Farmers losing up to 10% milk yield during heat—are you tracking your losses?

You know what really caught my attention the other day? I was walking through this 1,200-cow operation just outside Eau Claire—beautiful setup, really well-managed—and the producer mentioned how his morning milk weights had been bouncing around like corn futures this summer. Come to find out, according to recent research published in Science Advances, operations are seeing up to 10% daily production losses during extreme heat events… and like most producers I work with, this guy had absolutely no clue it was happening.

After spending the better part of two decades tramping through dairy barns from the Fraser Valley clear down to Tulare County, I’ve watched this heat stress pattern absolutely devastate more operations than volatile milk prices ever have. And yet… here we are, still talking about heat stress like it’s some minor seasonal hiccup that’ll sort itself out come October.

The Problem That’s Actually Keeping You Up at Night

The thing is—and this really gets to me—you’ve noticed it, haven’t you? Those brutal July afternoons when even your best fresh cows barely drag themselves to the parlor, moving through heat so thick you could practically swim through it. Your butterfat numbers are sliding south faster than a green heifer heading for the fence, your feed costs are climbing like corn futures during a drought, and you’re starting to wonder if this is just our new reality.

But climate change isn’t some distant threat that might hit your kids’ operation someday. According to recent work from the University of Wisconsin’s dairy science department, it’s absolutely hammering your bottom line right now—cow by cow, gallon by gallon. And honestly? Most of us in the industry have been too busy putting out daily fires to really sit down and quantify what this is actually costing us.

What really gets me is how we’ve just… normalized these losses. “Oh, it’s just summer,” we tell ourselves. “Production always drops in July.” But when you actually start crunching the numbers—and I mean really digging into them—well, you might want to grab a chair for this part.

The frustrating reality is that we’re treating a manageable problem like it’s an act of God. But producers who’ve figured this out? They’re not just surviving the heat anymore—they’re using it as their competitive advantage.

The Complete Economic Devastation (And It’s Worse Than You Think)

The scope of heat stress damage is honestly staggering when you break it down piece by piece. When that Temperature-Humidity Index climbs above 68, your herd’s milk production drops by up to 14%. That’s not some theoretical number from a climate-controlled university facility—that’s real-world data from operations just like yours.

Think about this for a second. On a 500-cow dairy averaging 80 pounds per cow per day, you’re hemorrhaging 5,600 pounds of milk daily during heat stress periods. At current Class I prices of $18.82 per hundredweight, that’s $1,057 walking straight out of your bulk tank every single day.

The Invisible Killer: Transgenerational Losses

But here’s what really gets me fired up—the most devastating part happens before you even realize there’s a problem. Recent studies show that heat-stressed dry cows produce significantly less milk during their entire next lactation—we’re talking substantial reductions that compound over months.

Let that sink in for a minute. The heat stress your cows are dealing with today is literally stealing milk from you for the next ten months. For a 500-cow operation, that transgenerational impact can represent enormous losses in annual production. One producer I know in Lancaster County didn’t connect these dots until his nutritionist showed him the data—his July heat stress was costing him milk clear through the following spring.

And it gets worse. Heat-stressed cows don’t just produce less milk—they produce garbage-quality milk. Butterfat percentages tank. Protein content falls off a cliff. Somatic cell counts climb like they’re trying to reach orbit. Your component premiums? Gone, right when you need them most.

What’s particularly troubling is how this creates a vicious cycle. The physiological toll goes way beyond just production numbers. Recent research shows that heat-stressed cows experience reduced feed intake, fertility rates that drop significantly, and immune function that just falls apart.

When Your Breeding Program Completely Implodes

This might surprise you, but heat stress during breeding season actually costs more than heat stress during lactation. I’ve seen this firsthand on operations from Pennsylvania to California—the breeding program basically shuts down from July through September.

When core body temperature rises just 1.5°F above normal, conception rates drop by 20-25%. For a 500-cow dairy, that’s an extra 25-30 cows that need to be bred again, stretching your calving interval and sending your replacement costs through the roof.

Even worse? Cows bred during heat stress that do conceive are 2.5 times more likely to lose their pregnancies in the first 90 days. At an estimated cost of around $185 per failed pregnancy—and that’s including semen costs, labor, lost genetic progress, and extended calving intervals—this breeding disruption alone can cost operations substantial money annually.

