Your eyes miss 75% of lame cows—costing $143 per case in lost milk yield. Time to upgrade your detection game.

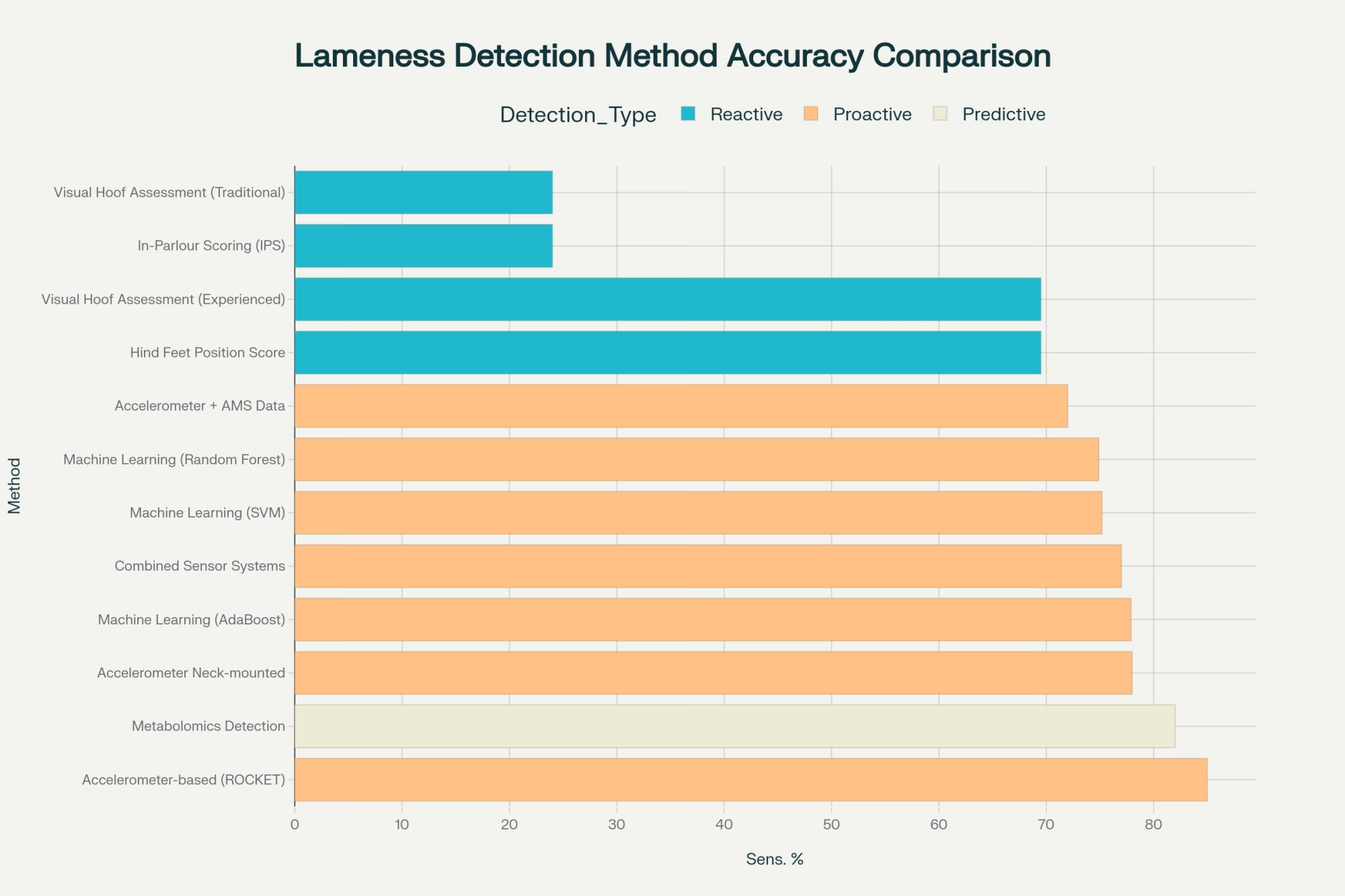

EXECUTIVE SUMMARY: You know that feeling when you walk the pens thinking you’ve got lameness under control? Well, here’s a wake-up call that’ll make your coffee taste bitter. Traditional visual assessment is missing three out of four lame cows in your herd right now – and each missed case is costing you $143 in direct milk losses alone. With Class III bouncing around $18.50 per hundredweight and feed costs still brutal, that’s money you can’t afford to lose. The kicker? Automated detection systems are hitting 85% accuracy while we’re stumbling along at 24% with our eyes. Dairies across the Midwest are already seeing 35% reductions in chronic lameness cases within the first year of installation. This isn’t some fancy gadget – it’s becoming the baseline for competitive operations in 2025.

