79% of U.S. milk runs on immigrant labor. One Idaho dairy lost a third of its crew in 3 weeks—no raid, just fear from one 50 miles away. You have 72 hours.

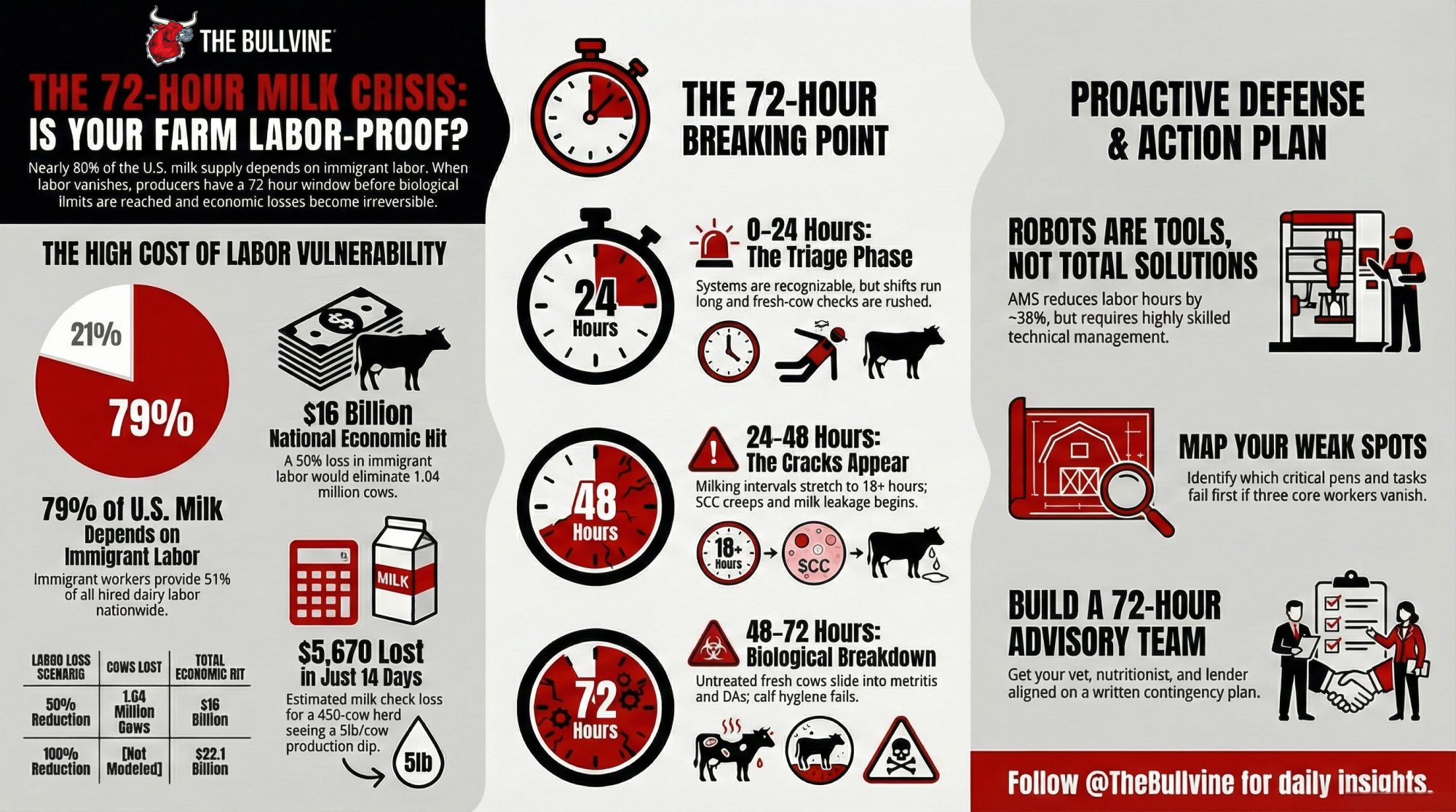

Executive Summary: Seventy-nine percent of U.S. milk comes from farms that depend on immigrant labor. When that labor vanishes, you don’t have weeks to pivot—you have 72 hours before milking intervals stretch, SCC climbs, and fresh cows slide into DAs and metritis while you’re too short-staffed to catch them. A Texas A&M modeling study found that losing half of immigrant dairy workers would eliminate 1.04 million cows and 24.2 billion pounds of milk, causing $16 billion in economic damage. One Idaho dairy saw a third of its crew disappear in three weeks—not from a raid on their farm, but from fear after enforcement hit a plant 50 miles away. For a 450-cow herd at $18/cwt Class III, losing 5 lb/cow/day for two weeks means $5,670 off the milk check before you count the fresh cows that went south. This article delivers a working 72-hour contingency plan: map your weak spots, quantify your labor exposure, stress-test your AMS assumptions, build a crisis reserve, and get your vet, nutritionist, and lender in the same room before you need them.

