Every lame cow costs you $337. A Wisconsin farmer saves $20,000/year with footbaths, not $45,000 cameras. Here’s his exact protocol.

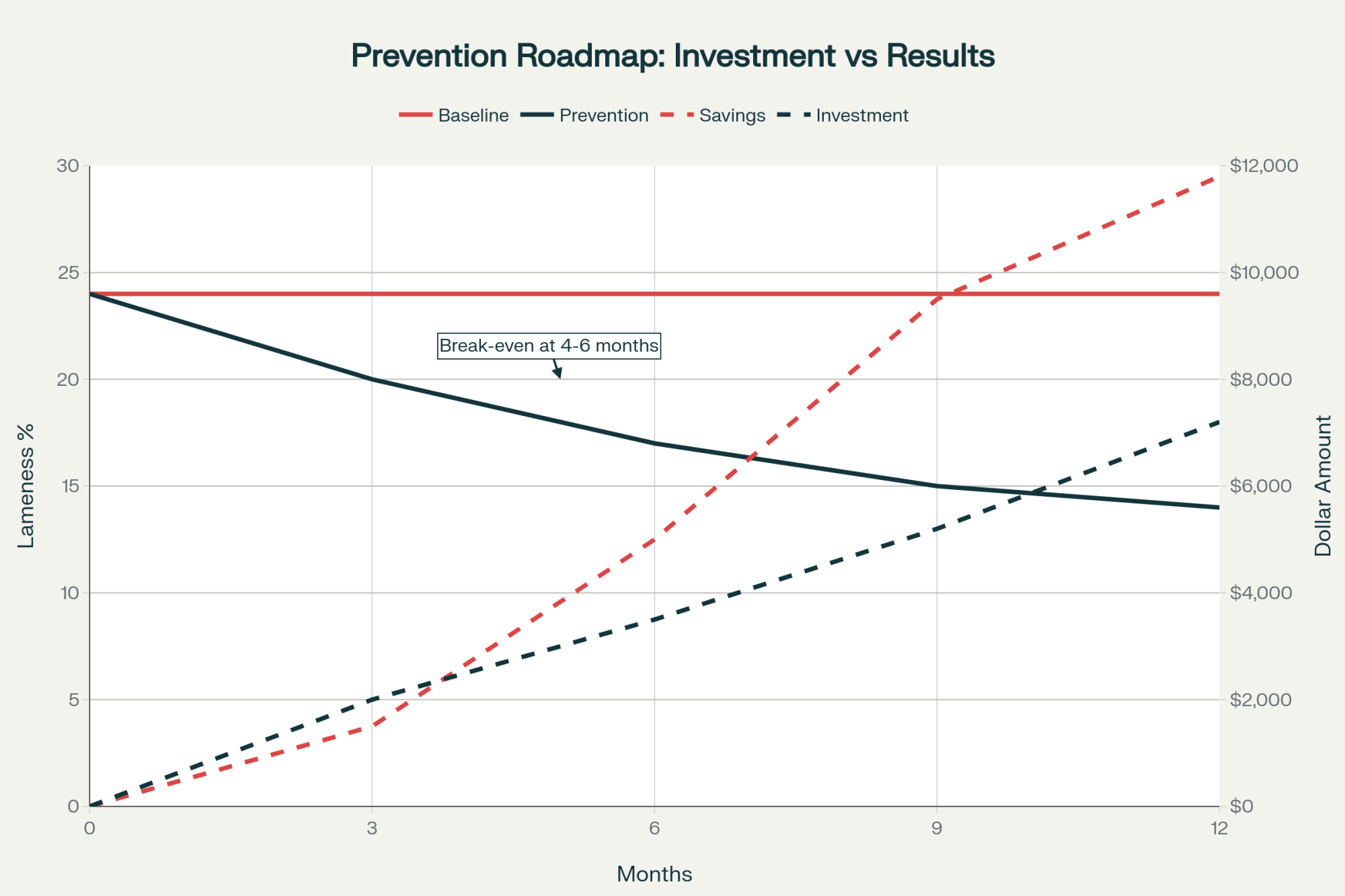

EXECUTIVE SUMMARY: While the industry pushes $45,000 lameness cameras, a Wisconsin farmer cut lameness by 42% for $3,100 by practicing disciplined prevention. Analysis of 600+ farms shows that the Prevention Bundle—footbaths 4x weekly, strategic dry-off trimming, and weekly scoring—reduces lameness by 40-50% for just $7,200 annually. At $337 per lame cow, this approach saves typical 350-cow operations $10,000+ yearly with a 4-6 month payback, versus 2-4 years for technology ROI. Technology excels for 1,000+ cow operations and robot barns where manual observation becomes impossible, but most farms achieve better results by solving the root problem with prevention. The industry’s ‘reality correction’ confirms what successful producers already know: you can’t detect your way out of a prevention problem—and you shouldn’t try when prevention costs 86% less.

