Think BMR’s unbeatable for silage? This new research may completely flip that script around.

Here’s something that caught everyone off guard at this summer’s dairy meetings: Michigan State has just published research showing that these new short-stature br2 corn silages outperform brown midrib on nearly every metric that actually pays bills. The data are real—and honestly surprised me—but they come from one herd in a drought year, so let’s dig into what this really means for your operation.

I’ll be straight with you… when I first saw Dr. Mike VandeHaar’s numbers in the Journal of Dairy Science Communications this August, I assumed there was a mistake somewhere. BMR has been our go-to for high-quality forage since most of us were learning the business. But this Michigan State trial? It’s fundamentally challenging what we thought we knew about corn silage genetics.

Quick Industry Reference

- BMR (Brown Midrib): Corn with reduced lignin for better fiber digestibility—has been the premium forage standard for decades

- br2 (Brachytic-2): New gene creating short-stature corn with completely different plant architecture

- ECM: Energy-Corrected Milk—what actually matters for your milk check

- DMI: Dry Matter Intake—how much feed your cows are actually consuming

What Actually Happened (And Why It’s Got Nutritionists Talking)

This wasn’t some small-scale university trial. Michigan State put three different br2 short-stature hybrids head-to-head against Pioneer’s P0956AMX BMR and a conventional tall hybrid, using 40 mid-lactation cows over three 21-day periods. This is a fairly standard protocol for this type of work.

But here’s where it gets interesting—and why feed reps are scrambling to understand the implications…

