Feed waste’s eating $570 out of every cow you own—how much are you leaving in the alley every season?

EXECUTIVE SUMMARY: So, here’s the real story, neighbor. Most dairies bleed margin at the bunk, losing up to $570 per cow every single year—and it’s not just a “bad day” problem. Extension folks say waste hits $1.40–$1.60 per cow, per day. Stack that across 250 head… you’re looking at $140,000 flying out the door just from spoiled silage and feed refusals. Doesn’t matter if you’ve got 80 Holsteins or 500 Jerseys—weather and storage make or break your numbers. Technologies like automated feeders can reduce waste by 38% and cut labor hours in half. And those rumination collars? They catch sick cows two days before your eyes will—saving thousands in vet bills, not to mention milk lost. Farmers in the Netherlands, Brazil, and even India are utilizing precision rations and mobile apps, achieving a payback period of 18 months or less. The kicker? Top herds focus on feeding smarter, not adding cows. That’s what drives margins in today’s market—especially with feed prices climbing in 2025.

You oughta run a shrink check on your own bunk this month. It’s the best money-saving step you’ll take all year.

KEY TAKEAWAYS:

- Feed waste isn’t just spilled hay—it’s $500–$650 lost per cow, year in, year out. Run your own daily shrink test.

- Automated feeding systems, such as Triomatic, slash waste by up to 38%, with tech payback often achieved within two years. Don’t just feed more—feed smarter.

- On-farm rumination sensors catch illness 1–2 days earlier than the naked eye, trimming vet bills and boosting milk flow. Ask your nutritionist for options.

- Global dairy leaders—from Dutch to Brazilian herds—are scaling rapidly with precision feeding, not herd size. That’s what’s moving ROI in 2025.

- Want to plug the leak? Start by tracking refusals and shrink. Call your extension—get a feed waste worksheet. The profit’s waiting in your alley, not your next cow purchase.

Let me tell you, if you’re still thinking “more cows, more milk, more margin,” you’re playing last year’s game. Give this new approach a real shot, and watch your dairy pencil look a whole lot fatter.

Step into any 240-cow barn in Central Wisconsin in March—slush up to your ankles—and you’ll see feed push-offs stacking up like cordwood. In north Fond du Lac, a local nutritionist recently told me, “You’re shoveling away the price of a new headgate every month.” Stories like that, echoing recent farm visits from the Upper Midwest, pretty much sum up what’s biting into real dairy margins. Nearly every conversation comes back to shrinkage and refusal. As Luiz Ferraretto and Randy Shaver noted in a University of Kentucky Extension analysis, lost pounds at the bunk are a universal challenge for U.S. dairies.