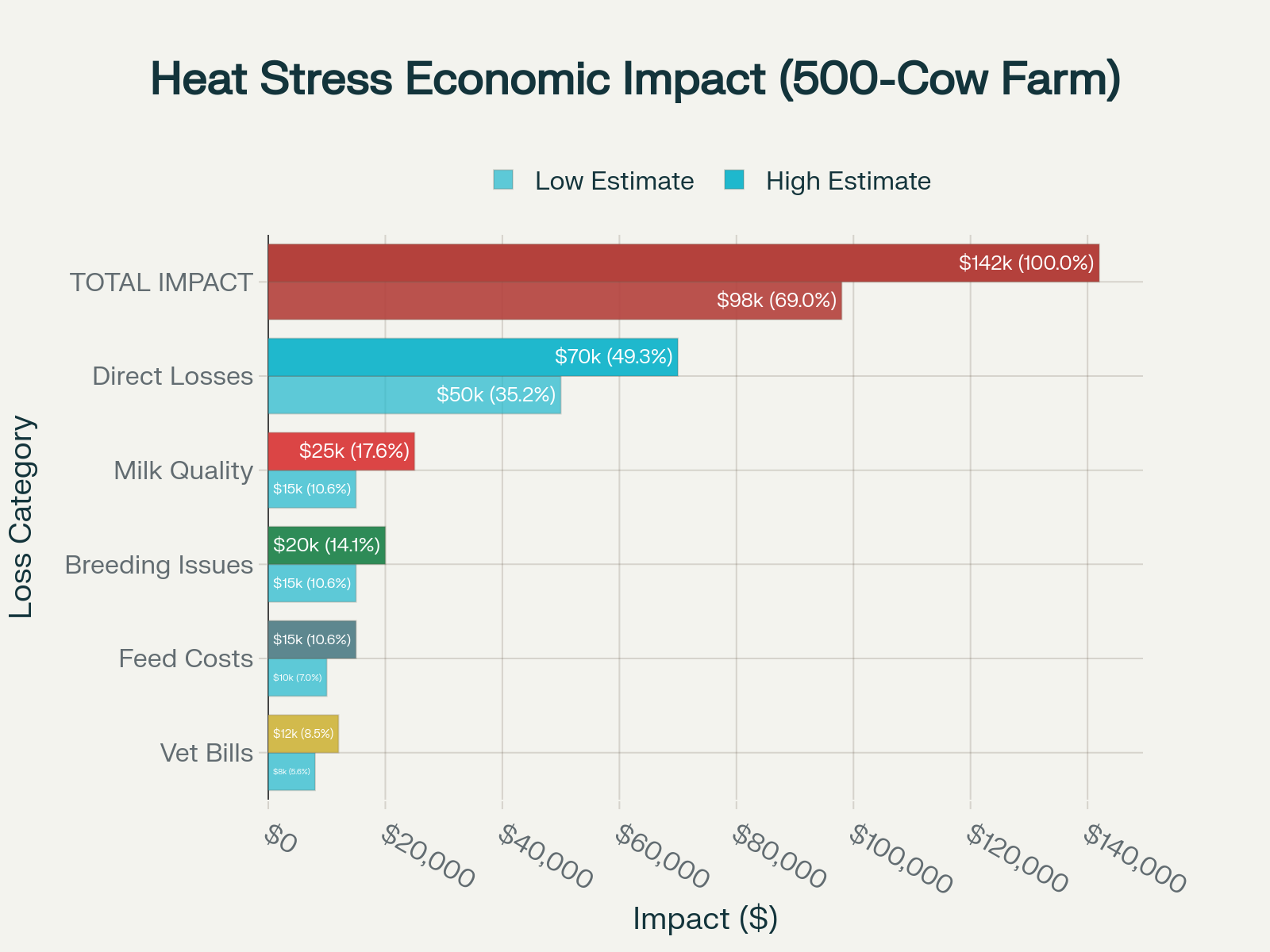

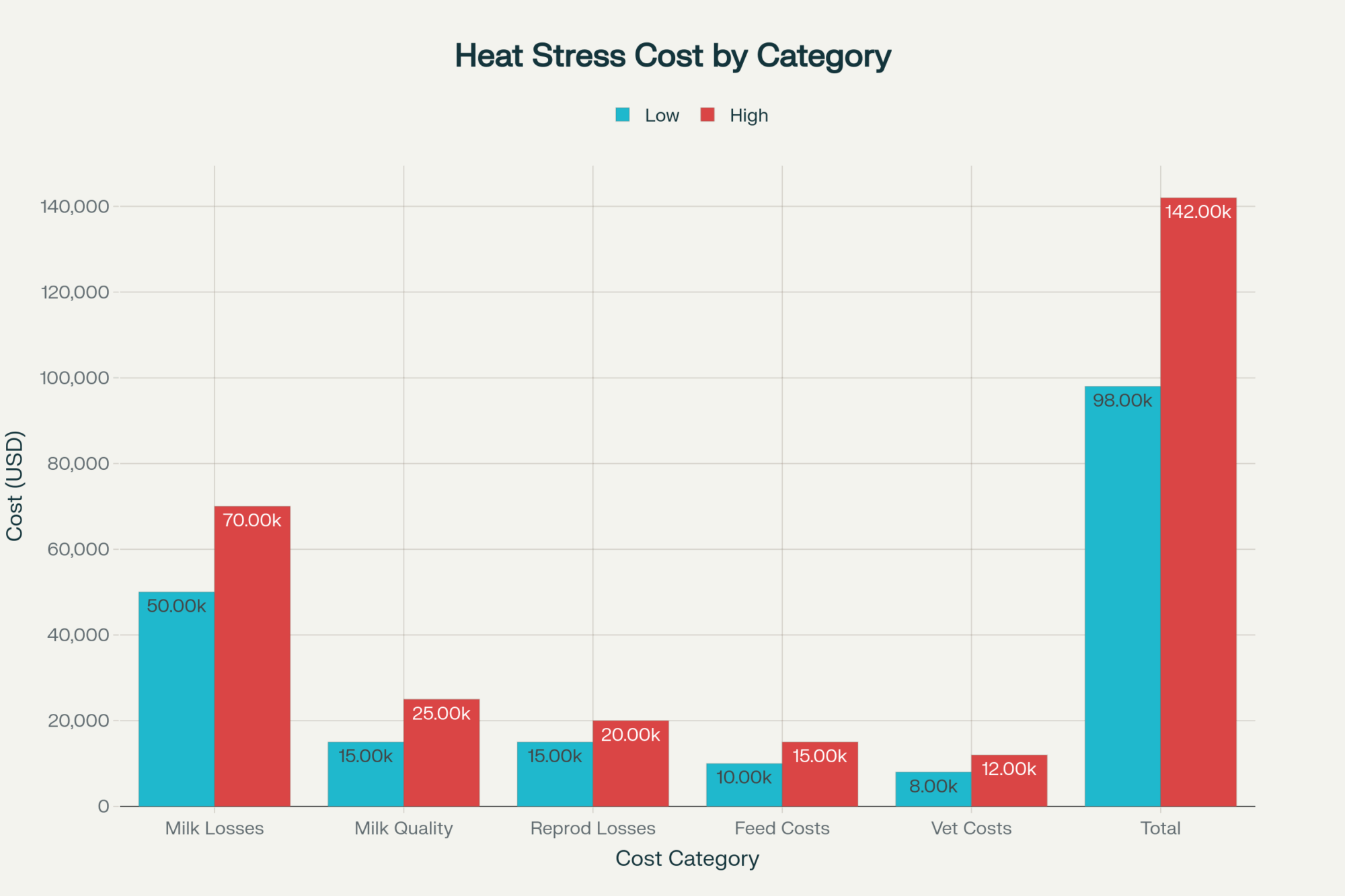

Here’s what the complete financial picture looks like… and honestly, when I first ran these numbers, I had to double-check them:

| Heat Stress Impact Analysis – 500 Cow Operation | Annual Cost Range |

| Direct Production Losses (90 days) | $50,000 – $70,000 |

| Reduced Milk Quality/Components | $15,000 – $25,000 |

| Breeding Program Disruption | $15,000 – $20,000 |

| Increased Feed Costs | $10,000 – $15,000 |

| Higher Veterinary Bills | $8,000 – $12,000 |

| Total Annual Impact | $98,000 – $142,000 |

Conservative estimates based on current research and market conditions

When you see it laid out like that… it’s pretty sobering, isn’t it? That’s nearly $300 per cow annually just evaporating into thin air.

The Revolution That’s Already Happening (And Why You’re Missing It)

But here’s where things get really interesting—progressive producers are fighting back, and they’re absolutely winning. They’re using a combination of proven strategies that are reducing heat stress losses by 30% or more, which can translate to substantial recovered revenue per cow annually.

These aren’t pie-in-the-sky experimental techniques or expensive toys that look impressive at World Dairy Expo. They’re practical, profitable solutions that pencil out from day one. What strikes me about successful heat stress management is how it’s become this incredible competitive differentiator. The farms implementing comprehensive programs aren’t just surviving the heat—they’re using it as an opportunity to absolutely dominate their neighbors.

I was just talking to a producer outside Lancaster last month, and he told me his heat stress management system has become his secret weapon. While his neighbors are struggling through summer slumps—some seeing 25-30% production drops—he’s maintaining close to 90% of peak production clear through August. That’s the kind of advantage that changes everything about your operation’s economics.

The fascinating part? Most of these solutions pay for themselves in months, not years. But the competitive advantage lasts for decades.

