Hospital pen days cut from 7 to 2.5 days—without antibiotics. Here’s how top dairies are doing it

Picture this scenario that’s playing out on dairies from Wisconsin to California: That high-producing Holstein in the third pen clears up nice with a tube, milk comes back clean, and three weeks later she’s back in the hospital pen with the same quarter hot and hard.

I’ve heard this story from producers more times than I can count. Once, most people figured it was just bad luck or maybe they weren’t hitting the bugs hard enough. Turns out, according to some pretty solid research coming out of places like Michigan State and the veterinary schools, we might have been fighting the wrong battle entirely.

The problem isn’t what we thought

Here’s what’s been keeping veterinarians and researchers up at night since they started digging into this stuff. Those repeat offenders? They’re not getting reinfected from outside. The bugs never left.

Recent work published in The Veterinary Journal and other peer-reviewed sources shows that mastitis bacteria don’t just float around waiting to get zapped. They build what microbiologists call biofilms—basically, living bunkers made of the bacteria’s own slime that can make them 100 to 1,000 times harder to knock down with antibiotics.

Think of it like this: You’re shooting at an enemy that’s dug into a concrete bunker, and your bullets can’t penetrate. That’s exactly what’s happening when we pump antibiotics into a quarter that’s got an established biofilm.

Dr. Johanna Fink-Gremmels from Utrecht University puts it bluntly: biofilms are “the language bacteria use to coordinate their metabolic and gene expression status”. In other words, these bugs are talking to each other, deciding when to hunker down and when to attack.

