If $600 in LEDs can match the performance of $6,000 systems, what else are we overcomplicating in modern dairy farming?

You know, there’s something telling about the fact that we’ve had twenty years of solid research on barn lighting, yet walk into most dairy operations and you’ll still find those fixtures from decades ago. Makes you think about how our industry actually adopts technology, doesn’t it?

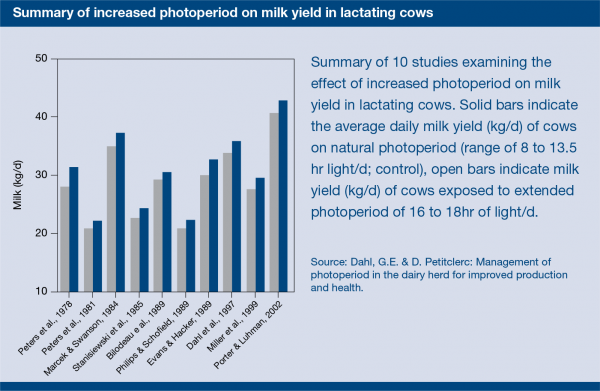

What’s interesting here is that Dr. Geoffrey Dahl, down at the University of Florida, has been publishing rock-solid research in the Journal of Dairy Science since the early 2000s. His team’s work shows that when lactating cows receive 16 to 18 hours of light at the right intensity—approximately 100 to 200 lux, comparable to the light in a decent office—their hormones respond in ways that directly affect production.