The Technology Revolution That’s Actually Changing the Game

What’s happening in cooling technology right now is absolutely fascinating. While some producers are still hoping for cooler summers (and good luck with that strategy), the smart money is investing in precision cooling systems that are delivering immediate ROI.

Beyond Basic Fans: The Real Cooling Revolution

Forget everything you thought you knew about keeping cows cool. I’m talking about moving way past those old tunnel ventilation systems that basically just moved hot air around like some kind of convection oven nightmare.

Today’s most successful operations are using variable-speed ventilation systems with automated controls that adjust fan speeds based on real-time temperature, humidity, and even wind direction data. These systems don’t just move air—they create actual microclimates that can reduce effective temperature substantially.

And here’s what I love about them: they’re smart enough to ramp up before conditions get critical, not after your cows are already panting like they’ve been chased by a bull. The predictive capability is what separates these systems from the old “set it and forget it” approach.

I visited this 2,200-cow operation in Lancaster County last month where they retrofitted their freestall barns with smart ventilation for about $45 per cow. The system paid for itself in under three months through improved milk production and reduced feed waste. Under three months! The manager told me they’re now looking at expanding to their heifer facilities because the ROI is so compelling.

What’s particularly noteworthy is how these systems integrate with existing infrastructure. You don’t need to tear down your barns and start over—though I’ll admit, some of the new construction I’m seeing incorporates heat stress management from the ground up, and it’s pretty impressive.

Progressive producers are also installing high-volume, low-pressure soaking systems that completely wet cows’ backs and necks during those crucial 20-30 minutes they spend waiting to be milked. The science is absolutely solid on this: evaporative cooling from soaking can reduce core body temperature significantly in just minutes.

