While you’re spending $3,000/cow on cooling, Brazilian Gyrs are cranking 11L daily without a single fan. Ecuador just figured it out.

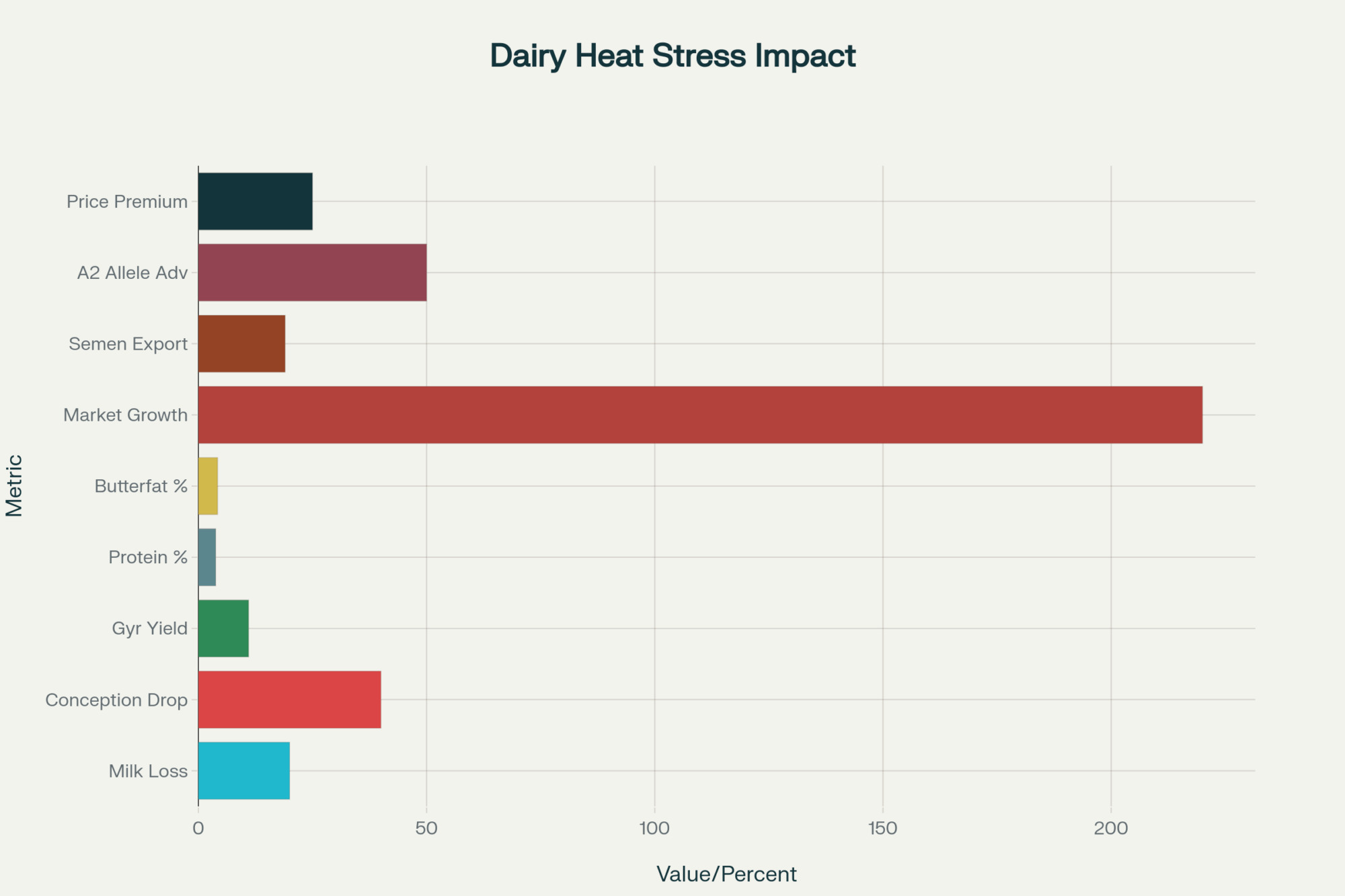

EXECUTIVE SUMMARY: Listen, I just got back from covering the most eye-opening genetics move I’ve seen in decades. Ecuador’s betting their dairy future on heat-adapted Gyr cattle instead of million-dollar cooling systems—and the math is brutal for anyone still fighting their climate. Here’s what’s got me fired up: while your Holsteins lose 25% production when summer hits, these Brazilian Gyrs keep pumping 11 liters daily with zero performance drop. We’re talking about a $306 million global genetics market that’s exploded because smart producers realized something… cooling bills that eat half your feed budget aren’t sustainable. The kicker? These aren’t experimental genetics—they’re million-year-old solutions with 85% genomic prediction accuracy backing every breeding decision. Brazil’s producers learned this lesson decades ago, and now Ecuador’s 300,000 dairy families are following suit. If you’re still mortgaging your future for climate control infrastructure, you might want to run these numbers before your next summer burns through another year’s profits.