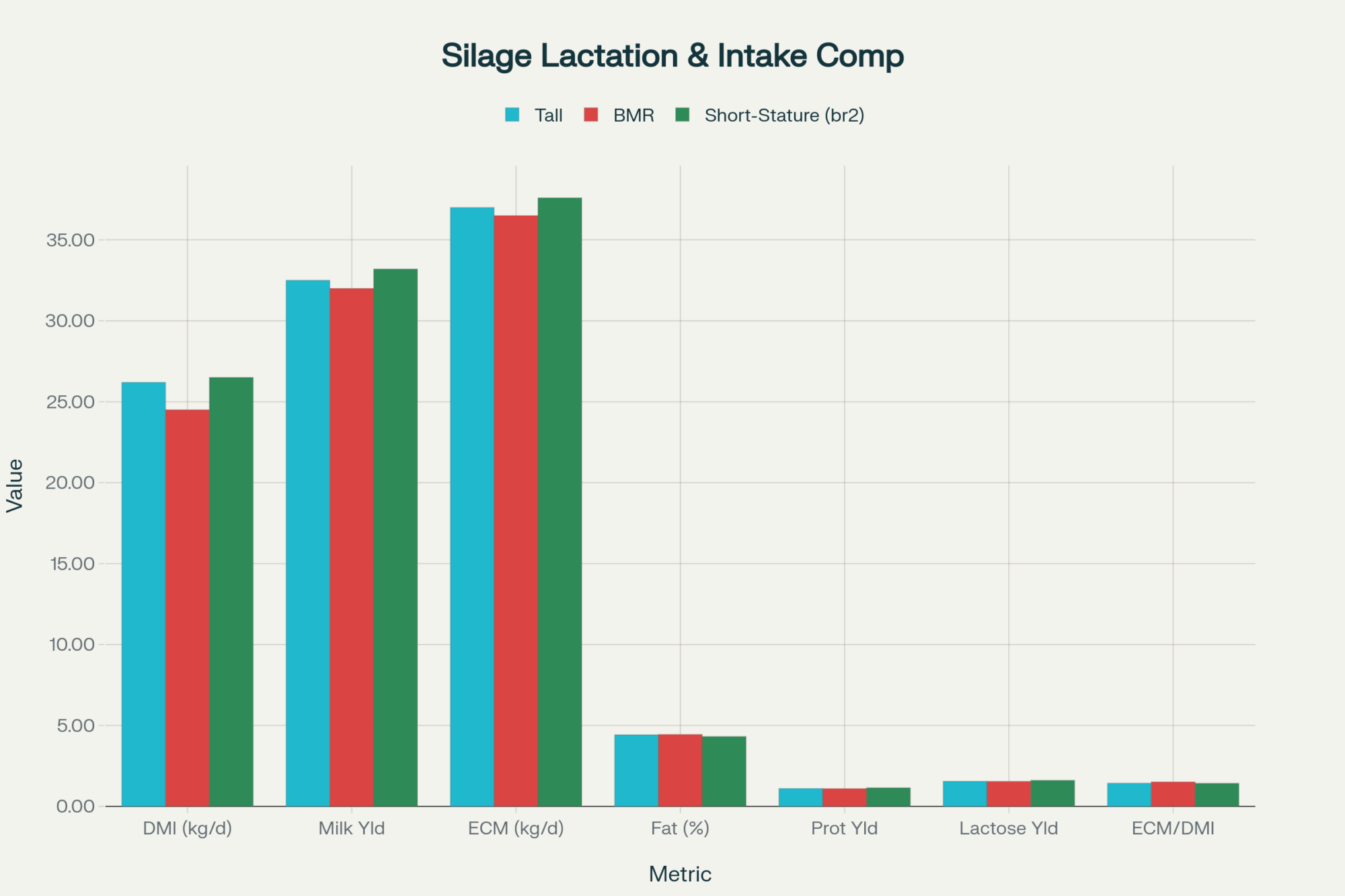

The BMR that was supposed to drive higher intake because of its legendary fiber digestibility? It actually had the lowest intake of the bunch. I’m talking 24.5 kg of dry matter daily versus 26.5 kg for the br2 hybrids. That’s over 4 pounds more feed consumed every single day.

Key Finding: br2 corn drove 8% higher daily feed intake than BMR, translating to significantly more milk production and component yields.