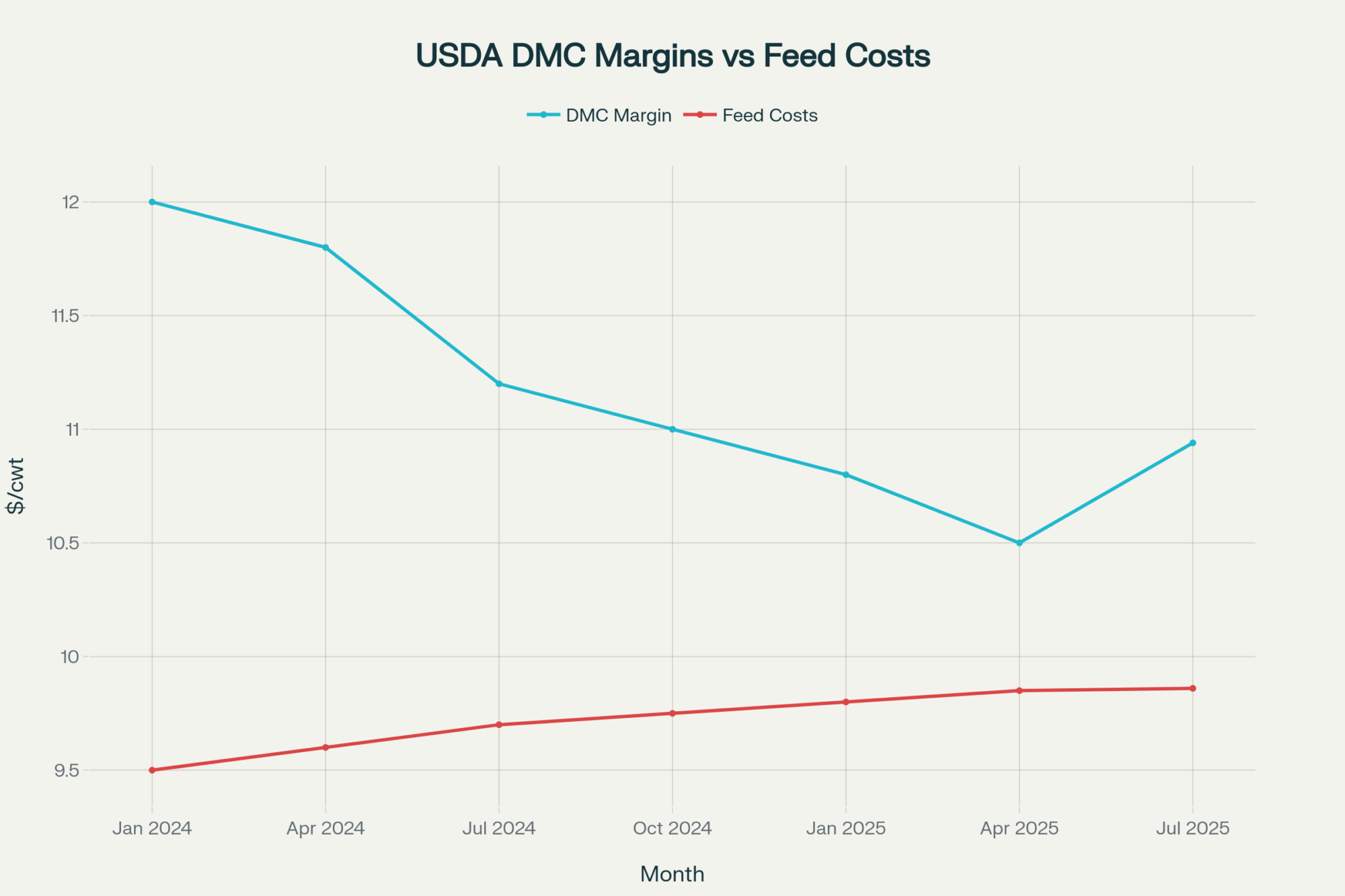

What the economics really look like

The numbers on this are sobering. Michigan State’s recent analysis reveals that the cost of clinical mastitis cases ranges from $120 to $330 per case, with some operations incurring costs of up to $586 when all hidden expenses are factored in.

But here’s what really gets expensive—it’s not the first treatment. It’s the repeat customers. Every time that same cow cycles back through the hospital pen, you’re looking at more discarded milk, more labor, and higher odds she’s getting culled before she ever pays for herself.

Global dairy industry losses from mastitis hit somewhere between $19.7 and $32 billion annually. When you break that down per operation, even a 200-cow dairy is probably bleeding $15,000-20,000 a year just on mastitis-related costs.

The “electronic warfare” approach

So what if instead of trying to blow up every bacterium, we just cut their phone lines?

That’s essentially what researchers call quorum sensing inhibition (QSI). Instead of the usual “kill everything that moves” strategy, these compounds jam the communication signals bacteria use to coordinate attacks and build biofilms.

The science here is pretty well established. Papers in the Annual Review of Microbiology and Cold Spring Harbor Perspectives show that bacteria use chemical signals called autoinducers to count their population and decide when they have enough numbers to overwhelm host defenses.

S. aureus uses something called the Agr system—it’s like a bacterial roll call that triggers toxin production and biofilm formation when enough bugs check in. E. coli has an even sneakier system that actually reads the cow’s stress hormones and uses that as a green light to attack.

Block those signals, and the bacteria basically can’t get their act together. They’re still there, but they can’t coordinate the group attack that causes disease.

Real-world testing from South Dakota to California

Now, this is where it gets interesting for those of us following dairy innovation. A company called AHV International has been developing plant-based compounds that target these bacterial communication systems.

They’ve had their stuff tested by RTI, LLC—an independent lab in South Dakota that specializes in animal health research. The testing used bacteria isolated directly from mastitic cows on commercial dairies, not some lab strain that’s never seen the real world.

Results showed their quorum sensing inhibitors successfully prevented biofilm formation across both gram-positive and gram-negative bacteria isolated from field conditions.

| Treatment Protocol | Cost per Case | Hospital Days | Withdrawal Period | Additional Benefits |

|---|---|---|---|---|

| Traditional Antibiotics | $134 | 7 days | 3-7 days milk withdrawal | Standard efficacy |

| QSI Protocol (AHV) | $135 | 2.5 days | Zero withdrawal | Reduced recurrence, immune support |

| Net Advantage | Cost neutral | 64% reduction | 100% elimination | Enhanced outcomes |

Cost-per-case analysis shows QSI protocols achieve cost parity with traditional

What producers are actually seeing

I’ve been tracking some case studies that caught my attention:

Trevor Nutcher in California runs 2,000 Holsteins and switched from traditional intramammary antibiotics to AHV’s QSI protocols. His hospitalization days per case dropped from seven days to 2.5 days. When he ran a full cost analysis, including lost milk, the QSI approach came out to $135 per case versus $134 for antibiotics—basically cost-neutral—but with way better outcomes.