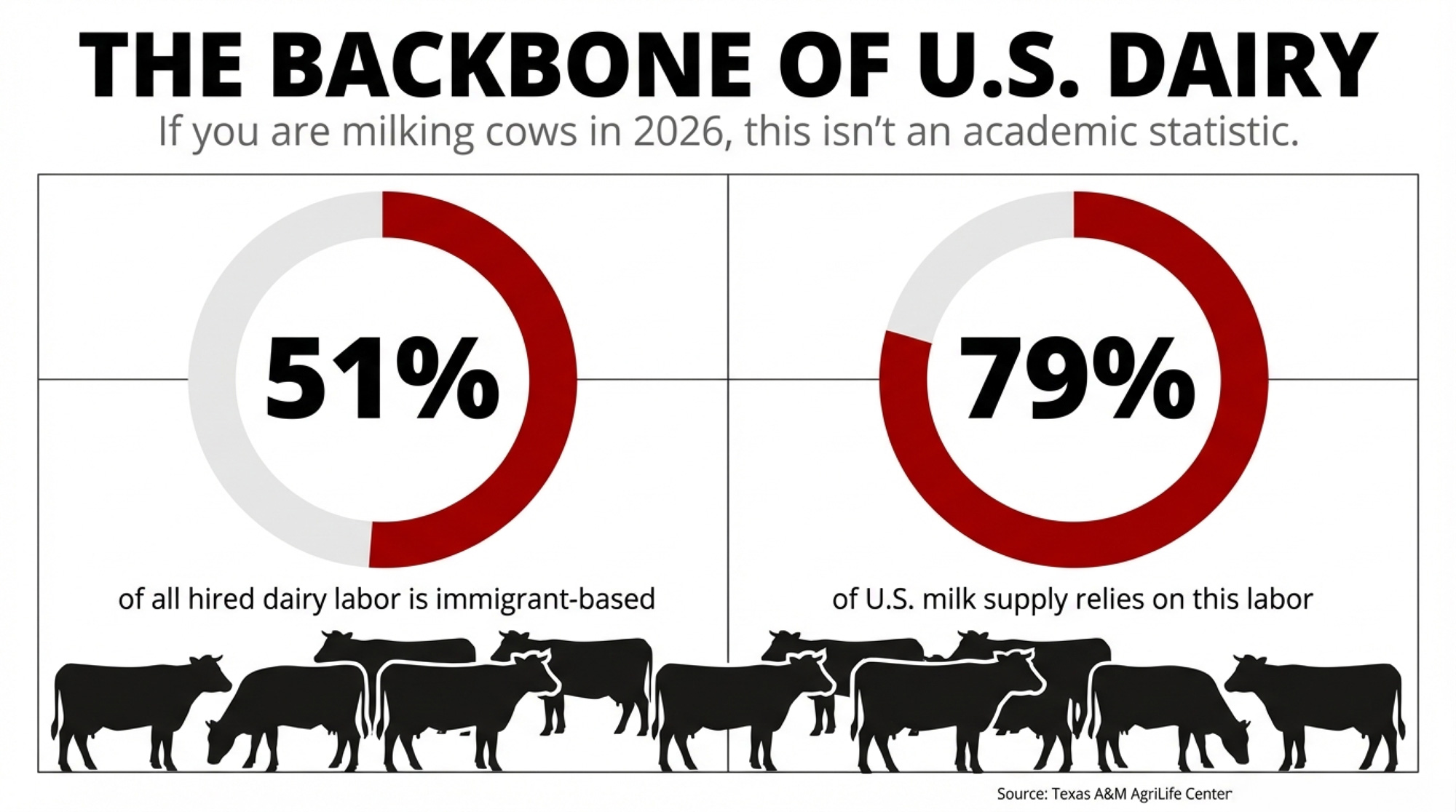

If you’re milking cows in 2026, the fact that immigrant workers provide about 51% of hired dairy labor and help produce roughly 79% of U.S. milk isn’t an academic statistic—it’s the foundation of your pay price. When that foundation cracks, you don’t have months to pivot. You have a 72-hour window before your herd health and your balance sheet start taking hits.

