The hardest‑working dairy farmers are actually the least profitable—Irish research proves 51‑hour weeks outperform 70‑hour grinds by 20% ROI.

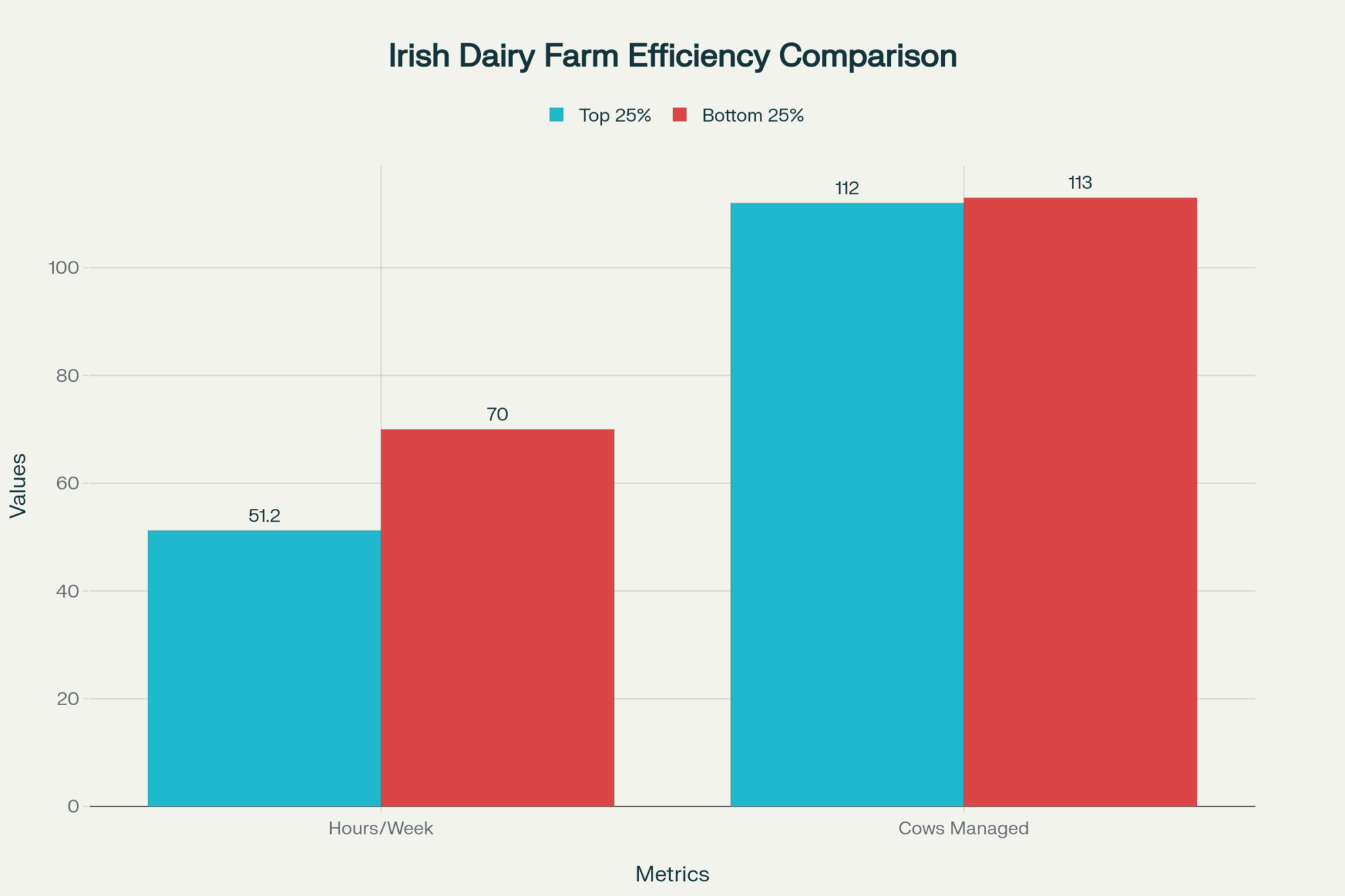

What if the hardest‑working dairy farmers in your area are actually the least profitable? Here’s a question that should make every dairy operator uncomfortable: When did “never stopping” become more important than never failing? The dairy industry has built its entire identity around a myth that’s costing farms millions; we celebrate exhaustion, glorify the “always working” mentality, and treat burnout like a badge of honor, while the most profitable operations quietly prove that strategic rest isn’t weakness—it’s a competitive advantage. Ireland’s Agriculture and Food Development Authority (Teagasc) compared the top 25% most efficient farms with the bottom 25% and uncovered a finding that should change how dairy success is judged. The most efficient farmers worked 51.2 hours per week managing 112 cows, while the least efficient worked 70 hours managing virtually identical 113‑cow herds—nearly 19 extra hours weekly for the same size herd. “The greater profitability achieved on the most labour‑efficient farms indicates that the extra workload on less efficient farms does not contribute to farm profitability,” a conclusion that translates to wasted hours, higher risk, and lower returns. The uncomfortable truth many still won’t acknowledge is this: “Dedication” without design is incompetence disguised as virtue.

The 51-Hour Advantage

- Strategic rest and structured schedules deliver measurable returns; farms adopting a 51‑hour target see fewer fatigue‑driven errors and can capture $15,000–$67,500 in avoidable losses tied to missed heats, nutrition drift, mastitis, breakdowns, turnover, and injuries.

- Flexible milking is a profit lever, not a concession; a New Zealand 10‑in‑7 system held milk solids per cow while cutting farm working expenses 4.3% and lifting profit/ha by 60.3%.

- Automation liberates management time without sacrificing output; Australian AMS herds report comparable physical and economic performance to conventional parlors while redeploying labor to higher‑value work.

- The cognitive link is real and costly; long‑term agricultural work is associated with a 46% higher odds of dementia, and burnout undermines decisions driving genetics, DMI/ME balance, SCC control, and capital allocation.

- The “51‑Hour Challenge” works because it forces time ROI discipline—delegation, scheduling, and technology focus—turning hours saved into better breeding, feeding, and health execution.

The industry’s dirty secret: why “always on” is financial suicide

