The ingredients dairy farmers feed their cows impact overall cow health so much that Dr. John Goeser believes that universities should merge veterinary science with nutritional science. Goeser, an adjunct assistant professor in the UW-Madison Dairy Science Department, is also the nutrition director at Rock River Lab, Inc.

The ingredients dairy farmers feed their cows impact overall cow health so much that Dr. John Goeser believes that universities should merge veterinary science with nutritional science. Goeser, an adjunct assistant professor in the UW-Madison Dairy Science Department, is also the nutrition director at Rock River Lab, Inc.

He joined several other speakers last week at two sessions on dairy nutrition sponsored by the Professional Dairy Producers of Wisconsin (PDPW.)

In his position at the commercial feed testing laboratory he sees what’s happening on dairy farms and how it’s affecting cows. In 2016 many farmers were experiencing listeria and salmonella in their cows.

He related the story of one Wisconsin dairy farm that switched from their 2015 to their 2016 high moisture shell corn and saw their cows drop precipitously in production, from a normal high of 90-plus pounds per cow per day. It was enough to get the farm’s attention – the cows dropped 100,000 pounds of milk production in a month. When they looked for a reason, they found that the corn was high in wild yeast and mold. The problem was diagnosed by testing the total mixed ration (TMR.)

They tackled the problem by adding commercial yeast products and mold inhibitors to the feed, which added a cost of 10 cents per cow per day and the cows came back to about 86 pounds per cow per day, he said.

Though the industry outlook for milk prices isn’t good into the coming year, Goeser told the farmers and nutritionists in attendance at the Arlington Agricultural Research Farm that feeding the cows carefully and monitoring things like mold, yeast and aflatoxins in their feed can show results on the bottom line. It can mean the difference between finding or losing several pounds of milk production per cow and a positive versus a negative margin.

Feed gets “dirty” he noted, at harvest, and during fermentation and at feed out. He showed data from his lab on the amount of “ash” or dirt that is in feed. In 2010, samples averaged 8-8 ½ percent and today it is 10-11 percent and the trend has been up every year. That’s important because pathogens like yeast, mold, mycotoxins and bacteria live in the soil. The more soil in the feed means there are more of those hitchhikers along to wreak havoc on the feed – and eventually the cow.

Bearing that out, he showed a chart of samples tested for fungal loads at his lab; both yeast and mold in feeds and TMR samples are on an upward trend since 2014. He speculated that reduction in tillage may play a role in this trend.

Goeser said that yeast fed in commercial products are designed to be good for cows but wild yeast generally have a negative effect on rumen metabolism and should be prevented from taking over the feeds. He notes that we have a lot to learn about fermentation but we do know that we need to get the air out and drop the pH to get the feeds acidified as soon as possible. Molds and fungi are born in the field and in silage if there is aerobic instability.

Some bad actors in the feed – aflatoxins, mycotoxins — are produced when plants are stressed. “Once present they will be there,” he said. “Fermentation won’t knock them back.” Research is suggesting that these various toxins affect different organ systems in the cow. Some suppress the immune system or reproduction. Some target the liver and kidney. “Very rarely do we have only one toxin present.”

The levels of these toxins found in feed depend on the growing season. Goeser showed a chart with large numbers of samples, dating from 2011-2016 and last year’s corn was double the (1 ppm) threshold in large numbers of samples. The chart is black with data points above the threshold for 2016.

Toxins down this year

However, Goeser noted that toxins in this year’s corn are down significantly. “It looks like cleaner feed.” Balancing that is the fact that many of the samples the lab has tested are very dry – he called them “dry moisture corn” – and they are not going to ensile or ferment.

However, Goeser noted that toxins in this year’s corn are down significantly. “It looks like cleaner feed.” Balancing that is the fact that many of the samples the lab has tested are very dry – he called them “dry moisture corn” – and they are not going to ensile or ferment.

“October was dry and warm and 16-percent-moisture corn just isn’t going to ferment,” he said. Corn that gets harvested at 24-25 percent moisture may still ferment but if it’s less than 23 percent, he said it won’t “soften up” and he advised grinding it up as small as possible.

He encouraged farmers to keep an eye on bacterial contamination in their feed as well, which comes mostly from manure. “Don’t put manure on your growing crops. After the alfalfa comes off you may have a day or two to put manure on it but if that alfalfa starts to grow back and then you apply manure, you’re inoculating all those plants.”

Challenges for dairy managers also come when feeding the stored forages and corn. When silage is re-exposed to air, yeast will reproduce by feeding on sugars and carbohydrates and then start to eat lactic acid. When that happens the pH goes up and when it reaches a certain level, bacteria start to grow.

