$1,000 lost per production run? Most processors don’t even know their aseptic milk is bleeding money through protein settling.

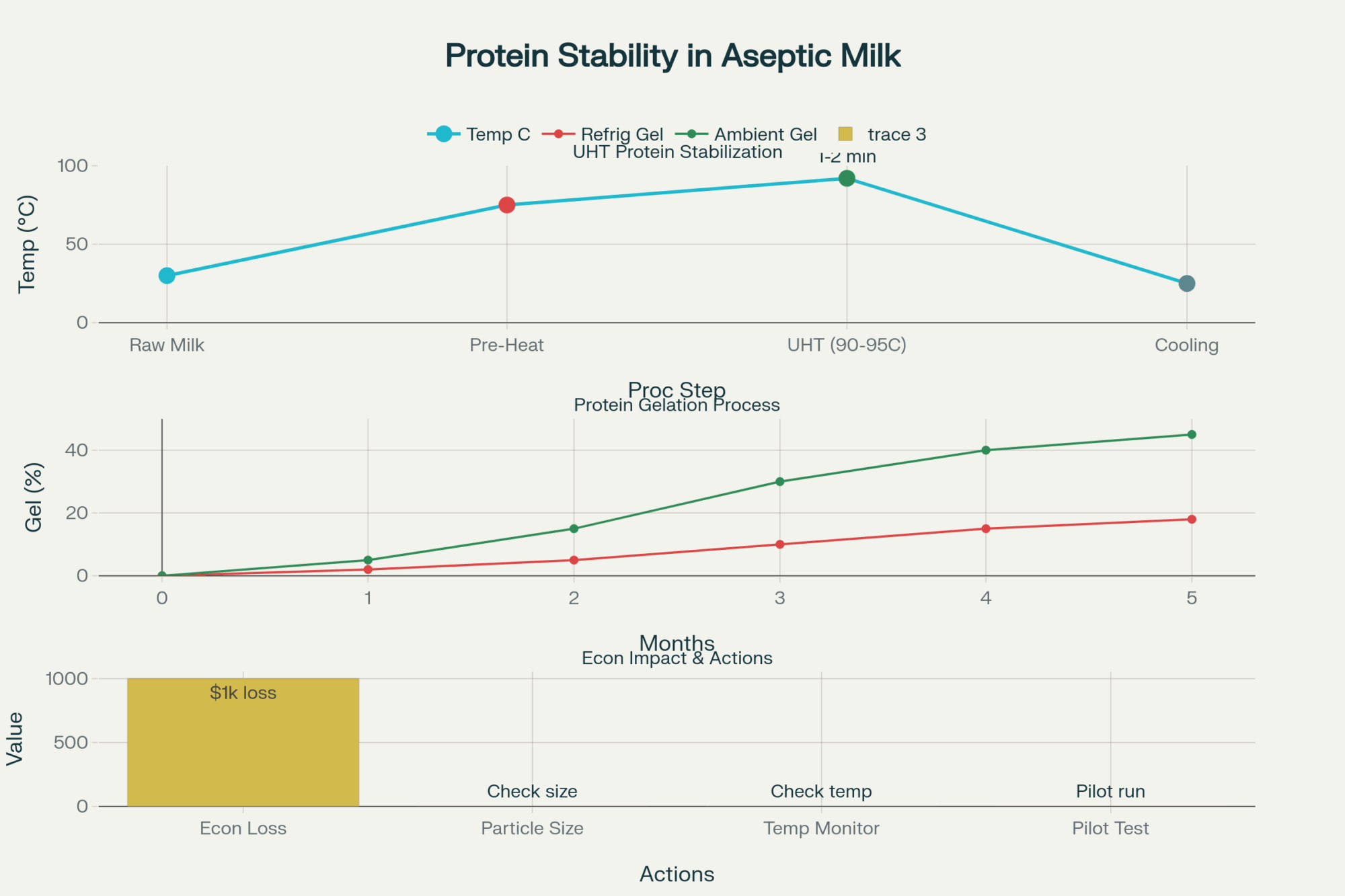

EXECUTIVE SUMMARY: Look, here’s something that’ll make your coffee go cold… most dairy processors are losing product volume and failing spec compliance because of protein stability issues they can’t even see happening. We’re talking about a 0.5% volume loss on a 50,000-gallon run that equals $1,000 straight out of pocket—and that’s conservative. With Class III sitting around $18.50 per hundredweight and over $8 billion in new processing infrastructure coming online, this blind spot is costing serious money. The Journal of Dairy Science just published research showing that UHT processing creates protein complexes that settle out during storage, whether you’re keeping it cold or at room temperature. What’s crazy is there’s a simple fix—protein stabilization at 90-95°C for just 1-2 minutes can extend shelf life by 5-30 days. You need to get your quality team on particle size analysis yesterday, because the processors figuring this out first are going to separate themselves from the pack.

KEY TAKEAWAYS

- Catch the problem before customers do — Add particle size analysis to your standard QC protocols to detect protein aggregation weeks before visible gelation occurs, potentially saving 2-3% of sellable volume with 2025’s tight margins

- Implement the 90-day action plan now — Start with temperature monitoring audits and pilot test protein stabilization heating (90-95°C for 1-2 minutes) on one product line to see measurable shelf life improvements within your first quarter

- Turn quality into competitive advantage — Operations implementing these protocols are securing premium contracts with major buyers who cite product consistency as a deciding factor, especially critical with $8+ billion in new processing capacity creating intense competition

- Stop losing money on invisible problems — Track protein degradation patterns in retained samples to identify the $1,000+ losses per production run that most QC systems never flag, giving you data to justify equipment upgrades and process changes

- Get ahead of the curve on industry standards — With feed costs at multi-year lows but protein quality becoming the differentiator, plants mastering stability management will set tomorrow’s industry benchmarks while others are still playing catch-up

