Many dairy farmers have followed a tradition of making contracts informally – perhaps orally and with a handshake, or in the case of a milk contract it may have been a one-pager signed on the hood of the field man’s pickup truck. But one experienced attorney is advising farmers to take a close look and see how that contract may affect them. And they should get it in writing.

Many dairy farmers have followed a tradition of making contracts informally – perhaps orally and with a handshake, or in the case of a milk contract it may have been a one-pager signed on the hood of the field man’s pickup truck. But one experienced attorney is advising farmers to take a close look and see how that contract may affect them. And they should get it in writing.

“In many cases the contracts have been vague and both parties have liked the flexibility they had to get out of the arrangement,” says Troy Schneider, an attorney with Twohig, Rietbrock, Schneider and Halbach, S.C. in Chilton. With low prices and the marketplace awash in milk, he is advising dairy producers to be aware of how contracts may affect their businesses.

Last year’s move by Grassland, which caused 50 producers to lose their milk markets and similar action taken recently by Dean Foods, highlights the importance to farmers of having a contract in place so they know they have a market for their milk. Wisconsin has always been a marketplace where there were ample buyers for all of state farmers’ milk, but that has changed with current supply and demand conditions.

Schneider was a featured speaker at the Professional Dairy Producers of Wisconsin (PDPW) annual business conference in Madison, March 14 – 15. His personal observation is that all processors are currently trying to limit the amount of milk they purchase. Even farmers who are patron/members of a cooperative, and as such are “owners,” do not have any greater protection in this area of contract law, he said.

Most milk plants today use written contracts with the farmers who supply their milk, he said, and contracts that span two or three paragraphs are generally okay. If those contracts run for several pages, he adds, they are “probably skewing toward the processor, because quite frankly they wrote it. This really has been the Wild West of contract law.”

When he looks at various milk procurement contracts there’s “very little in them, it’s shocking,” he said. Because of what has happened to dairy farmers who lost their milk market, most farmers are looking at their milk contracts differently. Farmers and their lenders are demanding more detailed contracts.

Contracts have been skewed toward the milk buyer rather than the farmer and include vague language like “standards we adopt from time to time.” Schneider said more attention has to be paid to what contracts say.

No ‘Silver Bullet’

While there is no “silver bullet” he urged farmers to be careful that the contract isn’t “watered down” with “escape clauses” for the processor.

In many cases a lender may want a dairy farmer to have a contract in place, especially if money is being loaned for a farm expansion; in those cases the contract should include a reasonable term during which the processor will take the farm’s milk — from six months to a year.

A milk supply contract, he explained, is an “open quantity” contract because a specific quantity of milk to be sold and purchased is not specified. These contracts are governed by case law and precedents that have been previously set by courts and also by statutes and regulations.

Milk contracts are also affected by the Uniform Commercial Code (UCC), a set of binding guidelines that has been in place for decades. Schneider said Article 2 of the UCC was adopted as Wisconsin law and governs these contracts between milk buyers and milk producers.

In an “open quantity” contract, in line with Wisconsin law, a change in either output or requirement may be made if it is in “good faith” however, in such “open quantity” contracts, no changes in either output or requirement can be made if it is “substantially disproportionate” from a stated estimate.

“You can see how important it may be to include an estimate,” he said.

He also urged farmers to beware of contract clauses that limit damages (payments to the injured party) in case the contract is broken. A clause stating “liquidated damages” usually works to the advantage of the milk plant and farmers should try to get them eliminated from the contract, he said.

A typical milk supply contract is most likely to be an output contract in which the dairy farmer agrees to sell the entire farm’s production to the milk plant, who in turn agrees to purchase the entire output. However the milk plant may try to include provisions that allow it to become the “quantity determining” party” and may seek contract language that allow it to adjust its intake of milk according to fluctuations in the markets.

Constant demand for milk

Farmers need to make sure the contracts they enter into will assure a constant demand for their milk. In negotiating these contracts, Schneider urged farmers to assure that their contracts do the following:

- Include an estimate of milk to be purchased so that the milk plant does not have the ability to drastically vary or eliminate the amount of milk purchased;

- Address issues of non-performance by the parties;

- Delineate standards, requirements and specifications and avoid vague clauses like “from time to time adopted by the purchaser”;

- Provide adequate notice periods and rights and address remedies for breaching the contract;

- Address what will happen if milk output is increased due to expansion or purchase of another dairy operation.

Having said of all that, Schneider admitted that now is a “very difficult time to add details” to a contract and noted that the farmer is negotiating the contract from a position of weakness since there is so much milk in the market. “Now the scale is tipped toward the milk processor.”

At some point that power may return to farmers, but it if doesn’t he suggested that maybe lawmakers will have to fix the situation with new statutes. “That may be something that gets looked at.”