KEY TAKEAWAYS

- Cut lameness losses by 65% – Automated systems catch problems at 85% accuracy vs 24% visual detection, potentially saving $21,500+ annually on a 300-cow operation. Start with baseline locomotion scoring this week to establish your current detection rate.

- Payback in 12 months or less – Systems range $8,000-25,000 for smaller herds, $30,000-80,000 for larger operations, but early adopters report conception rate improvements of 12 percentage points from catching cases before they impact breeding performance.

- Feed efficiency gains matter more than ever – Lame cows systematically underperform the 1.5-1.8 milk-to-feed ratios that top herds achieve, and with current feed costs averaging $5.50+ per cow daily, every efficiency gain directly impacts your bottom line.

- Technology integration beats replacement – Smart producers are using accelerometers and camera systems to complement (not replace) skilled observation, creating detection protocols that work with existing milking facility workflows instead of adding extra handling stress.

You know what keeps me awake at night? Walking through operations across the Midwest and seeing the same pattern over and over… producers who think they’re on top of their lameness issues, but the numbers tell a completely different story.

Here’s what’s really happening out there – and this might sting a little. We’re missing three out of four lame cows in our herds every single day. And with Class III futures bouncing around $17.37 to $18.82 per hundredweight this month and feed costs still eating into everything, every missed case is literally money walking away from your operation.

The thing about visual assessment… it’s failing us in ways we’re just starting to understand.

What’s Really Going Wrong in the Parlor

I’ve been digging into some eye-opening research coming out of Austria, and honestly? The numbers are sobering. Traditional visual lameness detection achieves only 24% sensitivity. Think about that for a second – we’re catching one out of four lame cows. The other three? They’re out there producing less milk, cycling poorly, and bleeding margins we don’t even realize we’re losing.

What strikes me about this problem is how it compounds. I was talking to a producer in Wisconsin last week – he’s been milking for over 20 years, really knows his cows. He thought he had maybe 8-10% lameness in his herd. When we did do systematic locomotion scoring? It was 24%. That’s not unusual. Research consistently shows we underestimate lameness prevalence by two to four times what veterinary assessments reveal.

Here’s what’s particularly frustrating… even experienced observers using in-parlor scoring systems struggle with these detection rates. The specificity might be decent – 96% in some studies – but that 24% sensitivity figure keeps showing up. We’re catching the severely lame animals, sure, but missing all those subtle cases where intervention would be most effective.

The fresh cow group? Don’t get me started. Those first-lactation heifers we’ve invested so much in show only 12-26% detection sensitivity with traditional methods. We’re missing problems right when early treatment would make the biggest difference.