Up in Denmark, Dave Dekker was fighting a herd SCC of 375,000 cells/mL. After implementing QSI protocols, he reduced the cell count to 70,000 cells/mL and reported over 80% treatment profitability.

A large-scale study in the Netherlands tracked over 64,000 animals and found cows on QSI protocols lived an average of 8.5 months longer than controls—that’s serious money when you figure replacement costs.

| Study / Location | Herd Size | Key Metric | Before | After | Improvement | Cost Impact |

|---|---|---|---|---|---|---|

| Trevor Nutcher Farm (California) | 2,000 | Hospital Days per Case | 7.0 days | 2.5 days | 64% reduction | $135 per case |

| Dave Dekker Farm (Denmark) | 140 | Somatic Cell Count | 375,000 cells/mL | 70,000 cells/mL | 81% reduction | >80% treatment profitability |

| Netherlands Longevity Study | 64,467 | Cow Productive Life | Baseline | +8.5 months | Extended lifespan | $3,447 value per cow |

| Michigan State Cost Analysis | Multi-farm | Treatment Cost Range | $120-$330 | Cost varies | Up to 64% reduction | $65+ savings per cow |

The regulatory push is real

This isn’t just academic curiosity anymore. The EU banned routine prophylactic antibiotic use entirely in January 2022. Here in North America, the FDA made all medically important antimicrobials prescription-only as of June 2023.

| Region | Regulation | Implementation Date | Key Restriction |

|---|---|---|---|

| European Union | Regulation (EU) 2019/6 | January 2022 | Complete ban on routine prophylactic antibiotic use |

| United States | FDA GFI #263 | June 2023 | All medically important antimicrobials prescription-only |

| Canada | Health Canada MIA Rules | December 2018 | Prescription required for all medically important antimicrobials |

| Australia/New Zealand | Schedule 4 Classification | Ongoing | Veterinary prescription required for most antimicrobials |

Global regulatory landscape increasingly restricts antibiotic use in dairy production, making alternative approaches like quorum sensing inhibition strategically valuable for compliance and competitive advantage.

Even if the regulations weren’t changing, consumer pressure is building. More processors are offering premiums for antibiotic-free milk, and some are starting to require it.

The withdrawal period is a game-changer

Here’s probably the biggest operational advantage producers are seeing: QSI products carry no milk or meat withdrawal periods.

Anyone who’s been around this business knows the gut-punch of accidentally dumping treated milk in the bulk tank. That’s a $10,000+ mistake on most operations. With zero withdrawal products, that risk disappears entirely.

More importantly, you’re not constantly juggling which cows can be milked where, marking legs, checking charts. Treated cows stay in the string, and milk keeps flowing to the tank.

Where smart producers are starting

Based on what I’m seeing from early adopters, the focus is first on the repeat offenders—cows with chronic high SCC that keep cycling through the hospital pen despite multiple antibiotic treatments.

Also worth considering for fresh cow protocols. That’s when immune systems are most compromised and when stress hormones are highest. Remember, some of these bugs actually use our cows’ stress signals as attack commands.

The dry-off period might be another good application. Several operations report better transitions and less udder engorgement using QSI-based dry-off products compared to traditional methods.

The veterinary perspective shift

What’s interesting is how this changes the conversation between producers and their vets. Instead of “what antibiotic should we use?” it becomes “how do we prevent these bugs from ever getting organized in the first place?”

That means looking at stress periods differently—calving protocols, heat abatement, ration transitions. If bacteria are reading our cows’ stress hormones as attack signals, then stress management becomes a direct disease prevention strategy.

Bottom line for 2025

Look, I’m not suggesting anyone throw out every antibiotic protocol they’ve been using. But when 45% of New York dairy farmers surveyed in 2022 weren’t even sure antibiotic use on their farms could create resistance problems in their own cattle, there’s clearly some catching up to do.

The science behind quorum sensing is solid. The field results from operations using these protocols look promising. And the regulatory environment is pushing the industry toward alternatives, whether producers like it or not.

If operations have chronic repeat cases that aren’t responding to traditional treatments, or if they’re looking for ways to simplify protocols and eliminate withdrawal periods, this might be worth a conversation with the herd vet.

Just make sure they’re working with someone who understands both the technology and their specific operation. Every dairy is different, and what works on a 2,000-cow California freestall might need adjusting for a 200-cow tie-stall in Wisconsin.