The Lab vs. Reality Disconnect

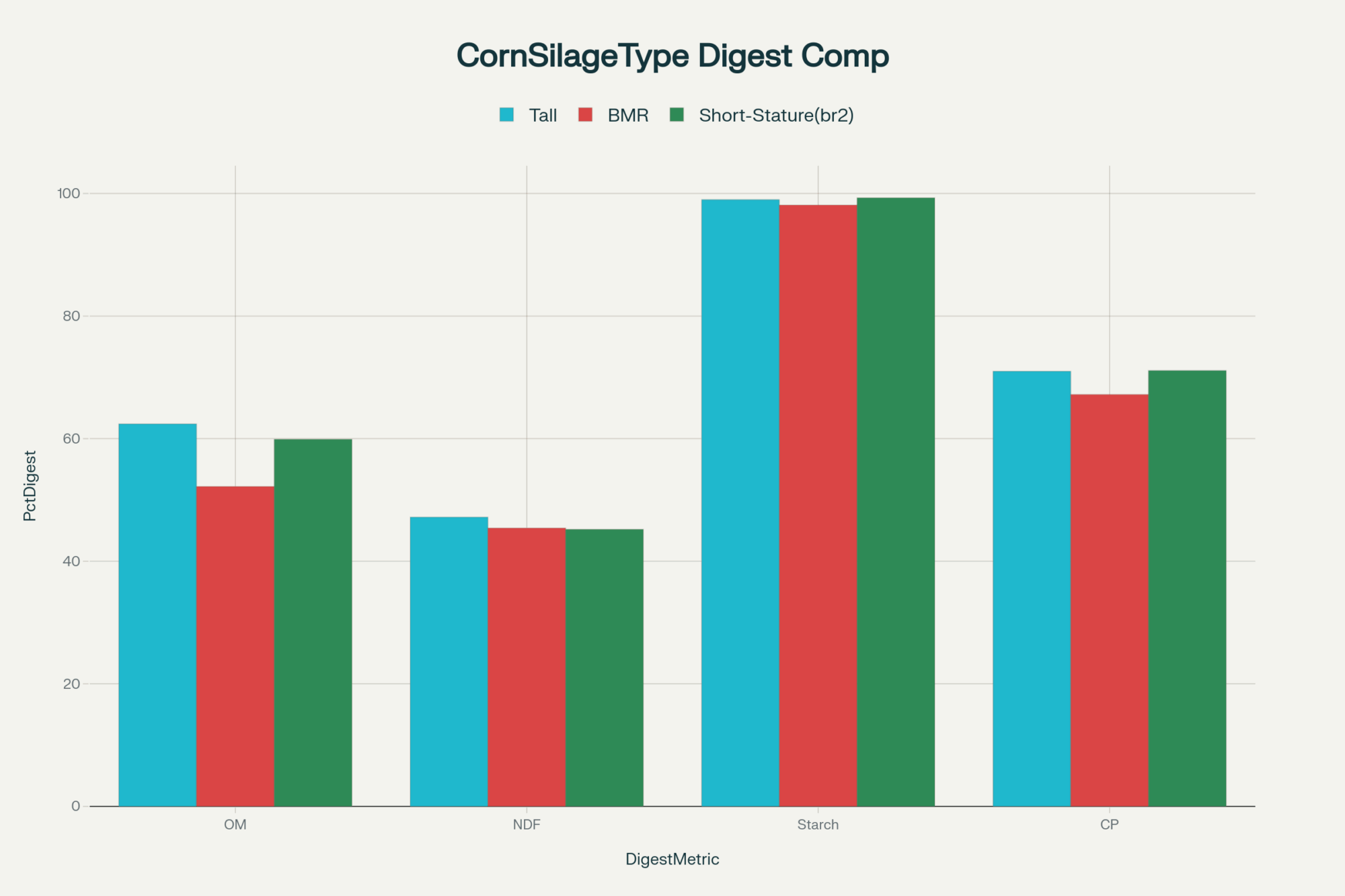

Here’s what really has us scratching our heads in the world of nutrition. The pre-trial lab work showed exactly what you’d expect—BMR crushed the competition for fiber digestibility at 63% IVNDFD after 30 hours versus just 57-60% for the br2 hybrids.

But when they measured actual total-tract digestibility in live cows? That laboratory advantage completely vanished. NDF digestibility was essentially identical: 45.4% for BMR, 45.2% for br2 (P=0.88).

What strikes me about this disconnect is how it challenges our heavy reliance on 30-hour IVNDFD numbers when making forage purchasing decisions. Perhaps we’ve been missing something more significant here.

The Production Numbers That Actually Matter

Let me walk you through what happened in the parlor, because this is where we make our money…

Daily Production Comparison:

| Metric | BMR Diet | br2 Average | Difference | Your Bottom Line |

| Feed Intake | 24.5 kg | 26.5 kg | +8.2% | More feed purchased, but… |

| Milk Production | 32.0 kg/day | 33.2 kg/day | +3.8% (+2.6 lbs/day) | Extra 2.6 lbs/cow/day |

| Milk Protein | 1.10 kg/day | 1.15 kg/day | +4.5% | Higher component premiums |

| Feed Efficiency | 1.51 ECM/DMI | 1.43 ECM/DMI | -5.3% | BMR is still more efficient |

Data from Sarmikasoglou et al., August 2025

The br2-fed cows didn’t just eat more—they produced more of everything that matters for today’s component-heavy pricing. Daily milk yield jumped from 32.0 kg on BMR to 33.2 kg on br2 diets. More importantly for those of us dealing with protein premiums reaching $3.50/cwt in some markets, protein yield increased from 1.10 kg to 1.15 kg per day.

Now, there’s a trade-off we need to talk about. Milk fat percentage dropped from 4.45% on BMR to 4.32% on br2. That 0.13 percentage point hit isn’t nothing—especially with some plants getting pickier about butterfat standards this year. However, the total pounds of fat remained about the same due to the higher volume.