Working harder doesn’t mean earning more; in modern dairying, it often means compounding risk, magnifying errors, and draining the decision‑making capacity that actually drives margins. Running a dairy today demands the cognitive performance of a tech CEO—genomic selections, ration optimization across DMI and ME targets, SCC management, AMS/monitoring data interpretation, and milk marketing—yet many make million‑dollar decisions on four hours of sleep. Poor farmer mental health correlates with compromised herd outcomes and profit erosion; when leadership is exhausted, cows, people, and finances pay.

The mental‑health crisis that’s bankrupting farms

Depression affects 29.3% of agricultural producers versus 8.4% of U.S. adults, and anxiety hits 27% versus 19% in the general population. Among beginning farmers in the U.S. Midwest, 58% report mild to severe symptoms, and 89% cite “too much to do and too little time,” with one farmer noting, “The farm has an insatiable appetite… it will just eat everything if you allow it.” A systematic review places severe burnout among farmers at 13.72%, reaching 25% in New Zealand, and male farmers/ag managers die by suicide at 43.2 per 100,000—nearly double other occupations. Sleep deprivation and burnout reduce innovation, rigidify thinking, and block the adoption of novel strategies, compounding financial pressure and operational mistakes.

The hidden profit killers you’re not tracking

Working more than eight hours a day raises injury risk dramatically, and agriculture’s fatal injury rate sits at 21.5 per 100,000—more than six times the all‑worker rate. The real financial damage accumulates in silent leaks: missed heats add $3–$5 per cow per day for 21 days, mastitis incidence rises 15–20%, operator error drives roughly a quarter of equipment failures, turnover runs 22–43%, and one “minor” tractor injury can wipe out $6,000 in gross income during recovery. Bankers report stalled loan work when mental-health concerns remain unaddressed, underscoring that profitability and wellness are inextricably linked business variables.

The cognitive revolution: your brain is the highest‑value asset on the farm

The USDA ERS shows that larger, well-managed herds grow productivity at a rate of around 2.99% annually, compared to 0.63% on smaller farms, due to technological progress, scale/mix efficiency, and technical efficiency—not longer hours. Leisure and hobby time improves memory, attention, and processing speed—the exact skills that protect breeding choices, DMI/ME balance, SCC control, and capital allocation. Long‑term agricultural work is also associated with a 46% higher odds of dementia, underscoring the need to protect cognitive capacity as a core business asset. Running exhausted is like operating a high‑precision rotary on contaminated oil—it turns, but it won’t perform to spec or last.

