Oh, the era of modernization and artificial intelligence (AI)! It’s both a blessing and a curse, isn’t it, fellow dairy farmers? We welcomed technology, convinced that machines and AI can achieve the same purity of results that, traditionally, only human hands and hearts could muster. But, oh, were we punctured with the raw needle of reality! Technology’s silver promises turned out to be nothing more than poisoned elixirs, igniting a flurry of unanticipated complexities and challenges on our bucolic beauty of dairy farms.

“Artificial intelligence (AI) is more than just a tool—it’s a double-edged sword that cuts both ways.”

These sophisticated algorithms and machines, supposedly our stalwart allies, are all too eager to hijack our traditional practices. We dreamt of efficiency, we dreamt of seamless farming, but what we got was a maze that’s difficult to understand and even harder to navigate.

Approximately 38% of dairy farmers have already adopted some form of AI technology in their operations.

Though we might wonder at times, ‘should we abandon this ship and swim towards the ages-old shores of manual farming?’ Yet, in order to thrive – and not just survive – in an increasingly competitive market, we’re left with no other choice but to grapple with these challenges. Otherwise, we risk losing our beloved occupation to the clutches of ruthless technology.

- To flourish in this new epoch, we must calibrate our understanding of AI.

- We must tackle the issues that sprout like venomous snakes, threatening to choke our hard-earned accomplishments.

- We must continue to navigate through the muddled waters of technology, balancing between traditional values and contemporary necessities.

Let’s not sugarcoat it – mastering this balance will not be easy. But, dairy farming is in our bones, isn’t it? We are made of sterner stuff – we will not be bested. Together, we’ll dive into the rough seas of technological change. Unflinchingly, together, we will look these challenges dead in the eye, and grasp the bull by its horns.

By 2022, the AI in agriculture market is expected to grow to $2.6 billion, a significant portion of which will be in dairy farming.

Opportunities for AI in Dairy Farming

As we navigate the whirlpools of change in our industry, we must face cringe the creeping specter of artificial intelligence – a marvel both revered and feared, capable of propelling us to stratospheric heights or, if mishandled, into jagged abyss. Do you hear what I’m saying, fellow dairy farmers? This is not an evasion of responsibility or a noble retreat into obscurity. On the contrary, this is an invitation to stand up and fight, to challenge the status quo and seek mastery of this new tool in our arsenal.

While we all dream of streamlined operations and exponential growth, the actualization of these dreams begs the question of AI’s skills and its capability to adapt. Complexity abounds, and as always, the devil is in the details. What behavioral patterns will AI learn? What false positives will it spew out, and with what costly ramifications?

“One cannot ignore the lurking hardships. AI holds promise, but in the absence of vigilance and discretion, it may sow discord in our endeavors.”

We, the collective presence behind this dairy farming industry, have a responsibility to address these questions and challenges. In order to deploy AI effectively and efficiently, we must confront these issues head-on. We need fortified systems in place, elaborate checks and balances that address not just the functionality of this AI, but its implications.

- Are we prepared to handle any unintended consequences of its execution?

- Do we understand the ramifications of any gaps in the AI’s learning process?

- Does the technology have the flexibility to adapt as our industry evolves?

We must delve deep, confront these challenges, and harness the massive potential AI holds for our future. The essence of our resolve hinges on one truth: AI is only as good as its implementation. And I say to you, my fellow dairy farmers, let us rise to this occasion, learn the intricacies of this tool, embody its true spirit, and unleash the phenomenal power of artificial intelligence in dairy farming.

AI technology can increase milk production by up to 20%.

AI-powered systems can analyze vast amounts of data

Think for a moment about the uncharted territory we are about to venture into, where large volumes of layered data pulse through the veins of our operations. This colossal influx is not just idle chatter; it’s a profound dialogue, a conversation between us, our farms, and our dairy cattle. Yes, my compatriots, we’re talking about AI-powered systems that can ingest vast amounts of data, harvested from an intricate network of sensors, drones, and sundry sources.

But what, you might ask, is the crux of this data deluge? Ah, that lies in the rich insights into the health, nutrition, and behavior of our precious livestock that it provides. Just imagine the possibilities. Dairy farming ceases to be a minefield of guesswork, instead transforming into a calculated chess game, where we can predict, react, and strategize with certainty and precision. We can detect the onset of a disease before the first physical symptom shows—it’s like being granted superhuman perception.