Two Different Feeding Philosophies

Here’s where this gets nuanced, and why I think we’re looking at tools for different situations rather than a simple “winner.”

BMR was still the efficiency champion—1.51 ECM per unit of feed versus 1.43 for br2. The Michigan State data also show that BMR cows maintained a slightly better body condition, with a small positive BCS change, versus slight losses on Br2.

Think about it this way:

- BMR seems built for efficiency and condition maintenance—maybe better for fresh cows that need to recover condition while producing

- br2 looks like a high-throughput production driver—possibly better for well-conditioned cows in mid-to-late lactation, where you want to maximize component output

This isn’t necessarily about “better” or “worse”… it’s about having the right tool for the right cow at the right time.

Why BMR Stumbled (And What That Teaches Us About Real-World Feeding)

The researchers were refreshingly honest about BMR’s unexpected underperformance. Their explanations matter because they affect how we should interpret these results for our own operations.

Context Issues That Affected This Trial:

First, this was a 2023 Michigan corn year—a brutal drought year that likely impacted BMR more severely than the more structurally robust br2 hybrids. Anyone who has dealt with drought-stressed BMR knows that it can become extremely challenging when water becomes scarce.

Second, these were mid-lactation cows (average 150 DIM), not fresh cows, where BMR typically shows its greatest advantages. Mid-lactation animals aren’t as constrained by physical fill, so BMR’s faster passage rate matters less.

Third—and this caught my attention—when they switched the herd from their normal diet to the study diets, intake and milk yield dropped by 3.6 and 4.8 kg/day, respectively. That suggests the experimental diets weren’t optimal for these cows, which could have masked what we’d normally expect to see.

The study also didn’t include mycotoxin analysis, which, in a drought year, is something you’d want to rule out when you see unexpected intake patterns.

Industry Reality Check: This trial perfectly illustrates why we can’t just rely on lab numbers. Real cows, real environmental stresses, real management constraints—they all matter more than we sometimes admit.

Equipment Reality: The Challenge Nobody Wants to Discuss

Let’s be honest about the elephant in the machine shed… actually harvesting this stuff.

Industry sources report ear heights for BR2 ranging from 20 to 26 inches, compared to 34 to 40 inches for conventional models, depending on the hybrid and environmental conditions. That’s not just an adjustment—it’s often below the operating range of existing headers.

What Equipment Dealers Are Telling Producers:

Based on conversations I’ve had across the Midwest, preliminary estimates for header modifications are running $15,000 to $22,000 per machine for older equipment. Newer machines adapt better, but you’re still looking at setup changes and potentially slower ground speeds.

Early adopters I’ve spoken with suggest budgeting extra time for adjustments and expecting some learning curve losses during the first year, until you get your settings dialed correctly in.

Quick Loss-Check Protocol for br2 Trials:

- Stop periodically and count ears behind the header across several transects

- Weigh measured swaths to estimate loss percentages

- Adjust deck plates, snout angles, and header height accordingly

- Target kernel processing scores above 70% on your standard lab analysis

Ration Management: Protecting Butterfat While Maximizing Component Yields

If you’re thinking about trialing br2 silage this coming season, get your nutritionist involved early on that fat depression issue. That 0.13 percentage point drop adds up fast with current component pricing.

The enhanced starch digestibility means potentially faster rumen fermentation, so you’ll want to watch peNDF levels carefully. Monitor fecal starch closely during any transition periods. Consider adjusting buffer levels based on rumen pH patterns, and monitor the total unsaturated fatty acid load to prevent exacerbating milk fat depression issues.

The good news? That protein response was solid and consistent across all three br2 hybrids tested. In today’s market, that consistency matters.

Economics: The Real Numbers for 2025

Let me run realistic numbers based on current pricing in the Midwest. Suppose br2 gets you an extra 2.6 lbs of milk daily with protein premiums running $3.50/cwt in many markets. In that case, that’s roughly $1.25 per cow per day in additional revenue—assuming you maintain butterfat standards.