Global innovators proving “work harder” is dead

Case 1 — New Zealand: the 60.3% profit‑per‑hectare jump

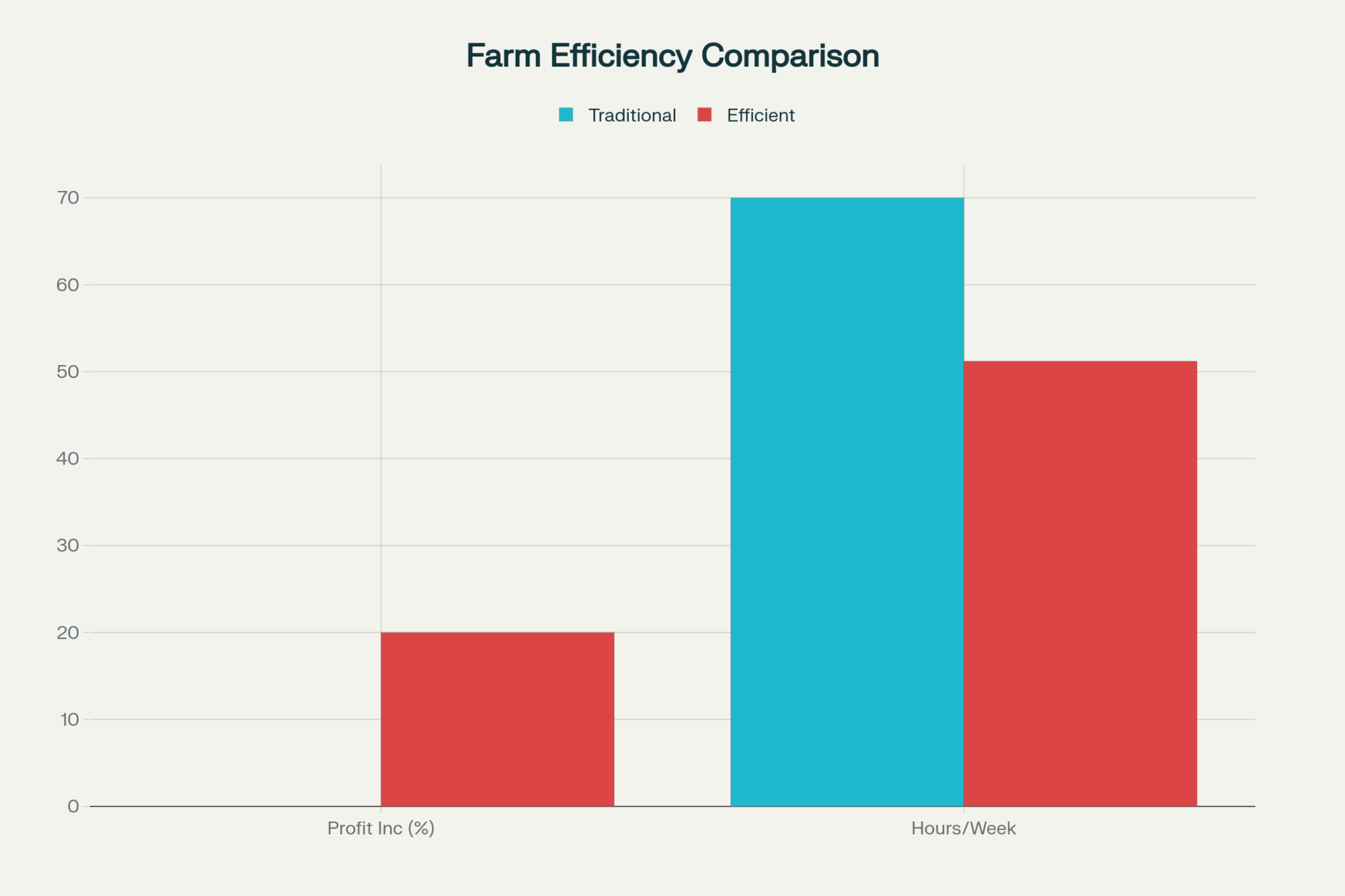

John Totty’s shift to a 10‑in‑7 schedule resulted in production at 378 kgMS/cow, compared to 377, and reduced farm working expenses from $4.90/kgMS to $4.69/kgMS (−4.3%), while profit per hectare rose from $2,271 to $3,641 (+60.3%).

| Metric | Traditional (2019/20) | Flexible 10‑in‑7 (2020/21) | Impact |

| Production (kgMS/cow) | 377 | 378 | +0.3% |

| Farm working expenses ($/kgMS) | 4.90 | 4.69 | −4.3% |

| Profit per hectare ($/ha) | 2,271 | 3,641 | +60.3% |

DairyNZ trials also found no statistically significant difference in milk solids per cow across flexible milking intervals, underscoring that schedule design can protect yield while improving people and profit metrics.