The Real Money We’re Talking About Today

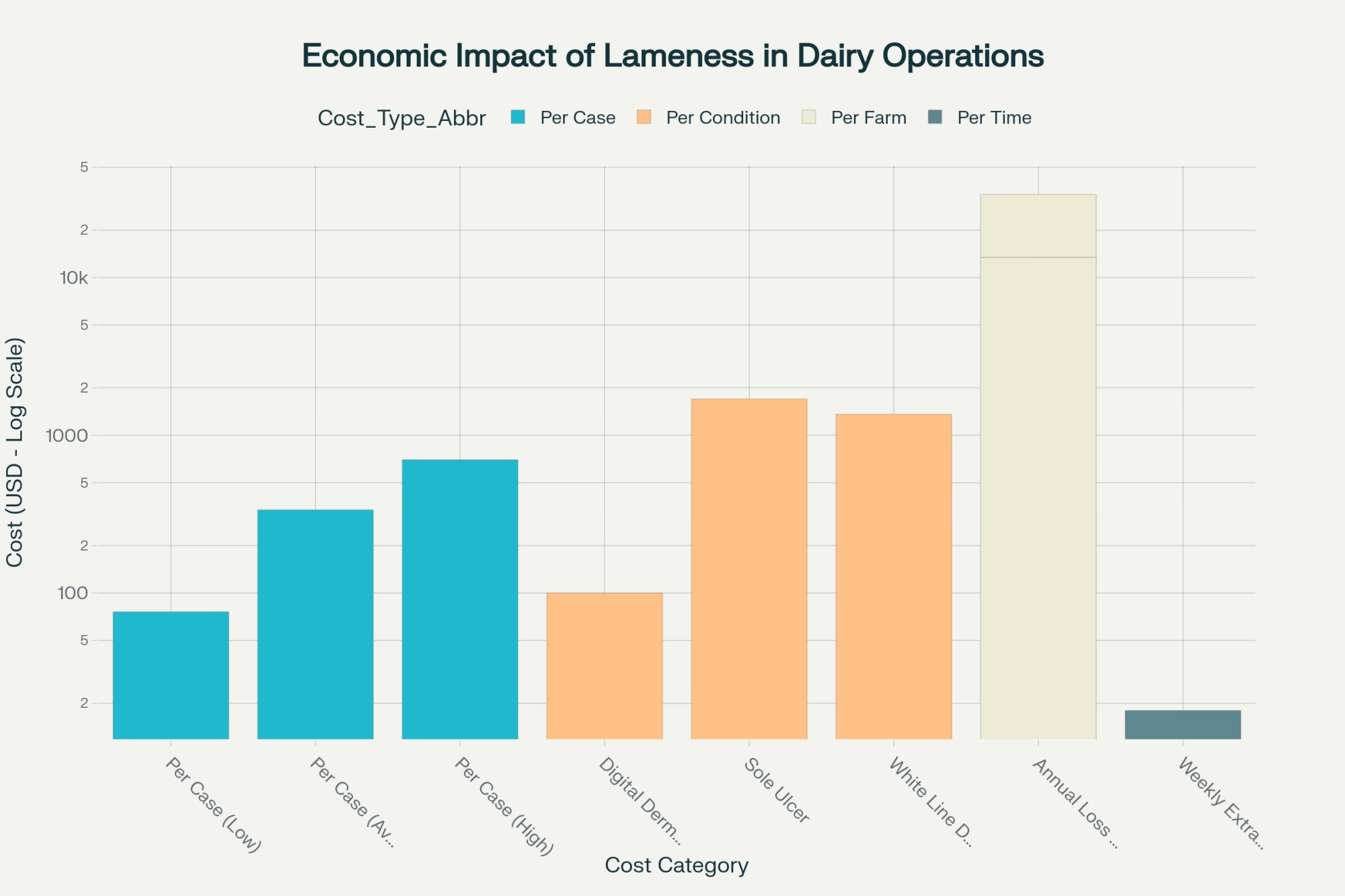

Let me break this down with current numbers, because this isn’t theoretical anymore. Research from the University of Wisconsin shows that severe lameness cases reduce 305-day milk yield by 772 pounds per cow. At today’s milk prices – we’re looking at around $18.50 per hundredweight – that’s $143 per cow in direct milk loss alone.

But here’s the kicker… that’s just the beginning. The economic analysis that really opened my eyes came from industry work showing that fertility and reproduction impacts represent 39% of total lameness costs. Milk production losses? That’s 45% of the total economic impact.

I was working with a 300-cow operation in Pennsylvania recently – typical freestall setup, decent management. We calculated their annual losses from undetected lameness at over $21,500. That’s before treatment costs, extra labor, or extended voluntary waiting periods. And this isn’t some poorly managed operation… this is a progressive dairy doing a lot of things right.

What really gets me is how this impacts feed conversion efficiency. Top-performing herds are hitting 1.5 to 1.8 pounds of milk per pound DMI, but lame cows systematically underperform these benchmarks. When operations are managing feed costs averaging $5.50+ per cow daily during normal periods, undetected lameness creates a double burden – reduced output while maintaining full input costs.

The Technology That’s Actually Changing Everything

Here’s where things get exciting… and I mean genuinely exciting. The automated detection systems coming online aren’t just incrementally better – they’re revolutionizing how we think about lameness management.

