The thing about lameness is it’s often the quiet money-drainer on your farm—the kind that creeps in unnoticed until the bill gets too big to ignore.

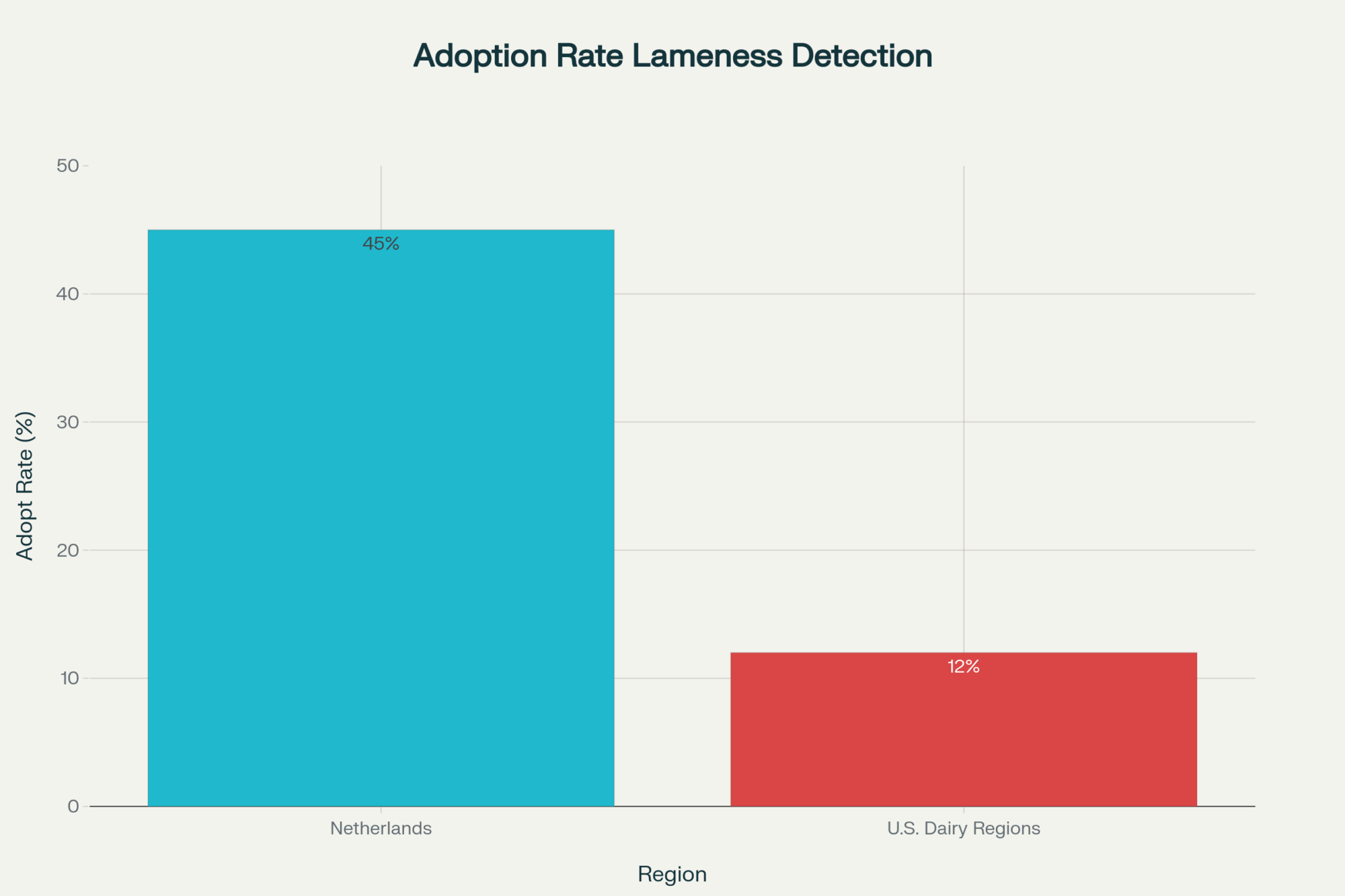

EXECUTIVE SUMMARY: Here’s the deal: up to 70% of lame cows slip past farmers unnoticed—and that’s costing around $337 per case, according to University of Wisconsin research. With milk prices hovering near $21.60/cwt and feed costs hitting $280/ton in 2025, those hidden losses could drain $40,000+ annually from a 500-cow operation.The University of Minnesota team, working with CattleEye (now owned by GEA), has cracked the code on spotting lameness up to four weeks earlier using AI camera systems. Europe’s already way ahead—45% adoption versus our measly 12%—and it shows in their bottom lines.Look, this isn’t just another tech toy. It’s proven, it’s here, and if you’re serious about protecting your margins, you need to pay attention.

KEY TAKEAWAYS:

- Slash feed waste by up to 20% when you catch lameness early—lame cows burn more feed for less milk.

Action step: Start tracking mobility scores with AI monitoring to spot inefficient cows before they tank your feed conversion. - Tighten up reproduction and cut calving intervals by 32-47 days—that’s huge money in 2025’s tight market.

Action step: Use AI alerts to time breeding decisions better and stop missing heat cycles on compromised cows. - Drop treatment costs 15-25% through proactive management instead of crisis response.