Perfect storm

Dairy cows can ward off certain bacterial challenges if they are not stressed by other factors, he said, like overcrowding or poor cattle handling methods, but if they are also enduring environmental stress they can experience a “perfect storm.”

Goeser further noted that some research is showing that bacteria can “sense” the stress hormones given off by a cow when she’s got problems and this allows them to take advantage of her.

He gets questions all the time about what additives are best to add to dairy rations. Some are useful for binding toxics, boosting the immune system of out-competing pathogens. His advice is to always “test before throwing 10-15 cents per cow per day into a ration. It takes a comprehensive approach.”

The most critical time is harvest and the decision-maker should be on the packing tractor, at the silo or on the bagger, he said, so they can make key decisions about the crop. If it’s too wet there will be ineffective fermentation; if it’s too dry there will be too much air in the feed. “You need to watch the crop coming in and make key decisions,” he advised. Another piece of advice at harvest is to use a research-proven inoculant.

Not your Daddy’s fiber

Dr. David Combs, a professor of dairy science at the UW-Madison, talked with the group about new technologies and innovations in forages that have improved feeding programs for livestock. On the plant side, brown mid-rib (BMR) was a natural mutation in corn that led to improved digestibility of fiber. Alfalfas have been developed with reduced lignin – some by natural breeding and some with genetic modification – and those have led to improved NDF (neutral detergent fiber) digestibility.

Even grasses have been improved for use in high-producing dairy cows, he said, and some of them have higher digestible fiber than alfalfa or corn silage.

The improved fiber digestibility of BMR corn, Combs said, has been shown to increase milk production by 2-3 pounds per cow per day. The reason some of these newer forages can do that is that “every mouthful the cow takes is effectively utilized or she can eat more,” he said.

However, while crops have been improved genetically, that only accounts for about a third of the fiber digestibility in the eventual feed. Two thirds is due to environmental conditions like moisture, growing temperatures and sun intensity. “California dairy producers like the high elevation alfalfa crops because of the growing conditions there,” he noted.

There have also been advances in laboratory testing and analysis of feeds including one that tests for indigestible fiber – uNDF-240 – and one that simulates the cow’s digestive tract to predict total digestibility. That test is called the total tract NDF digestibility or TTNDFD.

Values vary widely

The reason such tests are important Combs said is that fiber digestibility varies widely in forages. “There’s a huge difference and a lot of energy can be left on the table,” he said. Alfalfa hay and silage can vary from 25-70 percent of NDF; corn silage varies from 25-80 percent and grass hay and silage varies from 15-80 percent. “Two units increase in dietary TTNDFD can potentially increase milk yield by a pound.”

Combs noted, and some farmers in attendance confirmed, that garden chippers are being used in the field just before harvest to determine the fiber digestibility of the crop so the farmer can use that information to determine how to use that feed and which group of animals to feed it to.

In corn silage, 25-30 percent of the energy comes from the fiber portion of the feed. In addition, milk fat will increase in cows as fiber digestibility is improved. As margins continue to be tight on the dairy farm, Combs added that corn grain can be pulled out of the ration “if you have more digestible forages.”

Source: Wisconsin State Farmer

Sometimes it looks like Wall-E has gone into the dairy business.

Sometimes it looks like Wall-E has gone into the dairy business.

Calf management impacts a heifer’s survival and future success in the milking herd. Calves’ nutrition and health needs become increasingly important as the temperature drops. Follow these management tips to help set a successful foundation for your future herd.

Calf management impacts a heifer’s survival and future success in the milking herd. Calves’ nutrition and health needs become increasingly important as the temperature drops. Follow these management tips to help set a successful foundation for your future herd. The most critical and most expensive period of calf growth in raising dairy calves is the pre-weaning period. During this period calves are highly susceptible to cold stress with a lower critical temperature of 50°F for newborn calves and 32°F for older calves. Cold stress can result in calves turning to stored body fat to generate body heat, essentially losing weight. In addition, calves experiencing cold stress will have compromised immune systems making them more susceptible to disease.

