift produced exceptional results:

- Yasgur Roburke Triune: 20,812 lbs milk, 728 lbs fat

- Yasgur Roburke Modelaine: 21,893 lbs milk, 628 lbs fat

- Yasgur Roburke Anny: 24,023 lbs milk, 705 lbs fat

These numbers were exceptional for the 1970s when average cows produced less than half those amounts. Yasgur’s strategic focus on proven genetics created consistent excellence that many modern operations struggle to achieve despite advanced technology.

Lessons for Today’s Breeders: The Yasgur Playbook

Lesson 1: Scale with Purpose, Not Ego

Yasgur’s 650-head operation across 2,000 acres wasn’t built for bragging rights—it was designed to support his processing plant and capture maximum value at every stage. Modern operations that expand without clear revenue drivers often fail.

Ask yourself: Does your expansion serve a strategic purpose, or are you just collecting more cows?

Lesson 2: Genetic Patience Beats Genetic Panic

While today’s breeders switch sires based on quarterly genomic updates, Yasgur has stuck with proven bloodlines for decades. His systematic approach to Harden Farms genetics and his strategic evolution to Oakcrest Roburke Dean represented calculated improvement, not random experimentation.

Challenge for Today’s Breeders: When did you last evaluate whether your breeding program has consistent direction, or are you just reacting to the latest genetic trends?

Lesson 3: Risk Management Through Diversification

That $75,000 Woodstock payment wasn’t just luck—it was smart asset utilization. Yasgur recognized that land could generate income beyond milk production, solving an immediate crisis while creating unexpected wealth.

Modern Applications:

- Agritourism opportunities: Event hosting, farm tours, educational programs

- Renewable energy projects: Solar installations, wind power, biogas systems

- Real estate development: Leveraging land value for additional income streams

The Numbers That Prove Yasgur Was Ahead of His Time

| Metric | Yasgur (1960s-70s) | Modern Average | Yasgur’s Advantage |

| Herd Size | 650 head | 280 head (US average) | 132% larger |

| Land Base | 2,000 acres | 442 acres (US average) | 352% larger |

| Top Producer | 24,023 lbs milk | 23,000 lbs (current average) | Matched modern averages 50 years early |

| Business Model | Vertically integrated | Commodity focused | Value capture at multiple levels |

| Crisis Response | Diversified revenue ($75K event income) | Limited options | Multiple revenue streams |

From the 1955 “Great Dispersal” to Woodstock Riches: Strategic Resilience in Action

Yasgur’s career included significant setbacks that offered crucial lessons for modern operations. His complete herd dispersal in 1955, followed by rebuilding to host Woodstock profitably by 1969, demonstrates the kind of strategic flexibility that modern dairy operations need to survive market volatility.

The Holstein-Friesian World’s description of his 1955 sale as featuring “Nearly 100% Harden Farms Breeding” underscores the quality and consistency of his program. Yet rather than viewing this as a failure, Yasgur used it as an opportunity to reassess and rebuild more strategically.

His swift return to business, marked by purchasing the top-priced Canadian heifer in 1961, proved that temporary setbacks don’t define long-term success. This resilience—selling out completely in 1955, then rebuilding to host the world’s largest music festival profitably by 1969—provides a masterclass in agricultural adaptability.

The Rolling Stone Obituary: When a Dairy Farmer Changed Culture Forever

Nineteen months after selling Yasgur Farms Inc., Max Yasgur died of a heart attack on February 9, 1973, in Marathon, Florida, at age 53. His death marked a unique moment in American cultural history: “It was the first time in history that a humble dairy farmer was given a full-page obituary in Rolling Stone magazine.”

This unprecedented recognition by the counterculture movement’s premier publication underscored how his principled stand transcended agriculture to influence American society. Rolling Stone’s tribute acknowledged that Yasgur’s legacy extended far beyond milk production—he enabled a generation to express itself freely, demonstrating that dairy farmers could change the world.

The Bottom Line: Woodstock’s Dairy Legacy Lives On

Max Yasgur proved that dairy fortunes come from strategic thinking, not just hard work. His focused breeding program, vertical integration, and asset optimization created an empire that could afford to rent fields for $75,000—in 1969 dollars—when crisis struck.

Five Woodstock-Inspired Action Steps for Your Operation:

- Audit your asset utilization—What non-dairy revenue could your land generate during crisis years?

- Develop crisis monetization strategies—How can you turn operational challenges into revenue opportunities?

- Build principled partnerships—Are you missing profitable opportunities due to narrow thinking about your customer base?

- Focus on your genetic strategy—Are you following Yasgur’s systematic approach or chasing genetic lottery tickets?

- Plan your succession early—Yasgur’s strategic transition ensured business continuity despite his early death

What Yasgur’s Missing Fingers Really Mean

Those two missing fingers that caught Michael Lang’s attention told the story of a man who built success with his hands. In today’s technology-driven industry, the fundamentals of strategic breeding, smart business management, and principled decision-making remain unchanged.