KEY TAKEAWAYS:

- Cut summer production losses by 80%: Gyr genetics maintain 95% output during heat stress while Holsteins crash 25%. For a 100-cow operation, that’s 40-50 liters daily you’re not losing to heat—start with AI programs from proven tropical genetics suppliers this month.

- Slash infrastructure costs by ditching cooling dependency: Ecuador producers were quoted millions for climate control before discovering Gyr operations running profitably with zero cooling systems. Calculate your current cooling costs per cow and compare against genetic investment ROI—the payback timeline might shock you.

- Tap into the $306M global heat-tolerance boom: Brazilian genetics are penetrating Australia, New Zealand, and even Germany as traditional markets wake up to climate reality. Contact your genetics supplier about heat-adapted semen availability and pricing—this trend isn’t slowing down.

- Leverage 85% genomic accuracy for breeding decisions: Modern tools predict heat tolerance in calves before they’re born, eliminating guesswork from your genetic investments. Work with suppliers offering genomic testing to build your heat-adapted herd strategically over the next 3-5 years.

- Future-proof against rising energy costs: With cooling expenses ranging $0.50-$0.85 per cow daily during peak season, heat-adapted genetics become more valuable every summer. Track your energy bills from last summer and project them forward—genetic solutions look better every year.

If you had told me a year ago that two cargo planes filled with Brazilian Gyr cows landing in Quito would fundamentally alter tropical dairying, I’d have been skeptical. But those 110 head made a clear statement: the way to beat the tropical heat just got smarter.

Ecuador’s Dairy Reality Check

Ecuador churns out roughly 2.4 billion liters annually from close to 300,000 producers—mostly family operations grinding it out in challenging conditions². Nearly half that milk flows through informal channels, which puts a ceiling on modernization and growth.

Up in the highland regions around Pichincha and Cotopaxi, producers face a double whammy: altitude challenges at 2,700+ meters reduce oxygen levels and stress cows even before heat becomes a factor. Recent research from the University of Liège shows these operations average 15.1 kg daily production under rotational grazing systems.

Based on conversations with multiple producers near Cayambe, there’s a shared frustration: “Our cooling bills are eating almost half what we spend on feed. That’s money we’d rather put back into genetics or better pastures.”

Why Gyr Genetics Are Game-Changers

Standing in a Minas Gerais pasture with Dr. Roberto Silva—one of Brazil’s top zebu geneticists—changed everything I thought I knew about tropical dairy. Watching Gyr cows stroll calmly to milking while Holstein crossbreds desperately sought shade was eye-opening.

These aren’t just heat-tolerant cows—they’re heat-adapted machines. Gyrs maintain performance at Temperature-Humidity Index levels of 77.5, while Holsteins start shutting down around 72-73. That translates to a consistent 10-12 liters daily with 4.2% butterfat, even when the mercury soars.

Breed Performance Reality Check

Data compiled from peer-reviewed studies; individual results vary

| Performance Metric | Gyr | Holstein | Girolando |

| Daily Milk (Tropical) | 11L | 7L | 9.5L |

| Butterfat Content | 4.2% | 3.6% | 4.0% |

| Heat Tolerance (THI) | 77.5 | 72 | 75 |

| Summer Production Loss | 5% | 25% | 12% |

A Brazilian farm manager near Uberaba told me: “My Holstein crossbreds might hit 18 liters in cool weather, but come summer, they crash to 8. These Gyrs? Rock solid at 11 liters every single day, no matter how hot it gets.”

The Hidden Challenge: Feed Quality and Mycotoxins

What most producers don’t realize is that heat stress is just part of the battle. Ecuador’s coastal regions get hammered with aflatoxin contamination during dry seasons, destroying feed quality and milk safety.

Highland pastures face their own challenges—protein levels fluctuate between 12-18% seasonally, with fiber digestibility dropping during dry periods. When you combine altitude stress, heat, and compromised feed, conventional genetics simply can’t keep up.

That’s where Gyr genetics shine. Evolved in harsh environments, their efficient metabolism and robust digestive systems give them distinct metabolic resilience to multiple stressors simultaneously—heat, altitude, and suboptimal feed quality that would cripple temperate breeds.