How Exposed Is Your Operation?

The Texas A&M AgriLife Center for North American Studies surveyed 973 dairies across 18 states to quantify who’s actually doing the work on U.S. farms. Their findings still anchor most labor discussions:

- Immigrant labor accounts for about 51% of all dairy labor.

- Farms employing immigrant workers ship nearly 80% of the U.S. milk supply.

- Compared with earlier surveys, both the immigrant share of the labor force and milk production had increased, not decreased.

That’s the national backbone. How it lands on your farm depends on where you milk and how you’re set up.

Wisconsin: Fewer Herds, More Cows Per Farm

Wisconsin had about 5,661 licensed dairy herds as of January 2024—down from 9,304 in 2017 and roughly 29,000 in 1995. Average herd size climbed from roughly 138 cows in 2017 to about 224 cows in 2023.

That’s 86 more cows per farm in six years. Nobody added 86 new family members to the payroll.

Consultants working with 300–600-cow freestall dairies in the Fox Valley and central Wisconsin see a consistent pattern: farms that used to run on family plus a couple of locals now rely heavily on immigrant workers. The larger ones simply don’t operate without them.

Northeast: Smaller Herds, Same Reliance

In New York and Vermont, herd sizes tend to run smaller on average, but labor dependence looks familiar once you hit commercial scale. Research on Latino dairy workers in both states shows they’re concentrated in milking, cow-side treatment, bedding, and health-spotting roles.

Vermont-focused studies estimate roughly 1,000–1,200 Latinx immigrant farmworkers support that state’s dairy sector at any given time.

Those workers don’t show up in your DHIA printout. They show up in whether the parlor, fresh pen, and calf barn stay on schedule when somebody disappears.

West and Southwest: Thousands of Cows, 24/7 Systems

In Texas, Idaho, New Mexico, and Arizona, many dairies run herds in the thousands across multiple sites. Multi-shift parlors, feed centers, and hospital pens operate around the clock. Foreign-born workers sit at the center of that system.

Take that labor away, and the math turns ugly fast.

Bottom Line: If immigrant labor wobbles, it doesn’t just hit someone else’s mega-dairy. It hits the backbone of the U.S. milk supply and any herd depending on hired help to keep parlors, fresh cows, and calves on schedule.

