Trial: 60 cows. Mandate: 1,400 farms. Crisis: 6 weeks. This is why Denmark’s methane ‘solution’ became a dairy disaster

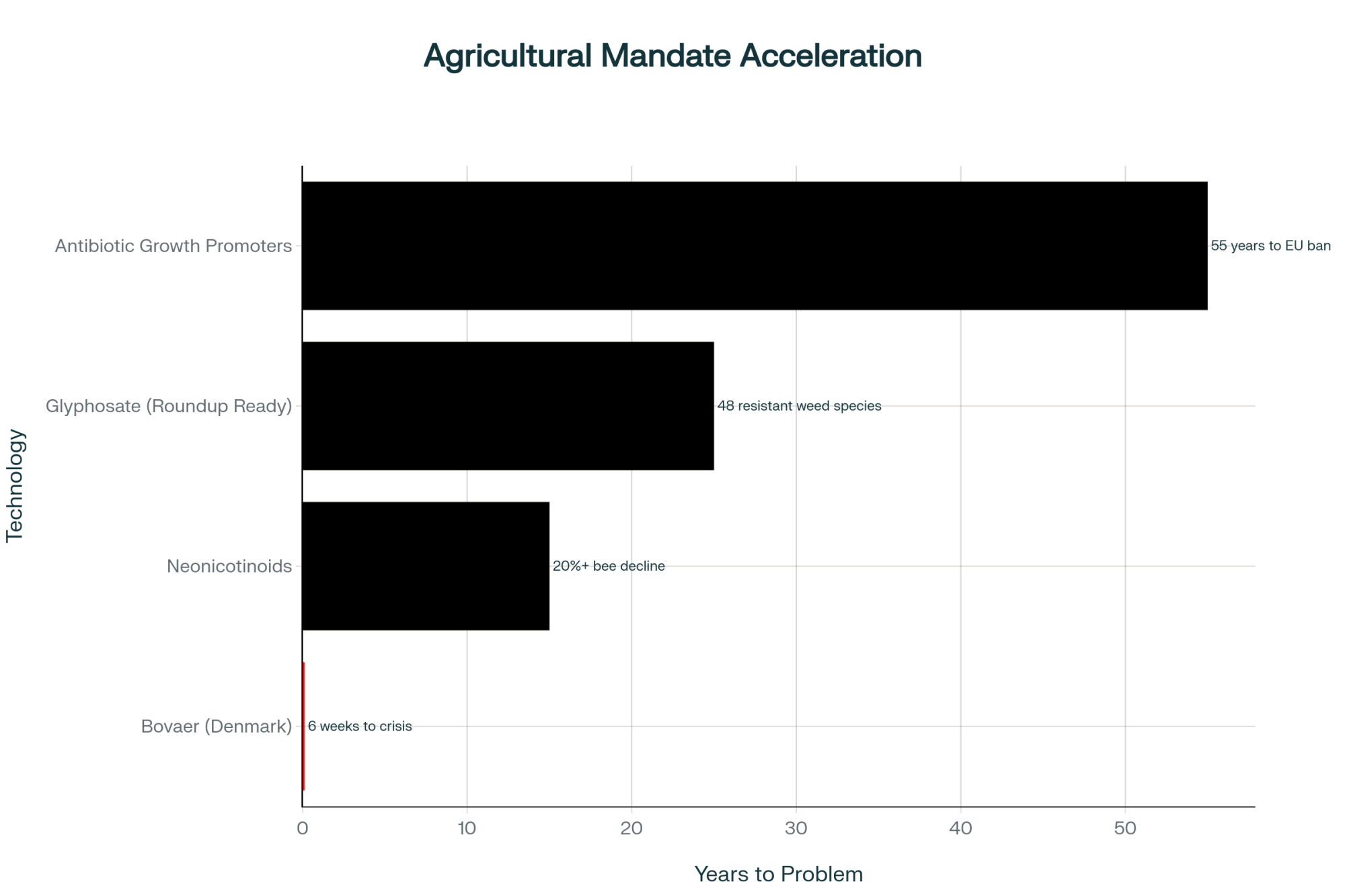

EXECUTIVE SUMMARY: Denmark mandated Bovaer on October 1; by November 15, 1,400 farms reported sick cows and production losses that reversed within 48 hours of stopping. Norway suspended it preemptively—no crisis needed. This six-week collapse follows a predictable pattern: antibiotics created superbugs (a 55-year delay in a ban), glyphosate spawned 48 resistant weeds, neonicotinoids crashed bee populations—all were ‘thoroughly tested’ and ‘safe.’ The difference now? Mandates are moving faster than science, and your decades of genetic progress hangs in the balance. Your defense: monitor daily ($150-300/cow for basic systems), test 10-20% of your herd first, set clear exit triggers (e.g., 20% SCC increase = stop), and document everything. Bottom line: regulatory approval means it won’t poison your cows immediately—it doesn’t mean it’s right for your farm.

When Norwegian dairy cooperatives announced their suspension of Bovaer use this November, I found myself thinking about a conversation I’d had with a Wisconsin producer just weeks earlier. He’d asked me whether new methane-reduction technologies were worth the risk, given his operation’s tight margins. Looking at what’s unfolding in Scandinavia, his caution seems particularly prescient.

We aren’t looking for controversy, but we can’t ignore the red flags flying over Danish barns. Following Denmark’s October implementation of mandatory Bovaer use for operations with more than 50 cows—a regulatory approach covered extensively by agricultural media across Europe—producers began reporting health concerns in their herds. The symptoms ranged from digestive issues to lameness, with some operations reporting measurable production impacts.

What’s particularly noteworthy is how one Danish producer described his experience to Farmers Guardian: his somatic cell counts improved markedly after discontinuing the additive. Now, while Danish agricultural authorities continue their investigation—they’ve been quite transparent about not having established causation—the pattern emerging warrants our industry’s attention.

Recognizing Historical Patterns in Agricultural Innovation