Recent work using accelerometer-based machine learning systems is achieving 85% accuracy rates. That’s more than three times better than human observation. Think about that impact on your operation’s bottom line – we’re talking about catching problems you’d never see otherwise.

The camera-based systems are even more impressive. We’re achieving 98.9% identification accuracy with tracking systems that monitor gait patterns, which are invisible to the naked eye. These systems track spine curvature, hook bone positioning, and step length variations —subtle indicators that would take perfect conditions and an expert eye to catch.

What’s particularly noteworthy is how Dr. Claudia Kamphuis at Wageningen University explains it: “We are creating an algorithm that detects deviations from the standard gait pattern… Then we teach the algorithm what the normal gait for each cow is. If the gait starts to deviate, due to a hoof disorder, for example, we can flag it up early on.”

What I find fascinating is the consistency factor. While human observers struggle with fatigue, weather conditions, and varying cow behavior, these systems maintain the same level of accuracy whether it’s 6 AM or 6 PM, whether it’s January in Minnesota or July in Texas.

What This Means for Your Operation Today

The economics make sense when you really dive into the numbers. Sure, there’s an upfront investment – and I’m being honest about the costs here. From industry observations, smaller operations might look at $8,000-25,000 for basic monitoring systems, while larger facilities could invest $30,000-80,000 for comprehensive sensor networks. But here’s what I’m seeing from producers who’ve made the jump…

A 500-cow operation in Ohio reduced their chronic lameness cases by 35% in the first year after installing accelerometer systems. A 1,200-cow dairy in California saw their treatment costs drop by 28% while their detection rates more than doubled. These aren’t isolated success stories – this is becoming the norm for operations that implement these technologies properly.

The payback calculation gets compelling when you factor in current market realities. With feed costs staying elevated and milk prices volatile, we can’t afford the production inefficiencies that come with undetected lameness. The continuous monitoring these systems provide means early intervention – catching problems before they become chronic, expensive cases.

Implementation Reality… And Why Some Fail

Here’s the thing, though… buying the technology isn’t the same as implementing it successfully. I’ve seen operations spend $35,000 on monitoring systems and then ignore 60% of the alerts because they weren’t prepared for the workflow changes.

What’s interesting is that successful implementation requires commitment to acting on the data. That means training your team on interpreting alerts, establishing clear treatment protocols for different severity levels, and – this is crucial – maintaining calibration standards. Most systems need 2-3 months to establish baseline patterns for your specific herd.

The technology’s effectiveness depends on consistent data collection and proper sensor maintenance. Commercial experience indicates that systems perform optimally when integrated with existing milking facility workflows, utilizing natural cow movement patterns for data collection. No extra handling, no additional stress on the animals.

The producers who struggle? They’re usually the ones who expect the technology to work independently of their management systems. These tools complement skilled observation – they don’t replace it entirely. For complex cases requiring veterinary assessment, human expertise remains essential.

Regional Differences I’m Seeing

The adoption patterns vary significantly across dairy regions, and it’s fascinating to watch. Upper Midwest operations – Minnesota, Wisconsin, Michigan – are leading early adoption, probably because they’re dealing with concrete surfaces and confinement systems where lameness detection is more challenging.

Western dairies are taking a different approach. The larger herd sizes mean they’re investing in more comprehensive systems, but the dry lot environments actually make some traditional detection methods more effective. A 2,500-cow operation in Colorado told me they’re using hybrid approaches – automated monitoring for the milking herd, visual assessment for dry cows and heifers.

Southeastern operations face unique challenges, including higher somatic cell counts and heat stress, which complicate lameness patterns. The technology appears particularly valuable in this region because environmental stressors make consistent human observation more difficult.

What’s particularly noteworthy is how feed costs are driving adoption decisions. With feed efficiency becoming the critical metric for profitability, operations can’t afford the hidden losses from undetected lameness affecting cow performance.

The Technology Limitations We Need to Discuss

Let me be honest about something… these systems aren’t perfect. Recent research shows that while accelerometer-based detection can achieve good sensitivity (up to 39.2%), specificity ranges from 79.6% to 99.1%. This means you’ll get some false positives along with the accurate detections.

The other challenge? Data overload. These systems generate enormous amounts of information, and smaller operations might struggle with the management time required to process and act on alerts effectively. I’ve seen farms where the technology was excellent, but the implementation failed because they didn’t have protocols in place to handle the increased detection capability.