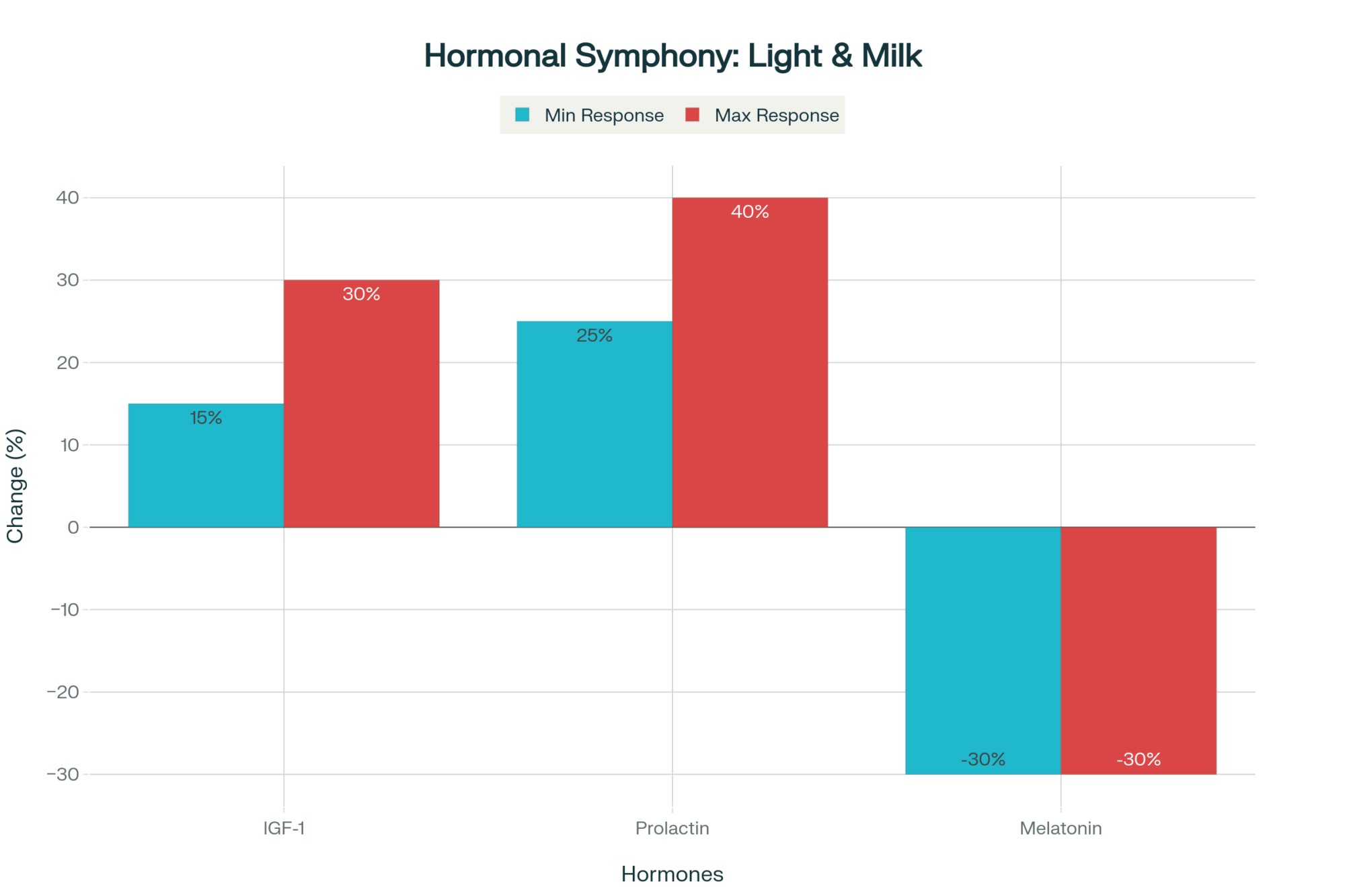

The numbers are pretty compelling when you look at them. IGF-1, an insulin-like growth factor, increases by 15 to 30%, improving feed conversion efficiency. Prolactin increases by 25 to 40%, directly stimulating the mammary tissue. These aren’t minor tweaks we’re talking about—these are significant changes that are reflected in the bulk tank.

So why aren’t we all rushing to upgrade? Well, that’s where things get interesting…

Understanding the Biology (Because It Actually Matters)

Let me walk you through what’s happening inside these cows, because once you get this, the whole conversation about lighting starts making more sense.

When cows get those extended light periods, their pineal gland—that little pine cone-shaped thing in the brain—cuts way back on melatonin production. Dahl’s team has extensively documented this over the years, with studies published in the Journal of Dairy Science from 2000 to 2024.

Less melatonin means more IGF-1, and that’s improving how efficiently our cows convert feed. The prolactin boost? That directly works on milk synthesis in the mammary tissue.

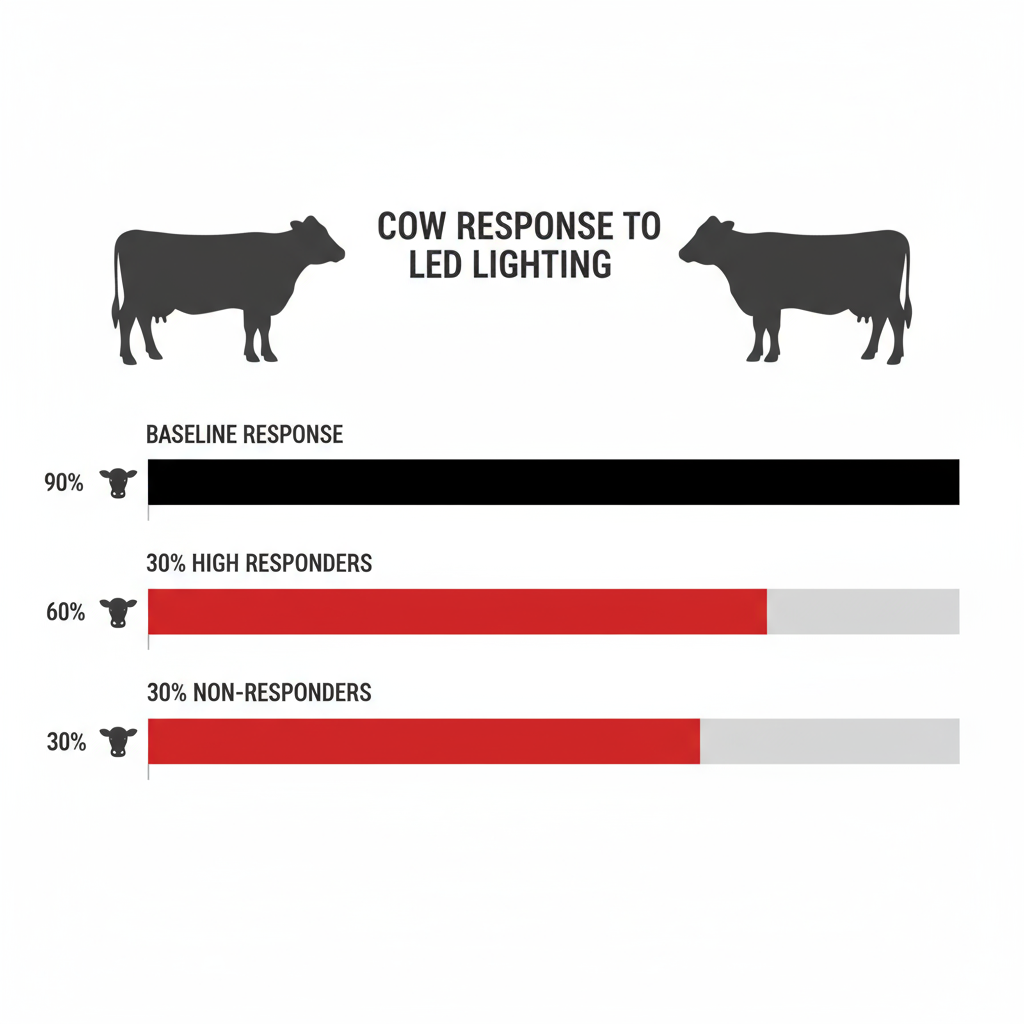

However, what’s truly fascinating is that this discovery emerged from research published by Dr. Dong-Hyun Lim’s team in the Animals journal in 2021. They found massive individual variation between cows—up to 10-fold differences in baseline melatonin levels within the same herd. Some cows showed melatonin suppression at just 50 lux, others needed 200 lux for the same response.