Fancy feeding your cows with tailored nutrition, adapted for each individual? AI delivers us this reality. What once seemed like science fiction now sets up residence on our farms. With AI at our side, we are detectives, surgeons, nutritionists, and psychologists—all rolled into one. This, my brave dairy farmers, is the transformative power of artificial intelligence. As we venture forth, let us wield this power with prudence, responsible stewardship, and an unyielding commitment to our noble profession.

Predictive analytics algorithms can forecast the future

What if, in the dairy farming industry, we were able to predict the seemingly unpredictable? Visualize the power of peeking through the opaque mist of tomorrow and effectively forecasting milk production. Foreseeing when a disease is going to strike, even before the first telltale signs appear in the herd. Or, optimizing feed management to the extent that waste becomes a concept of the past. Yes, these possibilities are within reach today, thanks to predictive analytics algorithms.

The immense potential of predictive analytics lies not merely in its prowess to transform the curative into the preventive, but also in providing a significant advantage to the dairy farmer in managing the herds. Real-time actionable insights can lead to improving herd management strategies. Isn’t it better to prevent the flame rather than to fight the fire?

Now, visualize a scenario where abundance becomes the norm rather than the exception, thanks to these algorithms. The most tangible and impactful benefit comes in the form of increased yields. To say that it’s like finding the proverbial needle in the haystack would be an understatement. It’s like finding a needle in a haystack when you didn’t even know you were looking for one. It is an efficiency game-changer, a silent revolution. And guess who’s leading this dairy coup? AI and dairy farmers, making allies in unexpected places.

Artificial Intelligence, deep learning, machine learning — whatever you’re doing if you don’t understand it — learn it. Because otherwise you’re going to be a dinosaur within 3 years.

– Mark Cuban1

AI-driven robotic systems can automate tasks

So, what can these AI-driven robotic systems do that’s so impressive? What if I told you they’ve been redefining the traditional roles in dairy farming? The dismissal of manual labor isn’t something we suggest lightly, but the reality of the situation is inescapable. We need to understand and accept the benefits these technological marvels have to offer.

Think about the typical mundane chores on your farm like milking, feeding, or regular herd monitoring – dull and time-consuming, aren’t they? Isn’t it a struggle to complete these tasks consistently and efficiently? Well, let’s change that narrative. The brilliant minds behind AI advancements have developed robotic systems to take over amazingly these roles. Yes, you read it right! Automation of milking, feeding, and health surveillance are no longer a dream, but a reality we can reach for. Robotic milking machines efficiently extract milk from cows, automated feeders ensure a timely, balanced diet for our herds, and surveillance robots maintain real-time health monitoring, nudging us immediately about any ill-health symptoms.

Now before you refute, I see you asking – what about the investment it requires? How can small and medium dairy farmers afford it? We got this covered, my friend. These AI systems can be integrated with a reasonable investment, proving to be more cost-effective in the long run due to the increased efficiency and the hiked productivity they provide.

So you see, breaking your back over daily chores is no longer a necessity. AI-driven robotic systems can let your farm run like a well-oiled machine, saving your valuable time and energy. Don’t you think it’s time to step into this new age revolution? Are you ready to embrace the dawn of AI-driven automation and reimagine the future of dairy farming?

AI can reduce the labor needs on a dairy farm by as much as 50%.

Precision dairy farming techniques enabled by AI

Imagine this: Each of the thousand cows on your farm, treated as an individual, receiving hydrated feed tailored to their specific nutrition needs, being monitored for any health issues or for performance discrepancies. This isn’t some distant utopia. It’s an achievable reality, presently within grasp, thanks to the precision dairy farming techniques enabled by AI.

The gold mine that is artificial intelligence has begun to reveal its untapped potential in this facet of dairy farming. Each cow becomes a unique cog in the complex machinery that is your dairy farm operation. With the AI detailed monitoring system, farmers can closely adjust and optimize the health and productivity of every single cow. This not only amplifies the overall performance of your herd but also promised enhanced longevity and better welfare for the animals.

Consider this. AI-powered systems track the daily milk yield, monitor the feed intake, supervise the animal’s behavior, providing data-driven insights that can effectively maximize the production efficiency and health of each cow in your herd. And yes, hold on to your hat, even disease prediction becomes a proactive process rather than reactive.

Yet, we challenge you. We ask you: Is it not time for you to make this dramatic shift in your operations?