This situation brings to mind a presentation I gave at World Dairy Expo a few years back about technology adoption cycles in our industry. There’s a remarkably consistent pattern we’ve observed across decades of innovation.

Consider the antibiotic growth promoter experience. Back in the 1940s, researchers discovered that low-dose antibiotics could improve feed efficiency by 10-20 percent—revolutionary for its time, especially for operations in warmer climates dealing with heat stress. The science was solid, the economics compelling.

Yet it took decades for us to understand the broader implications of antimicrobial resistance. The European Union’s 2006 ban came 55 years after initial approval—a sobering timeline for any of us thinking about long-term consequences.

The Roundup Ready story offers another perspective. I remember the enthusiasm at those mid-90s farm shows—this technology promised to revolutionize weed management. And initially, it delivered.

But as any producer who’s dealt with palmer amaranth or waterhemp knows, nature adapts. The International Herbicide-Resistant Weed Database now documents 48 species with confirmed glyphosate resistance. Those early adopters who built their entire weed management program around a single mode of action learned an expensive lesson.

More recently, we’ve watched the neonicotinoid situation unfold. Initial safety assessments focused on acute toxicity to pollinators at field-relevant doses. What emerged later—through research like the comprehensive Nature Communications study by Woodcock and colleagues—were subtle, population-level effects that took years to document. Some bee species showed population declines exceeding 20 percent in treated agricultural landscapes.

Each case teaches us something valuable: technologies that perform well in controlled trials may behave differently when deployed across the diverse real-world farming systems.

Understanding the Current Timeline

What distinguishes the Bovaer situation is the compressed timeline. Denmark mandated use on October 1. By early November, producer organizations were documenting concerns from their members—the Danish Dairy Farmers’ Association received dozens of formal reports, though informal networks suggested broader concerns.

Danish authorities responded with revised guidance allowing welfare-based exemptions. Norwegian cooperatives announced their precautionary suspension by mid-November.