Last February, I stood watching a young dairy farmer in Pennsylvania delete yet another unopened alert from his $52,000 lameness detection system. The dashboard showed 14 flagged cows that morning. He’d been up since 2 AM with a difficult calving, looked at the screen, and just closed it. “I’ll check them later,” he said.

You know how it goes. Later never came.

This scene’s been playing out on more farms than you’d think. AgFunder’s investment reports tell us precision livestock technology adoption has really picked up since 2023, though it’s tough to nail down what individual farms are actually spending. Meanwhile, Dr. Nigel Cook’s ongoing work at the University of Wisconsin continues to show lameness hovering around 20-25% across most operations.

What’s particularly interesting—and I’ve been thinking about this a lot—is how we’re investing heavily in detection while the actual problem isn’t getting much better. The pattern I’m seeing suggests we might be looking at this whole thing backwards.

And here’s what really gets me: the most effective solution costs about 86% less than what many of us are being told we need.

What’s the Real Cost of Each Lame Cow?

So there’s this figure that keeps coming up in the research, and it’s worth paying attention to: $337 per lameness case. Robcis and colleagues nailed this down in their 2023 Journal of Dairy Science analysis, building on what Dr. Karin Dolecheck and Dr. Jeffrey Bewley developed at the University of Kentucky. Really solid economic work that actually captures what we’re dealing with.

If you’re running 350 cows with 20% lameness—and let’s be honest, that’s probably where many of us sit—you’re looking at about $23,590 in annual losses. That matches up pretty well with what producers tell me they’re seeing.

But here’s where it gets interesting…

Technology presentations often reference different numbers. Dr. Y.H. Cha’s 2010 research in Preventive Veterinary Medicine documented costs from $121 for foot rot up to $216 for sole ulcers—good, solid data. But somehow, in sales materials, these morph into $400-$533 per case. They’ll cite a 30-40% prevalence rate as the “industry standard,” which might not apply to your farm at all.

Through that lens, suddenly your 350-cow operation looks like it’s losing $60,000 or more annually. Makes that $45,000 camera system seem pretty reasonable, doesn’t it?

The Dolecheck-Bewley model from their 2018 Animal journal work breaks it down like this:

- Milk production losses: $80-120 per case (that’s 30-35% of your total hit)

- Reproductive impacts: $42-70 (another 20-30%)

- Treatment costs themselves: just $40-60 (15-20%)

- Culling risk: $25-50 (10-15%)

- Labor and overhead: $20-40 (10-15%)

What I’ve noticed visiting farms from Wisconsin to California is that prevention effectiveness—not detection speed—drives most of these costs.

And good prevention? Well, that doesn’t require artificial intelligence.

Worth noting, though—these figures vary by region. California operations might see $380 per case with their labor costs, while Wisconsin farms might be closer to $310. But the principle stays the same.