Think about what that means for a minute. You could have perfect, uniform lighting throughout your barn, and yet, only some of your cows are still not getting the full benefit. That’s not a technology failure—that’s just biology being messy, as usual.

“And here’s the thing: this messiness actually makes the case for simple solutions even stronger. Why invest in complex, expensive systems trying to optimize for individual variation when you can’t predict which cows will respond? Better to stick with the proven basics—16 to 18 hours at adequate intensity—and accept that biology will do what biology does.”

Oh, and dry cows? They need the complete opposite. Dahl’s research shows that 8 hours of light and 16 hours of darkness during the dry period actually prime their prolactin receptors. Sets them up better for the next lactation.

But managing two completely different lighting protocols in the same facility? That’s tough, especially if you’re running less than a couple hundred head without separate dry cow housing.

What Research Tells Us vs. What Actually Happens

The Journal of Dairy Science has published multiple studies over the years on photoperiod manipulation. Dahl and colleagues documented production increases averaging 2.5 pounds per day—about 8% improvement—in commercial settings (published in multiple papers between 2012 and 2020).

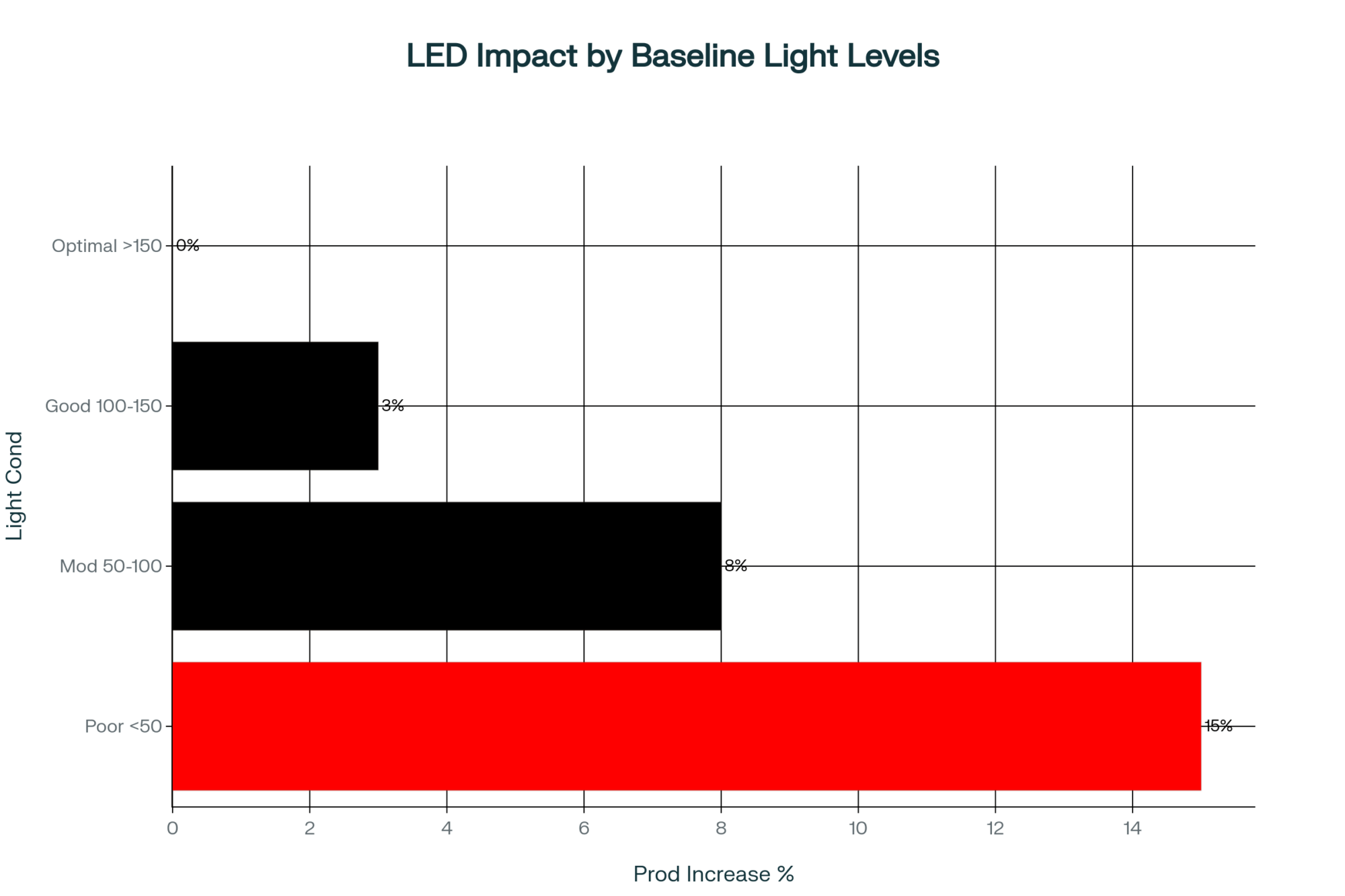

Some research has shown responses up to 15% under certain conditions, particularly when starting from very poor baseline lighting.