This six-week progression from mandate to suspension represents either enhanced responsiveness to producer concerns or potentially more acute issues than we’ve seen with previous technologies. Perhaps both factors are at play.

The issuance of welfare exemption guidance particularly catches my attention. While it’s encouraging that authorities responded to producer concerns, one wonders why such flexibility wasn’t built into the original implementation framework.

The Gap Between Testing and Practice

Having reviewed both EFSA’s 2021 approval documentation and FDA’s 2024 assessment, I can appreciate the thoroughness of the regulatory process. These reviews examine toxicology at multiple doses, verify efficacy claims—in this case, that 27-30 percent methane reduction—and assess environmental safety under standardized conditions.

Yet researchers at Aarhus University are only now conducting what they describe as the first comprehensive welfare assessment under commercial conditions. This is three years after initial market approval. As they noted in their August announcement, the symptom patterns some producers are reporting weren’t observed in controlled trials.

This isn’t a criticism of regulators—it’s an acknowledgment of inherent limitations. Your operation, with its unique combination of genetics, forages, management practices, and environmental conditions, isn’t a research facility. The interaction of these variables creates complexity that controlled trials simply cannot fully replicate.

Here’s something else to consider: We spend generations breeding for longevity, mobility, and metabolic efficiency.

“We cannot afford to compromise twenty years of genetic progress for a mandate that hasn’t been stress-tested on high-production herds.”

The daughters of bulls like Frazzled, Montross, and Supersire weren’t developed to be test subjects for rushed climate solutions.

A Framework for Thoughtful Technology Adoption

Based on conversations with producers who’ve successfully navigated new technology adoption, and drawing from extension recommendations from programs like Cornell’s PRO-DAIRY, here’s a framework worth considering:

Critical Questions Before Implementation

– What was actually tested versus what wasn’t?

- Trial duration (most feed additive studies run 12-16 weeks)

- Number and diversity of animals tested

- Which metrics were evaluated (efficacy vs. comprehensive welfare)

– Can you monitor impacts quickly?

- Daily tracking capability for SCC, components, and intake patterns

- Locomotion scoring systems

- Modern sensor technology ($150-300/cow basic, $500-800/cow comprehensive—typically pays for itself by preventing one health crisis)

– What’s your exit strategy?

- Clear triggers for discontinuation

- Legal ability to stop if concerns arise

- Understanding of financial burden allocation

– Is this voluntary or mandatory?

- Welfare exemption procedures

- Compensation mechanisms

- Reporting pathways

| Phase | Action | Threshold | Why It Matters |

| BEFORE (30 days) | Document baseline metrics | 30 days minimum | Legal protection & clear comparison |

| DURING (10-20%) | Test on 10-20% of herd | NOT your best genetics | Limit exposure, preserve value |

| MONITOR (Daily) | Track SCC, intake, mobility | $150-300/cow basic systems | 48-72 hour problem detection |

| EXIT TRIGGER 1 | Somatic Cell Count increase | 20% = STOP | Anders Ring’s SCC jumped 20%+ |

| EXIT TRIGGER 2 | Conception rate drop | 15% = STOP | Reproduction issues widely reported |

| EXIT TRIGGER 3 | Dry matter intake decrease | 10% = STOP | Early warning of metabolic stress |

| DOCUMENT | Everything, in writing | Set triggers BEFORE starting | Don’t adjust thresholds mid-trial |

Implementation Best Practices

Start conservatively:

- Begin with 10-20 percent of your herd (not the highest genetic merit animals)

- Maintain control groups under identical management

- Document baseline performance for at least 30 days

Establish thresholds before you begin:

- 20% increase in somatic cells = stop

- 15% drop in conception rates = stop

- 10% decrease in dry matter intake = stop

- Write these down in advance—don’t adjust later

Operational Considerations

Smaller operations (under 200 head):

- Your intimate cow knowledge is an advantage

- Daily observation during milking catches subtle changes

- Focus on individual cow behavior patterns

Larger operations (500+ cows):