A wave of innovation is sweeping across the dairy farming industry, altering the very dynamics of traditional farming methods. The provocation and the question is clear: are you prepared to ride this tide, or will you stand idly, watching this revolution from the sidelines?

A new era in dairy farming bathed in the light of AI is fearless. However, it requires the daring and determination of industry players like you to transcend from the known horizon into unprecedented territories. We, as a community, must not shy away but instead embrace this technological prowess. It won’t be long before such precision dairy farming techniques become not just a choice, but a necessary norm in a world striving towards sustainability.

In conclusion, human decision-making will always play a vital role in this ecosystem of dairy farming, indeed. Nevertheless, the integration of AI in our farming techniques is not just an attractive tryst, it’s a call for us, a call for change, a call for a better future.

AI can detect diseases in cows up to 3 days earlier than traditional methods, with an accuracy rate of 95%.

Challenges in Implementing AI in Dairy Farming

Indeed, we cannot ignore that integrating AI into the very essence of dairy farming presents a myriad of obstacles, some of which our community is yet to fully comprehend. With the realm of AI being reshaped every passing moment, we face the constant challenge of keeping ourselves abreast with the modifications. It’s like a colossal wave, constantly growing and threatening to overpower us if we fail to equip ourselves with the necessary knowledge and technique. Rhetoric aside, are we really prepared for this?

“Embracing AI is not merely about buying into new technology. It’s about understanding its core principles, learning to adapt and making it an integral part of our workflows. If our industry is to remain competitive, we’ll have to surpass these challenges.”

Let’s pause for a moment and dissect these challenges in the context of dairy farming. First, there is a significant learning curve involved. Adopting AI requires a shift from conventional practices and a willingness to learn what, for many, will feel like a foreign language. Second, the financial implications cannot be overlooked. Next-generation AI technologies are a considerable investment. Weighing them against the potential returns is a precarious task, yet a critical one that we cannot avoid. Additionally, the emerging ethical concerns involving artificial intelligence open a whole new Pandora’s box.

- Learning and Adaptation: The shift from conventional methods to AI-based ones presents a significant challenge in terms of learning and adaptation.

- Financial Implications: Next-generation AI technologies require a hefty investment which raises the question – are the potential benefits worth the cost?

- Ethical Concerns: The use of AI comes with its own set of ethical concerns which need to be addressed alongside other practical difficulties.

So, what do we, as custodians of our farms and foresightful leaders, do? Should we retreat, retracing our steps back into our comfortable, known ways? Or do we face these challenges head-on, despite all adversities? Do we have what it takes to overcome, to adapt, and to be a part of something revolutionizing? We urge, through every line and word of this article, the necessity to confront – not cower. Because the future, dear friends, is irrevocably and uncompromisingly AI.

Only about 30% of dairy farmers feel they have the necessary skills to implement AI technology.

Data Quality and Standardization

And what of the quality and standardization of data, the silent heroes in the saga of AI implementation? They, too, are often overlooked, yet their role is a crucial one. The very lifeblood pumping through the veins of AI – data – needs to be accurate, reliable, and consistent for any algorithm to deliver its promised results.

Think about it, dairy farmers. You’ve got these grand AI-powered systems churning out valuable insights based on data analysis. But what if that data is flawed—misleading, inaccurate, imprecise? Can you see the danger? Altered baselines, skewed results, and, ultimately, misguided actions that can impact the day-to-day management of your operations and the long-term viability of your enterprise.

Thus, high-quality data is not just a need—it’s a necessity. You must establish standardization protocols. Your data collection methods need to be rigorous and meticulous ensuring all data are derived from reliable sources and tested for accuracy. You must institute quality control measures that monitor and validate your data at every stage. Trust us, anything less is not just unacceptable, it’s perilous. Back away from the danger, dairy farmers.

When you look at data through the lens of quality and standardization, the perspective shifts. It’s no longer just about capturing information—now, it’s about validating the information captured. It’s about raising bar and demanding more from the data that propels your AI initiatives. After all, isn’t that what we crave from a truly advanced, AI-powered dairy industry?

So, heed these words. Tackle head-on the challenge of data quality and standardization. It’s an uphill task, but the result—trustworthy, reliable and potent AI—will make it all worthwhile.

About 70% of dairy farmers are concerned about data privacy and security when using AI technology.

Cost of Technology

Bring on the bravado, dairy farmers, because taking the leap into the realm of artificial intelligence is not for the fainthearted or frugal. Fact or fiction? You be the judge. The cost associated with this innovation can be as mammoth as the data it crunches. Let’s delve into the finer details. Brace yourself.