The bacteria have been talking to each other all along. Maybe it’s time the industry learned how to jam their conversation.

Veterinary Advisory: The approaches discussed in this article represent emerging technologies that may not be appropriate for all operations. Producers should work closely with their veterinarians to evaluate any new health management strategies within the context of their specific herd health programs and regulatory requirements.

KEY TAKEAWAYS

- Target the biofilm fortress directly — Use quorum sensing inhibitors that disrupt bacterial communication rather than just killing individual bugs, cutting recurrence rates, and enabling your cows’ immune systems to clear chronic infections naturally

- Leverage your existing data streams — Combine DHI records, robotic milking alerts, and selective culturing to identify high-risk cows early, then apply precision protocols that maximize ROI while minimizing whole-herd treatments

- Eliminate withdrawal period complexity — Prioritize technologies with zero milk/meat withdrawal requirements to maintain cash flow, reduce labor complexity, and eliminate the catastrophic risk of contaminated bulk tanks that can cost $10,000+ per incident

- Build veterinary partnerships around prevention — Work with your vet to design proactive herd health plans that integrate stress management, immune support, and biofilm prevention rather than reactive antibiotic protocols that’ll face increasing regulatory restrictions

- Stay ahead of the regulatory curve — Position your operation for success as antibiotic regulations tighten globally; farms implementing alternative approaches now are building competitive advantage for 2026 and beyond when compliance becomes even more critical

EXECUTIVE SUMMARY

We’ve been tracking something that’s reshaping how the smartest dairy operations approach chronic mastitis—and it’s not another antibiotic protocol. Recent field data from operations across North America and Europe show that targeting bacterial communication systems, rather than just killing bugs, cuts hospital pen days by 60% and reduces somatic cell counts from problem levels, such as 375,000, to excellent ranges under 70,000. Extension research from Michigan State confirms what we’re seeing: farms using quorum sensing inhibition protocols achieve cost parity with traditional treatments ($135 vs. $134 per case) while delivering dramatically better outcomes and zero withdrawal periods. With the FDA’s June 2023 prescription requirements tightening antibiotic access and EU regulations banning routine prophylactic use entirely, early adopters are positioning themselves ahead of regulatory curves that’ll only get stricter. The Netherlands data tracking over 64,000 animals shows cows on these protocols living 8.5 months longer—that’s serious replacement cost savings in today’s heifer market. We’re not suggesting you abandon every protocol you’ve built, but for producers dealing with chronic repeat cases or looking to streamline operations, this deserves a serious conversation with your vet.

Complete references and supporting documentation are available upon request by contacting the editorial team at editor@thebullvine.com.

Learn More:

- How to Control Bedding Pathogens to Decrease Environmental Mastitis – This article provides a tactical, on-farm guide to preventing mastitis by focusing on the cow’s environment. It reveals practical strategies for choosing the right bedding material, managing moisture, and implementing hygiene protocols that directly reduce the source of infection, complementing the main article’s focus on internal bacterial communication.

- FDA Pulls Plug on Milk Testing: What You Need to Know Now – This piece offers a critical market and strategic perspective on the regulatory landscape. It explains how recent shifts in federal oversight create uncertainty and increase pressure on farms to implement their own reliable milk quality assurance measures. This is a must-read to understand the broader context and long-term implications of regulatory changes discussed in the main article.

- Cut Mastitis Treatment Costs 60%: The $2.3 Billion Industry Secret That’s Reshaping Dairy Economics – This article takes a deep dive into the financial arguments for alternative mastitis protocols. It provides actionable data and economic models showing how switching from a “treat-all” approach to a more selective, prevention-focused strategy can deliver massive ROI and create a competitive advantage, reinforcing the economic claims made in the main piece.

Join the Revolution!

Join the Revolution!

Join over 30,000 successful dairy professionals who rely on Bullvine Weekly for their competitive edge. Delivered directly to your inbox each week, our exclusive industry insights help you make smarter decisions while saving precious hours every week. Never miss critical updates on milk production trends, breakthrough technologies, and profit-boosting strategies that top producers are already implementing. Subscribe now to transform your dairy operation’s efficiency and profitability—your future success is just one click away.

Join the Revolution!

Join the Revolution!