- Leverage DeLaval, Lely, or BouMatic management systems

- Configure alerts for baseline deviations

- Your technology is your early warning network

Grazing operations:

- Confinement-tested technologies may perform differently on pasture

- Watch grazing behavior changes as early indicators

- Pasture-based systems add complexity, and trials don’t capture

Industry Perspectives and Balance

The manufacturer’s position deserves fair consideration. In their November statements, dsm-firmenich emphasized Bovaer’s successful use across multiple countries over several years, noting that previous investigations haven’t identified the additive as a causal factor in reported health concerns. This track record matters.

Danish authorities are taking a measured approach, investigating reports while avoiding premature conclusions. Their November ministry statements emphasize following evidence wherever it leads.

What I find instructive is the contrast between Danish and Norwegian responses. Norway implemented a precautionary pause despite no domestic reports of problems. This represents a philosophical difference in risk management that is worth discussing across the industry.

Broader Trends Shaping Our Decisions

Several converging trends affect how we should evaluate emerging technologies:

Climate regulations are intensifying. The European Union’s Farm to Fork strategy targets 55 percent reductions in emissions by 2030. California’s SB 1383 mandates a 40 percent reduction in methane over the same period. These aren’t distant goals—they’re reshaping market access and milk pricing today.

Producer networks have transformed information flow. Through online forums and messaging platforms, experiences that once took months to circulate now spread in hours. This acceleration can amplify both legitimate concerns and unfounded fears.

Consumer awareness has reached unprecedented levels. When major cooperatives trial new technologies, social media responses are immediate and increasingly shape market dynamics. Market perception increasingly affects on-farm decisions.

Meanwhile, monitoring technology continues advancing. Modern systems can detect subclinical changes that would have gone unnoticed a decade ago. This capability fundamentally changes our ability to manage risk.

Learning from Producer Experience

In preparing this piece, I’ve spoken with numerous producers who’ve evaluated methane-reduction technologies. Their experiences offer valuable insights.

A 450-cow Jersey operation in California’s Central Valley shared that detailed documentation in her management software proved invaluable when addressing concerns about a previous feed additive. “Document everything,” the owner emphasized. “Not because you expect problems, but because good data protects everyone—you, your nutritionist, and yes, even the manufacturer.”

Cooperative networks are proving their value. A Wisconsin cooperative chair (speaking on condition of anonymity) told me how their producer WhatsApp group helped multiple members avoid issues when three farms reported similar concerns with a product. “That collective knowledge saved us collectively hundreds of thousands in potential losses,” he noted.

What consistently emerges is advice to approach new technologies as if running a research trial. Test methodically, monitor comprehensively, and be prepared to adjust based on evidence.

Practical Takeaways for Your Operation

As we navigate increasing pressure to adopt climate-smart technologies, several principles deserve emphasis:

Regulatory approval represents a starting point for evaluation, not an endpoint. The gap between “approved” and “optimal for your specific operation” remains yours to assess and bridge.

Rapid problem detection—whether through technology or observation—can mean the difference between minor adjustments and major losses. The ability to identify issues within 48-72 hours should be considered essential infrastructure.

Starting small isn’t timidity—it’s prudent management. Even under pressure to adopt quickly, gradual scaling based on documented performance protects your operation’s viability.

Collective producer experience matters. When multiple operations report similar observations, patterns emerge that individual experiences might not reveal. Your voice, combined with others, shapes industry understanding and regulatory response.

Above all, animal welfare must remain paramount. If a technology compromises your herd’s health, discontinuation is appropriate regardless of other pressures. Danish authorities’ eventual acknowledgment of welfare exemptions validates this principle.

Charting a Productive Path Forward

The path forward doesn’t require choosing between innovation and caution, or between environmental progress and animal welfare. I’ve seen numerous operations successfully integrate new technologies by taking measured approaches.