But here’s what you need to budget for:

- Seed premiums: 15-25% higher per bag (varies by company)

- Higher planting populations: 38,000-42,000 plants/acre vs. typical 32,000-36,000

- Equipment modifications: $15,000-22,000 per machine, amortized over useful life

- Learning curve: Potential harvest losses and slower speeds in the first year

For a 500-cow operation with 800 acres of corn silage, you’re looking at significant upfront investment. The economics work if you achieve the full production response, but there’s little margin for error.

How to Trial It Right for 2025

Start Smart, Document Everything:

Plant 50-100 acres of br2 alongside your current hybrid in the same soil zone. Harvest at 32-35% DM with your processor dialed in tight—you want kernel processing scores above 70%. Set the theoretical length of cut between 17-22 mm based on your peNDF goals.

Track DMI, milk, ECM, butterfat, protein, and fecal starch for at least 3-4 weeks minimum. This isn’t optional data—you need it to make informed decisions about expanding acres.

Before You Plant Next Spring:

- Get definitive answers on header modifications and actual costs for your equipment

- Confirm seed availability and population recommendations for your area

- Budget for higher seed costs and population changes

- Map your most uniform field for the trial—you want to eliminate as many variables as possible

The key thing everyone’s learning is that header setup and ground speed matter more than they ever have. Start with low-profile snouts, if available, and tighter deck plates, along with responsive header-height control. Establish a loss-check routine before you start chopping, not after you see problems.

What We Still Need to Know

Here’s the thing, though—we’re still working with limited data. This Michigan State work is solid, really solid, but it’s one trial, one year, specific conditions. I’d love to see:

Early lactation data, where BMR typically shows its biggest advantages. Multi-location trials across different climates and management systems. Performance data from actual commercial dairies, not just research facilities where everything’s controlled.

That Italian work mentioned in the MSU paper? Apparently found “no effects on DMI, ECM, or bodyweight”—that’s a pretty different story from Michigan’s results. Makes you wonder about genotype-by-environment interactions and how much location and management truly matter.

Important caveat: These results pertain specifically to br2 genetics. Other short-stature platforms using different mechanisms may not deliver the same performance. Don’t assume all short corn is created equal.