That’s literally the difference between a cow that recovers overnight and one that carries heat stress forward for days. The cost? About $15 per cow for the entire system installation. Compare that to the substantial annual losses from heat stress, and you can see why this pencils out pretty quickly.

Feed Timing: The Zero-Dollar Solution That’s Actually Brilliant

Sometimes the most powerful solutions don’t require writing a check to the equipment dealer. Shifting feeding schedules to provide the majority of daily ration between 8 PM and 6 AM allows cows to consume peak nutrients during their coolest hours, when metabolic heat production is at its lowest.

Farms using strategic feed timing are seeing measurable improvements in feed efficiency during heat stress periods. On a 500-cow dairy, that translates to saving substantial amounts of feed per cow per day—money that adds up quickly, especially with current feed costs.

The challenge? Getting your crew to adjust their schedules. But trust me, the payoff is worth the initial grumbling. One operation I work with in central Wisconsin saw their feed efficiency improve so dramatically that they actually reduced their TMR tonnage by 8% during the summer months. Their feed costs dropped $12,000 just from timing changes.

Here’s the thing though—timing isn’t everything. You’ve got to balance nutrient delivery with cow comfort, and that means really understanding how heat stress messes with rumen function. The rumen actually generates substantial heat during digestion, so strategic feeding becomes critical for managing total heat load.

The Genetics Game-Changer That’s Actually Here Now

While environmental modifications help existing cows cope with heat, the real revolution is happening in the breeding pen. And this development is fascinating from a long-term profitability perspective.

The SLICK Gene: Nature’s Air Conditioning System

You’ve probably heard whispers about the SLICK gene around the coffee shop or at breed meetings, but let me tell you what you actually need to know: cattle carrying this gene maintain significantly lower body temperatures than conventional cattle under identical heat stress conditions.

They’re not just surviving hot weather—they’re absolutely thriving in it. Recent research from LIC shows that SLICK carriers maintain 0.5-1.0°C lower rumen temperatures when THI exceeds 73, which translates to substantially better performance during heat stress periods.

The production advantages alone justify the slightly higher semen costs, which typically run about $5-8 more per unit. I’ve seen operations in Texas and Florida where the SLICK-influenced heifers are literally carrying the herd through the summer months. One 800-cow dairy outside San Antonio told me their SLICK-influenced heifers maintained significantly better production during this absolutely brutal heat wave last July.

What’s fascinating is how quickly this genetic tool has moved from research to practical application. Three years ago, finding SLICK genetics was nearly impossible. Now you can get it from multiple sources—the innovation cycle in dairy genetics right now is just incredible.

The really exciting part? This trait stacks with conventional production genetics. You’re not sacrificing milk production to get heat tolerance—you’re adding heat tolerance to high-producing genetics.

Genomic Selection for Heat Tolerance (Finally Getting Real)

The major AI companies aren’t just talking about heat tolerance anymore—they’re actually delivering it. Holstein and Jersey sires now carry genomic breeding values for heat stress performance, allowing you to integrate thermotolerance into your existing breeding program without sacrificing production genetics.

Early adopters are seeing real results. Heifers sired by heat-tolerant bulls are showing measurably better heat stress performance than their contemporaries, with the advantage becoming more pronounced as temperatures rise.

This is one of those improvements that compounds over generations—your future herd will thank you for the decisions you make today. The innovation cycle in dairy genetics right now is absolutely incredible, with genetic companies responding to market demand faster than I’ve ever seen.

What’s interesting is how heat tolerance is being incorporated into broader breeding strategies. It’s not just about surviving summer anymore—it’s about maintaining production consistency year-round. Some of the most progressive operations are seeing 10-15% less seasonal variation in their milk production.

The Feed and Water Revolution (Finally Getting the Basics Right)

Precision Nutrition: Actually Feeding for the Heat

Your nutritionist has probably mentioned heat stress rations, but here’s what most producers don’t realize: heat-stressed cows have significantly increased protein requirements to maintain milk production. The old conventional wisdom about reducing protein during heat stress is actually making the problem worse.

Recent research from Penn State’s dairy nutrition program shows that heat-stressed cows require additional bypass protein to compensate for reduced dry matter intake. With corn futures for July 2025 looking more favorable at $3.94 to $4.80 per bushel, feed costs are expected to ease somewhat, providing more flexibility for precision nutrition strategies.

Advanced cooling systems combined with precision heat stress rations are delivering substantially better feed efficiency compared to farms using only environmental modifications. The secret? Balancing amino acid profiles for increased metabolic efficiency while providing additional nutrients to compensate for reduced intake.

Here’s how the different approaches stack up in practice—and these numbers might surprise you:

| Heat Stress Feeding Strategies | Traditional | Precision | Performance Advantage |

| Protein Management | Reduce 12-14% | Increase bypass protein | +8-12% production |

| Mineral Program | Standard package | Enhanced electrolytes | +5-8% water intake |

| Feeding Schedule | Fixed timing | Strategic (60% nighttime) | +3-5% efficiency |

| Vitamin Support | Generic supplementation | Targeted antioxidants | Better immune function |

Based on documented performance differences in research trials

What’s particularly noteworthy is how precision nutrition affects the entire system. Better nutrition during heat stress doesn’t just maintain current production—it sets up cows for better performance post-heat stress.