Case 2 — Ireland: the 51‑hour breakthrough

Teagasc’s analysis showed that top‑quartile farms had 51.2 hours/week on 112 cows, compared to bottom‑quartile farms at 70.0 hours on 113 cows, with earlier finish times (18:25 vs. 19:58), indicating operational efficiency. A 119‑cow spring‑calving case demonstrated effective farming under 3,000 total labor hours per year, with the principal farmer working 2,314 hours (≈47 hours per week) while meeting herd targets.

Case 3 — Australia: AMS as a labor‑liberation strategy

NSW DPI findings show AMS herds typically milk 150–240 cows across 3–4 robots, 19.3–26.3 kg milk/cow/day, ~2.17 milkings/cow/day, and ~1,200 kg/robot/day while enabling managers to redirect time into herd health, pasture, and business oversight.

Case 4 — Netherlands: sustainable systems out‑earn intensive ones

Wageningen research identified “sustainable” farms with more extensive systems earning over €28,500 more at the farm level, led by craftsmanship, consistent strategy, and smart AMS adoption for safer, more satisfying workdays.

Case 5 — UK: flexible rotas done right

Dourie Farm’s “4‑on/4‑off” and “10‑four” schedules, plus deliberate pastoral care, sustain team performance, while Hollings Hill Farm’s move from 3× to 2× milking, herd size right‑sizing, and a full‑time herdsperson sharpened both quality of life and execution.

Your 90‑day transformation to a 51‑hour work week

Days 1–30: Assess and baseline

- Time ROI audit: log hours by task; tag high‑value CEO work (genetics, finance, systems, people) vs. medium (nutrition oversight, repro) vs. low (routine milking, feed delivery, basic maintenance).

- Health & errors audit: document sleep, stress, near‑misses, treatment slips, and breakdowns to build a fatigue‑risk ledger.

- Tech due diligence: model AMS/activity monitoring/auto‑feeding ROI scenarios aligned to labor‑saving bottlenecks.

- Team baseline: run a 10‑minute pulse survey; identify quick delegation wins and training gaps.

Days 31–60: System optimization and scheduling

- Implement the first automation or outsourcing play (e.g., slurry contracting, auto‑feeding, or monitoring) and hard‑cap weekly hours at 60 with fixed start/finish times.

- Introduce one flexible‑schedule element (e.g., 4‑on/4‑off or a single weekly one‑milking day) to test fatigue relief without yield loss.

- Establish a protected 90-minute midday reset for the principal decision-maker on peak cognitive load days.

Days 61–90: Lock in 51 hours and measure gains

- Reduce to 55 hours per week in week 9 and 51 hours by week 12 through delegation/automation; track missed heats, mastitis cases, equipment downtime, and turnover intent.

- Expected ROI envelope (500 cows): 15–20 labor hours/week saved ($15,000–$20,000/year), 2–3 lb milk/cow/day recovered ($45,000–$67,500/year), and 15% lower treatment costs ($8,000–$12,000/year).

- Cement weekly downtime: one four‑hour no‑farm block for the principal to preserve decision quality and adoption bandwidth.

U.S. scheduling and compliance note

At the federal level, many agricultural employees are exempt from FLSA overtime requirements; however, states are increasingly imposing stricter thresholds—confirming weekly caps before setting new rosters. California applies overtime after 8 hours/day or 40 hours per week for agricultural workers, as of January 1, 2025, with double time beyond 12 hours/day. Washington has completed its phase‑in to 40 hours/week overtime for all agricultural workers, including dairy. Oregon requires overtime after 48 hours/week in 2025, stepping to 40 hours in 2027. New York is phasing down its farm overtime threshold from 56 hours toward 40 by 2032, with related tax credits—plan schedules and budgets accordingly. OSHA highlights fatigue hazards associated with extended or irregular shifts; integrate predictable finish times, minimum rest periods, and fatigue checks into standard work procedures.

Challenge your peers: five uncomfortable questions that change behavior

- If working harder equals more profit, why do the hardest workers keep going broke when Teagasc’s 51.2‑hour cohort outperforms 70‑hour grinders?

- What’s the actual ROI on those extra 20 hours—can it be quantified without ignoring error costs and turnover?

- How many five‑figure mistakes happened while exhausted—one mastitis flare, one missed heat group, one mixer failure?