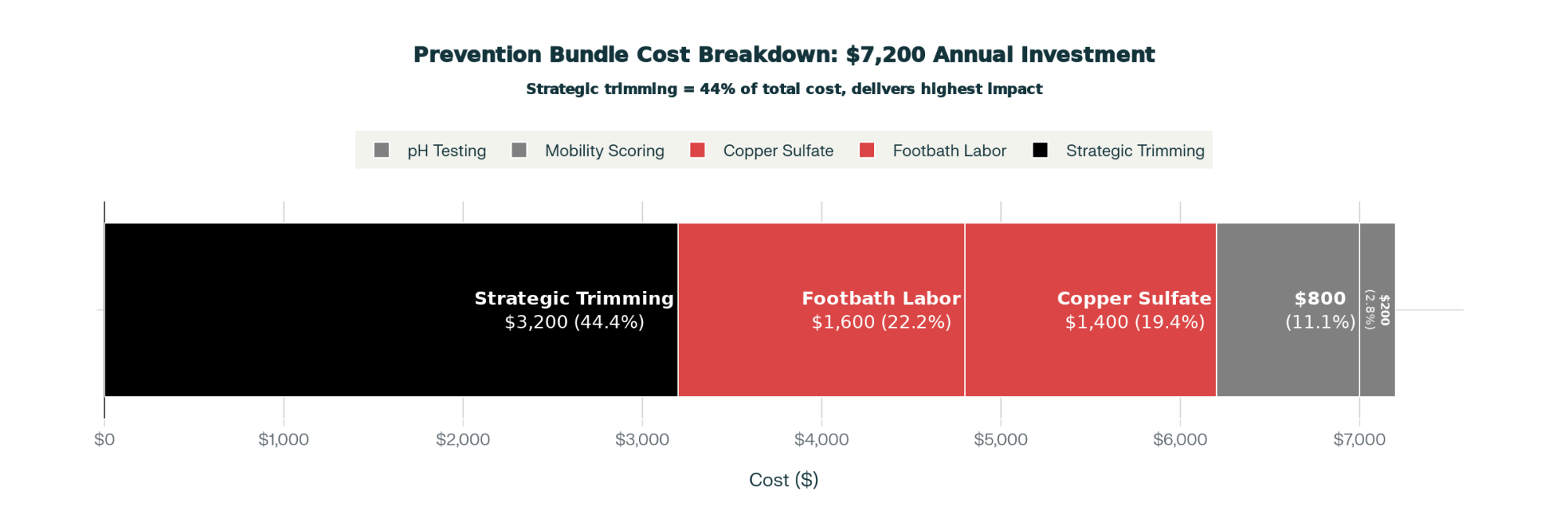

Quick Reference: Prevention vs. Technology Investment

Prevention Bundle

- Annual cost: $7,200-8,200

- Lameness reduction: 40-50%

- Year 1 ROI: Positive $3,400-4,600

- Break-even: 4-6 months

Technology Investment

- Initial cost: $45,000-80,000

- Detection advantage: 7-10 days earlier

- Year 1 ROI: Typically negative

- Break-even: Years 2-4

Decision Threshold: Technology makes sense for operations >1,000 cows or running AMS

What Prevention Package Actually Works?

Dr. Laura Solano’s Alberta Lameness Reduction Initiative, which she published in the Journal of Dairy Science in 2019, really opened my eyes. Combine that with Dr. Gerard Cramer’s work at Minnesota, and you see this encouraging pattern. Farms implementing what they’re calling the “Prevention Bundle” are hitting 40-50% lameness reductions for about $7,200 annually.

No fancy cameras. No algorithms. Just good management.

Now, costs vary by region—copper sulfate in Vermont costs different than Arizona, and California labor rates aren’t the same as South Dakota’s. But the principles? Those work everywhere I’ve looked.

Is Your Footbath Actually Working?

Dr. Dörte Döpfer at Wisconsin has spent decades documenting digital dermatitis control—you’ve probably seen her work in the veterinary journals. What she consistently finds is that regular footbath protocols can knock DD prevalence down 40-60% within 16 weeks.

Producer Success Story: Foundation Over Technology

Location: Near Fond du Lac, Wisconsin

Herd Size: 600 cows

Starting Lameness: 24%

Current Lameness: 14%

Time Frame: 18 months

Investment: $3,100/year in footbath protocols

This Wisconsin producer transformed his herd health without any technology investment. His approach was refreshingly straightforward.

“We treat footbaths like milking—non-negotiable, same times, same concentrations, every single week,” he explains. “That consistency matters more than any camera could.”

Key Success Factors:

- Footbaths 4x weekly (Tuesday, Thursday, Saturday, Monday)

- 5% copper sulfate is changed every 200 cow passes

- Dedicated employee ownership of the protocol

- pH monitoring to maintain effectiveness

Results: 42% reduction in lameness, saving approximately $20,000 annually based on that $337 per case figure

Here’s what’s fascinating—and Dr. Jan Shearer’s Iowa State research backs this up—the specific chemistry matters way less than consistency. Whether you’re using 5% copper sulfate, 2-5% formalin, or those newer zinc products, it’s the frequency that makes the difference.

Four times weekly beats “when we remember” every single time.