You know what keeps me up at night? It’s not just the usual stuff—Class III prices sitting around $18.50 per hundredweight, feed costs, labor shortages. It’s this protein stability issue in aseptic milk that most processors don’t even realize is happening. And trust me, it’s costing real money.

I was talking to a guy who runs a mid-sized cooperative in Wisconsin last month—they process around 30 million pounds of milk weekly—and they’re losing product volume to something they can’t even see coming. Their aseptic milk looks perfect, passes every safety test, meets every regulatory standard… but there’s this protein degradation happening during storage that’s literally eating into their margins. The plant manager, who has been in the business for twenty years, had no idea this was even a thing until they started tracking it properly.

What’s Really Going on Here (And Why Nobody’s Talking About It)

The thing about protein stability research—it’s been turning everything we thought we knew upside down. According to recent work by Pranata and colleagues in the Journal of Dairy Science, they tracked commercial 1% aseptic milk for a full 12 months, examining both refrigerated (4°C) and ambient (21°C) storage conditions. And what did they find? It challenges nearly every assumption we’ve been operating under.

Here’s where it gets interesting… and expensive. We’ve all been focused on enzyme activity, right? Those proteases that supposedly break down proteins during storage. But this research showed zero—and I mean zero—evidence of proteolysis from native milk proteases or heat-stable microbial proteases during storage.

What’s actually happening is way more complex than most of us realized. The UHT process itself creates heat-induced disulfide bonds between whey proteins and κ-casein at the surface of the casein micelle. This forms larger, more hydrophilic protein complexes that change entirely how the milk behaves during storage. What’s fascinating is that the research shows storage time creates these nonlinear effects across all the major protein fractions.

And here’s the kicker… both refrigerated storage and ambient storage end up at the same place—complete gelation. The cold just slows it down. So much for thinking refrigeration would solve everything.