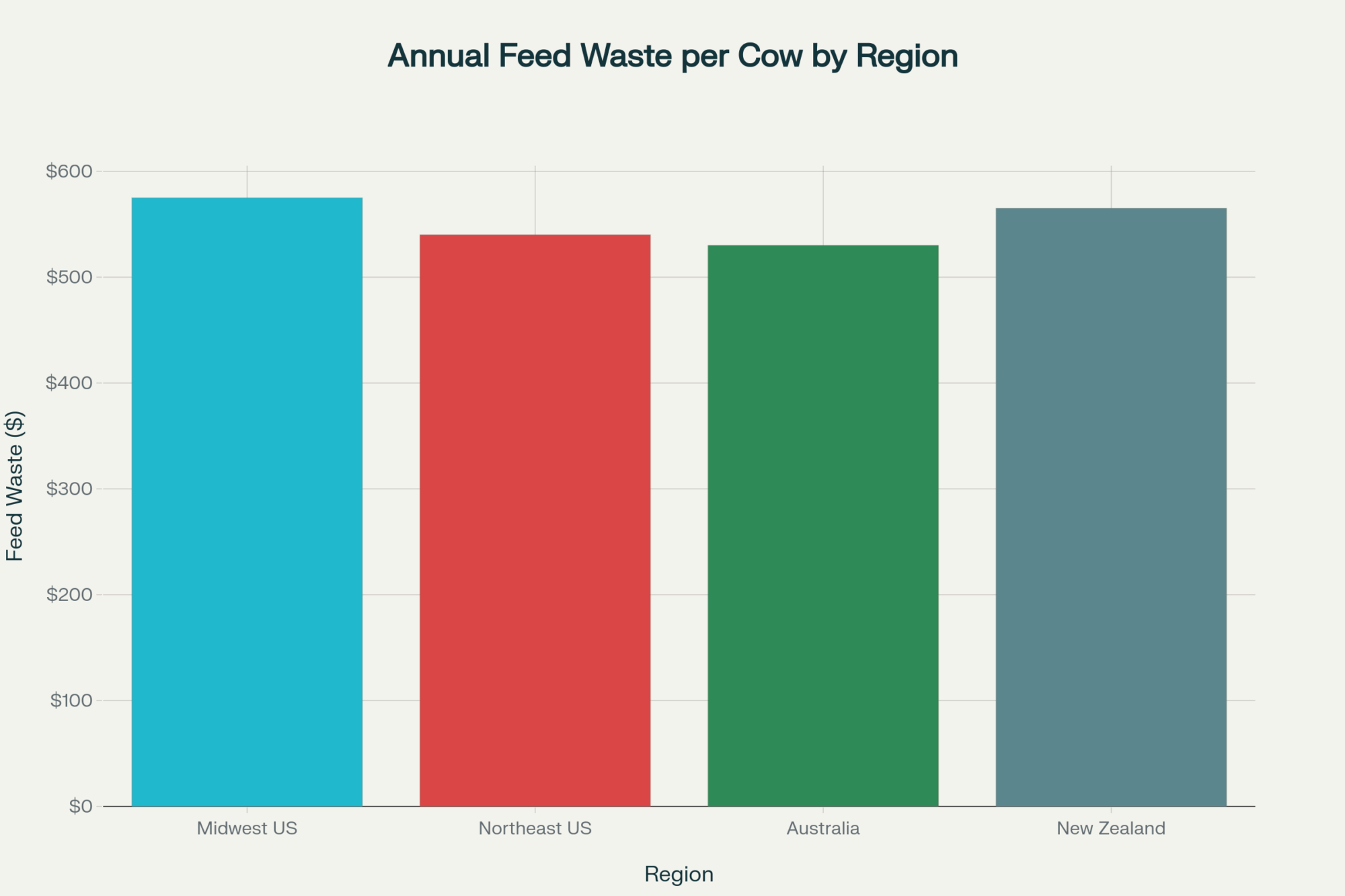

Extension analyses from Kentucky and Wisconsin peg the real cost of feed waste at $1.40 to $1.60 per cow, per day—between $500 and $650 per cow over the year, with peaks much higher on the worst days. Do the math: at an average of $1.55 per day, that’s the $570-per-cow problem that hits your bottom line every single year. Run your own workbook and see if it shakes out differently, but for most, that’s real money lost.

Why “More Cows” Doesn’t Fix Feed Waste

If you’ve ever argued the “bigger is better” side at the co-op table, you’ve probably heard the comeback: “If you’re behind on feed management, more cows just means a bigger hole.” Big herds with the right gear can sometimes get shrink below average, especially in those elite Indiana and Idaho TMR setups. Most average farms—especially with roughage in bunker silos and unpredictable weather—fall into the same trap. Putting on 50 head before you plug the waste is like topping up a worn-out tire before patching the hole.

As Dr. Randy Shaver of UW-Madison often emphasizes, a typical scale doesn’t guarantee typical intake. He often states, “A producer might be delivering 50 pounds of dry matter to the bunk, but the cows are only consuming 42. That 8-pound gap is where your profit disappears, and it shows up directly in the milk check.” His findings in Wisconsin align with what I’ve seen in upstate New York TMR barns the same week.

Break down those on-farm records—from Michigan’s sand-bedded freestalls losing 8% to Ohio’s drive-over pile herds at 15%—and you’ll see weather, bunk, and storage make or break you.

According to Penn State Extension, $0.50 per cow daily in classic shrink is common, but with energy and protein factored in, annual losses climb to $500–$650 per cow. A typical 250-cow herd in the Midwest can lose the feed equivalent of an entire semi-load of corn silage every year, enough to buy a new used skid-steer.