The adoption of AI in dairy farming isn’t just a simple swipe of a credit card, oh no. Entrepreneurs must be ready to pump capital into several key areas. We’re talking about hardware, software, and training—each a beast in its own right.

Consider hardware, for instance. Those shiny new sensors and robots driven by AI sure look pretty, but they come with a hefty price tag. For our smaller operations, that can be a noose around the neck, squeezing out traditional farming methodologies and practices to pave the way for the new. Are we prepared for that reality?

And let’s not even start on the cost of software. AI is propelled by advanced algorithms that sift through data like farmers through wheat. These algorithms demand sophisticated software that often requires a significant, if not outrageous, investment.

Finally, training. Well, isn’t this the sneaky little add-on cost? Sure, you’ve secured the hardware, wrangled the software, and now you’re faced with teaching your team the ropes. The learning curve isn’t just steep; it’s akin to climbing Everest with a single pickaxe. Budgets will undoubtedly take a pounding from the cost of upskilling and training.

So, are we ready, dairy farmers, to leap headfirst into the financial chasm that is AI? For those of us on a smaller scale, the numbers seem intimidating. Please take a moment to ponder, are the benefits worthy of the cost? Is your move to AI a calculated risk or a reckless gamble?

Technical Expertise

Let’s unpack this, shall we? Do we expect our dairy farmers, the very pillars upon which our community’s health and nutrition rest, to suddenly become wizards in data science, mavens of machine learning, and prodigies of computer programming? Both you and I are aware that traditional dairy farming communities may lack these specialized skills. Yet the pervasive reach of artificial intelligence unabashedly demands these proficiencies.

Think about it. What is a dairy farmer to do when Artificial Intelligence swans through the barn door, inviting itself into the daily routine? The answer, dear reader, lies not in the superficial imitation of the modern world’s techno-elite, but in the earnest and conscientious pursuit of continuous learning. Our farming communities do not shy away from challenge or innovation. No, we dust off our boots and face it head-on. This, ladies and gentlemen, is a call to arms, not merely a casual conversation about the intricacies of adopting AI in dairy farming.

This, in essence, is the barefaced challenge thrown at us: the widespread and successful implementation of AI technology in dairy farming necessitates an urgent evolution in our skill set, primarily centered around acquiring and honing skills in data science, machine learning, and computer programming. It is a daunting task and one that cannot be taken lightly. However, the rewards are plentiful and the potential profound. So, shall we cower and keel, or shall we conquer?

Regulatory and Ethical Considerations

Let’s talk about compliance, shall we? Those arduous stacks of papers no one is ever thrilled to wade through, yet remain fundamentally integral to your farming operation. Navigating the labyrinth of AI adoption isn’t solely about grappling with technology – it’s also understanding and respecting the legal framework and ethical standards that bind us. Those working in the dairy sector, we urge you to carefully consider compliance with regulations regarding data privacy, animal welfare, and environmental impact. In fact, Dr. Jeffrey Bewley at Holstein USA has underscored the importance of addressing ownership rights to the data generated on-farm – a concern not to be dismissed lightly.

You ask why? We retort, why not! Are we not the stewards of our own lands and herds, responsible for the welfare of our animals and the purity of our environment? And are we not morally bound to safeguard both from harm? Yes, adapting AI may lead us on the path to higher efficiency, reduced waste, and improved financial outcomes. But we challenge you, fellow dairy farmers, to remember that it is our collective responsibility to fulfil these prospects in a manner that respects established regulations and ethical codes.

Consider the growing demand for incredibly high levels of traceability in the dairy – and broader food – chain. To meet this demand, adopting the right technologies is key, ensuring not just optimal yields but also enhanced food safety, improved animal welfare, and upgraded waste management – all under the auspices of AI assistance. The path to AI integration may seem steep, but the potential benefits to human nutrition, animal welfare enhancement, and overall sustainability can’t be ignored.

But let’s not forget the elephant in the room – the ethical concerns of AI. The perceived threat of unemployment or the intensification of agri-food systems due to AI advancements must be openly addressed. It is true that cost barriers for new entrants are significant, but can we not equally acknowledge the potential for AI to drive efficiency and, in the long run, potentially reduce costs? We challenge the narrative of fear around AI – instead, let’s lean towards curiosity and caution, towards understanding and preparation. That, dear comrades, is the way forward.