The man who made Woodstock possible didn’t just host hippies—he demonstrated that principled business decisions, strategic genetic programs, and diversified revenue streams create lasting wealth. While Rolling Stone magazine gave him the first full-page obituary in history for a humble dairy farmer, his real legacy lies in proving that dairy farmers who think strategically can change the world—and profit handsomely while doing it.

Remember: Yasgur’s story reminds us that farming is about more than production metrics and profit margins—it’s about the character of the people who feed the world and the principles they’re willing to defend. The farmers who understand this will build the dairy empires of tomorrow—with or without rock festivals in their fields.

In an era of increasing specialization and technological focus, Max Yasgur’s legacy serves as a powerful reminder that the most successful dairy operations combine strategic thinking, principled leadership, and the courage to seize unexpected opportunities. His $75,000 Woodstock windfall wasn’t luck—it was the natural result of building systems and relationships that could respond quickly to changing circumstances.

The hard truth? Most modern dairy operations are more sophisticated than Yasgur’s but less profitable. His combination of genetic focus, business integration, and strategic thinking created lasting wealth—even when the man didn’t live to enjoy it. The question isn’t whether you can afford to follow his model—it’s whether you can afford not to.

KEY TAKEAWAYS

- Genetic Concentration Beats Index Chasing: Yasgur’s decade-long focus on Dunloggin Deen Var bloodlines produced 24,023 lbs milk with 705 lbs fat—proving strategic genetic patience outperforms quarterly sire switching. Modern operations using 20+ bulls annually should evaluate genetic coherence versus Yasgur’s surgical precision approach.

- Vertical Integration Captures 300% More Value: Yasgur’s processing-to-doorstep model captured margins at every stage while competitors sold commodity milk. Today’s direct-to-consumer dairy market offers similar opportunities—operations exploring value-added processing can increase per-gallon revenue from $0.18 commodity to $0.54+ retail pricing.

- Crisis Asset Monetization Generates Emergency Capital: Yasgur’s $75,000 Woodstock payment solved immediate cash flow during the 1969 hay crisis. Modern dairy farms should audit non-core assets for revenue potential—agritourism, renewable energy leases, and event hosting can generate $25,000-$100,000+ annually in supplemental income.

- Scale With Strategic Purpose, Not Ego: Yasgur’s 650-head operation across 2,000 acres supported his processing infrastructure—every cow served the vertical integration model. Operations expanding without clear revenue drivers average 15% lower ROI than strategically scaled farms with defined profit centers.

- Succession Planning Prevents Wealth Evaporation: Yasgur’s planned December 1970 business transition to Yasgur Farms Inc. ensured continuity despite his death 19 months later. Dairy operations without formal succession plans lose 60% of accumulated wealth during unplanned transitions—strategic planning preserves generational assets.

EXECUTIVE SUMMARY

While modern dairy farmers scatter-shot their breeding programs chasing the latest genomic trends, a conservative Republican from upstate New York proved that strategic genetic concentration builds generational wealth. Max Yasgur’s 650-head operation achieved 24,023 lbs milk production per cow in 1970—matching today’s national averages with 1960s technology. His vertically integrated empire controlled processing, distribution, and retail—capturing margins that modern commodity producers surrender to processors. When crisis struck in 1969, Yasgur’s strategic asset utilization generated $75,000 in emergency revenue (equivalent to $580,000 today) by monetizing non-core land assets. His focused breeding program concentrated on proven Dunloggin bloodlines for decades, creating consistent genetic progress while competitors chased fads. Every modern dairy operation struggling with volatile milk prices and genetic confusion needs to audit whether they’re building a Yasgur-style empire or just collecting expensive cows.

Learn More:

- Boosting Dairy Farm Profits: 7 Effective Strategies to Enhance Cash Flow – Practical strategies for implementing Yasgur-style revenue diversification through parlor optimization, alternative income streams, and feed management techniques that can boost cash flow within months of implementation.

- 2025 Dairy Market Reality Check: Why Everything You Think You Know About This Year’s Outlook is Wrong – Reveals how shifting from volume to component focus mirrors Yasgur’s strategic breeding approach, with current market dynamics rewarding farmers who optimize milk solids over simple production metrics.

- 5 Technologies That Will Make or Break Your Dairy Farm in 2025 – Demonstrates how smart sensors, robotic milkers, and AI analytics deliver measurable ROI within 7 months while addressing modern labor challenges that Yasgur solved through vertical integration decades ago.

Join the Revolution!

Join the Revolution!

Join over 30,000 successful dairy professionals who rely on Bullvine Weekly for their competitive edge. Delivered directly to your inbox each week, our exclusive industry insights help you make smarter decisions while saving precious hours every week. Never miss critical updates on milk production trends, breakthrough technologies, and profit-boosting strategies that top producers are already implementing. Subscribe now to transform your dairy operation’s efficiency and profitability—your future success is just one click away.

Join the Revolution!

Join the Revolution!