The Big Math

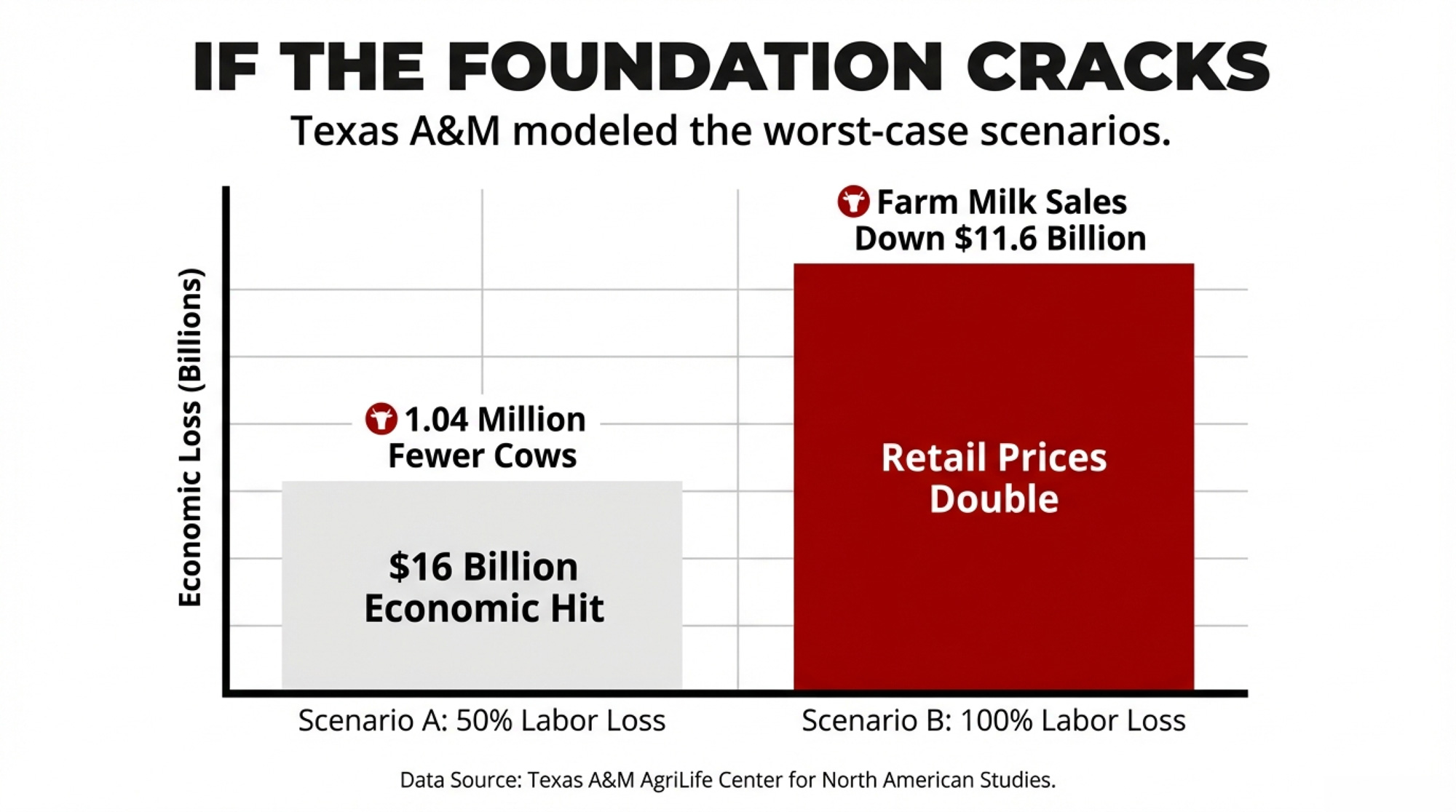

Texas A&M stress-tested what would happen if immigrant labor dropped. Here’s what the models show:

| Scenario | Cows Lost | Milk Production Change | Economic Hit | Retail Impact |

| 50% labor loss | 1.04 million | −24.2 billion lb (−11.7%) | −$16 billion | Moderate increase |

| 100% labor loss | Not modeled | Farm sales down $11.6B | −$32.1 billion total | Prices nearly double |

These are modeled scenarios, not guarantees. But they frame what’s on the line when policy shifts—or enforcement heats up.