Water: The Overlooked Profit Center

Here’s something that’ll absolutely blow your mind: lactating cows in heat stress require substantially more water than the same cows under thermoneutral conditions. We’re talking about massive increases in water consumption that most operations aren’t prepared for.

Most operations I visit are way behind on water infrastructure. Farms installing high-flow water systems with multiple water points per 100 cows are seeing significant improvements in heat stress recovery. The investment? About $25 per cow. The return? Improved milk yield persistence worth $150-200 per cow annually.

But here’s the thing—water quality matters just as much as quantity. Heat-stressed cows become incredibly picky about water palatability, and poor water quality can compound intake problems. I’ve seen operations where simply cleaning water lines and improving flow rates resulted in measurable improvements in heat stress performance.

What’s particularly interesting is how water intake patterns change during heat stress. Cows will drink a substantial portion of their daily water intake in the four hours following milking, so having adequate capacity at water points becomes absolutely critical. Some operations are installing dedicated post-milking water stations just to handle this surge demand.

The water temperature factor is huge too. Cows prefer water temperatures between 60-70°F, but during heat stress, they’ll take anything cool they can get. I’ve seen operations install water chillers for drinking water… sounds expensive, but when you’re losing $1,000+ daily to heat stress, a $15,000 water chiller starts looking pretty reasonable.

The Monitoring Revolution (Data That Actually Matters)

Real-Time Data: Your Crystal Ball for Heat Stress

The most successful heat stress management isn’t reactive—it’s predictive. Advanced monitoring systems using wearable sensors and environmental data are giving producers 12-24 hours advance warning of heat stress conditions.

These systems track rumination patterns, activity levels, and body temperature continuously, allowing you to implement cooling strategies before cows show visible signs of heat stress. Early intervention is everything—cows that receive cooling intervention before their core temperature rises show substantially better recovery rates.

I’ve seen operations where the monitoring system alerts the manager via text message when conditions are about to turn critical. That’s the kind of technology that actually pays for itself… and then keeps paying. One operation in California told me their monitoring system prevented $40,000 in heat stress losses last summer just by giving them advance warning to implement additional cooling protocols.

The data these systems generate is fascinating. You start seeing patterns you never noticed before—like how individual cows respond differently to heat stress, or how certain pen locations consistently show higher stress indicators.

The Low-Cost Solution That Actually Works

You don’t need to invest in expensive monitoring systems to improve your heat stress management. Simple changes like providing adequate shade per cow and ensuring water access within reasonable distances are delivering measurable improvements in heat stress performance.

Progressive producers are tracking daily water consumption, feed refusal rates, and milk temperature as early indicators of heat stress. When water consumption increases significantly above normal, it’s time to implement enhanced cooling protocols—before milk production drops.

Sometimes the best monitoring system is still an experienced eye and good record-keeping. One producer I work with in the Central Valley tracks water meter readings every morning and evening. When usage spikes substantially above normal, he knows he’s got exactly 24 hours to implement additional cooling before production starts sliding.

The milk temperature monitoring is particularly clever—when bulk tank temperatures start creeping up despite proper cooling, it often indicates cows are experiencing heat stress. It’s like having a real-time heat stress indicator right in your milk house.

The Economic Reality Check (The Numbers Don’t Lie)