Now, when you dig into these studies, you generally find the biggest improvements come from farms that started with really inadequate lighting. We’re talking old barns with maybe 30 or 40 lux from ancient fixtures.

When farms already have decent lighting—say, modern T8 fluorescents providing 100-plus lux? The improvements get harder to measure.

And let’s be honest here—how often does anybody change just their lighting? Usually, it’s part of a bigger renovation. New ventilation, better cow comfort, and different feed systems. Everything changes at once, and suddenly you can’t tell what’s doing what. That’s the reality of farming, not the controlled conditions of research trials.

The Technology Landscape (Without the Sales Pitch)

So what’s actually in these LED systems everyone’s trying to sell us?

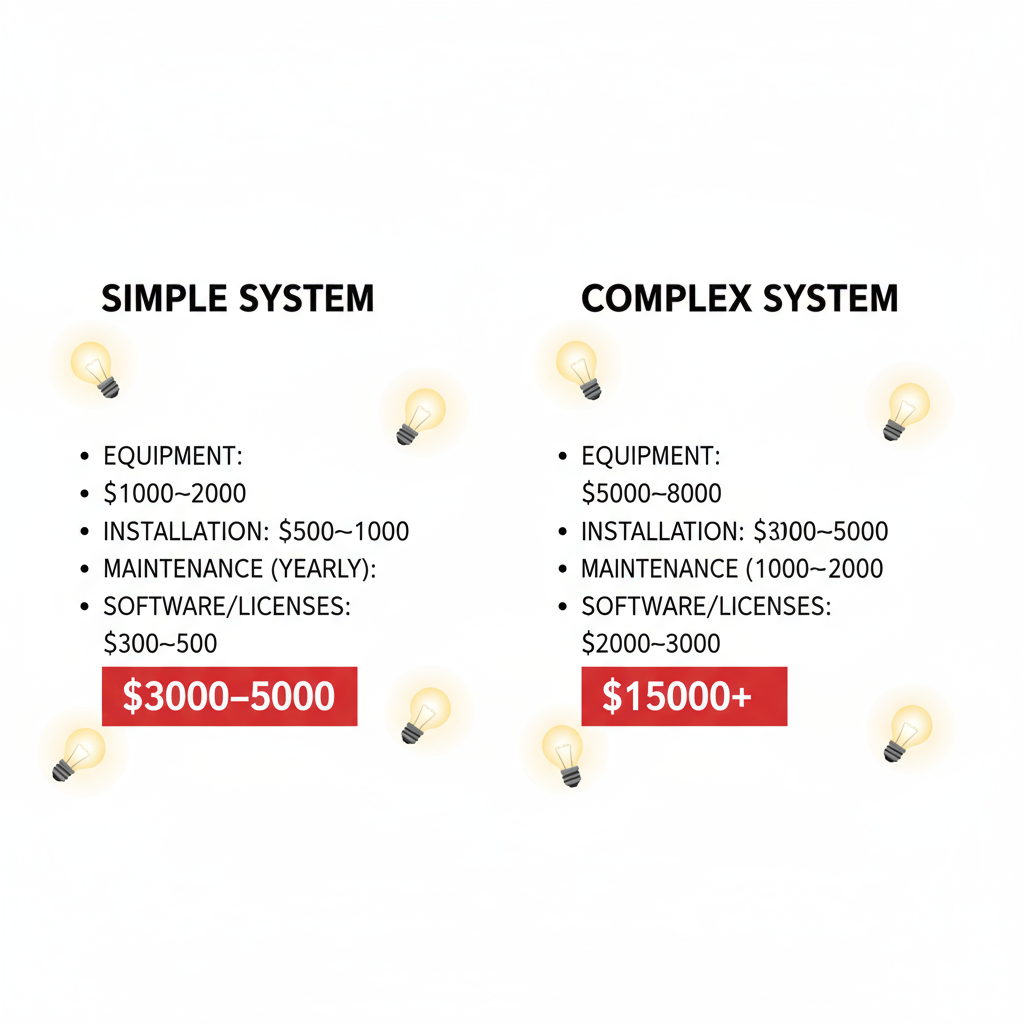

They’re all using LED chips from major manufacturers, such as Samsung, Osram, and Cree. Same suppliers that make chips for warehouses and parking lots. Nothing magical there. The control systems? Most are basic timers set for that 16-hour on, 8-hour off cycle. Some have fancy sensors, but honestly, a good mechanical timer from the hardware store does the same job.