Solutions for Successful AI Implementation

So, do we dare to look beyond these challenges? Isn’t it high time we stood toe-to-toe with our fears, addressing the elephant in the room?

Dairy farming, as we know it, is teetering on a technologically advanced precipice. Artificial Intelligence (AI), once a far-fetched concept relegated to the realm of sci-fi and tech whispering, treads heavily upon our doorsteps. However, are we fully equipped for an AI revolution in dairy farming? Are we ready to take the leap, upend tradition and embrace the evolution or will we bury our heads in the sand, yanking the chains of tradition?

Now, before you start conjuring up images of cow-milking robots taking the place of honest, hardworking farmers, take pause. We’re not here to sow hysteria or champion the cause of unnerving automation blindly. We’re standing, not on the precipice of annihilation, but on the brink of transformation!

Change is often intimidating, yet endlessly rewarding!

I ask you, are we to succumb to fear, or shall we muster the courage and resilience to negotiate the AI-enabled new age? This article aims precisely to address this paradigm shift for dairy farmers, especially focusing on the obstacles laying in our path towards artificial intelligence and the plausible solutions to these challenges. We, as active participants or observers, play a pivotal role in this transition, and being well-informed is our first step on this journey.

Before we delve deeper into the details, let’s bookend this introduction with one critical caveat. An AI-enabled future in dairy farming is not devoid of challenges and queries. On the contrary, it’s laden with them! And herein lies the crux of our discussion:

- Identifying the challenges in implementing AI in dairy farming

- Proposing practical solutions to overcome these hurdles

So, let’s lace up our boots, straighten our backs, and march forth into this brave new AI-driven world of dairy farming.

Data Collaboration

From our grassy knolls to the dusty halls of academia, huddled in board rooms and governmental chambers alike, we’re on the cusp of a seismic shift in how operations are undertaken within the heartlands of dairy farming – and it hinges unerringly on stirred joint action, a collaborative bond! Picture it – the well-worn hands of our farmers joining forces with the sharp minds of researchers, the inventive spirit of technologists, and the guiding vision of policy makers.

We need to ask ourselves: why haven’t we capitalized on this alliance yet? The gales of Big Data surge around us, potent with the whisperings of forgotten potentials and unseen possibilities. As farmers, we’ve always been wardens of the land, keepers of our herds. Imagine the rolling fields and fenced-in spaces as a tempest of data points waiting to be harvested. Machine learning, Internet of Things solutions, talismans of modern technology that hold the blueprints for an optimized future of farming.

Lo and behold the new age of data collaboration, which converges the diverse sectors in the race towards efficacious AI implementation in our dairy farms. The common thread that binds us all in this quest is standardization and knowledge exchange. In this daring new frontier, we won’t be just sweating away under the sun; we’re collaborating under the far-reaching expanse of the cloud, shaping profound data-powered narratives.

The reciprocal exchange of wisdom, the shared understanding of AI’s practical applications – they illumine novel pathways warding off ensnared progress. Simon Drake from the company’s data science solutions spoke of enhancements in efficiencies. This can be our shared goal we aim for – unified as an industry, strengthened as a community, we can break new ground in ushering AI’s influence in our dairy farms. As farmers, have we not tilled the soil year in, year out, braved the elements, and labored against the toil of pests and disease? If we can navigate these hardships, navigating the intricacies and mapping the uncharted territories of AI technology should not daunt us.

Data ownership is raising its head as a likely stumbling block. But surely, as knowledgeable as Dr. Jeffrey Bewley of Holstein USA suggests, this ‘concern’ can be transformed into a challenge ready to be overcome? Forewarned is forearmed – we can set about deliberating and drafting the legal frameworks that protect us while we nurture this exciting venture.

Yes, we are dairy farmers, but that does not constrain us from also being pioneers, innovators, and trailblazers reaching for the dawn of the AI era. So let us, with open minds and hearts, embrace this collaborative undertaking. Our blood, sweat, and tears have nurtured this industry – after all, who better than us to midwife the birth of the new AI revolution in dairy farming?

Scalable Solutions

So then, what are we to do, as forward-thinking dairy farmers ever on the front lines of industry revolution? Are we to meekly step back in the face of the lie that AI benefits only sprawling, cash-ridden industry giants? No! Permit me, fellow farmers, to dispel this falsehood: a key solution to the AI implementation challenge lies in developing scalable AI solutions.