Environmental factors also play a role. Extreme weather, unusual cow behavior, or facility changes can impact system accuracy. The technology performs best when integrated into a comprehensive management approach, rather than being a standalone solution.

Looking at the Economics of Doing Nothing

Let me put this in perspective with a real example. I worked with a 400-cow dairy in New York that was hesitant about the technology investment. We calculated their current losses from undetected lameness at $18,500 annually. The monitoring system they were considering cost $20,000 installed.

The math was pretty straightforward – payback in just over 12 months, even with conservative assumptions about improvement rates. But what really convinced them was the breeding efficiency impact. Their conception rates improved by 12 percentage points in the first year after installation, largely because they were catching and treating lameness cases before they impacted reproductive performance.

Current trends suggest this window for competitive advantage won’t stay open forever. As more operations adopt these technologies, the bar for what constitutes acceptable lameness management continues to rise.

Where We’re Heading – And Why It Matters

The technology evolution is accelerating faster than most producers realize. What we’re seeing now is just the beginning. Machine learning algorithms are getting better at pattern recognition, sensor technology is becoming more affordable, and integration with existing management systems is improving rapidly.

What’s particularly exciting is the development of predictive capabilities. Instead of just detecting lameness when it occurs, we’re moving toward systems that can predict which cows are at risk based on subtle behavioral changes, environmental factors, and individual cow characteristics.

The operations that are positioning themselves for this future are the ones investing in these technologies now. They’re building the data foundation and developing the management expertise that will give them significant competitive advantages as the technology continues to evolve.

Bottom Line Insights for Your Operation

This isn’t just about animal welfare, though that’s critically important. This is about operational efficiency in an industry where margins are thin and getting thinner. Missing three-quarters of your lame cows isn’t just a welfare issue; it’s an economic crisis happening on your farm right now.

The technology to solve this problem exists today. The financial justification is solid when you calculate the real costs of undetected lameness. The implementation pathway is proven by early adopters who are seeing measurable results.

Here’s what I’d recommend if you’re serious about addressing this:

Start with baseline locomotion scoring using standardized protocols – you need to know where you are before you can measure improvement. Then, evaluate neck-mounted accelerometers or integrated sensor systems based on your herd size and facility configuration. Budget realistically – factor in training time, system calibration, and workflow adjustments.

The question isn’t whether you can afford to implement automated lameness detection – it’s whether you can afford not to. I’ve seen too many operations struggling with reproductive performance, somatic cell issues, and high culling rates that could trace back to undetected lameness.

The farms that recognize this opportunity and act on it are going to have substantial competitive advantages in the years ahead. The lameness detection revolution isn’t coming – it’s here. The only question is whether you’ll lead the charge or be left behind trying to catch up with operations that moved early on this technology.

The math is clear. The technology works. The question is: what are you going to do about it?

Complete references and supporting documentation are available upon request by contacting the editorial team at editor@thebullvine.com.

Learn More:

- Effective On-Farm Training for Early Lameness Detection in Dairy Cows: Boost Recovery and Enhance Herd Health – Practical strategies for implementing weekly locomotion scoring protocols and training your team to catch lameness early, delivering immediate cost savings through improved detection consistency.

- Global Dairy Cattle Diseases Cost Farmers $65 Billion Annually: How Comorbidities Impact Your Bottom Line – Reveals the broader economic context of lameness within the $65 billion disease burden, demonstrating how overlapping health issues multiply your losses and strategic prevention approaches.

- AI Eyes on Your Herd: Why Automated Lameness Detection Is Revolutionizing Dairy Farming – Explores cutting-edge 2D imaging systems that detect lameness 23 days before human observers, offering detailed implementation guidance for next-generation automated monitoring technology.

Join the Revolution!

Join the Revolution!

Join over 30,000 successful dairy professionals who rely on Bullvine Weekly for their competitive edge. Delivered directly to your inbox each week, our exclusive industry insights help you make smarter decisions while saving precious hours every week. Never miss critical updates on milk production trends, breakthrough technologies, and profit-boosting strategies that top producers are already implementing. Subscribe now to transform your dairy operation’s efficiency and profitability—your future success is just one click away.

Join the Revolution!

Join the Revolution!