For now, he advised farmers to “be diplomatic if there are things in the contract you don’t like unless you have a Plan B in place.” That is, unless you have another place to market the milk. “This is a unique circumstance,” he said. “The buyers for your product are just not there.”

And since milk is a perishable product, unlike corn, it must be marketed on a regular basis.

This will leave a mark

Schneider commented that the 1980s put a lot of bad memories in farmers’ and lenders’ minds and these times in the dairy industry will put the issue of contract law firmly in dairy farmers’ heads and hearts.

“Farmers are looking at contracts a lot more carefully. When times get better farmers will continue to pay more attention to these contracts and so will their lenders and business partners,” he said. “They will demand more detailed contracts.”

Source: Wisconsin State Farmer

Double-cropping winter annuals after corn silage harvest is increasing in popularity among dairy farmers who have found that it provides numerous benefits, including increased per-acre forage production, reduced feeding costs, better cycling of manure nutrients and improvements in the farm’s overall bottom line.

Double-cropping winter annuals after corn silage harvest is increasing in popularity among dairy farmers who have found that it provides numerous benefits, including increased per-acre forage production, reduced feeding costs, better cycling of manure nutrients and improvements in the farm’s overall bottom line.

Four keys to calf health success

Four keys to calf health success The current price of hay is a frequent question asked by callers to the area county extension offices. It is an important question to cattle producers wanting to turn a profit because hay costs represent a significant overall expense in raising cattle.

The current price of hay is a frequent question asked by callers to the area county extension offices. It is an important question to cattle producers wanting to turn a profit because hay costs represent a significant overall expense in raising cattle. Livestock manure contains beneficial soil-building ingredients and plant nutrients, but they could be wasted if the manure spreader isn’t calibrated correctly.

Livestock manure contains beneficial soil-building ingredients and plant nutrients, but they could be wasted if the manure spreader isn’t calibrated correctly. Significant advances in dry cow nutrition have been made in the last 20 years. Most recently, interest has shifted to the protein needs of transition cows. Advancements in the models for ration balancing have made it possible to estimate the metabolizable protein (MP) supply and needs of dry cows, while the use of crude protein still remains important. This gives nutritionists the opportunity to formulate diets for dry cows based on metabolizable protein and amino acids.

Significant advances in dry cow nutrition have been made in the last 20 years. Most recently, interest has shifted to the protein needs of transition cows. Advancements in the models for ration balancing have made it possible to estimate the metabolizable protein (MP) supply and needs of dry cows, while the use of crude protein still remains important. This gives nutritionists the opportunity to formulate diets for dry cows based on metabolizable protein and amino acids. Research could eliminate need for hormone protocols

Research could eliminate need for hormone protocols

Kent Nutrition Group (KNG) hosted nearly 100 dairy producers, nutritionists, and industry specialists at their inaugural KNG Dairy School held at Kent Corporation headquarters this week. The school entitled, Dedicated to Dairy, focused on transition cow nutrition and their crucial role in a dairy’s long-term success. Industry speakers shared their latest research findings and management protocols for moving these cows into milk production.

Kent Nutrition Group (KNG) hosted nearly 100 dairy producers, nutritionists, and industry specialists at their inaugural KNG Dairy School held at Kent Corporation headquarters this week. The school entitled, Dedicated to Dairy, focused on transition cow nutrition and their crucial role in a dairy’s long-term success. Industry speakers shared their latest research findings and management protocols for moving these cows into milk production. 6 calving tips that can make a lifetime of difference

6 calving tips that can make a lifetime of difference Southwest Missouri dairy producer David Gray is one of the first in his area to use compost bedded pack barns. Cows raised using this system enjoy greater comfort, produce more milk and have fewer health problems. ( Linda Geist, University of Missouri Extension )

Southwest Missouri dairy producer David Gray is one of the first in his area to use compost bedded pack barns. Cows raised using this system enjoy greater comfort, produce more milk and have fewer health problems. ( Linda Geist, University of Missouri Extension )

Robotic or automatic milking systems (AMS) have steadily increased in popularity in the dairy industry since the installation of the first commercial unit in 1992 in the Netherlands. In 2015, the number of AMS units installed was over 25,000 worldwide. Here in Nebraska, there are two commercial dairy farms that having installed multiple AMS units, Demerath Farms (Plainview, NE) and Beaver’s Dairy (Carleton, NE). Demerath Farms installed four AMS units in February 2017 and are set up to milk 240 cows. Beaver’s Dairy began milking with five AMS units in May 2017 and is set up to milk 300 cows. Additionally, there are several other dairies that are looking into milking robots for their farm. Typically, 60 cows are milked on one robot. One robot will likely cost the producer anywhere from $150,000- $200,000.