Your Parlor, Your Numbers

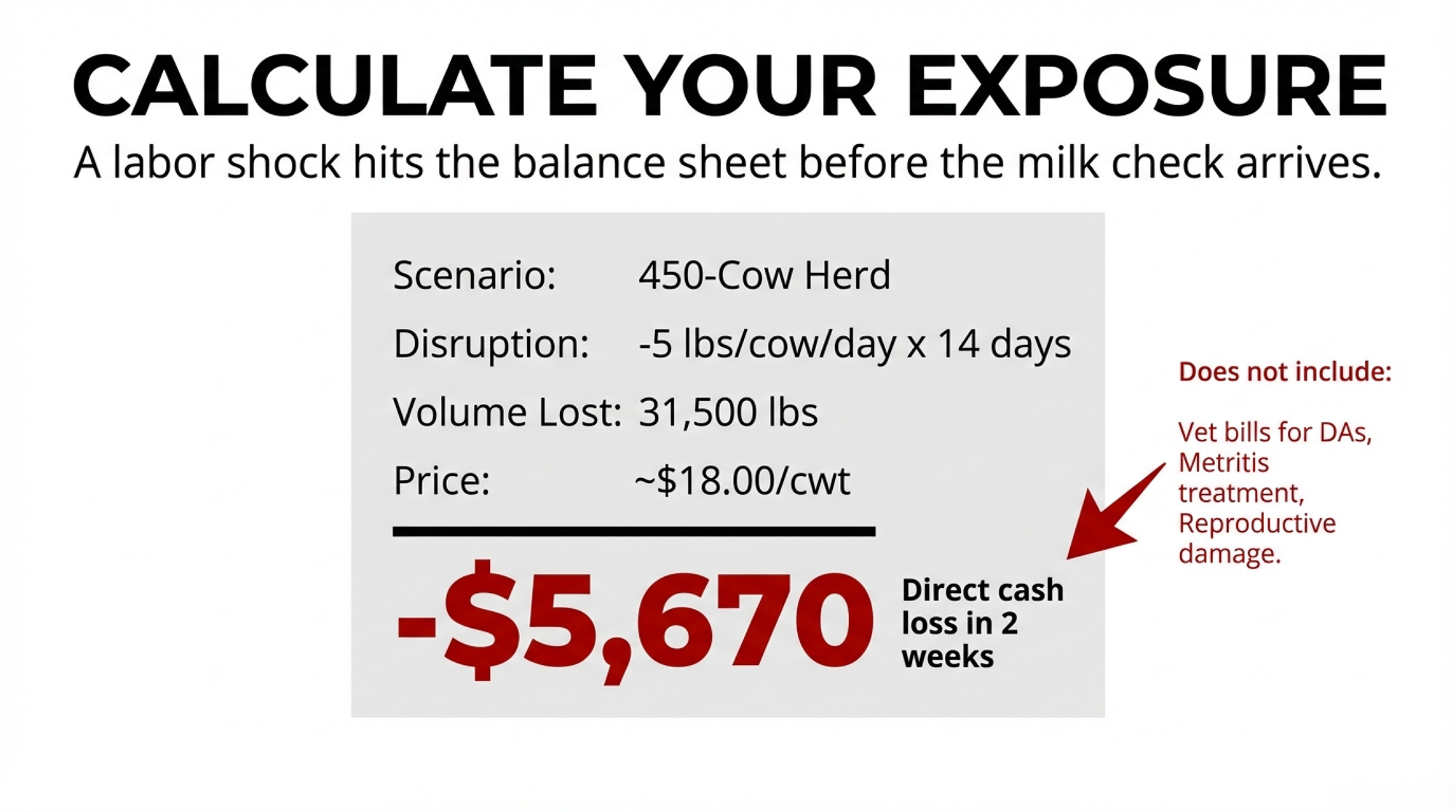

Say you’re milking 450 cows at 80 lb/cow/day. A labor shock doesn’t close your doors, but it drags your routine enough to cost you 5 lb/cow/day for two weeks:

- 450 cows × 5 lb × 14 days = 31,500 lb less milk

- 31,500 lb ÷ 100 = 315 cwt

| Herd Size | Lost Milk (cwt) | Milk Price ($/cwt) | Milk Check Loss |

| 300 cows | 210 | $18.00 | −$3,780 |

| 450 cows | 315 | $18.00 | −$5,670 |

| 1,000 cows | 700 | $18.00 | −$12,600 |

The November 2025 Class III price hit $17.18/cwt, $2.77 below the November 2024 price. The 2025 benchmark Class III averaged about $18.01/cwt. At $18:

- 315 cwt × $18 = $5,670 off your milk check in 14 days

That’s just the volume loss. It doesn’t count fresh cows sliding into DAs or metritis while you were short-staffed, or calves getting shorted on bedding.

Bottom Line: The national models tie immigrant labor to millions of cows and tens of billions of dollars. At the farm level, a modest production slip in a 450-cow herd means a four-figure hit in two weeks—before you count health and calf costs.