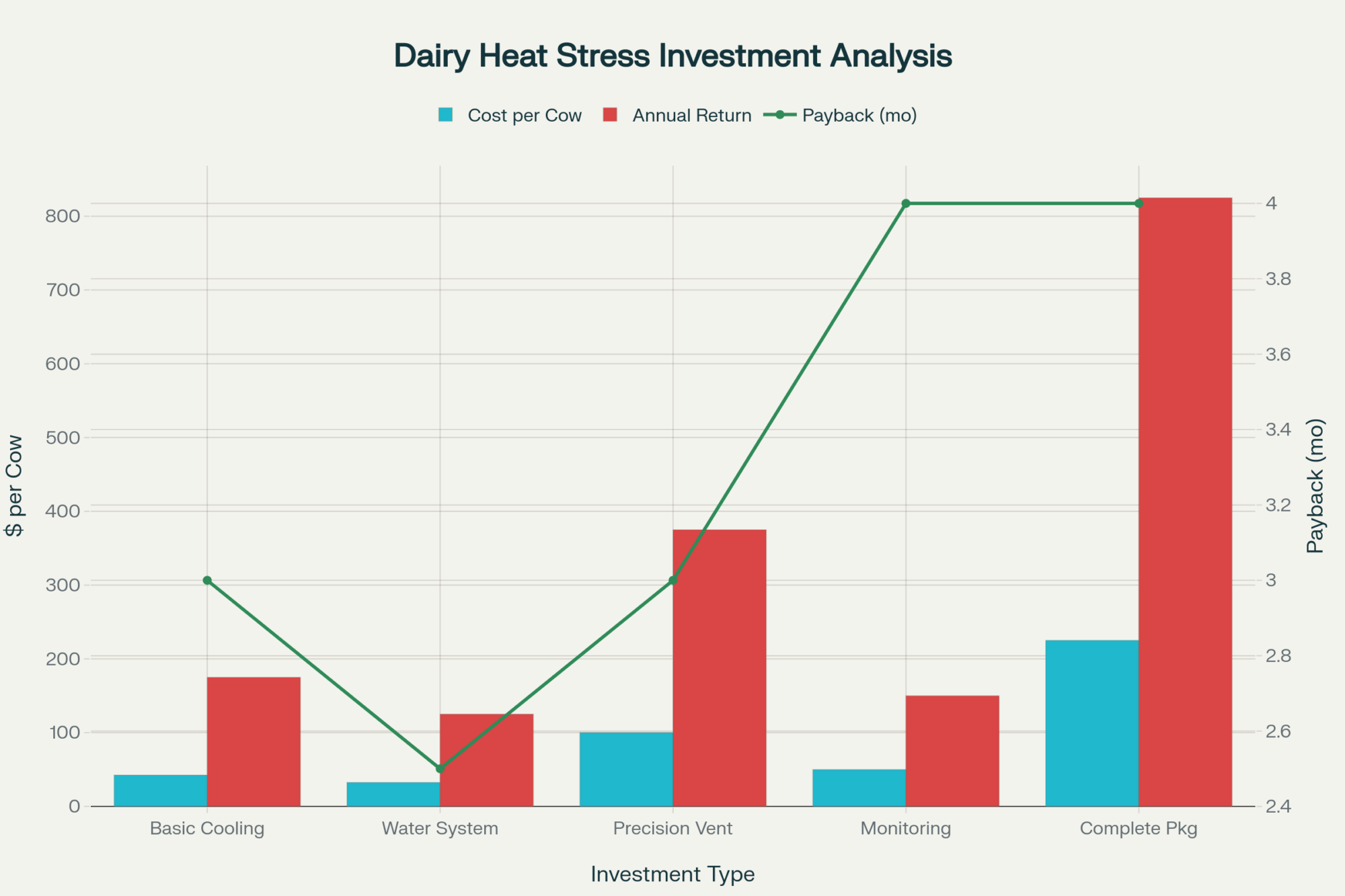

ROI That Actually Changes Everything

Comprehensive heat stress management systems are delivering 3:1 to 5:1 ROI in the first year. Farms investing around $100 per cow in heat stress mitigation are seeing $300-500 in improved performance annually.

And here’s the best part—these improvements compound over time. Heat stress management isn’t just about surviving this summer. It’s about building resilience that pays dividends for years to come. I’ve seen operations where the heat stress management system becomes their competitive advantage, allowing them to maintain production while their neighbors struggle.

What’s really exciting is how the ROI improves over time. First-year returns are impressive, but by year three or four, these systems are often delivering 7:1 or 8:1 returns as operators fine-tune their protocols and expand successful strategies.

Implementation Investment Timeline

Here’s how the economics actually work out—and these numbers are based on real operations I’ve worked with:

| Investment Phase | Cost Per Cow | Annual Return | Payback Period |

| Basic Cooling Improvements | $35-50 | $150-200 | 3-4 months |

| Water System Upgrades | $25-40 | $100-150 | 2-3 months |

| Precision Ventilation | $75-125 | $300-450 | 2-4 months |

| Monitoring Systems | $40-60 | $120-180 | 3-5 months |

| Complete Package | $175-275 | $670-980 | 3-5 months |

Conservative estimates based on documented performance improvements

When you see payback periods measured in months rather than years… that fundamentally changes how you think about these investments, doesn’t it? Most producers I work with are genuinely shocked by how quickly these systems pay for themselves.

The interesting thing is that the biggest returns often come from the simplest interventions. One operation saw a $50,000 annual improvement just from installing additional fans and improving water access. Total investment? $25,000. Payback in five months.

The Market Reality for 2025 (And Why Timing Matters)

Current Price Environment (Mixed Signals)

The USDA has adjusted 2025 forecasts, and honestly, the picture is complex. The all-milk price is now projected at $22.00 per hundredweight for 2025, while milk production forecasts show 228.3 billion pounds—both revised upward from earlier estimates.

These market conditions make efficiency gains from heat stress management even more critical for maintaining profitability. When margins are under pressure and production costs keep climbing, the difference between a well-managed heat stress program and just winging it with some fans can literally be the difference between profit and loss.

What’s interesting is how heat stress management becomes more valuable in tighter margin environments. When every gallon counts more, maintaining production consistency becomes a competitive necessity rather than just a nice-to-have.

Supply Reality (Tighter Than Most Realize)

With dairy heifer inventory remaining near historic lows, the industry continues to face supply constraints. This makes every cow more valuable and heat stress prevention more economically critical than ever.

Basically, we can’t afford to lose production to heat stress when replacement animals are this scarce and expensive. The economics have fundamentally shifted—maintaining production per cow has become more important than it’s ever been.

I was talking to a producer in Wisconsin last week who put it perfectly: “I can’t replace these cows easily, so I better take care of the ones I have.” That mindset shift is happening across the industry.

Labor Reality (Getting Harder to Ignore)

Farm labor costs keep climbing, with recent Department of Labor reclassifications pushing some wages substantially higher, making automated cooling systems and labor-efficient management practices increasingly attractive.