Why This Hits Your Bottom Line Harder Than You Think

| Production Run Size (gallons) | Volume Loss (0.5%) | Volume Lost (gallons) | Dollar Loss (@$4.00/gal) | Weekly Loss (5 runs) | Annual Loss (260 runs) |

|---|---|---|---|---|---|

| 10,000 | 0.5% | 50 | $200 | $1,000 | $52,000 |

| 25,000 | 0.5% | 125 | $500 | $2,500 | $130,000 |

| 50,000 | 0.5% | 250 | $1,000 | $5,000 | $260,000 |

| 75,000 | 0.5% | 375 | $1,500 | $7,500 | $390,000 |

| 100,000 | 0.5% | 500 | $2,000 | $10,000 | $520,000 |

Financial impact of protein settling losses across different production scales, assuming conservative 0.5% volume loss at $4.00 per gallon milk value.

Here’s what’s happening—these protein complexes settle out and form gel layers that stick to package bottoms. The liquid that pours out? Reduced protein concentration. You’re losing sellable volume and failing spec compliance at the same time.

Let me put this in perspective. Consider a production run of 50,000 gallons… even a conservative 0.5% volume loss due to protein settling in packaging equates to 250 gallons of lost product. At a value of $4.00 per gallon, that’s a $1,000 loss on a single run that most QC systems would never even flag.

Now multiply that across your weekly production schedules.

With more than $8 billion in dairy processing infrastructure investment happening right now—I mean, we’re talking about a complete transformation of processing capacity—everyone’s competing harder for consistent product quality. What’s particularly frustrating? Feed costs are at multi-year lows, which should provide us with some breathing room on margins. However, if you’re losing product volume and spec compliance due to protein settling, those feed cost savings disappear quickly.

Here in the upper Midwest, where we’re dealing with longer haul distances to processing plants, this becomes even more critical. Operations I’ve visited in Minnesota and Iowa are seeing this issue compound during peak summer months when ambient temperatures stress the cold chain… and honestly, nobody’s tracking it systematically. It’s one of those blind spots that’s costing more than we realize.

What’s particularly challenging down in places like Texas and Arizona is dealing with extreme temperature swings during transport. I’ve seen plants struggle more with this issue during the summer months, when ambient temperatures can reach 110°F and stress even the best refrigerated systems.

What Smart Operations Are Starting to Do

| Testing Method | Traditional Approach | Enhanced Approach | Detection Timeline | Implementation Cost | Effectiveness |

|---|---|---|---|---|---|

| Visual Inspection | End-stage gelation only | Visual + early warning | 8-12 weeks vs 2-4 weeks | Low | Basic vs High |

| Compositional Testing | Standard protein analysis | Protein + particle size | Weekly vs Daily | Medium | Limited vs Comprehensive |

| Temperature Monitoring | Key checkpoints only | Continuous cold chain | Reactive vs Proactive | Medium | Reactive vs Preventive |

| Shelf Life Testing | Standard microbial focus | Protein stability tracking | End-point vs Progressive | High | Limited vs Predictive |

| Process Controls | Basic UHT sterilization | UHT + protein stabilization | Standard vs Optimized | High | Standard vs Enhanced |

First thing? Your quality control protocols need updating, and I mean yesterday. Traditional testing methods completely miss the early stages of protein complex formation. This stuff happens long before you see visible gelation. You should discuss with your lab the possibility of adding particle size analysis to your standard compositional testing. It’ll catch protein aggregation before your customers start calling… and trust me, you don’t want those calls.

The processing side is where things get really interesting, though. There’s some fascinating work in Chinese patent research on UHT optimization showing that protein stabilization steps can make a real difference. We’re talking controlled heating at 90-95°C for just 1-2 minutes between homogenization and UHT sterilization. The results? Shelf life extension of 5-30 days. That’s not trivial when you’re managing inventory and distribution costs.

According to industry observations, processors who’ve implemented this approach are seeing significant reductions in complaints within six months. One operation I know mentioned that they secured a new contract with a major coffee chain, which cited product consistency as a key factor in their decision—that’s the kind of competitive advantage this creates when you get ahead of the curve.