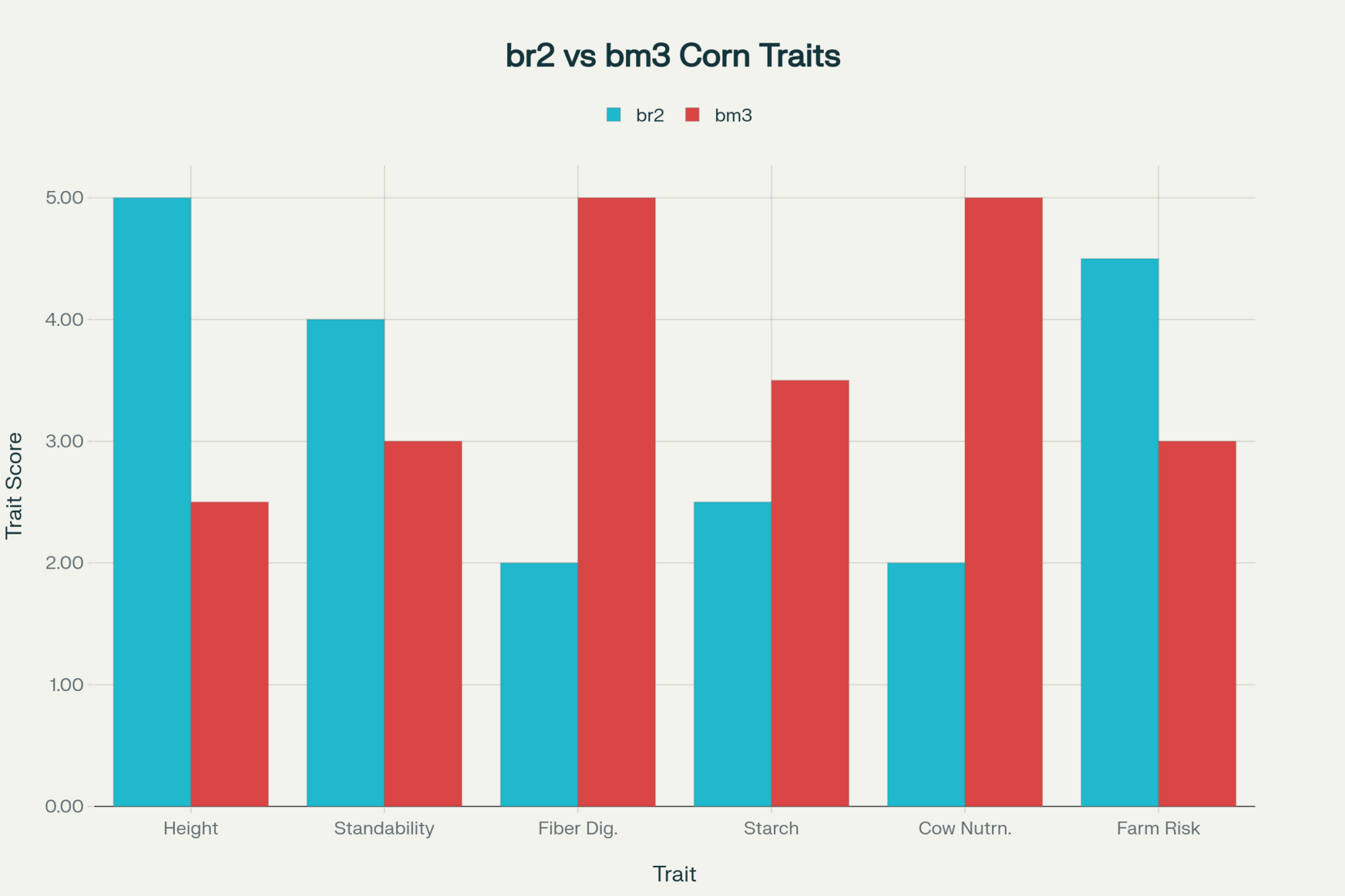

What’s Coming Down the Pike

Penn State and Cornell are reportedly planning trials for next year, which should help fill in the picture. The most intriguing possibility on the horizon is combining Br2 with BM3 genetics—potentially achieving standability with enhanced digestibility. But that’s still in development.

What we really need is honest feedback from commercial producers willing to try these hybrids under real-world conditions. University trials are valuable, but they don’t capture the reality of tight harvest windows, equipment limitations, and economic pressures that actual farms face on a daily basis.

The Bottom Line for Your Operation

Three things stand out from this work that matter for your 2025 decisions…

The production potential appears real based on Michigan State’s data. We’re talking about a 4+ pound higher daily intake and meaningful milk protein increases that could translate to $1.00-$ 1.25 per cow daily in additional revenue with current pricing.

Equipment challenges are significant and expensive. Budget $15,000-22,000 per machine for older equipment modifications, plus expect a learning curve on harvest management. This isn’t just swapping seed varieties.

This isn’t plug-and-play technology. It requires proactive nutritional management, careful monitoring, and a willingness to adjust rations to protect butterfat while maximizing the intake advantages.

Your Move?

If you’re running newer equipment and have financial flexibility for experimentation, a 50-100-acre trial makes sense for 2025. Start with your most uniform field, work with your nutritionist from day one, and document everything meticulously.

For most operations—especially those with older equipment or tighter margins—I’d recommend watching and waiting for more diverse research results and real-world feedback from early adopters. Let someone else work through the learning curve first.

What I’m Watching For:

The disconnect between lab predictions and cow performance in this trial should prompt us to question how we evaluate forages. If br2 corn can consistently deliver higher intake and milk production while maintaining agronomic advantages, it could reshape our approach to corn genetics.