The math’s straightforward:

- Copper sulfate: $2-3 per pound, about 22 pounds per mix

- For 300 cows: roughly $1,200-1,500 annually in materials

- Labor at $15-20/hour: another $1,600

- Total commitment: $2,800-3,100 per year

Are You Trimming at the Wrong Time?

Dr. Sarel van Amstel’s research really changed how I think about trimming timing. Cows trimmed at dry-off show way fewer lesions next lactation compared to waiting until problems show up.

Dr. Gerard Cramer, who’s leading this big USDA-funded lameness project at Minnesota, puts it perfectly: “Strategic trimming at dry-off and around 100 days in milk is proactive management, not reactive.”

The economics are compelling. Multi-year projects tracking thousands of cows show that strategic trimming delivers returns several thousand dollars better than whole-herd trimming every six months.

Do You Really Need Cameras to See Lame Cows?

This might surprise you, but research comparing trained observers against automated systems shows weekly mobility scoring catches problems within 7-10 days of AI cameras.

That 23-day advantage you hear about? That’s comparing technology to casual observation at milking, not systematic weekly scoring.

A Lancaster County producer I know spent two hours with her vet learning proper scoring. Now it takes about three hours every Tuesday morning to score the whole herd.

“We catch 75% of problems before they’re severe,” she says. “For our 450 cows, that’s good enough.”

You can get free scoring guides from Wisconsin’s Dairyland Initiative, AHDB Dairy in the UK, or Cornell’s NYSCHAP program.

When Does Technology Actually Pay?

Now don’t get me wrong—I’m not anti-technology. I’ve seen plenty of operations where automated detection delivers real value. But specific conditions need to line up.

How Big Is Big Enough?

Dr. Marcia Endres at the University of Minnesota has modeled the economics, and automated systems typically hit positive ROI in herds of over 1,000 cows. At that scale, manual scoring becomes a logistical nightmare. Even small improvements mean big savings.

I visited a large dairy near Turlock recently—1,850 cows across two sites with both robots and conventional parlors. At 21% lameness, they’re looking at annual costs of $131,000.

A 30% improvement through earlier detection saves nearly $40,000 yearly. That justifies the technology pretty quickly.

Their herd manager made a good point: “Dedicated mobility scoring would cost us $65,000 annually in wages and benefits. The camera system costs less and runs 24/7.”

Dr. Robert Hagevoort at New Mexico State works with those massive Southwest dairies. As he says, when you’re managing multiple sites with thousands of cows, manual scoring isn’t just difficult—it’s impossible. Technology becomes essential.

What About Robot Barns?

Dr. Trevor DeVries at Guelph has documented some concerning patterns in robot herds—lame cows make fewer trips, produce less milk. These “invisible” lame cows are exactly what cameras help identify.

What’s interesting is how different robot systems integrate.

Lely’s approach differs from DeLaval’s or GEA’s, and each affects how well lameness detection meshes with your existing setup.

Technology consistently delivers value when you’ve got:

- Over 1,000 cows where manual scoring needs dedicated labor

- Robots where voluntary cow flow hides problems

- Genetic selection programs needing continuous data

- Persistent labor challenges

- Already maximized prevention, but still over 15% lameness

An Ontario producer I know runs 2,200 cows with his brothers. “We did everything right,” he told me. “Footbaths four times weekly, strategic trimming, the works. Still had 18% lameness. The cameras showed us facility design problems we couldn’t see ourselves.”

Can You Have Both?

I should mention—some of the best results I’ve seen come from farms combining both approaches. A 1,500-cow operation in Idaho implemented the full Prevention Bundle first, reduced lameness to 12%, then added cameras to capture the remaining percentage. They’re now running at 8% consistently.

That’s the sweet spot some larger operations are finding—prevention as the foundation, technology as the refinement.

And it’s not just the big guys. I know a 400-cow registered Holstein operation in Vermont that uses cameras specifically for their high-value genetics program. With cows worth $15,000-20,000, that 7-10 day earlier detection can mean the difference between saving a valuable bloodline or losing it. For them, the technology investment makes sense even on at smaller scale.

What’s the Hidden Cost of All This Technology?

What worries me—and I hear this from Extension folks everywhere—isn’t the technology itself. It’s what happens to our ability to read cows when we let computers do all the observing.

From farm visits and conversations over the past couple of years, I’m noticing younger employees on tech-heavy farms sometimes struggle with visual problem identification. Makes sense when you think about it.