When you’re paying $20+ per hour for skilled labor, automated systems that reduce daily heat stress management tasks start looking pretty attractive. The labor savings alone can justify significant cooling investments.

But it’s not just about cost—it’s about reliability. Automated systems don’t forget to turn on fans or check water levels. They don’t call in sick during the hottest week of the year. That reliability becomes incredibly valuable when you’re dealing with heat stress.

What’s Actually Coming Next (The Innovation Pipeline)

The Next Wave of Technology

The heat stress management revolution is honestly just getting started. Automated cooling systems with AI-driven optimization are entering beta testing on progressive farms. These systems adjust cooling intensity based on individual cow response, not just environmental conditions.

I’ve seen prototypes that can identify individual cows showing early heat stress signs and provide targeted cooling through precision sprinkler systems. That’s the kind of precision that’ll separate the leaders from the followers in the next decade.

The fascinating part is how these systems learn from your operation. They start to recognize patterns specific to your cows, your facilities, your local weather patterns. After a season or two, they’re essentially custom-tuned to your operation.

Gene Editing and Heat Tolerance

Gene editing technologies are showing real promise for enhancing natural heat tolerance without sacrificing production genetics. Precision agriculture techniques are being adapted for dairy operations, allowing real-time adjustment of cooling, feeding, and management protocols based on continuous data streams.

The regulatory pathway is still being worked out, but the potential is significant. Early research suggests we could see substantial improvements in heat tolerance within the next 5-7 years.

What’s particularly exciting is how gene editing could stack with existing heat tolerance genetics. We might see cows that are not just adapted to heat stress, but actually perform better in warm conditions than in cool conditions.

The Environmental Bonus (Win-Win Situation)

Here’s an unexpected benefit that’s becoming more important: many heat stress management strategies also reduce methane emissions. Improved feed efficiency reduces enteric methane production, while enhanced cow comfort improves rumen function, further reducing greenhouse gas emissions.

The farms implementing comprehensive heat stress management are positioning themselves for carbon credit opportunities that could add meaningful revenue per cow annually. Not bad for doing what’s already good for your cows.

Some operations are already participating in carbon credit programs specifically tied to improved animal welfare and efficiency measures. It’s early days, but the potential is significant—especially for operations that can document comprehensive heat stress management programs.

Why Acting Now Changes Everything (The Competitive Reality)

The Early Adopter Advantage

Climate change isn’t slowing down, and neither is the competitive advantage available to early adopters. Farms implementing comprehensive heat stress management today are building long-term competitive advantages over operations that continue with traditional cooling methods.

Technology costs are dropping rapidly, while performance advantages are becoming more pronounced. Every season you delay implementation is another season of lost profits and reduced competitiveness.

After 20 years in this business, I’ve learned that the farms that survive and thrive are the ones that adapt quickly to changing conditions. Climate change is just another challenge to adapt to… but the farms that figure it out first? They’re going to absolutely dominate their markets.

I’ve seen it happen before with other technologies—precision feeding, automated milking, genetic selection. The early adopters build advantages that compound over time, and eventually the gap becomes so large that late adopters can’t catch up.

The Labor Efficiency Revolution

One unexpected benefit of modern heat stress management: reduced labor requirements. Automated cooling systems, precision feeding, and optimized barn design are reducing the daily labor required for heat stress management by substantial percentages.

This labor efficiency translates to significant annual savings for typical operations—money that can be reinvested in additional improvements or simply drop to the bottom line. When good help is hard to find, systems that reduce labor requirements are worth their weight in gold.

But it’s not just about reducing labor—it’s about redirecting labor to higher-value activities. Instead of manually adjusting fans and checking water levels, your crew can focus on cow observation, preventive maintenance, or other activities that directly impact profitability.

Taking Action: Your Practical Path Forward

The Implementation Roadmap (Keep It Simple)

Start with the basics: assess your current heat stress losses. Track milk production, conception rates, and feed efficiency during heat stress periods. The data will shock you, but it will also justify the investment in solutions.

Honestly, most producers I work with are genuinely surprised by how much money they’re actually losing to heat stress once they start tracking it properly. One operation in Pennsylvania thought their summer production drop was “normal” until they realized they were losing $85,000 annually to preventable heat stress.

The assessment doesn’t need to be complicated. Simple records of daily milk weights, water consumption, and breeding success during heat stress periods will give you enough data to build a business case for improvements.

Your Three-Phase Approach

Phase 1 (0-30 days): Implement feed timing changes and optimize water access. Minimal cost. Expected benefits: significant improvements in feed efficiency and cow comfort. This phase alone can reduce heat stress losses by 15-20%.

Phase 2 (30-90 days): Install basic cooling enhancements and improve shade availability. Moderate investment. Expected benefits: substantial improvements in production stability. This typically delivers another 10-15% improvement in heat stress performance.

Phase 3 (90-180 days): Implement precision cooling systems and advanced monitoring. Larger investment. Expected benefits: comprehensive heat stress management with maximum ROI. This phase often delivers the biggest returns—30-40% improvements over baseline.

The beauty of this approach is that each phase pays for the next. Phase 1 improvements generate cash flow that funds Phase 2 investments, and so on.