Imagine AI systems that are adaptable, that evolve with the size of your operation, that shift their functionality based on the peculiarities of your farm infrastructure, and that work within the tight confines of your resources. Indeed, imagine an AI solution as versatile as the animals we tend, that molds itself to the needs of each farm, whether it sprawls across hundreds of acres or nestles within the confines of a family plot.

Why should the size of the farm dictate the accessibility and affordability of revolutionary technology? The answer is: it should not! Scalable AI is not a distant dream, it’s an achievable reality. The enhancement of efficiencies, as Simon Drake of Ever.Ag mentioned, is not solely within the grasp of resources-rich, massive producers with the muscle to invest in expensive technologies.

Let us gaze upon the recently launched cheese yield optimization tool by Ever.Ag, an AI-driven solution that promises to revolutionize our production processes. This is not the future, my colleagues, this is the now! Shouldn’t such innovation be within the reach of every dairy farmer, big and small?

In the era of technology innovation, we stand on the cusp of a new dawn, where machine learning and Big Data bridge the chasm between small, medium, and large dairy producers. By focusing on scalable solutions, we seek not only to equalize our industry but to propel it into a new era of productivity and discovery. By harnessing this AI revolution, we empower ourselves to overcome longevity, performance, and health issues within our livestock, resulting in a boosted supply chain and an enriched dairy industry as a whole.

So, stand tall, fellow dairy farmers, for scalable AI affords us all the opportunity to join the cutting edge of agricultural technology, regardless of our farm size or resource constraints. The question stands then, will you seize this moment? Do you dare to revolutionize your production? Remember, a scalable solution is not just an affordable solution— it’s a strategic investment in the future of dairy farming.

Training and Education

So here we stand, on the precipice. Do we plunge into the unknown abyss of artificial intelligence, or do we retreat to the familiar comfort of past practices? The choice is ours, folks. But let’s get one thing straight – we’re not advocating for mindless technophilia. No, indeed! We’re talking about a future where our dairy farming is powered by artificial intelligence, yes, but we’re also talking about understanding that technology. We aren’t merely the users; we are the masters. How, you may ask? Through training and education, that’s how.

Imagine this: comprehensive training programs that transform you, the dairy farmer, from an outsider looking at artificial intelligence with suspicion, into an AI specialist who utilizes these powerful tools with ease and efficiency. Think interactive workshops where you rub shoulders with seasoned tech whizzes, absorbing their knowledge and translating it into the everyday context of your dairy operations. Visualize a future where we have at our fingertips, unlimited resources to continuously equip ourselves with new skills that keep us riding high on this AI wave.

Some may tap out, unable to face the onslaught of technological advances. But we, the brave and the bold, we thrive on challenges. We sneer in the face of fear. And, we’ll be damned if we let a little high-tech jargon stand between us and our progress. We will become the pioneers trailblazing the future of dairy farming.

Training and education are our secret weapons in this AI venture. And when we are skilled, knowledgeable, and ready to harness the full potential of AI, who can stop us? So, are you ready to join us in this journey? Because the AI revolution in dairy farming starts with you.

The adoption of technology in farming is not a luxury, but a necessity to ensure our future generations can eat.

– Gary Zhou

Integration with Existing Systems

Confronted by a technologically transforming landscape, dairy farmers are now facing the necessity of chess-matching their established routines with the rapidly unfolding realm of artificial intelligence. And yet, does that need to imply a disassembly of traditional infrastructure, a dismantling of proven systems that have serviced our farms for generations? One word: no.

For the notion is not to replace but to enrich, not to discard but to incorporate. As it stands, a key challenge in the industry is the integration of AI-enhanced solutions with existing farm management systems, sensing equipment, and tried-and-true machinery — an orchestration of the old and new in harmonious unison. A far cry from “out with the old and in with the new”, the intent is to ensure that innovation acts not as an intrusive interloper but as a cooperative partner, facilitating a seamlessly operational and compatible confluence of technologies on the dairy farm.

In other words, true progress does not demand sacrifice but collaboration. Safety and reliability precautions put in place across legacy frameworks need not be abandoned; they simply need to be synchronized with AI systems to promote strength and stability in this era of incremental transformation.

With strategic integration, AI’s novelty is paired with the reliability and familiarity of existing systems, creating a synergy wherein the dynamic intelligent capabilities of AI supplement and enhance the operational efficiency of these established mechanisms. The result? A dairy farming ecosystem that combines the best of modern innovation with valuable tradition.