Action step: Integrate lameness data with your vet protocols—catch problems before they become expensive emergencies. - Boost cow longevity and milk components by combining mobility data with your genomic testing program.

Researchers at the University of Minnesota, funded by the Foundation for Food & Agriculture Research (FFAR), are fine-tuning autonomous camera systems that identify lameness weeks before visual signs appear. This technology builds on solutions from CattleEye, a company acquired by Germany’s GEA in 2024, already keeping an eye on over 150,000 cows globally.

According to a 2022 study from the University of Wisconsin, the average cost per lameness case is about $337, primarily due to lost milk and reduced fertility. Most farms miss over 70% of lame cows relying on visual detection alone, allowing these hidden losses to quietly eat away at profits.

Lameness: The $40,000-a-Year Problem You Might Not See

Lame cows don’t just limp; they’re burning more feed for less milk. Research published in the Journal of Dairy Science shows lame cows can require up to 20% more feed per pound of milk produced. That means a typical 500-cow dairy paying approximately $280 per ton for feed could be losing over $40,000 a year, before considering reproductive setbacks or culling costs.

In 2025, tight margins and USDA projections of milk prices near $21.60 per hundredweight make these hidden losses a direct challenge to profitability.

Extension data confirms lameness can delay calving intervals by 32 to 47 days and reduce lifetime productivity by 8-12%. Many producers remain unaware of the true prevalence because of detection gaps.

How AI Detects Lameness Up to a Month Early

Autonomous camera systems mount 2D vision units about four meters above high-traffic walkways like parlor exits. The AI analyzes gait patterns—stride, back arch, head position—with 81-86% accuracy compared to veterinary assessments.

CattleEye’s platform detects lameness up to four weeks before human observation, using cloud-computed analytics to send alerts at approximately $1.45 per cow per month. This early signal enables timely intervention, reducing losses.

But implementation requires more than just camera placement. Successful adoption depends on:

- Reliable high-speed internet connection

- Staff trained to understand and act on alerts

- Integration with existing herd management software

Farms typically require six to eight weeks for full adjustment. Having dedicated technology specialists or consultants can improve outcomes.

Navigating Adoption and ROI

There remains a notable technology adoption gap between Europe and the U.S. Approximately 45% of Dutch dairies employ automated monitoring tools compared to about 12% in major U.S. dairy regions.

Automated detection also supports welfare documentation critical for sustainability certifications and premium market opportunities.

The Council on Dairy Cattle Breeding continues to lead the way by incorporating lameness detection data into genetic evaluations focused on hoof health, a key step to improve long-term herd resilience and profitability.

Investment in this technology requires careful planning. Farms need broadband infrastructure, skilled personnel, and strong partnerships with knowledgeable providers or consultants to achieve success.

With 9.4 million dairy cows in the U.S., automated lameness detection is expected to be a critical tool for improving welfare and economic performance.

Industry data estimates that lameness costs the global dairy sector billions every year—a compelling reason for producers to prioritize effective detection and management.

Ready to Adopt? Here’s How to Start

- Talk with your veterinarian, nutritionist, or extension agent about integrating early lameness detection into your herd health program.

- Attend webinars or demos from technology providers like CattleEye to understand capabilities and costs.

- Connect with other producers who have adopted these tools to learn about their experiences.

Precision livestock management, powered by AI monitoring, is quickly becoming essential for sustainable and profitable dairy farming. Early detection reduces treatment costs, supports longer cow longevity, and improves butterfat yields.

This technology doesn’t just improve detection—it offers a real competitive advantage by exposing hidden losses and helping maintain herd productivity in today’s challenging dairy market.

Complete references and supporting documentation are available upon request by contacting the editorial team at editor@thebullvine.com.

Learn More:

- The Lameness Detection Wake-Up Call: What Three-Quarters of Your Herd is Costing You – This article provides a crucial tactical perspective by diving into the specific economic triggers of lameness. It offers actionable insights on how to establish a baseline for your herd’s mobility and demonstrates how automated systems can cut losses by 65% by pinpointing problems far earlier than visual observation.

- Why the Global Dairy Market is Making Waves in 2025 (and What That Means for You) – This piece offers a strategic, market-focused view. It analyzes the broader economic shifts in 2025—from European production declines to changing component pricing—that make margin protection non-negotiable. It helps readers understand why investing in technologies like AI lameness detection is a vital defensive strategy against global volatility.

- Temple Grandin’s Message for Dairy Farmers: Why ‘Optimal’ Beats ‘Maximum’ – This article brings an innovative, welfare-oriented perspective. It features insights from Dr. Grandin on the concept of “bad becoming normal” and how focusing on cow comfort and subtle health cues leads to a more “optimal” and profitable herd. It underscores the connection between objective data, welfare, and long-term success.

Join the Revolution!

Join the Revolution!

Join over 30,000 successful dairy professionals who rely on Bullvine Weekly for their competitive edge. Delivered directly to your inbox each week, our exclusive industry insights help you make smarter decisions while saving precious hours every week. Never miss critical updates on milk production trends, breakthrough technologies, and profit-boosting strategies that top producers are already implementing. Subscribe now to transform your dairy operation’s efficiency and profitability—your future success is just one click away.

Join the Revolution!

Join the Revolution!