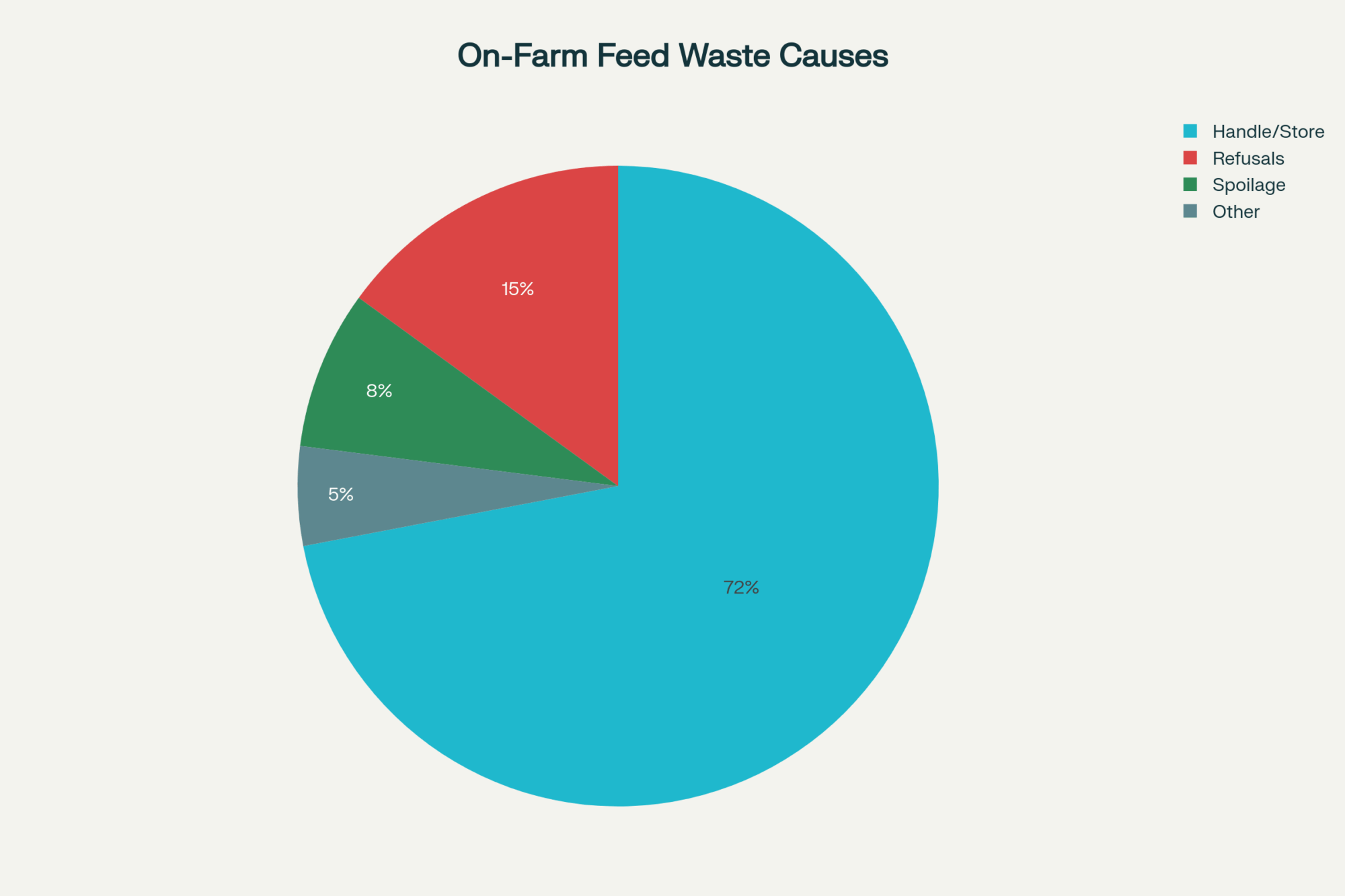

Looking overseas, the Australian Dairy Sector Food Waste Action Plan reports the industry loses over 700,000 metric tons of feed a year, with almost three-quarters of that occurring on farms rather than at the processor. DairyNZ’s numbers remind us that weather and region always matter.

How Tech Actually Delivers (And When It Doesn’t)

Forget the flashy dealer flyers—real farms want results. Here’s what’s moving the margin where it counts:

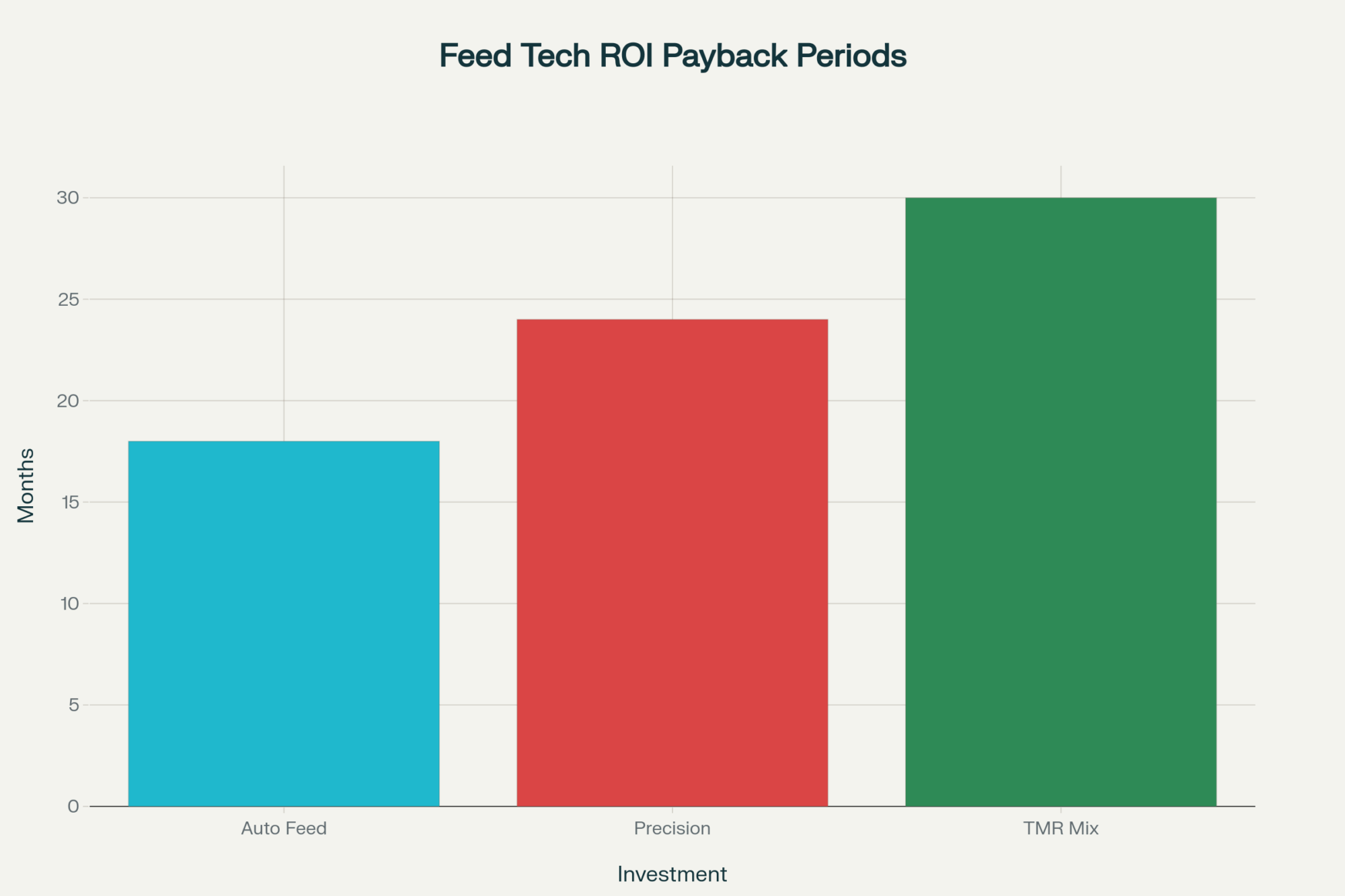

- Case Study: The Kruidhof family near Ommen, Netherlands—85 Holsteins—installed a Triomatic T30 feeding system, switched to six-times-per-day feeding, and cut waste by 38% while dropping labor needs by more than half. Their payback landed just shy of 18 months on a €95,000 investment. European extension trials back up these results, but U.S. herds still have to account for local dealer support, herd size, and that critical Midwest labor reality.

- Feeder Reliability: Lely units, now common from Sheboygan to Saskatchewan, achieve an uptime of upwards of 98%, and 60% of issues are resolved remotely before the wrenches are even taken out. As a Dodge County producer shared last month, “Fast dealer response counts for more than horsepower.”

- Cow Health Sensors: Rumination collars and eartags ($200–$250 a head) are game-changers for early illness detection. Studies by Gygax in Switzerland and Cornell’s Schirmann show these sensors can catch health problems a full one to two days earlier than visual signs, saving $2,000 or more each time they avert a health crisis.