Equipment-wise, advanced aseptic packaging with dry preform sterilization technology is showing real promise. Yeah, these systems require substantial capital investment, but current trends suggest favorable payback periods based on reduced product losses and premium pricing opportunities. The reduced thermal stress during packaging results in less protein complex formation from the outset. Some plants are reporting measurably better stability with these systems… though I’d caution that it’s still early days for ROI data.

And here’s something most operations haven’t thought about yet—your distribution strategy needs to account for protein degradation timelines, not just microbial safety windows. First-in-first-out rotation should consider protein stability alongside production dates. This is becoming more common in the Southeast, where summer heat stress compounds the problem.

Quick Implementation Checklist

Week 1: Get your quality team up to speed on particle size analysis protocols

Week 2: Review current temperature monitoring throughout your entire cold chain

Week 3: Audit product loss data for patterns correlating with storage time

Week 4: Arrange equipment supplier demos for detection upgrades

The Technical Reality (And What It Actually Costs You)

What strikes me about this research is how it completely changes our approach to monitoring. The κ-casein-whey protein complexes increase in the serum phase while your gel layers get enriched with the more hydrophobic caseins. This creates a separation pattern that gives you early warning signals… if you know what to look for.

Temperature management remains crucial, but now we understand that we’re controlling rates, not preventing the problem entirely. Recent research confirms that processing temperatures have a significant impact on protein stability, making upstream temperature control just as important as storage conditions.

But let’s be honest about the costs. Energy expenses for maintaining precise temperature control represent significant operational costs, especially with electricity prices hitting operations harder than ever. You have to balance quality management investments against operational expenses, and that calculation becomes tricky when dealing with infrastructure that may last 15-20 years.

Staff training is another consideration—these detection methods require technical expertise for accurate interpretation. Equipment calibration, maintenance, and ongoing monitoring all add up to operational requirements that plant managers need to build into standard protocols.

From industry observations, I’ve seen as many as a third of operations struggle initially with the technical complexity of these changes. The key insight? Start with one or two modifications rather than overhauling everything at once. The plants that try to implement everything simultaneously often end up with more problems than they started with.

What’s particularly interesting is how this varies by region. Plants in the Pacific Northwest, where temperatures are more stable year-round, seem to have an easier time with implementation compared to those in operations dealing with extreme seasonal swings in the upper Midwest or desert Southwest.

The Competitive Edge (If You Move Fast)

Here’s the thing, though—this research fundamentally changes how we should think about aseptic milk quality management. Instead of just focusing on preventing enzyme activity, successful operations will manage the consequences of heat-induced protein modifications that occur during processing itself.

The opportunity is real for processors willing to invest in better process control and monitoring systems. Understanding these protein complex formation mechanisms enables you to make targeted interventions that maintain functionality for a longer period. That translates directly to premium pricing support and reduced product losses.

What’s particularly encouraging is the industry optimism about 2025 profitability prospects. Producers and processors alike are recognizing that competitive advantages increasingly depend on operational sophistication and quality management capabilities… and this protein stability issue represents exactly that kind of opportunity.

We can’t keep assuming that achieving sterility ensures consistent quality throughout labeled shelf life—that thinking’s outdated now. Protein quality management needs the same priority as microbial safety protocols. The operations that get this right will have significant competitive advantages as industry awareness develops and consumer quality expectations keep rising.

What’s fascinating is how this connects to the broader trend toward component optimization we’re seeing across the industry. Plants that master protein stability management are also better positioned to capitalize on the higher component values everyone’s chasing.

This development is particularly noteworthy because it gives smaller and mid-sized processors a chance to differentiate themselves through quality rather than just competing on volume and price. That’s huge in today’s market environment.