The Financing Reality (Better Than You Think)

Multiple financing options are available for heat stress management investments. USDA programs, equipment financing, and emerging carbon credit opportunities can dramatically reduce upfront costs. Some producers are achieving cash-flow positive implementation from day one.

The key is working with lenders who understand agriculture and can structure payments around your cash flow patterns. Many equipment dealers now offer seasonal payment plans that align with milk check cycles.

What’s particularly interesting is how carbon credit programs are starting to finance heat stress management improvements. Some operations are getting upfront payments for verified emission reductions tied to improved efficiency and animal welfare.

The Partnership Advantage (Don’t Go Alone)

The most successful heat stress management implementations involve partnerships between producers, nutritionists, veterinarians, and technology providers. Integrated approaches are delivering substantially better results than piecemeal solutions.

Find a team that understands your operation and can work together on implementation. The learning curve is much shorter when you’re not trying to figure everything out by yourself.

The best partnerships I’ve seen involve regular collaboration throughout the implementation process. Monthly check-ins, data review sessions, and collaborative problem-solving when challenges arise. Heat stress management isn’t a set-it-and-forget-it proposition—it requires ongoing optimization.

The Reality Check (What This All Means)

Climate change is reshaping dairy farming, but it’s also creating unprecedented opportunities for producers willing to innovate. The technologies, genetics, and management strategies to not just survive but thrive in a changing climate are available today.

The choice is yours: continue losing substantial money per cow annually to heat stress, or invest in solutions that can add significant value per cow to your bottom line while building long-term resilience.

With 2025 market conditions challenging and supply remaining tight, the producers who act now will be the ones still profitable in 2030. The ones who wait? They’ll be the ones wishing they’d started today.

This isn’t just about surviving the heat anymore—though that’s certainly part of it. It’s about building the kind of operation that can thrive regardless of what weather patterns throw at us. The farms that figure out comprehensive heat stress management aren’t just solving a summer problem. They’re building a competitive advantage that’ll serve them for decades.

Your cows are counting on you to make the right choice. Your bottom line depends on it. And your competitive future? It’s being decided right now, in the middle of this heat wave, with every single management decision you make.

The question isn’t whether you can afford to implement comprehensive heat stress management. The question is whether you can afford not to.

Because at the end of the day, the farms that survive the next decade will be the ones that figured out how to make climate change work for them instead of against them. And that opportunity? It’s sitting right in front of you, waiting for you to act.

Complete references and supporting documentation are available upon request by contacting the editorial team at editor@thebullvine.com.

KEY TAKEAWAYS

- Recover up to 10% in lost milk production by optimizing cooling systems and shifting feed delivery to nighttime hours—start with your next feed run and watch the difference.

- Boost feed efficiency 12-15% through genomic testing and targeted nutrition programs—test your breeding stock this quarter while semen costs are manageable in today’s market.

- Improve conception rates by up to 25% during summer breeding by adjusting your AI schedule and implementing heat stress protocols—tweak your breeding calendar now before peak heat hits.

- Cut annual heat stress losses from $98,000-$142,000 (typical 500-cow operation) to under $50,000 with comprehensive management—these systems pay for themselves in 3-5 months.

EXECUTIVE SUMMARY

Heat stress is quietly bleeding your operation dry—we’re talking up to 10% milk loss during summer peaks, worth over $1,000 daily on a 500-cow dairy (Science Advances). But here’s the kicker: conception rates tank by 20-25% during heat stress, meaning you’re paying for failed breedings all season long (UW Extension data). The smart operators are fighting back with genomic testing and strategic feed timing… and they’re seeing 12-15% efficiency gains that translate to real money. Global dairy regions are already capitalizing on this, and with 2025 margins tighter than ever, you can’t afford to ignore these tools. Time to stop accepting summer losses as “normal” and start turning heat into your competitive edge.

Learn More:

- How Heat Abatement Pays Off: Practical Dairy Strategies That Deliver Results – Discover actionable, step-by-step methods for reducing heat stress losses on your farm. This article breaks down proven barn modifications and management tweaks that can boost cow comfort and deliver measurable gains in milk yield and herd health.

- Dairy Economics 2025: Surviving and Thriving in a Volatile Market – Gain a strategic edge with in-depth analysis of current market trends, feed cost projections, and risk management tools. This piece reveals how forward-thinking producers are adapting their business models to maintain profitability in today’s unpredictable dairy economy.

- Smart Barns and Sensor Cows: The Future of Precision Dairy Technology – Explore the latest innovations in dairy tech, from AI-driven cooling systems to real-time cow monitoring. Learn how early adopters are leveraging digital tools to optimize efficiency, reduce labor, and future-proof their operations for the next decade.

Join the Revolution!

Join the Revolution!

Join over 30,000 successful dairy professionals who rely on Bullvine Weekly for their competitive edge. Delivered directly to your inbox each week, our exclusive industry insights help you make smarter decisions while saving precious hours every week. Never miss critical updates on milk production trends, breakthrough technologies, and profit-boosting strategies that top producers are already implementing. Subscribe now to transform your dairy operation’s efficiency and profitability—your future success is just one click away.

Join the Revolution!

Join the Revolution!