Who’s Adopting? And What’s Holding Us Back?

U.S. adoption of full precision monitoring sits at just 12%, while Dutch herds are near 44%. Extension co-ops and lending groups here in the Midwest are making progress, but the whole team has to buy in—from feeders to family. The last Wisconsin Dairy Farm Business Summary found that cautious technology adopters logged a 15–25% ROI, with a payback period of two to three years—as long as staff were trained and support remained responsive.

Feeding Smarter—Not Just Adding Cows

Rather than adding cows, top herds focus on feeding smarter. Virginia Tech’s Self-Learning Dairy research showed individualized rationing puts $0.32 to $0.60 per cow per day back into your operation. That’s $100–$220 per cow per year, not counting earlier health catches. Dairy Business Association benchmarks from Wisconsin have shown a $250–$350 per cow per year profit increase from simply reducing shrinkage.

So what’s it mean for your own place? Run a feed trial. Track refusals for a month, batch by batch. The math you get might surprise you—and your accountant.

Are Environmental Gains Really Paying Off?

Precision feeding isn’t just for environmental headlines. According to the Journal of Environmental Quality, targeted protein feeding reduces nitrogen losses by 11–19%. Local extension data confirms Corn Belt and New York herds have matched or exceeded these savings with precision-driven TMR management. Reviews in Frontiers in Vet Science say certain feed additives can cut emissions by up to 22%. UC Davis life-cycle studies found precision feeding can reduce manure output by 14%.

Thinking about carbon credits? The USDA and NSAC report pilot farm payments of $6–$15 per tonne for CO2 reductions, but costs for paperwork and verification can run $3,000–$5,000 per year. New Zealand’s ETS market moves from NZ$30–$70/tonne depending on policy and feed prices, so buyers need to watch the rules before banking on returns.

Local Roadblocks and Financing

In Ontario, DFO and Farm Credit Canada negotiate annually with local banks—sometimes it’s a few thousand dollars upfront, while in other years, terms flip quickly. Always call your local office for up-to-date packages. In the U.S., the NRCS EQIP program can cover $50,000–$200,000 for feeding system upgrades, provided your plan fits the conservation and efficiency slots.

Brazil & India: Dairy Competition Goes Global

Across the globe, Brazil’s EMBRAPA notes over 500 new automated herds are built each year, integrating feeding tech from the start. NDDB’s digital push in India gives 150,000 herds smartphone ration calculators, with small farms seeing 15–19% better yields. International Dairy Federation researchers say it now takes less than two years from install to payback—compared to the decade-old five-year slog.

Bullvine Bottom Line: Local Data, Real Dollars

Feed waste isn’t an abstract table; it’s dollars left in the alley and pounds unmilked. Smart nutrition and management—backed by both hard data and local extension trials—pay off for farms that check, measure, and adapt. No matter the size, track your shrink, weigh refusals, and call the service crew before you trust a sales pitch.

Because in this business, size won’t hide waste. Only sharp feeding and tight records move the margin.

Complete references and supporting documentation are available upon request by contacting the editorial team at editor@thebullvine.com.

Learn More:

- The Feed Squeeze: Why Rising Milk Numbers Hide the Real Crisis on Dairy Farms – This strategic overview digs into the critical Income Over Feed Cost (IOFC) metric. It reveals how regional price differences and market volatility directly impact profitability, providing the high-level economic context for the main article’s operational focus.

- Feed Costs Just Rewrote the Dairy Playbook—and Your ZIP Code’s Calling the Shots – A practical look at how geography and logistics are reshaping feed strategy. This piece offers actionable advice on cooperative buying, storage, and transport solutions that directly address the cost issues highlighted in the main article.

- The Robotic Milker Hangover: The Hard Truths About Automation Your Dealer Won’t Tell You – Shifting from feed to milking, this article explores the realities of implementing another major automation system. It provides a valuable, complementary perspective on the management mindset and data-driven approach required to succeed with any precision technology investment.

Join the Revolution!

Join the Revolution!

Join over 30,000 successful dairy professionals who rely on Bullvine Weekly for their competitive edge. Delivered directly to your inbox each week, our exclusive industry insights help you make smarter decisions while saving precious hours every week. Never miss critical updates on milk production trends, breakthrough technologies, and profit-boosting strategies that top producers are already implementing. Subscribe now to transform your dairy operation’s efficiency and profitability—your future success is just one click away.

Join the Revolution!

Join the Revolution!