Your 90-Day Action Plan (With Reality Checks)

Look, the research is clear on this—protein stability issues in aseptic milk are real, they’re costing money, and most operations haven’t even identified the problem yet. But here’s the thing… understanding these mechanisms gives you options.

I was talking to a plant manager in California just last week. They’ve started implementing some of these monitoring approaches, and they’re catching quality issues weeks before they would have in the past. That’s the kind of operational intelligence that separates the leaders from the followers.

Day Zero: Build the Coalition

Convene a 1-hour meeting with your heads of Quality, Operations, and Finance. Present the core findings to get cross-functional buy-in on the need to investigate. You need everyone aligned before you start changing protocols… trust me on this one.

First 30 days: Task your Head of Quality to arrange a demo or training on particle size analysis with your lab equipment supplier. Assign your lead lab technician to begin tracking protein degradation patterns in retained samples. Review and improve temperature monitoring protocols throughout the cold chain—not just at key points, but continuously. Audit product loss data for patterns correlating with storage time.

Expect some pushback here. Quality teams are busy, and adding new testing protocols feels like more work without an immediate payoff. But the data will speak for itself once you start collecting it.

Days 30-60: Start pilot testing on a single, representative product line (e.g., 1% UHT white milk) using the protein stabilization heating step. Monitor stability over 90 days by comparing it against control runs using standard processing. Train lab and quality staff on new detection methods.

This is where things get interesting. You’ll probably see some unexpected results in your first pilot runs—that’s normal. The key is tracking everything meticulously so you can identify patterns.

Days 60-90: Scale up implementation based on pilot results. Conduct a detailed ROI analysis for advanced packaging upgrades tailored to your specific production needs. Assign a project manager to lead the packaging upgrade evaluation and potential capital investment decisions.

By this point, you should have enough data to make informed decisions about larger investments. The plants that systematically move through this process tend to have much better outcomes than those that skip straight to equipment purchases.

Success Benchmarks: You’re looking for a 10-15% reduction in customer complaints, 2-3% improvement in sellable volume, and measurable extension of functional shelf life within the first quarter.

The producers and processors who move quickly on this—updating quality protocols, optimizing processing parameters, and investing in better monitoring systems—they will separate themselves from the pack. Because while everyone else is still thinking about protein stability the old way, you’ll be managing it based on what the science actually shows.

That’s the kind of competitive edge that translates directly to the bottom line… and in this market, we need every advantage we can get. The operations that embrace this challenge now will be the ones setting industry standards two years from now.

Further Reading: Pranata, J., et al. (2025). Effects of Storage Time and Temperature on the Protein Fraction of Aseptic Milk. Journal of Dairy Science.

Learn More:

- Unlock Hidden Profits: The Dairy Producer’s Guide to Maximizing Component Value – This guide provides tactical strategies for maximizing the value of milk components at the source. It reveals how a deeper understanding of protein and fat economics drives profitability, reinforcing the high cost of the product losses discussed in our main article.

- Dairy’s Trillion-Dollar Opportunity: Navigating the Future of Food – Go beyond the plant floor with this strategic market analysis. It details the consumer trends and economic forces driving industry growth, putting the main article’s call for investment in quality control and innovation into a broader, forward-looking business context.

- Robots in the Dairy Aisle: The Automation Revolution Transforming Processing – Explore the cutting-edge technology changing dairy processing. This piece showcases how automation is delivering the process control and consistency needed to solve complex quality challenges, providing a real-world look at the advanced systems our main article recommends investigating.

Join the Revolution!

Join the Revolution!

Join over 30,000 successful dairy professionals who rely on Bullvine Weekly for their competitive edge. Delivered directly to your inbox each week, our exclusive industry insights help you make smarter decisions while saving precious hours every week. Never miss critical updates on milk production trends, breakthrough technologies, and profit-boosting strategies that top producers are already implementing. Subscribe now to transform your dairy operation’s efficiency and profitability—your future success is just one click away.

Join the Revolution!

Join the Revolution!