But we need more data, more locations, and more honest conversations about both the promise and the pitfalls before making wholesale changes to cropping systems.

One mid-lactation trial in a drought year isn’t enough to dethrone BMR. But it’s definitely enough to pay attention.

What’s particularly noteworthy is how this challenges our assumptions about forage evaluation. Perhaps we’ve been too focused on single lab metrics when, in reality, the real magic occurs in the complex interactions between plant genetics, environmental conditions, and cow metabolism.

In my opinion, we may be witnessing the start of a shift in how we approach corn silage genetics. Instead of chasing one trait—such as low lignin in BMR—perhaps the future lies in balanced genetics that perform consistently across various conditions and management systems.

That’s the kind of robustness our industry needs, as weather patterns become increasingly unpredictable and economic pressures continue to mount.

KEY TAKEAWAYS:

- Feed intake jumps 8% with br2 silage over BMR – that’s 4+ pounds more dry matter daily, driving serious milk volume increases you can bank on

- Milk production rises 3.8% (2.6 lbs/day extra) – with current protein prices around $1.87/lb, start calculating what that protein bump means for your annual milk check

- Better field standability reduces lodging risk – br2 hybrids stay upright in storms, protecting your silage tonnage when weather turns ugly this fall

- Watch your butterfat numbers closely – expect a 0.13 percentage point drop, so work with your nutritionist to fine-tune rations and protect component premiums

- Budget $15-22K per machine for header modifications – those low ear heights (20-26 inches) need equipment adjustments, but early adopters say it’s manageable with proper planning

EXECUTIVE SUMMARY:

Here’s something wild from Michigan State that’s got me rethinking corn silage completely. These new br2 short-stature corn hybrids are crushing BMR in the feed bunk – we’re talking 8% higher dry matter intake and 3.8% more milk production, which translates to roughly 2.6 extra pounds per cow daily. This increase in volume and components could add up to $1.25 per cow daily, or nearly $400 annually, to your milk check based on current market prices. What’s really interesting is that this happened during a drought year with mid-lactation cows, where BMR typically doesn’t shine anyway. The kicker? These br2 hybrids also give you better standability in the field, so less lodging risk when the weather gets nasty. Yes, there’s a slight drop in butterfat (approximately 0.13 percentage points), and you’ll need to budget $ 15,000-$ 22,000 for equipment modifications to handle those low ear heights; however, the economics look promising for 2025 operations.

Complete references and supporting documentation are available upon request by contacting the editorial team at editor@thebullvine.com.

Learn More:

- Corn Silage Harvest Management: From Field to Fermentation – This article offers practical strategies for optimizing harvest timing, processing, and packaging. It reveals methods for maximizing energy content and minimizing shrink, ensuring the genetic potential of any hybrid, including br2, is fully captured in the bunk.

- Cracking the Code on Milk Components: A Game-Changer for Dairy Profitability – Since br2 silage impacts butterfat and protein, this piece is essential. It demonstrates how to leverage genetic selection and nutritional strategies to maximize high-value components, turning the data from the main article into a concrete financial strategy for your milk check.

- Precision Dairy Farming: The Future of Herd Management is Here – This article places the br2 innovation in a broader context. It explores how sensor data and automation are revolutionizing herd management, offering a strategic look at how to integrate new technologies for long-term gains in efficiency and profitability.

Join the Revolution!

Join the Revolution!

Join over 30,000 successful dairy professionals who rely on Bullvine Weekly for their competitive edge. Delivered directly to your inbox each week, our exclusive industry insights help you make smarter decisions while saving precious hours every week. Never miss critical updates on milk production trends, breakthrough technologies, and profit-boosting strategies that top producers are already implementing. Subscribe now to transform your dairy operation’s efficiency and profitability—your future success is just one click away.

Join the Revolution!

Join the Revolution!