Technology is not a conquering invader, displacing conservation and tradition in the quest for improvement. No, it is, or should be, an enabler — a tool that facilitates, integrates, and synergizes; in doing so, it can enhance the efficiencies of producers’ products, as mentioned by Simon Drake, EVP of data science solutions.

Experience speaks to the fact that these integrations of AI systems can be implemented with reasonable investment by small and medium dairy farmers, the backbone of this industry. It stands to reason that the integration of existing systems with AI solutions is an exciting prospect, offering possibilities of increased resource efficiency, environmental friendliness, greater transparency, and enhanced security.

We must remember: change need not be an eradicator of the past; intelligently implemented, it can be the harmonization of tradition and innovation. Lack of integration is no longer an excuse. We, in the dairy farm sector, have both the requirement and the responsibility to pioneer such a future.

Ethical AI Frameworks

The ethical designing and deployment of artificial intelligence in dairy farming is a necessity that cannot be deemed a luxury. An AI Ethics Framework is something that guides us to make responsible decisions, ensuring the right balance between technological innovation and respect for fundamental rights. Farming, in particular, poses unique challenges when it comes to implementing AI. So, how do we steadfastly approach this?

In the arena of data privacy, AI systems must be designed to respect and protect the confidentiality of the farmer’s data. Farm tasks that involve data collection and analysis should only occur upon express permission, with a transparent disclosure of the information use. Is it not reasonable to ask, “Who owns the data?” and “How is it used?” It’s time we shifted from obscurity to transparency in data handling.

Animal welfare, too, is an integral part of ethical considerations. Even with AI’s potential to improve cow comfort and health, we must question, “Are we keeping the welfare of the animals at the heart of these technological advancements?” AI should not be used to the detriment of the animals; it should promote healthier and comfortable living conditions.

Moreover, farmers’ safety and the broader community must also be taken into account. Can we afford to gloss over how the impact of automation and robotics on the job market and work roles might affect humans deeply? This necessitates a focus not only on the developmental stages of AI but also on the repercussions of its implementation.

Embarking on this journey of AI implementation, we, the farming community, need to craft comprehensive ethical guidelines, underpinned by our commitment to data privacy, animal welfare, and human safety. In doing so, we can ensure that AI serves as a tool to boost the efficiency of our sector, rather than morphing into a bewildering predicament. It is time we acknowledged the enduring truth — every deployment of AI in dairy farming is also a decision of high ethical significance.

The Bullvine Bottom Line

Dairy farmers stand at the precipice of a technological revolution. Can they embrace this shift and harness AI to optimize herd management, ameliorate animal welfare, and secure their long-term success? The evidence speaks to the affirmative. Companies such as Cainthus of Ireland have demonstrated the power and viability of AI in tracking and analyzing herd behavior. This breakthrough, coupled with projects like the Galebreaker Ltd and Smartbell’s feasibility study, underpin AI’s tremendous mission-critical applicability in enhancing herd productivity through controlled environments.

The future of dairy farming is intertwined with the trajectory of AI. The task at hand is not to resist this inevitable tide, but to equip ourselves with the necessary know-how and adapt strategically in its wake.

Get original “Bullvine” content sent straight to your email inbox for free.

Other posts you might like:

In the perils of summer, the silent adversary of our dairy cattle herd often goes unnoticed. It’s the ubiquitous yet unseen threat that significantly impairs productivity and welfare – heat stress. But just how well equipped are we to recognize its potential and make the necessary preparations, effectively pre-empting the detrimental impacts? Is it not high time that we cease to underestimate the severity of the looming crisis that heat stress presents?

In the perils of summer, the silent adversary of our dairy cattle herd often goes unnoticed. It’s the ubiquitous yet unseen threat that significantly impairs productivity and welfare – heat stress. But just how well equipped are we to recognize its potential and make the necessary preparations, effectively pre-empting the detrimental impacts? Is it not high time that we cease to underestimate the severity of the looming crisis that heat stress presents?  As a dedicated dairy farmer, improving the health and productivity of your herd ranks high on your priority list. By now, you are certainly familiar with the critical role that rumen fermentation plays in ruminant nutrition. Yet, what you might not know is how recent discoveries in the fields of rumen fermentation and nutrient-rumen microbiota interactions can assist you in optimizing the health of your cows and bolstering