- Why invest heavily in cow comfort but nothing in operator cognition when leadership quality drives milk yield, butterfat, protein, SCC, and repro outcomes?

- What example is being set for the next generation—an attractive career or a 70‑hour cautionary tale?

The Bottom Line

A 70‑hour week isn’t a badge of honor; it’s a red flag for broken systems, poor delegation, and preventable risk. Across regions and farm sizes, flexible scheduling and time-liberating technology help protect milk solids per cow, trim costs, stabilize teams, and improve decision-making quality. Lock in a 51‑hour target to shift time from fatigue‑prone labor into high‑ROI management where margins are truly made.

- 70‑hour weeks signal inefficiency.

- Structured downtime improves margins and herd health.

- Decision quality—not endurance—wins.

- Tech adoption requires cognitive bandwidth.

- The next generation will not accept 70‑hour norms.

- Global leaders are already executing.

- Wellness programs return approximately $2.18 for every dollar invested after three years. Which side of history will be chosen—and is the 51‑hour operation ready to outperform tired competitors?

Trust me on this one—I’ve seen too many good operators burn themselves out thinking more hours equal more profit. The data tells a completely different story, and it’s time we listened.

KEY TAKEAWAYS

- Track your hours and aim for that 51-hour sweet spot—research shows you could see 15-20% productivity gains just from sharper decision-making when you’re not exhausted. Start logging your time with a phone app this week.

- Test flexible milking like those smart Kiwis—John Totty’s 10-in-7 system held milk solids steady while cutting working expenses 4.3% and boosting profit per hectare by 60%. Try shifting just one milking day to see how your team responds.

- Consider AMS as a strategic move, not just tech—Australian operations show comparable economics to conventional parlors while freeing up 15-20 hours weekly for high-value management tasks. That’s $15,000-$20,000 in labor savings alone.

- Protect your cognitive capacity like you would your best cow—University of Iowa research links long-term ag work to 46% higher dementia odds. Schedule weekly downtime and hobbies… your million-dollar breeding decisions depend on a sharp mind.

- Start the “51-Hour Challenge” immediately—document your decision quality, error rates, and productivity compared to those brutal 70+ hour weeks. The research guarantees you’ll see improvement, not decline.

EXECUTIVE SUMMARY

Look, I’ve been digging into some eye-opening research from Teagasc, and honestly? The hardest-working dairy farmers are actually the least profitable. We’re talking about Irish farms where the top 25% work just 51.2 hours per week managing 112 cows, while the bottom performers grind through 70 hours on nearly identical herds—and make less money doing it. That’s not just 19 wasted hours… that’s potentially $15,000 to $67,500 in avoidable losses from fatigue-driven mistakes like missed heats and equipment errors. Plus, I’m seeing similar patterns from New Zealand to Australia—farms using flexible milking and robotics are slashing costs by 4% while boosting profits by 60%. The USDA data backs this up too: it’s not about working more, it’s about working smarter. Bottom line? Your brain is your most valuable asset on the farm, and you’re probably burning it out for no good reason.

Complete references and supporting documentation are available upon request by contacting the editorial team at editor@thebullvine.com.

Learn More:

- How to Attract, Train, and Retain Top-Notch Dairy Farm Employees – Provides actionable strategies for hiring, training, and empowering your team. Learn to build reliable systems and delegate effectively, freeing your time for high-level management instead of being trapped by routine labor and staff turnover.

- Navigating the New Dairy Economy: Strategies for Success in a Changing Market – Explores key economic pressures facing the 2025 dairy market. This article reveals financial strategies to protect margins and shows why the operational efficiency gained from a 51-hour week is a crucial defense against rising input costs and market volatility.

- Robotic Milking Systems: Is the ROI Real? A Comprehensive Analysis for Modern Dairy Farms – Delivers a deep-dive analysis of the real-world ROI for robotic milking systems. This piece examines capital costs, labor savings, and production data from AMS-equipped farms to help you make a smarter technology investment decision.

Join the Revolution!

Join the Revolution!

Join over 30,000 successful dairy professionals who rely on Bullvine Weekly for their competitive edge. Delivered directly to your inbox each week, our exclusive industry insights help you make smarter decisions while saving precious hours every week. Never miss critical updates on milk production trends, breakthrough technologies, and profit-boosting strategies that top producers are already implementing. Subscribe now to transform your dairy operation’s efficiency and profitability—your future success is just one click away.

Join the Revolution!

Join the Revolution!