I visited a Wisconsin farm where the owner had invested heavily in monitoring—activity collars, cameras, body condition scoring, and feed monitoring.

Seven different dashboards across four platforms, none talking to each other.

“That investment taught me an expensive lesson,” he said over lunch.

Interestingly, his lameness had actually increased as he spent more time managing alerts than managing basics.

Six months later? He kept only the activity collars for heat detection and started what he called “tech-free management time”—two hours each morning spent walking pens and looking at cows. Lameness improved markedly.

When Do Alerts Become Noise?

Extension specialists keep telling me the same story: excessive alerts create decision paralysis.

You start ignoring low-priority stuff. Then moderate warnings. Eventually, you’re only responding to obvious problems—defeating the whole purpose.

A New Mexico large-herd manager described it perfectly: “Seven dashboards, four platforms, over a hundred daily alerts. I spend three hours sorting data before actual cow work begins. We’re managing information, not cattle.”

Key Questions for Technology Vendors

Before signing any purchase order, get clear answers to:

- What percentage of your customers achieve positive ROI within 18 months?

- Can you provide references from my region, my herd size?

- What’s the full 5-year cost, including everything?

- How many daily alerts should I expect?

- What happens if you get bought out or discontinue this product?

Your 12-Month Prevention Roadmap

If you’re sitting there wondering about that technology purchase order, here’s an alternative that’s worked for multiple operations:

Months 1-3: Build Your Foundation

Start with footbaths. Not exciting, I know. But Tuesday, Thursday, Saturday, Monday—mark it down.

Dr. Döpfer’s Wisconsin protocols say 5% copper sulfate is changed every 200 cow passes. Train multiple people on mobility scoring using those free university resources. Schedule dry cow trimming.

You’ll invest about $2,000 for training and initial supplies. Based on Alberta data, expect a 10-15% reduction in new cases.

Months 4-6: Dial It In

Monitor footbath pH—Dr. Shearer’s research shows effectiveness tanks above pH 5.5.

Start weekly systematic scoring. Add that 100 DIM trimming for fresh cows.

Investment: around $3,500. Expect another 15-20% drop in prevalence.

Months 7-12: Make It Stick

Evaluate monthly, develop your own protocols, and ensure backup training so vacations don’t derail progress.

About $1,700 more investment. You should stabilize around 12-13% prevalence—that’s 45-50% total reduction.

Total annual investment: $7,200

Expected savings at $337/case: $10,600-11,800

First-year net benefit: $3,400-4,600

Compare that to technology, where Year 1 typically shows negative returns, with break-even in Years 2-4 according to Dr. Jeffrey Bewley’s adoption models.

Is the Industry Finally Getting It?

AgFunder calls what’s happening a “reality correction.” After years of aggressive growth, investors want proof of real-world value.

Vendors are changing, too. A major camera manufacturer recently told me they’re now recommending some prospects work with Extension for 6-12 months before buying.

“Farms need foundational management before technology amplifies effectiveness,” they explained.

That’s a big shift from two years ago.

It reflects growing recognition that technology supplements good management—it doesn’t replace it.

Dr. Nigel Cook from Wisconsin, whose lameness work has shaped industry practices for decades, said it best: “Transformational results come from disciplined execution of proven prevention protocols, maintained consistently over time.”

What About Your Specific Situation?

Everything I’ve talked about needs adapting to your situation. Missouri pasture systems face different challenges than Idaho freestalls. Arizona heat stress impacts lameness differently than the Vermont mud season.

Dr. Peter Robinson at UC Davis has documented clear connections between heat stress and California lameness patterns. Meanwhile, Northeast research shows spring transitions can really spike lameness in pasture systems.

The Prevention Bundle principles stay constant, but implementation varies.

Texas operations might adjust footbaths during monsoons. Wisconsin farms see spikes during spring pasture transition. Know your specific challenges.

Check out these support programs:

- USDA EQIP funding for infrastructure (varies by state)

- State dairy grants in Vermont, Wisconsin, and New York

- Extension training cost-shares

What’s Your Bottom Line?

Know Your Real Costs

Use that $337 figure from Robcis, not inflated estimates. Most farms incur annual losses of $15,000-25,000, not the $50,000-60,000 sometimes suggested.

Prevention Pays Fast

The $7,200 Prevention Bundle typically pays back within 4-6 months, based on data from Alberta and Minnesota.