Robotic or automatic milking systems (AMS) have steadily increased in popularity in the dairy industry since the installation of the first commercial unit in 1992 in the Netherlands. In 2015, the number of AMS units installed was over 25,000 worldwide. Here in Nebraska, there are two commercial dairy farms that having installed multiple AMS units, Demerath Farms (Plainview, NE) and Beaver’s Dairy (Carleton, NE). Demerath Farms installed four AMS units in February 2017 and are set up to milk 240 cows. Beaver’s Dairy began milking with five AMS units in May 2017 and is set up to milk 300 cows. Additionally, there are several other dairies that are looking into milking robots for their farm. Typically, 60 cows are milked on one robot. One robot will likely cost the producer anywhere from $150,000- $200,000.

Zoetis announced the addition of three calf wellness traits to Clarifide® Plus for Holsteins. The new calf wellness traits include calf livability, respiratory disease and scours. This dependable genetic information enables dairy producers to genetically improve calf health and survival within their herds, as the calf wellness trait information helps identify and select for calves more likely to survive as well as animals that are less likely to become ill due to respiratory disease and scours. Minimizing disease risk improves calf health, results in fewer treatments and lowers calf mortality — all important animal well-being considerations for producers.

Zoetis announced the addition of three calf wellness traits to Clarifide® Plus for Holsteins. The new calf wellness traits include calf livability, respiratory disease and scours. This dependable genetic information enables dairy producers to genetically improve calf health and survival within their herds, as the calf wellness trait information helps identify and select for calves more likely to survive as well as animals that are less likely to become ill due to respiratory disease and scours. Minimizing disease risk improves calf health, results in fewer treatments and lowers calf mortality — all important animal well-being considerations for producers.

America’s Dairyland is undergoing a bit of a revolution, and it has nothing to do with the words on Wisconsin’s license plate or even the size of farms.

America’s Dairyland is undergoing a bit of a revolution, and it has nothing to do with the words on Wisconsin’s license plate or even the size of farms.

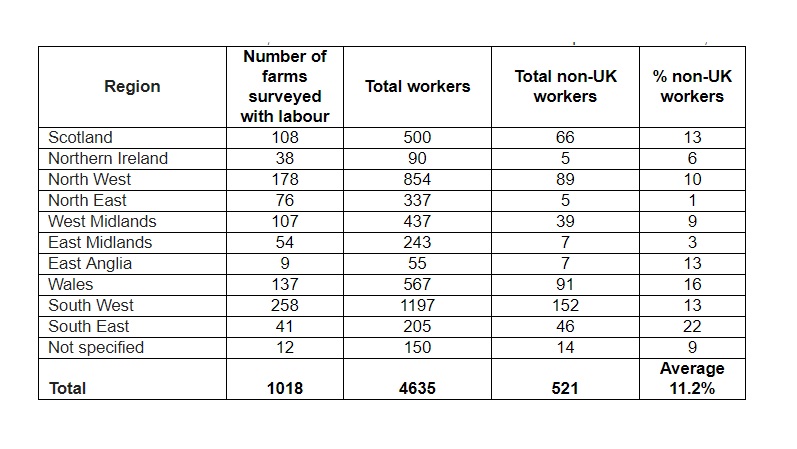

The dairy industry is concerned that a lack of skilled workers will make it unable to meet targets as the UK is responsible for a tenth of Europe’s total milk supply.

The dairy industry is concerned that a lack of skilled workers will make it unable to meet targets as the UK is responsible for a tenth of Europe’s total milk supply.

A new study in the Irish Medical Journal has found a high prevalence of work-related respiratory and upper airways symptoms among dairy farmers.

A new study in the Irish Medical Journal has found a high prevalence of work-related respiratory and upper airways symptoms among dairy farmers. Antibiotic dosages are determined by individual cattle body weight.

Antibiotic dosages are determined by individual cattle body weight.

Feeding pregnant dairy cows the vitamin niacin prior to giving birth improved the quality of their colostrum, which is the first milk calves drink, according to new research from the University of New Hampshire. Colostrum is essential to building the immune systems of calves, and thus, their survival.

Feeding pregnant dairy cows the vitamin niacin prior to giving birth improved the quality of their colostrum, which is the first milk calves drink, according to new research from the University of New Hampshire. Colostrum is essential to building the immune systems of calves, and thus, their survival. Bolstering a dairy farm’s bottom line involves convincing cows to consume proper amounts of the feed on their plate.

Bolstering a dairy farm’s bottom line involves convincing cows to consume proper amounts of the feed on their plate. Know which treatments are the most effective for managing mastitis

Know which treatments are the most effective for managing mastitis