What we need is more comprehensive pre-deployment testing that reflects actual farm diversity. Not just research stations, but grazing operations, high-production confinement systems, organic dairies, and everything between.

Regulatory frameworks should build in flexibility from inception, not add it reactively. Producer input should be integral to technology development, not an afterthought during implementation.

Most fundamentally, we need recognition that sustainable dairy farming requires both environmental progress and economic viability. These aren’t competing goals—they’re interdependent requirements for our industry’s future.

Final Thoughts for Our Industry

The Danish and Norwegian experience with Bovaer offers valuable lessons about innovation, regulation, and the realities of modern dairy farming. This isn’t about opposing progress or uncritically embracing every new technology.

It’s about developing wisdom to distinguish between what works in trials and what works in the complex reality of commercial dairy operations.

Research teams at universities and companies continue developing new approaches to methane reduction—enzyme inhibitors, probiotics, genetic selection, and management innovations. Each will eventually arrive at our farm gates with promises and peer-reviewed papers.

The question isn’t whether to embrace or reject these innovations wholesale. It’s about evaluating them thoughtfully, implementing them carefully, and monitoring them comprehensively. The producers who succeed will be those who trust their data, respect their experience, and maintain the confidence to act on both.

This balance—between openness to innovation and commitment to proven principles—isn’t just smart farming. It’s essential for navigating agriculture’s transformation while maintaining the animal welfare, environmental stewardship, and economic sustainability that will keep dairy farming viable for the next generation.

Here’s my challenge to you: Before the next mandate arrives at your farm gate, have your monitoring systems in place. Know your baseline metrics. Build your producer network. Because the best time to prepare for technology adoption isn’t when it becomes mandatory—it’s right now.

Key Takeaways:

- Your cows will tell you before regulators will: Danish farmers who acted on SCC spikes recovered in 48 hours; those who waited for “official guidance” lost weeks of production

- The 10-20-30 Shield: Before any new technology—Test 10-20% of herd, Document 30 days baseline, Set exit triggers in writing (20% SCC increase = stop)

- A $300/cow monitor beats a $30,000 crisis: Daily tracking catches problems in 48-72 hours; waiting for clinical signs means you’re already losing money

- Networks save herds: Denmark’s 1,400 affected farms found each other online before regulators admitted problems—your WhatsApp group is your first defense

- Remember the timeline: Antibiotics (55 years to ban), Glyphosate (48 resistant weeds), Bovaer (6 weeks to crisis)—the pattern is clear, mandates are getting faster, consequences aren’t

Complete references and supporting documentation are available upon request by contacting the editorial team at editor@thebullvine.com.

Learn More:

- Genetic Selection Strategies for Sustainable Dairy Cows: Feed Efficiency and Methane Reduction – Provides a tactical roadmap for breeding low-methane herds without sacrificing production. This guide details how to integrate feed efficiency traits into your sire selection protocols to proactively meet emission targets while protecting genetic longevity.

- US Dairy Market in 2025: Butterfat Boom & Price Volatility – How Farmers Can Protect Profits – Delivers essential strategies for navigating the economic pressures that make mandates like Bovaer so risky. Learn how to lock in component premiums and manage volatility to ensure your operation remains financially resilient against regulatory shocks.

- Tech Reality Check: The Farm Technologies That Delivered ROI in 2024 (And Those That Failed) – Offers a critical analysis of which monitoring investments actually pay off. Before buying sensors to track mandate compliance, use this audit to distinguish between high-ROI tools that save cows and “silver bullet” hype that wastes capital.

Join the Revolution!

Join the Revolution!

Join over 30,000 successful dairy professionals who rely on Bullvine Weekly for their competitive edge. Delivered directly to your inbox each week, our exclusive industry insights help you make smarter decisions while saving precious hours every week. Never miss critical updates on milk production trends, breakthrough technologies, and profit-boosting strategies that top producers are already implementing. Subscribe now to transform your dairy operation’s efficiency and profitability—your future success is just one click away.

Join the Revolution!

Join the Revolution!