LATAM’s Logistics Masterclass

Getting 110 head of elite genetics from Brazil to Ecuador wasn’t just impressive—it was a blueprint for international livestock transport. LATAM Cargo executed quarantine protocols stricter than most international borders, with veterinary teams monitoring every phase.

The economics tell the real story: strategic genetic investments are proving more cost-effective than infrastructure-heavy cooling solutions that drain margins year after year.

What This Actually Costs Your Operation

Let’s cut through the marketing fluff and talk real numbers. Investment costs vary dramatically based on your operation size, location, and current setup. What works in one climate might be overkill or inadequate in another.

The Reality Check:

- Heat-adapted genetics costs depend heavily on genetics quality, supplier, and regional availability

- Cooling system investments vary by barn design, local energy costs, and climate severity

- Ongoing energy and maintenance can be substantial during peak seasons

Note: Costs vary significantly based on operation scale, regional factors, and technology choices. Producers should obtain specific quotes for their circumstances, as investment requirements can range widely depending on genetics quality, supplier, and local infrastructure needs.

A producer near Cuenca summarized what I heard across the region: “We got infrastructure quotes that honestly scared us. Then I visited Brazilian Gyr operations—cows producing quality milk without a single cooling fan. That changed our whole thinking.”

Global Momentum Building Fast

This shift is happening worldwide. The international genetics trade reached $306 million in 2023, with Brazilian bloodlines gaining traction in traditionally temperate markets such as Australia and New Zealand.

Dr. Klaus Weber from Germany’s University of Hohenheim nailed it during our conversation: “Forcing European genetics to work in a warming climate is like wearing snow boots to the beach. Zebu genetics have the evolutionary head start we desperately need.”

Brazil represents a major force in South American dairy production for good reason—its producers learned to work with their environment, not against it.

Technology Meets Ancient Wisdom

Behind these cows, cutting-edge genomic selection is adding precision to natural selection. Brazilian researchers have now achieved 85% accuracy in predicting heat tolerance using genomic tools. This isn’t guesswork—it’s precision breeding based on millions of years of natural selection.

The combination of ancient genetics with modern reproductive technology enables you to rapidly improve your herd’s climate adaptation without the infrastructure investment required by traditional cooling methods.

Your Action Plan

If heat stress is bleeding your margins, here’s your roadmap:

This Week:

- Contact heat-adapted genetics suppliers and ask for performance data from herds in climates similar to yours

- Install simple, high-visibility thermometers in your barns and holding pens to establish a baseline Temperature-Humidity Index (THI) for your operation

- Calculate your actual cooling costs per cow during peak season

This Month:

- Track summer production losses: measure milk yield and conception rate drops from May through August

- Visit a Gyr or Girolando operation if you can swing it

- Connect with your local extension economists for regional cost data

This Quarter:

- Model ROI comparing genetic upgrades versus cooling infrastructure using your actual quotes

- Develop a realistic genetic improvement timeline for your operation

- Assess your feed quality management and mycotoxin protocols

Don’t waste another summer watching profits evaporate with your milk production.

The Bottom Line

Ecuador’s strategic investment proved something every tropical producer suspected—there’s a better way than fighting your climate with expensive cooling systems that drain margins year after year.

The genetics are proven. The economics make sense for many operations. The climate isn’t getting any cooler.

Time to run your numbers and make the call. The flight path from Brazil to Ecuador isn’t just news—it’s showing the way to profitability in our warming world.

Complete references and supporting documentation are available upon request by contacting the editorial team at editor@thebullvine.com.

Learn More:

- The Ultimate Guide to Dairy Sire Selection – This guide provides a tactical framework for making smarter breeding choices today. It details how to interpret proofs and prioritize traits, ensuring you can effectively implement the genetic shift towards heat tolerance discussed in the main article.

- Does Your Dairy Have A Strategic Plan? – Move from a single breeding decision to a long-term vision. This article outlines how to build a robust strategic plan, helping you position your entire operation to capitalize on market shifts like the move towards climate-adapted genetics.

- Genomics: The Crystal Ball of the Dairy Industry – Dive deeper into the technology mentioned in our feature. This piece explains how genomic testing provides an unprecedented look into future performance, allowing you to accelerate genetic gain and make breeding decisions with greater accuracy and confidence.

Join the Revolution!

Join the Revolution!

Join over 30,000 successful dairy professionals who rely on Bullvine Weekly for their competitive edge. Delivered directly to your inbox each week, our exclusive industry insights help you make smarter decisions while saving precious hours every week. Never miss critical updates on milk production trends, breakthrough technologies, and profit-boosting strategies that top producers are already implementing. Subscribe now to transform your dairy operation’s efficiency and profitability—your future success is just one click away.

Join the Revolution!

Join the Revolution!