There is one innovation I think is genuinely useful, especially for operations in Northern states or Canada, where winter nights are long. Some newer systems include red lighting for nighttime work. Since cows can’t see deep red wavelengths around 650 nanometers—that’s been documented in vision research—you can check animals, handle emergencies, whatever needs doing, without disrupting their dark period.

For operations running multiple shifts or dealing with calving season, that’s solving a real problem.

But most of the other “advanced features”? I’m not convinced they’re worth the premium. Cows need adequate light for the right number of hours. They’re not greenhouse tomatoes needing specific wavelength ratios.

The Hidden Costs of Upgrading

Here’s what often catches people by surprise when they start looking at lighting upgrades…

Older barns frequently need substantial electrical work to support new lighting systems. According to Wisconsin and Pennsylvania Extension electrical upgrade guides, we’re talking about potential panel upgrades, new wiring, and proper grounding—costs that typically range from $2,000 to $8,000,depending on your existing infrastructure.

And remember, this is all happening in a barn environment. Dust, moisture, ammonia—it’s tough on electronics. Industry experience suggests those fancy digital controllers don’t always hold up as well as simple mechanical timers in these conditions.

Additionally, LEDs have another advantage that is often overlooked. They generate significantly less heat than traditional lighting—about 50% less than metal halide. In summer months, that can make a real difference in barn temperatures, especially in the Southeast and Southwest, where heat stress is already a major concern.

Then there’s what I call the adjustment period. Any time you change routines in the barn, there’s a learning curve. New switch locations, different light patterns, areas that need tweaking. Your cows notice. Your workers notice.

It takes a few weeks to get everything dialed in, and during that time, things can get a bit chaotic.

Making Decisions Based on Reality, Not Hype

So, how do you determine if LED lighting is suitable for your operation?

First thing—measure what you’ve actually got. Get a light meter. They’re generally available for $60 to $100, or see if your Extension office has one to borrow. Measure at the cow eye level, about 4 feet high. Check your feed alleys, resting areas, and holding pens. Do it at different times and in different weather conditions. You need real numbers, not just “seems dark in here.”

Here’s your decision framework:

- Below 50 lux consistently: You’ve definitely got room for improvement

- Between 50 and 100 lux: Could be worth exploring, depending on milk prices and your situation

- Above 150 lux throughout: Your money’s probably better spent elsewhere

And here’s something critical—your herd health matters more than any lighting system. Research consistently shows that stressed cows don’t respond well to photoperiod manipulation.

High somatic cell counts, lameness issues, heat stress—fix those first. The stress hormones will completely override any benefit from better lighting.