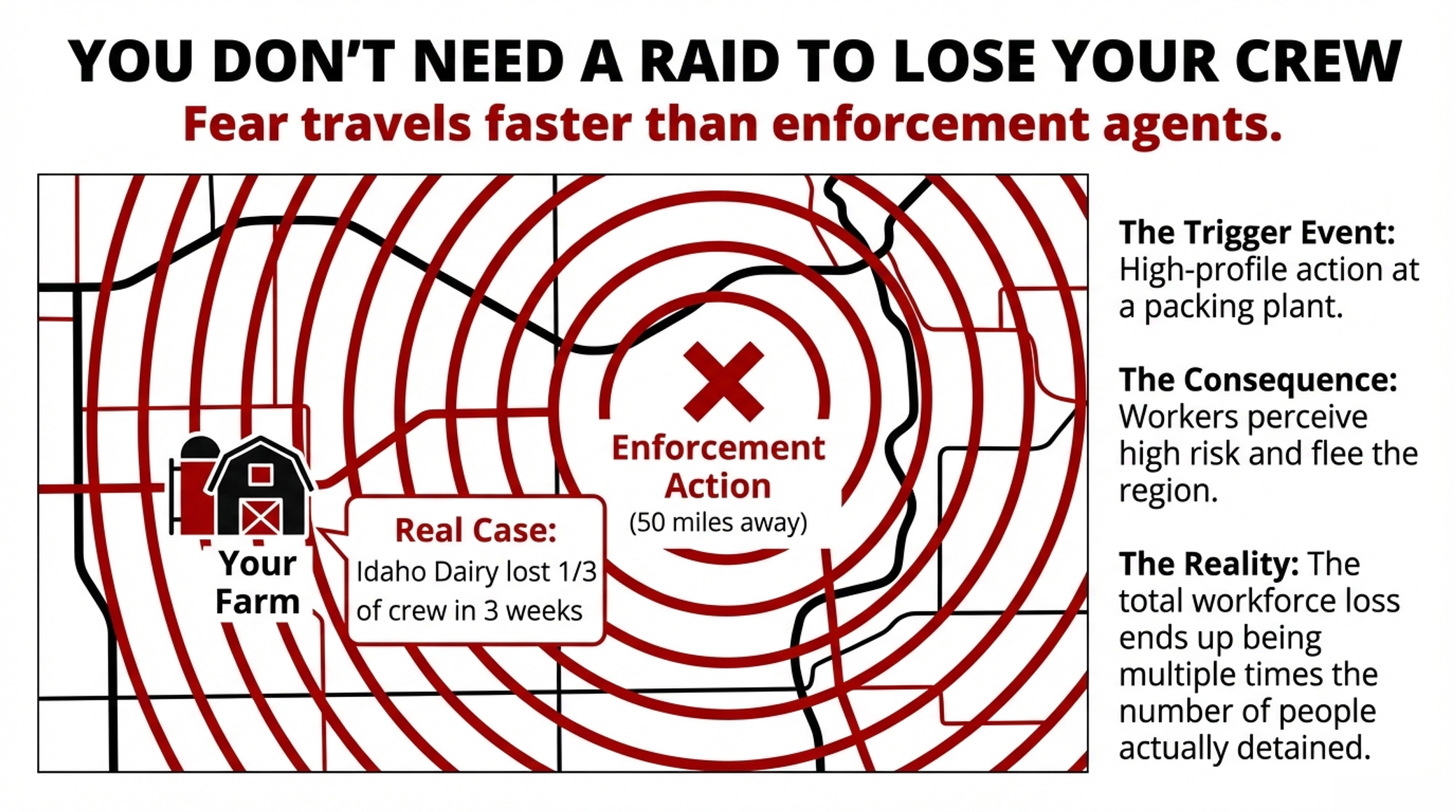

When Enforcement Heats Up: The Fear Effect

A working paper on 2025 ICE raids in California’s Oxnard/Ventura County estimated what happens when immigration enforcement ramps up in an agricultural region:

- 20–40% reduction in available agricultural workers

- $3–$7 billion in modeled crop losses

- 5–12% retail price increases for some produce

Those are estimates, not line-by-line ledgers. But they match what farmworker researchers describe as the “chilling effect.” Once enforcement becomes visible—raids, news footage, community chatter—workers don’t just leave the farm that got visited. They leave the region, the sector, or the country.

The total workforce loss ends up being multiple times the number of people actually detained.

A nutritionist servicing several 1,000-cow freestalls in Jerome County, Idaho, reports one client saw its workforce shrink by roughly a third within three weeks of a high-profile enforcement action at a nearby packing plant. Nobody came to the dairy. Workers simply decided the risk picture had changed.

You don’t need flashing lights in your driveway to wake up short-handed.

Even if agents never set foot on your yard, enforcement actions in your region can strip out a big share of the labor pool in weeks. Your exposure is bigger than the names on your own payroll.

Why 72 Hours Is the Breaking Point

On a well-run herd, milking locks in at 12-hour intervals for 2× herds, or tighter for 3× herds. Push high-yield cows beyond that, and you pay with SCC, mastitis risk, and lost milk.

Vets and consultants who’ve walked herds through blizzards, flu waves, and bad luck report a similar 72-hour patternwhen crews shrink faster than you can replace them:

0–24 hours: Scrambling, but intact. Every pen still gets milked and fed. Shifts run long. Fresh checks get rushed. Calf feeding technically happens, but not how you’d like. You’re triaging, but your system is still recognizable.