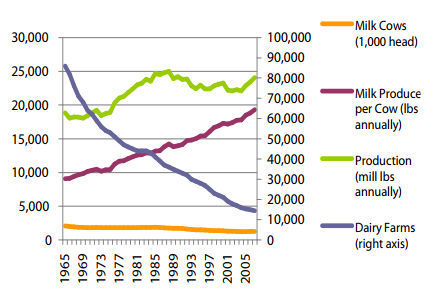

The most critical and most expensive period of calf growth in raising dairy calves is the pre-weaning period. During this period calves are highly susceptible to cold stress with a lower critical temperature of 50°F for newborn calves and 32°F for older calves. Cold stress can result in calves turning to stored body fat to generate body heat, essentially losing weight. In addition, calves experiencing cold stress will have compromised immune systems making them more susceptible to disease. The impending flip of the calendar page to a new year has many folks thinking of what lies ahead. That’s a fitting task, since the dairy industry is rapidly changing, and it’s imperative that you stay ahead of the trends or risk falling behind.

The impending flip of the calendar page to a new year has many folks thinking of what lies ahead. That’s a fitting task, since the dairy industry is rapidly changing, and it’s imperative that you stay ahead of the trends or risk falling behind. USDA Report Shows Slight Increase In Slaughter Numbers In 2017

USDA Report Shows Slight Increase In Slaughter Numbers In 2017 Cornell Pro-Dairy issued this alert regarding use of waste tires on livestock farms.

Cornell Pro-Dairy issued this alert regarding use of waste tires on livestock farms. If ten consultants were asked to name their top influencer to a positive cash flow, there would probably be ten different answers. It is human nature to draw from one’s area of expertise whether it be as a nutritionist, agronomist, economist, or another specialty. The ten responses may not be incorrect, but they may not be the most significant factor affecting the cash flow and breakeven cost.

If ten consultants were asked to name their top influencer to a positive cash flow, there would probably be ten different answers. It is human nature to draw from one’s area of expertise whether it be as a nutritionist, agronomist, economist, or another specialty. The ten responses may not be incorrect, but they may not be the most significant factor affecting the cash flow and breakeven cost.

“With grandkids running around here, abandoned manure pits can be a death trap,” said Ogilvie farmer Brian Besser. Besser along with his son, Blaine, own adjoining farms south of Ogilvie. They each had an abandoned manure pit that they wanted to fill in and were considering doing it on their own and paying for it out of their own pockets. That is when they asked for help from Rick Martens, owner of Martens Manurigation pumping business.

“With grandkids running around here, abandoned manure pits can be a death trap,” said Ogilvie farmer Brian Besser. Besser along with his son, Blaine, own adjoining farms south of Ogilvie. They each had an abandoned manure pit that they wanted to fill in and were considering doing it on their own and paying for it out of their own pockets. That is when they asked for help from Rick Martens, owner of Martens Manurigation pumping business. Even the quietest cows can be anxious and aggressive after calving with attacks from freshly calved cows one of the greatest risks on livestock farms. Calving is one of, if not, the most stressful periods on dairy and suckler farms.

Even the quietest cows can be anxious and aggressive after calving with attacks from freshly calved cows one of the greatest risks on livestock farms. Calving is one of, if not, the most stressful periods on dairy and suckler farms.

.jpg)

.jpg)

.jpg)

.jpg)

Land O’Lakes study confirms even pasteurized waste milk suffers from quality issues.

Land O’Lakes study confirms even pasteurized waste milk suffers from quality issues. A Canadian goat producer designed the scanning system to help detect abnormalities in udders to allow early treatment

A Canadian goat producer designed the scanning system to help detect abnormalities in udders to allow early treatment A study of the UW dairy herd looked at 141 lactating Holstein cows. (Courtesy of UW-Extension)

A study of the UW dairy herd looked at 141 lactating Holstein cows. (Courtesy of UW-Extension) Holstein Association USA is excited to honor herds with the 2017 Progressive Genetics HerdSM award. This award is given annually to the Registered Holstein® herds excelling in type, milk production and genetic merit in their herds.

Holstein Association USA is excited to honor herds with the 2017 Progressive Genetics HerdSM award. This award is given annually to the Registered Holstein® herds excelling in type, milk production and genetic merit in their herds. I visit literarily hundreds of dairy farms across Canada each year. On most, pre-weaned dairy calves are raised away from the main lactation barn or older replacement heifer facilities. Whether these baby calves are housed in hutches, group pens or brand-new calf barns, when I find a group of calves that are sick and not growing, a lot of their poor performance can be traced back to poor nutrition causing indigestion.

I visit literarily hundreds of dairy farms across Canada each year. On most, pre-weaned dairy calves are raised away from the main lactation barn or older replacement heifer facilities. Whether these baby calves are housed in hutches, group pens or brand-new calf barns, when I find a group of calves that are sick and not growing, a lot of their poor performance can be traced back to poor nutrition causing indigestion. Animals are dying from preventable diseases because some vets are using “unscientific” homeopathic treatments, experts have warned.