Regional Considerations Matter Too

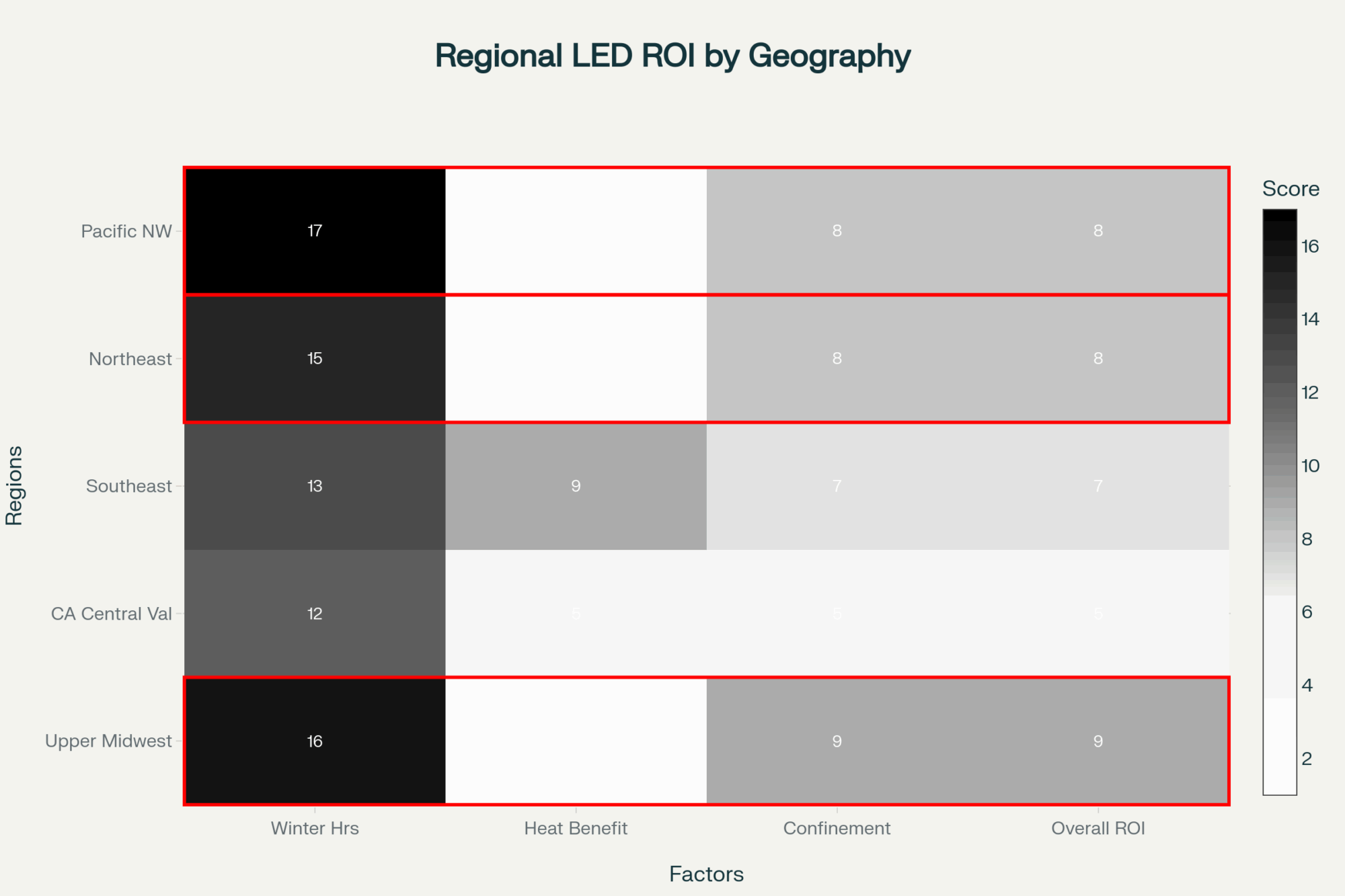

Looking at this from different regional perspectives, the economics change quite a bit.

In California’s Central Valley, where many operations milk year-round in open-sided facilities, the natural photoperiod already provides substantial light exposure during much of the year. The investment math looks different there compared to, say, a tie-stall barn in Vermont, where cows might spend 20 hours a day inside during winter.

Similarly, grazing operations in places like Wisconsin or New York, where cows are on pasture during peak production months, might see less benefit than total confinement operations. It’s not one-size-fits-all, and that’s something lighting companies often overlook.

Down in Georgia or Florida, where I’ve talked with producers dealing with heat stress eight months a year, the reduced heat load from LEDs might actually be more valuable than the photoperiod effects. Those old metal halide fixtures can really add to the heat burden.

I’ve noticed that operations in the Upper Midwest—specifically, Minnesota, Wisconsin, and Michigan—tend to see better returns on lighting investments simply because of those long, dark winters. When your cows are inside from October through April, that extended photoperiod makes a bigger difference.

The Smart Way to Test This

You know what approach makes sense to me? Start small.

Pick your darkest section—maybe that old part of the barn you’ve been meaning to renovate anyway. Install some good-quality LED bulbs—nothing fancy, just solid commercial fixtures. Add a simple timer. Then watch that specific group carefully for six to eight weeks. Document everything.

If you see clear improvement in production, reproduction, or cow behavior, great—expand gradually. No improvement? Well, you’ve learned something valuable without betting the farm on it.

Based on the 8% average production increase Dahl documented, here’s the rough ROI math:

For a 100-cow herd averaging 75 pounds daily at $19/cwt, that’s about $34,000 additional annual revenuefrom a 6-pound increase. Against a $3,000-5,000 simple LED installation (not counting major electrical work), you’re looking at payback in 2-6 months if you hit that average response.

But remember—that’s if you’re starting from poor lighting and your cows actually respond. And those LEDs should last 50,000+ hours, compared to perhaps 10,000 for traditional bulbs, so factor in the replacement savings as well.

Looking Ahead (Reality Check Included)

There’s always talk about what’s coming next in dairy technology. Universities are conducting interesting research—examining whether changes in circadian rhythms might predict health problems before clinical symptoms emerge. Research is exploring connections between light exposure and immune function. Could be valuable someday.

But let’s be realistic about timelines. Most of the “revolutionary” features being promoted are solutions looking for problems to solve. Your cows require adequate light for a sufficient number of hours. Period.

They don’t need smartphone apps, AI optimization, or blockchain-verified lighting schedules. (Yes, that last one’s actually been pitched at trade shows within the past year.)