24–48 hours: Cracks appear. Some pens stretch to 16–18 hours between milkings. Over-full udders and milk leakage show up. SCC creeps. Fresh cows that were “a bit off” yesterday now have fevers or poor appetite, and you don’t have enough eyes to sort through them. Calf hygiene slips.

48–72 hours: You’re not running the same herd. Low-priority groups can slip beyond 24 hours between milkings if you’re not ruthless about priorities. Untreated fresh cows slide into full-blown metritis, severe ketosis, or DAs. Calf scours or pneumonia spikes.

Those three days are the difference between “we had a brutal week” and “we’re still digging out a year later.”

Then there’s welfare and legal risk. States like California and Wisconsin have clear animal care standards. If a vet or inspector walks in on day three and sees over-distended udders, untreated down cows, and underfed calves, they’re not seeing a rough patch. They’re seeing whether you had a plan.

You don’t control when a labor crisis hits. You control whether those first 72 hours are organized around a written plan—or around panic and hope.

Robots: Strong Tools, Not Magic Exits

Whenever labor risk comes up, robots aren’t far behind. The real question: what can automatic milking systems (AMS) actually do in a 72-hour crisis—and what can’t they do?

What the Data Shows

A University of Wisconsin Extension survey of 50 U.S. farms that installed AMS found:

- Labor hours per cow dropped by about 38% on average

- Labor hours per cwt dropped by about 43%

- At $15/hr, that’s roughly $1.50/cwt in labor savings

But the same work shows wide variation:

- Around 8% of respondents reported no labor savings—maintenance and management ate the gains

- About 25% reported savings above $2.40/cwt at $15/hr

Producer comments make the point bluntly: “Still need experienced labor to keep robots running” and “AMS is not stress free… mentally stressful.”

Robots don’t replace management. They expose it.

The Capital Side

AMS projects can run into the high six- to low seven-figure range once you factor in robots, construction, electrical, and barn changes. Divide by cows, and you’re often looking at several thousand dollars per head.

For a modern 500–1,000-cow freestall with good records and a lender who understands dairy, AMS often pencils as a labor tool. For a 150–250-cow herd in an older barn, the math is tighter—those projects hinge as much on succession and lifestyle as on pure labor savings.

In a 72-hour crisis, robots keep milking. But they don’t fix weak fresh-cow protocols, poor cow traffic, or a lack of cross-training on feeding and troubleshooting. They lower your day-to-day labor needs. If you lose the few people who understand the system, the risk just changes shape.

Robots take real pressure off labor in milking, but they shift risk to capital and technical management. They’re a tool in your labor strategy, not an escape hatch.

Region by Region: Same Biology, Different Wrappers

The biology doesn’t care where you live. The economics and options do.

- Upper Midwest and Northeast: Many herds run 50–300 cows in older barns that have been upgraded over time. Deep processor relationships, tight land limits, and a mix of family and hired labor, where losing two or three key people can cripple the system. Their questions: How do we stay resilient without overleveraging? Where do we modernize without betting the whole place?

- Southwest and Mountain West: Larger herds, often multiple sites and shifts. Heavy reliance on immigrant crews. Strict water and environmental rules. Their playbook leans into formal HR and immigration counsel, larger capital projects, and multi-site risk management.

- Canada: Supply management and quota, with Temporary Foreign Worker (TFW) and provincial nominee programs. Federal and provincial reports show livestock sectors rely significantly on temporary foreign workers and wrestle with housing, retention, and program uncertainty. For an Ontario herd under quota, the labor crunch might first show up as missed butterfat targets and under-used quota days.

Quota or not, 50 cows or 5,000—the labor risk lands the same way. If key people vanish, you’re fighting biology and welfare expectations on a short clock.

| Region | Typical Herd Size | Labor Dependence | Policy/Program Tools | Risk Level |

| Upper Midwest / Northeast (WI, NY, VT) | 50–600 cows | Moderate to high; mix of family + immigrant workers | Limited H-2A access; state labor regs vary | High |

| Southwest / Mountain West (TX, ID, NM, AZ) | 500–5,000+ cows | Very high; multi-shift operations heavily reliant | Some H-2A use; strict environmental/water rules | Very High |

| Canada (ON, QC, AB) | 50–300 cows (quota) | Moderate; TFW + provincial nominees fill gaps | TFW program, provincial nominees; quota stability | Moderate |

| California | 1,000–10,000+ cows | Extremely high; industrial-scale reliance | H-2A limited for dairy; strict labor + animal welfare laws | Extreme |

The 72-Hour Contingency Plan

Treat this as a working plan, not just a read.