Animals are dying from preventable diseases because some vets are using “unscientific” homeopathic treatments, experts have warned. December temperatures have been unusually warm, but we can expect to soon be reminded of the realities of Cache Valley winters. Energy requirements for animals increase as air temperatures decrease, and in Cache Valley, January is often the coldest month of the year. As such, livestock and dairy producers must pay close attention to the needs o f their animals. Adequate housing and proper nutrition are the major considerations for all animals, but this is especially true for baby calves. Knowing how valuable calves are, successful producers will give careful attention to every detail.

December temperatures have been unusually warm, but we can expect to soon be reminded of the realities of Cache Valley winters. Energy requirements for animals increase as air temperatures decrease, and in Cache Valley, January is often the coldest month of the year. As such, livestock and dairy producers must pay close attention to the needs o f their animals. Adequate housing and proper nutrition are the major considerations for all animals, but this is especially true for baby calves. Knowing how valuable calves are, successful producers will give careful attention to every detail. When training dairy employees about proper livestock handling practices, it is important to remind them that if animals are not handled properly, they can cause injuries to employees, explained Tracey Erickson, South Dakota State University extension dairy field specialist.

When training dairy employees about proper livestock handling practices, it is important to remind them that if animals are not handled properly, they can cause injuries to employees, explained Tracey Erickson, South Dakota State University extension dairy field specialist. The increasingly important role that immigrant workers play in Wisconsin’s dairy industry is relatively new. On average, dairy farmers started hiring immigrant labor around the year 2000. However, Latino immigrants have worked on the upper midwest’s vegetable farms seasonally since at least the 1930s, and the region’s meatpacking and food processing industries have relied on immigrant workers throughout the 20th century.

The increasingly important role that immigrant workers play in Wisconsin’s dairy industry is relatively new. On average, dairy farmers started hiring immigrant labor around the year 2000. However, Latino immigrants have worked on the upper midwest’s vegetable farms seasonally since at least the 1930s, and the region’s meatpacking and food processing industries have relied on immigrant workers throughout the 20th century. A dairy farmer who lost 50 cows to botulism within a matter of days has urged others to vaccinate against the toxin.

A dairy farmer who lost 50 cows to botulism within a matter of days has urged others to vaccinate against the toxin. It always seems like winter sneaks up before we are ready for it every year. The fans are still hanging in the barn doors when they need shut, and the calf jackets are stuck in the back of the barn, impossible to reach.

It always seems like winter sneaks up before we are ready for it every year. The fans are still hanging in the barn doors when they need shut, and the calf jackets are stuck in the back of the barn, impossible to reach. The ingredients dairy farmers feed their cows impact overall cow health so much that Dr. John Goeser believes that universities should merge veterinary science with nutritional science. Goeser, an adjunct assistant professor in the UW-Madison Dairy Science Department, is also the nutrition director at Rock River Lab, Inc.

The ingredients dairy farmers feed their cows impact overall cow health so much that Dr. John Goeser believes that universities should merge veterinary science with nutritional science. Goeser, an adjunct assistant professor in the UW-Madison Dairy Science Department, is also the nutrition director at Rock River Lab, Inc. However, Goeser noted that toxins in this year’s corn are down significantly. “It looks like cleaner feed.” Balancing that is the fact that many of the samples the lab has tested are very dry – he called them “dry moisture corn” – and they are not going to ensile or ferment.

However, Goeser noted that toxins in this year’s corn are down significantly. “It looks like cleaner feed.” Balancing that is the fact that many of the samples the lab has tested are very dry – he called them “dry moisture corn” – and they are not going to ensile or ferment. There is a new concept afoot that offers dairy farmers a valuable key to more efficient milk production and herd health.

There is a new concept afoot that offers dairy farmers a valuable key to more efficient milk production and herd health. In the statistically driven world of modern agriculture, robotic milking machines are challenging the notion of what is supposed to be a correct cow.

In the statistically driven world of modern agriculture, robotic milking machines are challenging the notion of what is supposed to be a correct cow.

Dairy cows selectively consume their rations, generally sorting longer particles in favor of finer particles. Feed sorting decreases fiber intake while increasing the consumption of grains and co-products. It also creates instances where cows eat different rations throughout the day.

Dairy cows selectively consume their rations, generally sorting longer particles in favor of finer particles. Feed sorting decreases fiber intake while increasing the consumption of grains and co-products. It also creates instances where cows eat different rations throughout the day.