The Bigger Pattern We’re Seeing

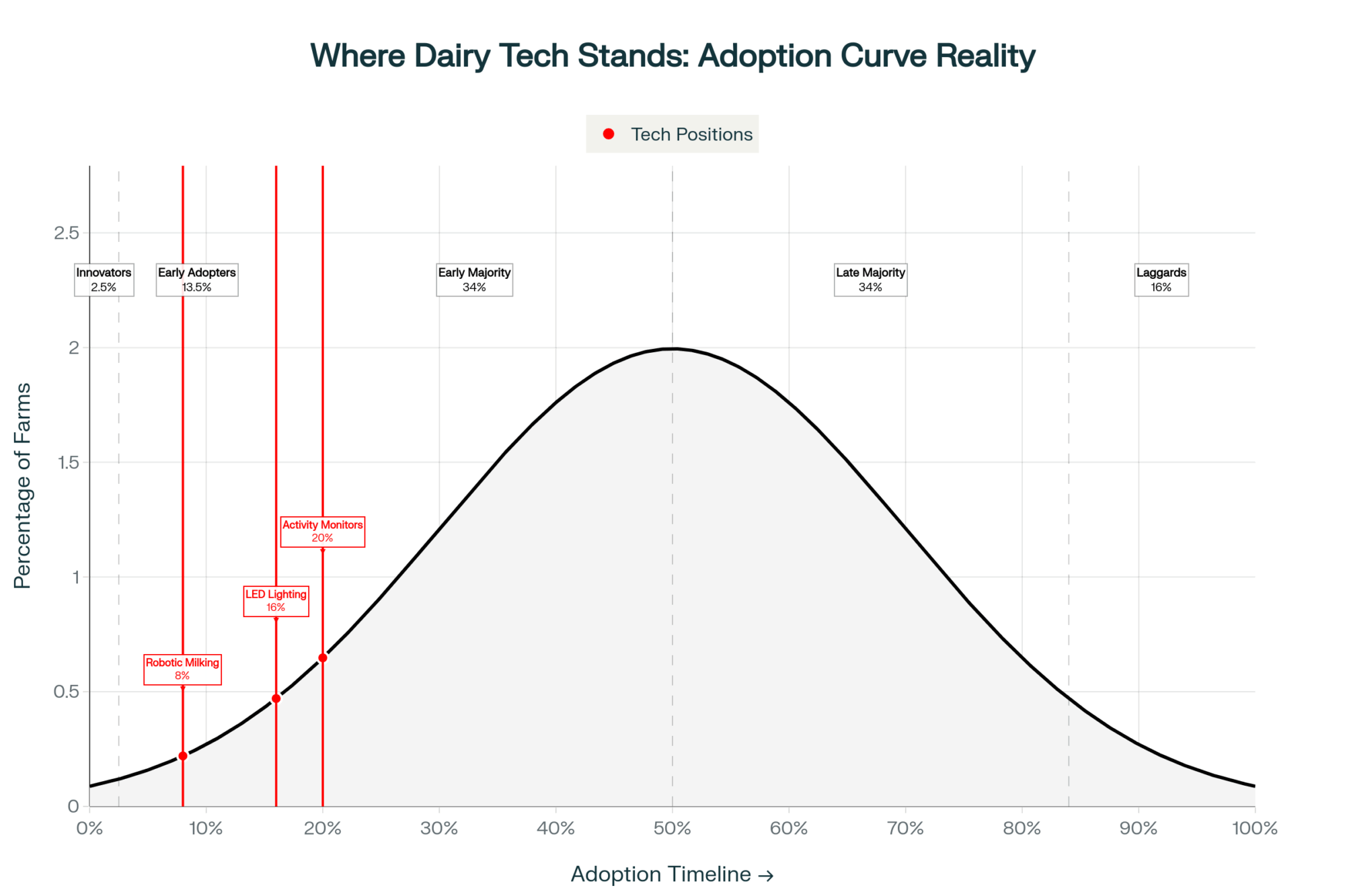

The LED lighting story is just one example of something we see across all dairy technology. Robotic milkers, activity monitors, precision feeding systems—same pattern every time. Proven benefits, but adoption stays low for years, sometimes decades.

Why? Well, most of us get maybe three or four decades of active farming decisions. Every technology bet risks one of those limited opportunities. That creates what I’d call justified caution, especially when margins are as tight as they’ve been.

It’s not that we’re against change. We’re against unnecessary risk.

What actually drives technology adoption in dairy? Usually, it’s either a crisis—something that forces efficiency improvements—or a generational change that brings fresh perspectives and possibly different risk tolerance.

Without those pressures, change happens slowly. And you know what? Given the stakes, maybe that’s not entirely wrong.

Your Next Steps (The Practical Ones)

This week, if you’re curious about your lighting situation, do some actual measuring. Get real numbers, not impressions. Our eyes adapt to low light better than we realize—what seems adequate to us might be way below what the cows need for optimal response.

Take an honest look at your management basics, too. How’s herd health tracking? Are your fresh cow protocols dialed in? Is nutrition optimized for your production level? If these aren’t solid, lighting won’t be your limiting factor.

If everything else looks good and your lighting truly is inadequate—we’re talking those sub-50 lux measurements—consider a small trial. Keep it simple, keep it affordable, and let actual results from your own cows guide you.

For those in transition planning or considering major renovations, that’s actually the ideal time to address lighting. When you’re already doing electrical work, adding proper lighting doesn’t add as much proportional cost. However, even then, simplicity often beats complexity.

Many states offer energy efficiency rebates through utility companies that can cover 20-40% of the costs associated with upgrading to LED lights. It’s advisable to check with your local provider before proceeding with any installation.