- Map your weak spots. Write out: if three core workers didn’t show tomorrow, which cows, pens, and tasks would be at risk within 72 hours? Make sure at least two people besides you know that plan and where it’s kept.

- Size your exposure. Look at how many critical roles are held by immigrant workers versus others. You don’t need to label anyone’s status—just understand where your labor risk actually lives.

- Run the math with your numbers. Plug your herd size, production, and current pay price into the 5 lb/cow/day scenario. If that milk-check hit makes you flinch, that’s your starting point for crisis-reserve and staffing goals.

- Treat AMS as one option, not salvation. If you’re considering robots, insist on farm-specific budgets, conservative labor-savings assumptions, and a clear plan for who will manage the system on day 1, day 100, and day 1,000.

- Use your advisory team together. Bring your vet, nutritionist, and lender into one conversation. Lay out your 72-hour plan, your crisis-reserve goals, and your automation ideas. Ask them where they see your blind spots.

- Benchmark by region and system, not emotion. Compare your staffing and cows-per-worker to operations like yours—same region, similar size and system—not just the biggest herd in the next state.

Key Takeaways

- Your labor risk isn’t theoretical. Immigrant workers are behind about half of the hired dairy labor and nearly 80% of U.S. milk. When enforcement heats up, that dependence can translate fast into fewer cows, less milk, and higher prices.

- The 72-hour window is real. Within two to three days of losing key workers, biology and welfare rules start calling the shots more than your intentions do.

- Robots lower labor, not responsibility. AMS can significantly reduce milking labor on average, but some farms see no savings, and many need more skilled staff.

- A crisis reserve buys decisions, not miracles. Money set aside for labor and legal shocks doesn’t guarantee a soft landing. It buys choices—legal help, overtime, temporary support—so you’re not making bad decisions because the account is empty.

- Cross-training and culling are cheap, powerful levers. Teaching extra people to handle key tasks and moving out cows that don’t fit your system cost far less than a new barn or robots.

The Bottom Line

A third-generation dairyman from Clark County, Wisconsin—someone who’s lived through the 1980s interest squeeze, the 2009 crash, and 2020’s chaos—put it this way at a winter meeting: he can’t control Washington or Ottawa, but he can control how hard his own farm is to knock over.

You don’t get to choose when the phone rings with bad news about your crew. You do get to choose whether that call lands on a blank slate—or on a 72-hour contingency plan, some cash in reserve, and a herd that actually fits the people you have.

Complete references and supporting documentation are available upon request by contacting the editorial team at editor@thebullvine.com.

Learn More

- More Milk, Fewer Farms, $250K at Risk: The 2026 Numbers Every Dairy Needs to Run – Delivers a concrete 2026 playbook to bridge the $250,000 margin gap. You’ll gain a step-by-step method to audit your processor position and stress-test your cash flow before market volatility decides your future for you.

- 2025 Dairy Year in Review: Ten Forces That Redefined Who’s Positioned to Thrive Through 2028 – Reveals the structural forces—from heifer shortages to the beef-on-dairy trap—that will dictate survival through 2028. It arms you with long-term foresight to position your equity where the market is heading, not where it’s been.

- How Holstein USA’s Million-Cow Study Should Change Your Linear Type Strategy – Exposes the critical genetic link between linear type choices and robot efficiency. You’ll gain a high-impact framework to breed the “functional cow” required to maximize your automation investment and eliminate technical drama in the parlor.

Join the Revolution!

Join the Revolution!

Join over 30,000 successful dairy professionals who rely on Bullvine Weekly for their competitive edge. Delivered directly to your inbox each week, our exclusive industry insights help you make smarter decisions while saving precious hours every week. Never miss critical updates on milk production trends, breakthrough technologies, and profit-boosting strategies that top producers are already implementing. Subscribe now to transform your dairy operation’s efficiency and profitability—your future success is just one click away.

Join the Revolution!

Join the Revolution!