Technology Has Its Place

Over 1,000 cows, running robots, doing genetic selection? Automated detection can deliver value—after you’ve nailed the basics of prevention. Even some smaller operations with high-value genetics programs find the ROI works for their specific situation.

Consider Everything

Beyond purchase price and subscriptions, think about alert management time, decision fatigue, and what happens to your team’s cow-reading skills.

Ask Yourself the Key Question

Before any technology purchase: “Would this money spent on prevention solve my lameness problem?” If yes, start there.

What’s Next for Lameness Management?

The exciting stuff I’m seeing isn’t coming from Silicon Valley—it’s coming from farms figuring out what actually works. Dr. Cramer’s USDA work at Minnesota is revealing interesting synergies between prevention strategies.

Several farms report better results combining strategic trimming with consistent footbaths than either practice alone would suggest. These are the practical insights that move the needle.

The Foundation for Food & Agriculture Research is supporting lameness research with equal focus on prevention refinement and appropriate technology development. The emphasis stays on integration, not replacement.

Making Your Decision

The path’s becoming clearer: nail the fundamentals first. Build management discipline that makes any tool work better. Then—and only then—evaluate if technology adds value for your specific situation.

This $337 reality check isn’t about rejecting innovation. It’s about aligning decisions with your farm’s actual needs, proven interventions, and management fundamentals rather than promised potential.

The fanciest detection system can’t fix prevention failures. But consistent prevention protocols, executed with discipline, can make detection systems unnecessary for many farms.

That might challenge what technology marketing tells us. But based on what I’m seeing coast to coast, it’s what’s actually working.

Your choice: invest $45,000-80,000 in cameras that might detect problems 7-10 days earlier than good observation, or invest $7,200 in prevention that stops 40-50% of problems from happening.

Each farm’s different. The question is: which approach fits yours?

Next Step: Call your Extension specialist this week to get those free scoring guides and start building your Prevention Bundle. The sooner you start, the sooner you’ll see results.

Free locomotion scoring guides are available through the University of Wisconsin’s Dairyland Initiative, Cornell’s NYSCHAP program, and AHDB Dairy UK. Prevention resources can be accessed through your state Extension dairy specialists. USDA EQIP funding information is available at your local NRCS office.

KEY TAKEAWAYS

- The $7,200 Prevention Bundle outperforms $45,000 technology for 90% of farms—delivering 40-50% lameness reduction with 6-month ROI vs 2-4 years

- One number changes everything: Operations under 1,000 cows achieve better results with prevention (footbaths 4x weekly, strategic trimming, weekly scoring) than cameras

- Wisconsin farmer proves it works: Cut lameness from 24% to 14% using just $3,100 in footbath protocols, saving $20,000 annually at $337/case

- Technology has its place: Large operations (>1,000 cows) and robot barns benefit from automated detection, where manual observation becomes impossible

- Start tomorrow: Download free scoring guides from Wisconsin Dairyland Initiative and implement footbaths this week—prevention costs 86% less than detection

Complete references and supporting documentation are available upon request by contacting the editorial team at editor@thebullvine.com.

Learn More:

- Is Your Footbath Protocol Actually Working? – For those ready to implement the main article’s advice, this guide provides the essential tactical details. It demonstrates how to audit your current setup, troubleshoot common failures, and maximize the effectiveness and ROI of your footbath investment.

- The Data-Driven Culling Strategy That’s Boosting Dairy Profitability – This article expands on the financial impact of lameness by providing a strategic framework for making tough culling decisions. It reveals how to use herd data to identify which animals are hurting your bottom line, optimizing overall herd value and profitability.

- Precision Dairy Farming: Is Your Farm Ready for the Data Revolution? – While the main article critiques a single technology, this piece offers a strategic roadmap for successful tech integration. It provides criteria to assess if your operation is culturally and logistically prepared to turn data into decisions, avoiding the common pitfalls of technology overload.

Join the Revolution!

Join the Revolution!

Join over 30,000 successful dairy professionals who rely on Bullvine Weekly for their competitive edge. Delivered directly to your inbox each week, our exclusive industry insights help you make smarter decisions while saving precious hours every week. Never miss critical updates on milk production trends, breakthrough technologies, and profit-boosting strategies that top producers are already implementing. Subscribe now to transform your dairy operation’s efficiency and profitability—your future success is just one click away.

Join the Revolution!

Join the Revolution!