The Real Lesson Here

What strikes me most about the entire LED lighting question is what it reveals about how our industry actually operates.

We’re not early adopters by nature, and there’s good reason for that. Every decision matters when you’re working with tight margins and biological systems that don’t forgive mistakes easily. Simple solutions that address real problems tend to work better than complex systems that promise to optimize everything.

The research on photoperiod manipulation is solid—Dahl’s work and others have proven that beyond doubt. The biology is real. But whether it make sense for your specific operation? That depends on your starting point, your management, your finances, and honestly, your comfort level with change.

Good dairy farming has always been about careful observation, testing what works, and scaling based on actual results—not projections or promises, but real, measurable results from your own operation. That approach has served us well for generations.

So maybe the fact that most barns still have old lighting isn’t about stubborn farmers resisting change. Maybe it’s about thoughtful operators who’ve learned that in dairy, the shiniest new technology isn’t always the best investment.

Sometimes the old ways work just fine. Sometimes they don’t. And knowing the difference? Well, that’s what separates good managers from the rest.

After all, if simple LED bulbs and a timer can deliver results similar to systems costing ten times more—and the research suggests they often can—then maybe we’re not behind the times. Maybe we’re just experienced enough to know the difference between what actually works and what’s just expensive.

And that wisdom? That’s worth more than any lighting system you could buy.

KEY TAKEAWAYS

- Measure first, invest second: Get a $60-100 light meter and check your barn at cow eye level—if you’re above 150 lux throughout, save your money for other improvements; below 50 lux means genuine opportunity for that 8% production boost

- Simple beats complex for most operations: Basic LED bulbs with mechanical timers ($3,000-5,000) deliver results matching systems costing 3-10X more, especially given that only 30-40% of cows respond strongly to photoperiod manipulation anyway

- Regional economics vary significantly: Upper Midwest operations see better ROI due to long winters keeping cows inside October-April, while California’s open-sided facilities and grazing operations in Wisconsin/New York may see minimal benefit during peak production months

- Test with your darkest section first: Install LEDs in one area, monitor that group for 6-8 weeks, then expand only if you see clear improvement—this approach minimizes risk while providing farm-specific data

- Factor in hidden costs and benefits: Budget $2,000-8,000 for electrical upgrades in older barns, but remember LEDs generate 50% less heat than metal halides (valuable in the Southeast) and last 50,000+ hours versus 10,000 for traditional bulbs

EXECUTIVE SUMMARY

What farmers are discovering through the adoption of LED barn lighting tells us something profound about how dairy technology really takes hold—or doesn’t. Research conducted by Dr. Geoffrey Dahl at the University of Florida indicates that 16-18 hours of proper lighting can increase production by 8% through hormonal changes, with IGF-1 levels rising 15-30% and prolactin levels increasing 25-40%. Yet despite two decades of solid science, most barns still run fixtures from the 1980s. Here’s what’s interesting: the farms seeing real returns are those starting with genuinely poor lighting—below 50 lux—who use simple, timer-controlled LEDs costing $3,000 to $ 5,000, not complex systems costing $ 15,000 or more. With individual cows showing 10-fold variation in light response (documented by Dr. Dong-Hyun Lim’s 2021 research), chasing optimization through expensive technology makes less sense than accepting biology’s messiness and sticking with proven basics. Looking ahead, this pattern—where simple solutions match complex ones—repeats across dairy technology adoption, suggesting we’re not resistant to change but appropriately cautious about unnecessary risk. The opportunity’s clear: measure your actual lighting this week, test small if you’re below 50 lux, and let your own cows’ response guide expansion decisions.

Complete references and supporting documentation are available upon request by contacting the editorial team at editor@thebullvine.com.

Learn More:

- 5 Technologies That Will Make or Break Your Dairy Farm in 2025 – This article provides a tactical blueprint for implementing other key technologies, revealing specific ROI timelines and cost-saving metrics for precision feeding, health monitoring, and calf care, extending your understanding beyond lighting.

- AI and Precision Tech: What’s Actually Changing the Game for Dairy Farms in 2025? – Get a strategic market perspective on the financial forces driving technology adoption, including projected market growth and how AI can provide a competitive edge in a volatile industry.

- Robotic Milking Revolution: Why Modern Dairy Farms Are Choosing Automation in 2025 – As a powerful case study, this article provides a deep dive into the practical benefits of robotic milking, with real data on labor savings and production increases, demonstrating how a single innovation can transform an entire operation.

Join the Revolution!

Join the Revolution!

Join over 30,000 successful dairy professionals who rely on Bullvine Weekly for their competitive edge. Delivered directly to your inbox each week, our exclusive industry insights help you make smarter decisions while saving precious hours every week. Never miss critical updates on milk production trends, breakthrough technologies, and profit-boosting strategies that top producers are already implementing. Subscribe now to transform your dairy operation’s efficiency and profitability—your future success is just one click away.

Join the Revolution!

Join the Revolution!