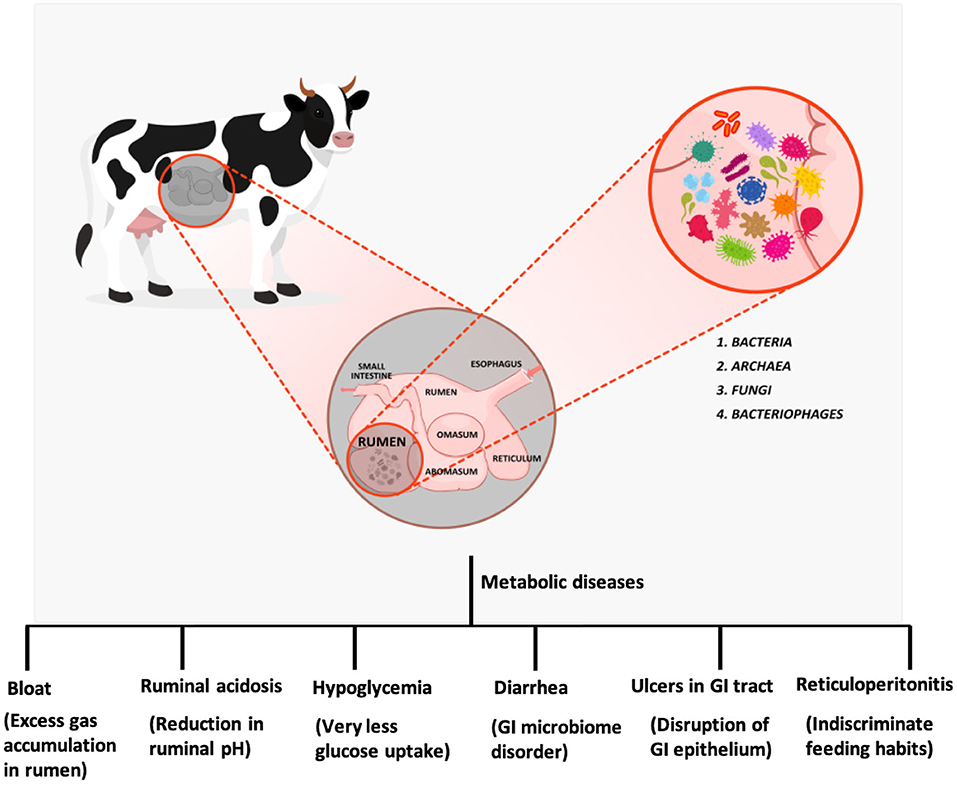

As a dedicated dairy farmer, improving the health and productivity of your herd ranks high on your priority list. By now, you are certainly familiar with the critical role that rumen fermentation plays in ruminant nutrition. Yet, what you might not know is how recent discoveries in the fields of rumen fermentation and nutrient-rumen microbiota interactions can assist you in optimizing the health of your cows and bolstering  Recently, the dairy farming community was shaken up by

Recently, the dairy farming community was shaken up by  Climate change is not simply a subject of debate; it’s a present and pressing issue, especially in our agricultural sectors. With its relentless rise in temperature, hot days and heat waves are becoming common occurrences. These changes are posing increasing risks of heat stress for livestock, particularly

Climate change is not simply a subject of debate; it’s a present and pressing issue, especially in our agricultural sectors. With its relentless rise in temperature, hot days and heat waves are becoming common occurrences. These changes are posing increasing risks of heat stress for livestock, particularly  Discover the hidden secrets of feed efficiency in US Holstein heifers through a comprehensive genomic evaluation. Will this change the future of dairy farming?

Discover the hidden secrets of feed efficiency in US Holstein heifers through a comprehensive genomic evaluation. Will this change the future of dairy farming? Discover the untapped potential in beef-on-dairy matings. Our in-depth analysis of mean breed performance could revolutionize your livestock strategy. Are you ready to unlock growth?

Discover the untapped potential in beef-on-dairy matings. Our in-depth analysis of mean breed performance could revolutionize your livestock strategy. Are you ready to unlock growth? It’s often said that social factors are key determinants of disease in both humans and laboratory animals. However, there appears to be a significant knowledge gap when it comes to the application of this understanding to farm animals. This article ties into a recent study which set out to determine if the unpredictability and competitiveness inherent in certain social environments affect the behavior and health of

It’s often said that social factors are key determinants of disease in both humans and laboratory animals. However, there appears to be a significant knowledge gap when it comes to the application of this understanding to farm animals. This article ties into a recent study which set out to determine if the unpredictability and competitiveness inherent in certain social environments affect the behavior and health of